Abstract

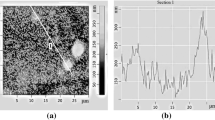

The study investigates an electron beam cladded coating of nitrogen-alloyed austenitic steel (24.4Cr, 16.4Mn, 0.18Ni, 1.1Si, 0.57С, 0.7N, rest Fe (wt %)). Cladding was performed by a continuous low-energy (27 keV) and low-current (0.02–0.04 A) focused electron beam on an electron beam system at a residual pressure of 0.1 Pa. The microstructure, phase composition, and chemical composition of the coating were examined by OM/AES/XRD/SEM/EDS methods. The coating has no pores and is characterized by high work hardening and wear resistance. The formation of М7(С, N)3 carbonitrides in the steel plays a crucial role in the control of the structure and wear resistance of the applied coating, because carbonitrides are able to distinguish between the lattice curvature zones and the stable translationally invariant lattice. Frictional loads arising during wear trigger a γ → α′ transformation. With increasing frictional load, the coefficient of friction decreases.

Similar content being viewed by others

REFERENCES

Scandella, F. and Scandella, R., Development of Hardfacing Material in Fe–Cr–Nb–C System for Use under Highly Abrasive Conditions, Mater. Sci. Technol., 2004, vol. 20, pp. 93–105. https://doi.org/10.1179/026708304225011234

Correa, E.O., Alcântara, N.G., Tecco, D.G., and Kumar, R.V., The Relationship between the Microstructure and Abrasive Resistance of a Hardfacing Alloy in the Fe–Cr–C–Nb–V System, Metall. Mater. Trans. A, 2007, vol. 38, pp. 1671–1680. https://doi.org/10.1007/s11661-007-9220-8

Correa, E.O., Alcântara, N.G., Valeriano, L.C., Barbedo, N.D., and Chaves, R.R., The Effect of Microstructure on Abrasive Wear of a Fe–Cr–C–Nb Hardfacing Alloy Deposited by the Open Arc Welding Process, Surf. Coat. Technol., 2015, vol. 276, pp. 479–484. https://doi.org/10.1016/j.surfcoat.2015.06.026

Filippov, M.A., Kulishenko, B.A., and Val’kov, E.V., Wear Resistance of Facing Alloy with Metastable Austenite, Met. Sci. Heat Treat., 2005, vol. 47, pp. 6–8. https://doi.org/10.1007/s11041-005-0021-7

Byrnes, M.L.G., Grujicic, M., and Owen, W.S., Nitrogen Strengthening of a Stable Austenitic Stainless Steel, Acta Met., 1987, vol. 35, pp. 1853–1862. https://doi.org/10.1016/0001-6160(87)90131-3

Lee, T.-H., Oh, C.-S., and Kim, S.-J., Effects of Nitrogen on Deformation-Induced Martensitic Transformation in Metastable Austenitic Fe–18Cr–10Mn–N Steels, Scripta Mater., 2008, vol. 58, pp. 110–113. https://doi.org/10.1016/j.scriptamat.2007.09.029

Güler, S. and Fischer, A., Fatigue Behavior of Cold-Worked High-Interstitial Steels, Metals, 2018, vol. 442. https://doi.org/10.3390/met8060442

Berns, H., Gavriljuk, V., and Riedner, S., High Interstitial Stainless Austenitic Steels, Germany: Springer Sience & Business Media, 2012. https://doi.org/10.1007/978-3-642-33701-7_6

Talha, M., Behera, C.K., and Sinha, O.P., Promising In Vitro Performances of Nickel-Free Nitrogen Containing Stainless Steels for Orthopaedic Applications, Bul. Mater. Sci., 2014, vol. 37, pp. 1321–1330.

