Abstract

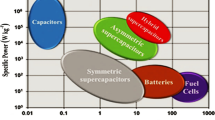

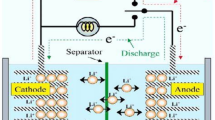

The review contains information on the properties of phase-change materials (PCM) and the possibilities of their use as the basis of thermal energy storage. Special attention is given to PCMs with a phase transition temperature ranging between 20 and 80°C since such materials can be effectively used to reduce temperature variations in residential and industrial rooms. Thus, the application of PCMs in the construction industry enables one to considerably reduce the power consumption and reduce the environmental impact of industrial facilities. Thermophysical characteristics of the main types of PCMs are presented. The heat balance for a room with walls made of PCM-added materials is estimated. The predictions demonstrate that such structures can stabilize the temperature in practical applications as a result of usage of such materials. The potential of wide application of PCMs as a basis for thermal energy storage is limited due to very low conductivity (less than 1 W/(m K)) specific for these materials. Hence, the option of increasing the material conductivity by adding some carbon nanotubes whose thermal conductivity is four to five orders of magnitude greater than that of the base material is examined. The numerical predictions of the heat-conduction enhancement in a PCM doped with carbon nanotubes and the preliminary experiments indicate that a PCM with approximately 20% carbon nanotubes can enhance the material heat conductivity by two to four times.

Similar content being viewed by others

Notes

A consistent theory is a theory that does not contain empirical assumptions.

The Brunauer–Emmett–Teller (BET) is a method of mathematical description of physical adsorption based on the theory of polymolecular (multilayer) adsorption. The name of the method is an abbreviation of the names of the authors (Brunauer, Emmett, and Teller) who proposed this method.)

Chemical deposition from the gas phase occurs in a chemical vapor deposition (CVD) reactor).

REFERENCES

N. P. Sharifi, A. A. N. Sakulich, and A. R. Sakulich, “Application of phase change materials in gypsum boards to meet building energy conservation goals,” Energy Build. 138, 455–467 (2017). https://doi.org/10.1016/j.enbuild.2016.12.046

M. A. Medina, E. J. B. King, and M. Zhang, “On the heat transfer rate reduction of structural insulated panels (SIPs) outfitted with phase change materials (PCMs),” Energy 33, 667–678 (2008). https://doi.org/10.1016/j.energy.2007.11.003

R. Vicente and T. Silva, “Brick masonry walls with PCM macrocapsules: An experimental approach,” Appl. Therm. Eng. 67, 24–34 (2014). https://doi.org/10.1016/j.applthermaleng.2014.02.069

K. Peippo, P. Kauranen, and P. D. Lund, “A multicomponent PCM wall optimized for passive solar heating,” Energy Build. 17, 259–270 (1991). https://doi.org/10.1016/0378-7788(91)90009-R

M. Kenisarin and K. Mahkamov, “Passive thermal control in residential buildings using phase change materials,” Renewable Sustainable Energy Rev. 55, 371–398 (2016). https://doi.org/10.1016/j.rser.2015.10.128

Y. Fang, J. Nin, and S. Deng, “Numerical analysis for maximizing effective energy storage capacity of thermal energy storage system by enhancing heat transfer in PCM,” Energy Build. 160, 10–18 (2018). https://doi.org/10.1016/j.enbuild.2017.12.006

R. S. Abdulrahman, F. A. Ibrahim, and S. F. Dakhil, “Development of paraffin wax as phase change material based latent heat storage in heat exchanger,” Appl. Therm. Eng. 150, 193–199 (2019). https://doi.org/10.1016/j.applthermaleng.2018.12.149

W. Q. Li, Z. G. Qu, Y. L. He, and Y. B. Tao, “Experimental study of a passive thermal management system for high-powered lithium ion batteries using porous metal foam saturated with phase change materials,” J. Power Sources 255, 9–15 (2014). https://doi.org/10.1016/j.jpowsour.2014.01.006

