Abstract

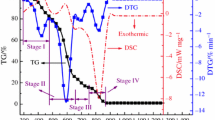

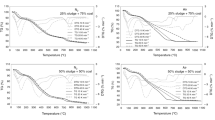

This paper concerned the thermal conversion characteristics, kinetics, thermodynamics, and incineration operation parameters and gas emissions of petrochemical wastewater (PW) and its sludge (PWS). The combustion properties of PWS were evaluated via thermogravimetric analysis, and the results showed that the combustion process of PWS had four stages, and the combustion pathway was typical “thermal degradation with char formation + char combustion”. With heating rates increasing, thermal curves shifted toward lower temperatures, and the ignition, burnout, and comprehensive combustibility improved significantly. The kinetic parameters were determined by Coats–Redfern approach, and the results confirmed the existence of kinetic compensation effect. The thermodynamic parameters (ΔH, ΔG, ΔS) from PWS combustion at maximum degradation rate temperatures were estimated by the activated complex theory. To make the research practical, operation parameters and gas emissions from a petrochemical wastewater incinerator were tested. The results showed that, except HCl, and CO at 4.50 t h–1 PW injection, the gas pollutants in the flue gas after the PW incineration did not exceed the discharge limits in China. The parameters of combustion efficiency of the incineration plant at different PW injections were very high, and met the requirement in GB 18484-2001.

Similar content being viewed by others

References

Wang S, Dai G, Yang H et al (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86

Liu C, Liu J, Sun G et al (2018) Thermogravimetric analysis of (co-) combustion of oily sludge and litchi peels: kinetics and thermodynamics. Thermochim Acta 667:207–218

Liu J, Huang L, Sun G et al (2018) (Co–) combustion of additives, water hyacinth and sewage sludge: thermogravimetric, kinetic, gas and thermodynamic modeling analyses. Waste Manage 81:211–219

Bach QV, Chen WH (2017) Pyrolysis characteristics and kinetics of microalgae via thermogravimetric analysis (TGA): a state–of–the–art review. Bioresour Technol 246:88–100

Vassilev SV, Baxter D, Andersen LK et al (2013) An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 105:40–76

Mohanakrishna G, Abu-Reesh IM, Kondaveeti S et al (2018) Enhanced treatment of petroleum refinery wastewater by short-term applied voltage in single chamber microbial fuel cell. Bioresour Technol 253:16–21

Ministry of Environmental Protection of the People's Republic of China. Annual Report on Environmental Statistics of 2015 [EB/OL]. http://zls.mep.gov.cn/hjtj/nb/2015tjnb/

EPA, Safe, Environmentally Acceptable Resources Recovery from Oil Refinery Sludge, U.S. Environmental Protection Agency (EPA), Washington DC, 1991

Wang X, Wang Q, Wang S et al (2012) Effect of biostimulation on community level physiological profiles of microorganisms in field-scale biopiles composed of aged oil sludge. Bioresour Technol 111:308–315

Hu G, Li J, Zeng G (2013) Recent development in the treatment of oily sludge from petroleum industry: a review. J Hazard Mater 261:470–490

BP, BP statistical review of world energy June 2019, London, 2019, p 28

Werther J, Ogada T (1999) Sewage sludge combustion. Prog Energy Combust Sci 25:55–116

Xie C, Liu J, Zhang X et al (2018) Co-combustion thermal conversion characteristics of textile dyeing sludge and pomelo peel using TGA and artificial neural networks. Appl Energy 212:786–795

Mu L, Zhao L, Liu L et al (2012) Elemental distribution and mineralogical composition of ash deposits in a large-scale wastewater incineration plant: a case study. Ind Eng Chem Res 51:8684–8694

Xu Y, Chen B (2013) Investigation of thermodynamic parameters in the pyrolysis conversion of biomass and manure to biochars using thermogravimetric analysis. Bioresour Technol 146:485–493

Chen J, Wang Y, Lang X et al (2017) Evaluation of agricultural residues pyrolysis under non-isothermal conditions: Thermal behaviors, kinetics, and thermodynamics. Bioresour Technol 241:340–348

Mendonça ARV, de Souza SMAGU, Valle JAB et al (2015) Thermogravimetric analysis and kinetic study of pyrolysis and combustion of residual textile sludge. J Therm Anal Calorim 121:807–814

Zhou L, Jiang X, Liu J (2009) Characteristics of oily sludge combustion in circulating fluidized beds. J Hazard Mater 170:175–179

Xie Z, Ma X (2013) The thermal behaviour of the co-combustion between paper sludge and rice straw. Bioresour Technol 146:611–618

