Abstract

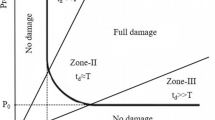

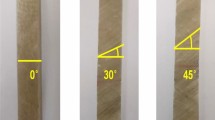

The geometry of cracked pipe, loading condition and crack size all can have a strong effect on its resistance against crack-tip plastic deformation and crack growth. Usually, specimens listed in test standards (e.g. CT specimen) are applied to evaluate the fracture resistance (J-R) curves, which may cause excessive safety margin in leak-before-break (LBB) design of nuclear pipes. In this study, standard (CT) specimen and constraint designed specimens, including curved CT and compact pipe (CP) specimens were applied to measure the J-R curves of nuclear pipes. Finite element analysis (FEA) was applied to derive J-equations to calculate J-R curves for newly designed specimens. Constraint effects in these specimens and full-scale pipes under various loading conditions were compared according to crack-tip plastic deformation level. Then, safety margins in LBB design using these specimens were quantitatively analyzed by constructing the critical crack length lines. Both the tests and FEA results verified the validity of these constraint designed specimens for reducing conservatism.

Similar content being viewed by others

References

G. Dundulis, R. Janulionis and R. Karalevičius, The application of leak before break concept to W7-X target module, Fusion Engineering and Design, 88 (11) (2013) 3007–3013.

Y. L. Chen, G. Z. Wang, F. Z. Xuan and S. T. Tu, Crack-tip constraint analyses and constraint-dependent LBB curves for circumferential through-wall cracked pipes, Nuclear Engineering and Design, 285 (15) (2015) 75–83.

H. Machida, N. Yamashita, S. Yoshimura and G. Yagawa, Seismic loads for crack stability assessment, in a review of leak-before-break (LBB) applicability, Nuclear Engineering and Design, 235 (1) (2005) 21–31.

N. Gong, G. Z. Wang, F. Z. Xuan and S. T. Tu, Leak-before-break analysis of a dis-similar metal welded joint for connecting pipe-nozzle in nuclear power plants, Nuclear Engineering and Design, 255 (2013) 1–8.

L. Y. Du, G. Z. Wang, F. Z. Xuan and S. T. Tu, Effects of local mechanical and fracture properties on LBB behavior of a dissimilar metal welded joint in nuclear power plants, Nuclear Engineering and Design, 265 (2013) 145–153.

ASTM, Standard test method for measurement of fracture toughness, ASTM Standard E1820-01 (2001).

BSI, Fracture mechanics toughness tests-part 4: method for determination of fracture resistance curves and initiation values for stable crack extension in metallic materials, BS 7448-4 (1997).

ISO, Metallic materials-unified method of test for the determination of quasistatic fracture toughness, ISO 12135 (2014).

X. K. Zhu, Review of fracture toughness test methods for ductile materials in low-constraint conditions, International Journal of Pressure Vessels and Piping, 139–140 (2016) 173–183.

C. Ruggieri, Low constraint fracture toughness testing using SE(T) and SE(B) specimens, International Journal of Pressure Vessels and Piping, 156 (2017) 23–29.

X. K. Zhu and B. N. Leis, Bending modified J-Q theory and crack-tip constraint quantification, International Journal of Fracture, 141 (1–2) (2006) 115–134.

T. Shen, K. T. Park, J. G. Choi, B. W. Moon, J. M. Koo and C. S. Seok, Transformation of fracture resistance curves by using bending modified Q (Qm) factor, International Journal of Precision Engineering and Manufacturing, 18 (1) (2017) 85–91.

Z. Liu, X. Wang, S. W. Shi, Y. Y. Shen and X. Chen, Application of modified normalization method for J-R curve determination using clamped SENT specimens with varying in-plane and out-of-plane constraints, Engineering Fracture Mechanics, 230 (2020) 106968.

S. Park, S. S. Yoo, J. K. Min, J. M. Koo and C. S. Seok, Evaluation of fracture toughness characteristics for nuclear piping using various types of specimens, International Journal of Pressure Vessels and Piping, 90–91 (2012) 9–16.

J. M. Koo, S. Park and C. S. Seok, Evaluation of fracture toughness of nuclear piping using real pipe and tensile compact pipe specimens, Nuclear Engineering and Design, 259 (2013) 198–204.

T. Shen, S. Park, J. K. Du, K. T. Park, J. G. Choi, B. W. Moon, J. M. Koo and C. S. Seok, A further study on fracture resistance evaluation of nuclear pipes using CP specimens, Engineering Fracture Mechanics, 235 (2020) 107167.

T. Shen, K. T. Park, J. G. Choi, B. W. Moon, J. M. Koo and C. S. Seok, Evaluation for fracture resistance curves of nuclear real pipes using curved equivalent stress gradient (curved ESG) specimens, Engineering Fracture Mechanics, 169 (2017) 89–98.

J. R. Rice, A path independent integral and the approximate analysis of strain concentration by notches and cracks, Journal of Applied Mechanics, 35 (1968) 379–386.

J. A. Begley and J. D. Landes, The J-integral as a fracture criterion, In: fracture mechanics, ASTM STP 514 (1972) 1–23.

J. R. Rice, P. C. Paris and J. G. Merkle, Some further results of J-integral analysis and estimates, Progress in flaw growth and fracture toughness testing, ASTM STP 536 (1973) 231–245.

M. H. Sharobeam, J. D. Landes and R. Herrera, Development of Eta factors in elastic-plastic fracture testing using a load separation technique, ASTM STP 1114 (1991) 114–132.

K. K. Shi, L. X. Cai, Y. M. Hu and D. Salmon, Experimental estimation of J integral from load-front face displacement record for compact tension specimens, Journal of Testing and Evaluation, 44 (6) (2016) 219–226.

ASTM, Standard test method for tension testing of metallic materials, ASTM Standard E8-13 (2013).

K. T. Park, J. G. Choi, B. W. Moon, J. M. Koo and C. S. Seok, Investigation of the safety evaluation method of piping system, Journal of Mechanical Science and Technology, 33 (2019) 3375–3381.

M. Mostafavi, D. J. Smith and M. J. Pavier, Fracture of aluminium alloy 2024 under biaxial and triaxial loading, Engineering Fracture Mechanics, 78 (2011) 1705–16.

J. Yang, G. Z. Wang, F. Z. Xuan and S. T. Tu, Unified correlation of in-plane and out-of-plane constraint with fracture resistance of a dissimilar metal welded joint, Engineering Fracture Mechanics, 115 (2014) 296–307.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No.2018R1A2A1A05077886) and the National Natural Science Foundation of China (grant No. 52005271).

Author information

Authors and Affiliations

Corresponding author

Additional information

Chang-Sung Seok is a Professor of the School of Mechanical Engineering, Sungkyunkwan University, Suwon, Korea. He received his Ph.D. in Mechanical Engineering from Sungkyunkwan University. His research interests include fracture characteristic assessment, structural integrity evaluation, degradation assessment and design of mechanical elements.

Rights and permissions

About this article

Cite this article

Shen, T., Park, S. & Seok, CS. Comparison of safety margin in LBB design of nuclear pipes based on various types of fracture resistance test specimens. J Mech Sci Technol 35, 2097–2105 (2021). https://doi.org/10.1007/s12206-021-0425-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0425-3