L. Zhu, Y. Yang, S. Chen, and Y. Sun, “Numerical study on the thermal performance of lightweight temporary building integrated with phase change materials,” Appl. Therm. Eng. 138, 35–47 (2018). https://doi.org/10.1016/j.applthermaleng.2018.03.103

N. Zhu, Z. Ma, and S. Wang, “Dynamic characteristics and energy performance of buildings using phase change materials: A review,” Energy Convers. Manage. 50, 3169–3181 (2009). https://doi.org/10.1016/j.enconman.2009.08.019

Y. Kusama and Y. Ishidoya, “Thermal effects of a novel phase change material (PCM) plaster under different insulation and heating scenarios,” Energy Build. 141, 226–237 (2017). https://doi.org/10.1016/j.enbuild.2017.02.033

S.-M. Wang, P. Matiašovsky, P. Mihálka, and C.-M. Lai, “Experimental investigation of the daily thermal performance of a mPCM honeycomb wallboard,” Energy Build. 159, 419–425 (2018). https://doi.org/10.1016/j.enbuild.2017.10.080

V. Yu. Borodulin and M. I. Nizovtsev, “Heat-inertial properties of walls of lightweight thermal insulation with phase change materials,” J. Phys.: Conf. Ser. 1105, 012108 (2018). https://doi.org/10.1088/1742-6596/1105/1/012108

B. Zalba, J. M. Marín, L. F. Cabeza, and H. Mehling, “Free-cooling of buildings with phase change materials,” Int. J. Refrig. 27, 839–849 (2004). https://doi.org/10.1016/j.ijrefrig.2004.03.015

R. Kandasamy, X.-Q. Wang, and A. S. Mujumdar, “Application of phase change materials in thermal management of electronics,” Appl. Therm. Eng. 27, 2822–2832 (2007). https://doi.org/10.1016/j.applthermaleng.2006.12.013

S. Gharbi, S. Harmand, and S. B. Jabrallah, “Experimental comparison between different configurations of PCM based heat sinks for cooling electronic components,” Appl. Therm. Eng. 87, 454–462 (2015). https://doi.org/10.1016/j.applthermaleng.2015.05.024

M. Temirel, H. Hu, H. Shabgard, P. Boettcher, M. McCarthy, and Y. Sun, “Solidification of additive-enhanced phase change materials in spherical enclosures with convective cooling,” Appl. Therm. Eng. 111, 134–142 (2017). https://doi.org/10.1016/j.applthermaleng.2016.09.090

M. M. Kenisarin, “Short-term storage of solar energy. 1: Low temperature phase-change materials,” Appl. Sol. Energy 29 (2), 48–65 (1993).

L. Royon, L. Karim, and A. Bontemps, “Optimization of PCM embedded in a floor panel developed for thermal management of the lightweight envelope of buildings,” Energy Build. 82, 385–390 (2014). https://doi.org/10.1016/j.enbuild.2014.07.012

Y.-J. Chiu, W.-M. Yan, H.-C. Chiu, J.-H. Jang, and G.-Y. Ling, “Investigation on the thermophysical properties and transient heat transfer characteristics of composite phase change materials,” Int. Commun. Heat Mass Transfer 98, 223–231 (2018).

A. Tokuç, T. Başaran, and S. C. Yesügey, “An experimental and numerical investigation on the use of phase change materials in building elements: The case of a flat roof in Istanbul,” Energy Build. 102, 91–104 (2015). https://doi.org/10.1016/j.enbuild.2015.04.039

C. J. Ho, C. P. Chen, and C.-M. Lai, “The effects of geometric parameters on the thermal performance of a rectangular natural circulation loop containing PCM suspensions,” Numer. Heat Transfer, Part A 70, 1313–1329 (2016). https://doi.org/10.1080/10407782.2016.1243966

E. N. Vasil’ev and V. A. Derevyanko, “The dynamics of phase changes in a heat storage of thermal control system for onboard radio-electronic equipment,” Thermophys. Aeromech. 25, 461–467 (2018).