Berns, H., Gavriljuk, V., Riedner, S., and Tyshchenko, A., High Strength Stainless Austenitic CrMnCN Steels–Part 1: Alloy Design and Properties, Steel Res. Int., 2007, vol. 78, pp. 714–719. https://doi.org/10.1002/srin.200706274

Petrov, Yu., Surface Structure of Different Interstitial Austenitic Steels after Impact Wear, Int. J. Mat. Res., 2012, vol. 103, pp. 551–553. https://doi.org/10.3139/146.110724

Berns, H., Increasing the Wear Resistance of Stainless Steels, Mat. Werkstofftech., 2007, vol. 38, pp. 464–472. https://doi.org/10.1002/mawe.200700154

Korshunov, L.G., Tereshchenko, N.A., Uvarov, A.I., Makarov, A.V., Chernenko, N.L., and Goikhenberg, Yu.N., Wear Resistance and Surface Structure of Nitrogen-Containing Stainless Austenitic Steels upon Friction and Abrasive Wear, Phys. Met. Metallogr., 1997, vol. 84, pp. 554–561.

Korshunov, L.G., Goikhenberg, Yu.N., and Chernenko, N.L., Effect of Silicon on the Structure, Tribological Behavior and Mechanical Properties of Nitrogen-Containing Chromium-Manganese Austenitic Steels, Phys. Met. Metallogr., 2003, vol. 96, pp. 535–544.

Zhao, L., Maurer, M., and Lugscheider, E., Thermal Spraying of a Nitrogen Alloyed Austenitic Steel, Thin Solid Films, 2003, vol. 424, pp. 213–218. https://doi.org/10.1016/S0040-6090(02)01047-7

Saker, S., Leroy, Ch., Michel, H., and Frantz, C., Properties of Sputtered Stainless Steel–Nitrogen Coatings and Structural Analogy with Low Temperature Plasma Nitrided Layers of Austenitic Steels, Mater. Sci. Eng. A, 1991, vol. 140, pp. 702–708. https://doi.org/10.1016/0921-5093(91)90500-M

Bourjot, A., Foos, M., and Frantz, C., Basic Properties of Sputtered 310 Stainless Steel–Nitrogen Coatings, Surf. Coat. Technol., 1990, vol. 43–44, pp. 533–542. https://doi.org/10.1016/0257-8972(90)90104-K

Kolpakov, A.S. and Kardonina, N.I., Experience of High-Nitrogenous Steel Powder Application in Repairs and Surface Hardening of Responsible Parts for Power Equipment by Plasma Spraying, Therm. Eng., 2016, vol. 63, pp. 150–155. https://doi.org/10.1134/S0040601516010067

Kalianov, V.N., Surfacing with Nitrogen Alloys, Paton Weld. J., 2002, vol. 10, pp. 46–48.

Narkevich, N.A., Ivanova, E.A., and Panin, V.E., Nitrogen-Doped Chromium-Manganese Cast Iron Used to Obtain Wear-Resistant Coatings by Electron-Beam Deposition, in Proc. Int. Conf. on High Nitrogen Steels, Beijing: Metallurgical Industry Press, 2006, pp. 462–468.

Panin, V.E., Beljuk, S.I., Durakov, V.G., Pribytkov, G.A., and Rempe, N.G., Electron Beam Vacuum Surfacing: Equipment, Technology and Properties of Coatings, Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1080/09507110009549234

Beljuk, S.I. and Durakov, V.G., RF Patent RU 2156321 C2. Process of Electron Beam Hardfacing, Appl. 23.12.97, publ. 20.09.2000.

Panin, V.E., Egorushkin, V.E., Kuznetsov, P.V., Galchenko, N.K., Shugurov, A.R., Vlasov, I.V., and Deryugin, Ye.Ye., Structural Turbulence of Plastic Flow and Ductile Fracture in Low-Alloy Steel under Lattice Curvature Conditions, Phys. Mesomech., 2020, vol. 23, no. 4, pp. 279–290. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1134/S1029959920040013

Tushinsky, L.I., Kovensky, I., Plokhov, A., Sindeyev, V., and Reshedko, P., Coated Metal: Structure and Properties of Metal–Coating Compositions, Berlin: Springer Sience & Business Media, 2013. https://books.google.ru/books?id=v7LrCAAAQBAJ&dq=rosival+method&hl=ru&sitesec=reviews

De, A.K., Murdock, D.C., Mataya, M.C., Speer, J.G., and Matlock, D.K., Quantitative Measurement of Deformation-Induced Martensite in 304 Stainless Steel by X-Ray Diffraction, Scripta Mater., 2004, vol. 50, pp. 1445–1449. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/j.scriptamat.2004.03.011