Peng X, Ma X, Xu Z (2015) Thermogravimetric analysis of co-combustion between microalgae and textile dyeing sludge. Bioresour Technol 180:288–295

Liu J, Jiang X, Zhou L et al (2009) Co-firing of oil sludge with coal–water slurry in an industrial internal circulating fluidized bed boiler. J Hazard Mater 167:817–823

Mu L, Chen J, Yin H et al (2015) Pyrolysis behaviors and kinetics of refining and chemicals wastewater, lignite and their blends through TGA. Bioresour Technol 180:22–31

Senneca O, Chirone R, Salatino P (2002) A thermogravimetric study of nonfossil solid fuels. 2. Oxidative pyrolysis and char combustion. Energy Fuels 16:661–668

Quan C, Li A, Gao N (2013) Combustion and pyrolysis of electronic waste: thermogravimetric analysis and kinetic model. Procedia Environ Sci 18:776–782

Jiang X, Feng Y, Lv G et al (2012) Bioferment residue: TG-FTIR study and cocombustion in a MSW incineration plant. Environ Sci Technol 46:13539–13544

Tahmasebi A, Kassim MA, Yu J et al (2013) Thermogravimetric study of the combustion of Tetraselmis suecica microalgae and its blend with a Victorian brown coal in O2/N2 and O2/CO2 atmospheres. Bioresour Technol 150:15–27

Du Y, Jiang X, Ma X et al (2013) Evaluation of cofiring bioferment residue with coal at different proportions: combustion characteristics and kinetics. Energy Fuels 27:6295–6303

Chen J, Liu J, He Y et al (2017) Investigation of co–combustion characteristics of sewage sludge and coffee grounds mixtures using thermogravimetric analysis coupled to artificial neural networks modeling. Bioresour Technol 225:234–245

Xie W, Huang J, Liu J et al (2018) Assessing thermal behaviors and kinetics of (co–) combustion of textile dyeing sludge and sugarcane bagasse. Appl Therm Eng 131:874–883

Meng F, Yu J, Tahmasebi A et al (2013) Pyrolysis and combustion behavior of coal gangue in O2/CO2 and O2/N2 mixtures using thermogravimetric analysis and a drop tube furnace. Energy Fuels 27:2923–2932

Ren X, Chen J, Li G et al (2018) Thermal oxidative degradation kinetics of agricultural residues using distributed activation energy model and global kinetic model. Bioresour Technol 261:403–411

Chen J, Mu L, Cai J et al (2015) Pyrolysis and oxy-fuel combustion characteristics and kinetics of petrochemical wastewater sludge using thermogravimetric analysis. Bioresour Technol 198:115–123

Chen J, Lang X, Wang Y et al (2018) Comparative evaluation of different non–condensable gases on thermal behaviors, kinetics, high pressure properties, and product characteristics of heavy oil. Energy Convers Manage 162:13–25

Du Y, Jiang X, Lv G et al (2014) Thermal behavior and kinetics of bio-ferment residue/coal blends during co–pyrolysis. Energy Convers Manage 88:459–463

Vlaev L, Nedelchev N, Gyurova K et al (2008) A comparative study of non–isothermal kinetics of decomposition of calcium oxalate monohydrate. J Anal Appl Pyrol 81:253–262

Li H, Niu S, Lu C et al (2015) Comprehensive investigation of the thermal degradation characteristics of biodiesel and its feedstock oil through TGA–FTIR. Energy Fuels 29:5145–5153

Li H, Niu S, Lu C et al (2015) Comparative evaluation of thermal degradation for biodiesels derived from various feedstocks through transesterification. Energy Convers Manage 98:81–88

Huang L, Liu J, He Y et al (2016) Thermodynamics and kinetics parameters of co–combustion between sewage sludge and water hyacinth in CO2/O2 atmosphere as biomass to solid biofuel. Bioresour Technol 218:631–642

Qian FP, Chyang CS, Huang KS et al (2011) Combustion and NO emission of high nitrogen content biomass in a pilot-scale vortexing fluidized bed combustor. Bioresour Technol 102:1892–1898

Acknowledgements

Financial supports for this work that has been provided by the China Postdoctoral Science Foundation (2018M633052), which are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, J., Xu, W., Zhu, L. et al. Thermal conversion behaviors, kinetics, and thermodynamics of wastewater sludge via thermogravimetric analysis, and emission characteristics from a large-scale incinerator. J Mater Cycles Waste Manag 23, 1466–1478 (2021). https://doi.org/10.1007/s10163-021-01228-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01228-1