Abstract

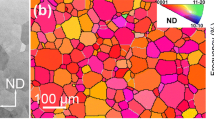

The quality of a hard WC–3% Co alloy after surface modification by focused UV laser beams is studied. Melting traces 1–3 μm in size are found on the alloy surface in the treated zone at a radiation energy density E ≥ 1.6 J/cm2. An increase in the radiation intensity to E ≈ 6.2 J/cm2 results in an increase in the cobalt concentration on the surface from 7 to 10% along with a decrease in the carbon concentration from 33 to 18%.

Similar content being viewed by others

REFERENCES

A. S. Kurlov and A. I. Gusev, “Phase equilibria in the W–C system and tungsten carbides,” Usp. Khim. 75 (7), 687–708 (2006).

D. V. Suetin, I. R. Shein, A. S. Kurlov, A. I. Gusev, and A. L. Ivanovskii, “Band structure and properties of polymorphic modifications of lowest tungsten carbide W2C,” Fiz. Tverd. Tela 50 (8), 1366–1372 (2008).

D. V. Suetin, I. R. Shein, and A. L. Ivanovskii, “Tungsten carbides and nitrides and ternary systems based on them: electronic structure, chemical bond, and properties,” Usp. Khim. 79 (7), 672–696 (2010).

V. A. Fal’kovskii and L. I. Klyachko, Hard Alloys (Ruda Metally, Moscow, 2005).

P. V. Petrenko, N. P. Kulish, V. A. Mel’nikova, A. L. Gritskevich, and O. P. Mishchenko, “Mechanism of radiation strengthening of tools made of a hard cobalt-based alloy,” Vopr. Atom. Nauki Tekh. Ser. Fiz. Radiats. Povrezhd. Radiats. Materialoved. 55 (1), 105–107 (1991).

R. Wei, J. J. Vajo, J. N. Matossian, and M. N. Gardos, “Aspects of plasma-enhanced magnetron-sputtered deposition of hard coatings on cutting tools,” Surf. Coat. Technol. 158–159, 465–472 (2002).

A. V. Sokolov, V. K. Koval’kov, Ya. Yu. Filippov, V. I. Shvedunov, D. S. Yurov, and B. N. Belyaev, “A method for surface strengthening of cutting tools from hard alloys based on tungsten carbides with a cobalt binder,” RF Patent 2564645, 2014.

V. Ya. Panchenko, Laser Technologies of Material Treatment: Modern Problems of Fundamental Research and Applied Developments (Fizmatlit, Moscow, 2009).

A. G. Grigor’yants and A. I. Misyurov, Technological Processes of Laser Treatment (MGTU im. N.E. Baumana, Moscow, 2006).

E. E. Ashkinazi, A. V. Khomich, V. E. Rogalin, A. P. Bol’shakov, D. N. Sovyk, M. A. Mytarev, I. I. Koshel’kov, P. M. Vasil’ev, and V. I. Konov, “Diamond tools with enhanced wear resistance for difficultly treated composite materials,” Fiz. Khim. Obrab. Mater., No. 5, 42–67 (2019).

J. M. Arroyo, A. E. Diniz, and M. S. Fernandes de Lima, “Cemented carbide surface modifications using laser treatment and its effects on hard coating adhesion,” Surf. Coat. Technol. 204, 2410–2416 (2010).

A. Veillere, T. Guillemet, Z. Q. Xie, C. A. Zuhlke, D. R. Alexander, J. F. Silvain, J.-M. Heintz, N. Chandra, and Y. F. Lu, “Influence of WC–Co substrate pretreatment on diamond film deposition by laser-assisted combustion synthesis,” ACS Appl. Mater. Interfaces 3 (4), 1134–1139 (2011).

F. Xu, J. H. Xu, M. F. Yuen, L. Zheng, W. Z. Lu, D. W. Zuo, “Adhesion improvement of diamond coatings on cemented carbide with high cobalt content using PVD interlayer,” Diamond Relat. Mater. 34, 70–75 (2013).