Ojima, M., Adachi, Y., Tomota, Y., Ikeda, K., Kamiyama, T., and Katada, Y., Work Hardening Mechanism in High Nitrogen Austenitic Steel Studied by In Situ Neutron Diffraction and In Situ Electron Backscattering Diffraction, Mater. Sci. Eng. A, 2009, vol. 527, pp. 16–24. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/j.msea.2009.07.066

Lee, T.-H., Oh, C.-S., Kim, S.-J., and Takaki, S., Deformation Twinning in High Nitrogen Austenitic Stainless Steel, Acta Mater., 2007, vol. 55, pp. 3649–3662. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/j.actamat.2007.02.023

Lee, T.-H., Ha, H.-Y., Hwang, B., Kim, S.-J., Shin, E., and Lee, J.W., Scale-Bridging Analysis on Deformation Behavior of High-Nitrogen Austenitic Steels, Microsc. Microanal., 2013, vol. 19(S5), pp. 77–82. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1017/S1431927613012385

Lee, T.-H., Ha, H.-Y., Hwang, B., Kim, S.-J., and Shin, E., Effect of Carbon Fraction on Stacking Fault Energy of Austenitic Stainless Steels, Metall. Mater. Trans. A, 2012, vol. 43, pp. 4455–4459. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1007/s11661-012-1423-y

Lee, T.-H., Shin, E., Oh, S.-C., Ha, H.-Y., and Kim, S.-J., Correlation between Stacking Fault Energy and Deformation Microstructure in High-Interstitial-Alloyed Austenitic Steels, Acta Mater., 2010, vol. 58, pp. 3173–3186. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/j.actamat.2010.01.056

Efstathiou, C. and Sehitoglu, H., Strain Hardening and Heterogeneous Deformation During Twinning in Hadfield Steel, Acta Mater., 2010, vol. 58, pp. 1479–1488. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/j.actamat.2009.10.054

Panin, V.E., Panin, A.V., Perevalova, O.B., and Shugurov, A.R., Mesoscopic Structural States at the Nanoscale in Surface Layers of Titanium and its Alloy Ti–6Al–4V in Ultrasonic and Electron Beam Treatment, Phys. Mesomech., 2019, vol. 22, no. 5, pp. 345–354. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1134/S1029959919050011

Bhadeshia, H.K.D.H., Bainite in Steels, Cambridge, UK: The University Press, 2001.

Wang, J.J., Fang, H.S., Yang, Z.G., and Zheng, Y.K., Fine Structure and Formation Mechanism of Bainite in Steels, ISIJ Int., 1995, vol. 35, no. 8, pp. 992–1000. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.2355/isijinternational.35.992

Fang, H.S., Yang, J.B., Yang, Z.G., and Bai, B.Z., The Mechanism of Bainite Transformation in Steels, Scripta Mater., 2002, vol. 47, pp. 157–162. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1016/S1359-6462(02)00122-7

Panin, V.E., Shulepov, I.A., Derevyagina, L.S., Panin, S.V., Gordienko, A.I., and Vlasov, I.V., Nanoscale Mesoscopic Structural States in Low-Alloy Steels for Martensitic Phase Formation and Low-Temperature Toughness Enhancement, Phys. Mesomech., 2020, vol. 23, no. 5, pp. 376–383. Weld. Int., 2000, vol. 14, pp. 580–584. https://doi.org/10.1134/S1029959920050021

Matsukawa, Y. and Zinkle, S.J., One-Dimensional Fast Migration of Vacancy Clusters in Metals, Science, 2007, vol. 318, pp. 959–962.

Funding

The work was performed according to the Government research assignment for ISPMS SB RAS, project No. FWRW-2021-0010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2020, published in Fizicheskaya Mezomekhanika, 2020, Vol. 23, No. 2, pp. 15–23.

Rights and permissions

About this article

Cite this article

Panin, V.E., Narkevich, N.A., Durakov, V.G. et al. Control of the Structure and Wear Resistance of a Carbon-Nitrogen Austenitic Steel Coating Produced by Electron Beam Cladding. Phys Mesomech 24, 53–60 (2021). https://doi.org/10.1134/S1029959921010082

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959921010082