Abstract

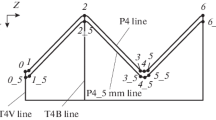

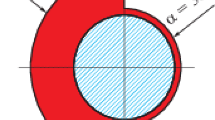

The article describes the main loads affecting shaped backups of the combined process unit of continuous casting and deformation during billet production. The importance of determining the temperature fields and thermoelastic stresses in shaped backups with collars is provided during the formation of several billets, at slab compression, as well as during idling water cooling of backups. The authors describe strength and thermophysical properties of steel from which the backups are made. Geometry of backups with collars used for obtaining billets of three different shapes in one pass is shown. Initial data of the temperature field calculation are given for backups with collars of the combined unit. Temperature boundary conditions are considered for the temperature field calculation of backups with collars. Boundary conditions determining temperature of such backups are described and the values of the heat flow and effective heat transfer coefficient are given. The calculation results of temperature fields are performed in four sections and are given for typical lines and points located on the contact surface of backups with collars and in contact layer at 5-mm depth from the working surface. The sizes of the finite element grid, which is used for the temperature field calculation of backups with collars, are provided. The temperature field of backups with collars is determined based on the solution regarding the unsteady thermal conductivity equation corresponding to initial and boundary conditions. When obtaining billets of three shapes in one pass at the unit of combined continuous casting and deformation, values and regularities of temperature distribution in the bases and tops of the middle and extreme edges of the shaped backups are presented during slab compression and at idle.

Similar content being viewed by others

REFERENCES

Lekhov, O.S. and Mikhalev, A.V., Ustanovka sovmeshchennogo protsessa nepreryvnogo lit’ya i deformatsii dlya proizvodstva listov iz stali dlya svarnykh trub. Teoriya i raschet (Unit of Combined Continuous Casting and Deformation for Production of Steel Sheets for Welded Pipes: Theory and Calculation), Yekaterinburg: Ural. Metod. Tsentr UPI, 2017.

Lekhov, O.S., Mikhalev, A.V., and Shevelev, M.M., Napryazheniya v sisteme boiki-polosa pri poluchenii listov iz stali na ustanovke nepreryvnogo lit’ya i deformatsii (Stresses in the Backup-Strip System when Making Steel Sheets at Unit of Continuous Casting and Deformation), Yekaterinburg: Ural. Metod. Tsentr UPI, 2018.

Lekhov, O.S. and Bilalov, D.Kh., Technological capabilities of units for combined processes of continuous casting and deformation for production of metal products, Proizvod. Prokata, 2016, no. 7, pp. 24–26.

Khloponin, V.N., Kosyreva, M.V., and Kosyak, A.S., Influence of cooling system on thermal conditions of roller surface work, Tr. Mosk. Inst. Stali Splavov, 1977, no. 100, pp. 90–93.

Boley, B.A. and Weiner, J.H., Theory of Thermal Stresses, New York: Wiley, 1960.

Lekhov, O.S., Study of stress-strain state of rolls-band system at rolling of broad-flanged beam in stands of universal beam mill: Report 2, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2014, vol. 57, no. 12, pp. 15–19.

Kushner, V.S., Vereshchaka, A.S., Skhirtladze, A.G., and Negrov, D.A., Tekhnologicheskie protsessy v mashinostroenii. Chast’ 2. Obrabotka metallov davleniem i svarochnoe proizvodstvo (Technological Processes in Mechanical Engineering, Part 2: Metal Forming and Welding), Omsk: Omsk. Gos. Tekh. Univ., 2005.

Bulanov, L.V., Karlinskii, S.E., and Volegova, V.E., Durability of CCM rolls at external and internal cooling, in Nadezhnost’ krupnykh mashin (Reliability of Large Machines), Sverdlovsk: NIItyazhmash, 1990, pp. 126–132.

Lykov, A.V., Teoriya teploprovodnosti (Theory of Heat Conduction), Moscow: Vysshaya Shkola, 1967.

ANSYS Mechanical APDL Structural Analysis Guide, Release 15.0, Canonsburg, PA: ANSYS, 2013.

Matsumia, T. and Nakamura, Y., Mathematical model of slab bulging during continuous casting, Proc. 3rd Process Technology Conf. “Applied Mathematical, and Physical Models in Iron and Steel Industry,” Pittsburgh, Pa, March 28–31, 1982, New York, 1982, pp. 264–270.

Takashima, Y. and Yanagimoto, I., Finite element analysis of flange spread behavior in H-beam universal rolling, Wiley Steel Res. Int., 2011, vol. 82, no. 10, pp. 1240–1247.

Kobayashi, S., Oh, S.-I., and Altan, T., Metal Forming and Finite-Element Method, New York: Oxford Univ. Press, 1989.

Karrech, A. and Seibi, A., Analytical model of the expansion in tubes under tension, J. Mater. Process. Technol., 2010, vol. 210, no. 2, pp. 336–362.

Kazakov, A.L. and Spevak, L.F., Numeral and analytical studies of nonlinear parabolic equation with boundary conditions of a special form, Appl. Math. Modell., 2013, vol. 37, no. 10–13, pp. 6918–6928.

Jansson, N., Optimized sparse matrix assembly in finite element solvers with one-sided communication, in High Performance Computing for Computational Science–VECPAR 2012, Berlin: Springer-Verlag, 2013, pp. 128–139.

Park, C.Y. and Yang, D.Y., A study of void crushing in large forgings: II. Estimation of bonding efficiency by finite-element analysis, J. Mater. Process. Technol., 2004, vols. 157–158, pp. 496–501.

Sorimachi, K. and Emi, T., Elastoplastic stress analysis of bulging as a major cause of internal cracks in continuously cast slabs, Tetsu-to-Hagane, 1977, vol. 63, no. 8, pp. 1297–1304.

Marciniak, Z., Duncan, J.L., and Hu, S.J., Mechanics of Sheet Metal Forming, Oxford: Butterworth-Heinemann, 2002.

Fujii, H., Ohashi, T., and Hiromoto, T., On the formation of the internal cracks in continuously cast slabs, Trans. Iron Steel Inst. Jpn., 1978, vol. 18, no. 8, pp. 510–518.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by S. Avodkova

About this article

Cite this article

Lekhov, O.S., Mikhalev, A.V. Calculation of Temperature and Thermoelastic Stresses in the Backups with Unit Collars of Combined Continuous Casting and Deformation during Steel Billet Production. Report 1. Steel Transl. 50, 877–881 (2020). https://doi.org/10.3103/S0967091220120086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220120086