M. A. Volosova, S. N. Grigoriev, E. A. Ostrikov, “Use of laser ablation for formation of discontinuous (discrete) wear-resistant coatings formed on hard carbide cutting tool by electron beam alloying and vacuum-arc deposition,” Mech. Ind. 17, 720 (2016).

Yu. A. Vashukov, S. F. Demichev, V. D. Elenev, T. V. Malinskii, S. I. Mikolutskii, Yu. V. Khomich, and V. A. Yamshchikov, “Laser surface treatment of metallic alloys for diffusion welding,” Prikl. Fiz., No. 1, 82–87 (2019).

V. Yu. Khomich and V. A. Shmakov, “Mechanisms and models of direct laser nanostructuring of materials,” Usp. Fiz. Nauk 185 (5), 489–499 (2015).

V. N. Tokarev, V. Yu. Khomich, V. A. Shmakov, and V. A. Yamshchikov, “Possibility of direct laser surface nanostructuring without melting of material,” Fiz. Khim. Obrab. Mater., No. 4, 15–25 (2008).

V. N. Elkin, T. V. Malinskii, S. I. Mikolutskii, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Influence of irradiation by nanosecond laser pulses on the surface structure of metallic alloys,” Fiz. Khim. Obrab. Mater., No. 6, 5–12 (2016).

Yu. A. Zheleznov, T. V. Malinskii, Yu. V. Khomich, and V. A. Yamshchikov, “Influence of a scanning beam of nanosecond laser pulses on the microtopography of ceramic Al2O3 coatings,” Fiz. Khim. Obrab. Mater., No. 4, 31–36 (2017).

T. V. Malinskii, S. I. Mikolutskii, V. E. Rogalin, Yu. V. Khomich, V. A. Yamshchikov, I. A. Kaplunov, and A. I. Ivanova, “Plastic deformation of copper as a result of the powerful nanosecond UV laser pulse action,” Pis’ma Zh. Tekh. Fiz. 20 (16), 51–54 (2020).

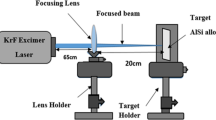

Yu. A. Zheleznov, T. V. Malinskii, S. I. Mikolutskii, V. N. Tokarev, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Experimental setup for direct laser micro- and nanostructuring of the solid surface,” Usp. Prikl. Fiz. 2 (3), 311–316 (2014).

Yu. A. Zheleznov, T. V. Malinskii, S. I. Mikolutskii, R. R. Khasaya, Yu. V. Khomich, and V. A. Yamshchikov, “Treatment of the titanium surface by nanosecond laser radiation,” Pis’ma Mater. 4 (1(13)), 45–48 (2014).

S. Kano and T. Inoue, “Surface softening and hardening of WC–Co using pulsed laser irradiation,” Surf. Coat. Technol., 201 (1–2), 223–229 (2006).

C. H. Liang, F. P. Tian, Z. B. Wei, O. Xin, and C. Li, “The synthesis of nanostructured W2C on ultrahigh surface area carbon materials via carbothermal hydrogen reduction,” Nanotechnology, 14 (9), 955 (2003).

ACKNOWLEDGMENTS

The authors are grateful to E.E. Ashkinazi for kindly presented hard alloy samples and useful discussions.

Funding

This work was carried out using the equipment of the Center for Collective Use of Tver State University in terms of state assignments nos. 0057-2019-0005 and 0817-2020-0007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Rights and permissions

About this article

Cite this article

Zheleznov, Y.A., Malinskiy, T.V., Mikolutskiy, S.I. et al. Surface Modification of a WC–3% Co Hard Alloy by Powerful Nanosecond UV Laser Pulses. Russ. Metall. 2021, 373–376 (2021). https://doi.org/10.1134/S0036029521040364

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521040364