M. I. Nizovtsev, V. Yu. Borodulin, V. N. Letushko, V. I. Terekhov, V. A. Poluboyarov, and L. K. Berdnikova, “Heat transfer in a phase change material under constant heat flux,” Thermophys. Aeromech. 26, 313–324 (2019).

Y. Kozak and G. Ziskind, “Novel enthalpy method for modeling of PCM melting accompanied by sinking of the solid phase,” Int. J. Heat Mass Transfer 112, 568–586 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.088

S. M. Usachev, V. T. Pertsev, and S. Khav’yarimana, “Heat storage materials for building materials and structures,” Nauchn. Zh. Stroit. Arkhit., No. 2 (50), 68–75 (2018).

I. O. Aimbetova, U. S. Suleimenov, M. A. Kambarov, E. N. Kalshabekova, and R. A. Ristavletov, “Thermophysical properties of phase transparent heat-storing materials used in construction,” Usp. Sovrem. Estestvozn., No. 12, 9–13 (2018).

A. Abhat, “Low temperature latent heat thermal energy storage: Heat storage materials,” Sol. Energy 30, 313–332 (1983). https://doi.org/10.1016/0038-092X(83)90186-X

G. A. Lane, Solar Heat Storage, Vol. II: Latent Heat Material (CRC, Boca Raton, Fla., 1983).

A. M. Khudhair and M. M. Farid, “A review on energy conservation in building applications with thermal storage by latent heat using phase change materials,” Energy Convers. Manage. 45, 263–275 (2004). https://doi.org/10.1016/S0196-8904(03)00131-6

V. A. A. Raj and R. Velraj, “Review on free cooling of buildings using phase change materials,” Renewable Sustainable Energy Rev. 14, 2819–2829 (2010). https://doi.org/10.1016/j.rser.2010.07.004

L. F. Cabeza, A. Castell, C. Barreneche, A. de Gracia, and A. I. Fernández, “Materials used as PCM in thermal energy storage in buildings: A review,” Renewable Sustainable Energy Rev. 15, 1675–1695 (2011). https://doi.org/10.1016/j.rser.2010.11.018

I. Dincer and M. A. Rosen, Thermal Energy Storage. Systems and Applications (Wiley, Chichester, 2011).

F. Souayfane, F. Fardoun, and P.-H. Biwole, “Phase change materials (PCM) for cooling applications in buildings: A review,” Energy Build. 129, 396–431 (2016). https://doi.org/10.1016/j.enbuild.2016.04.006

R. Zeinelabdein, S. Omer, and G. Gan, “Critical review of latent heat storage system for free cooling in buildings,” Renewable Sustainable Energy Rev. 82, 2843–2868 (2018). https://doi.org/10.1016/j.rser.2017.10.046

J. Jaguemont, N. Omar, P. Van den Bossche, and J. Mierlo, “Phase-change materials (PCM) for automotive applications: A review,” Appl. Therm. Eng. 132, 308–320 (2018). https://doi.org/10.1016/j.applthermaleng.2017.12.097

A. V. Eletskii, “Transport properties of carbon nanotubes,” Phys.-Usp. 52, 209–224 (2009). https://doi.org/10.3367/UFNe.0179.200903a.0225

A. V. Eletskii, I. M. Iskandarova, A. A. Knizhnik, and D. N. Krasikov, “Graphene: Fabrication methods and thermophysical properties,” Phys.-Usp. 54, 227–258 (2011). https://doi.org/10.3367/UFNe.0181.201103a.0233

F. Incropera, Introduction to Heat Transfer, 5th ed. (Wiley, Hoboken, N. J., 2005).

S. Bretsznajder, Prediction of Transport and Other Physical Properties of Fluids (Wydawnictwa Naukowo-Techniczne, Warsaw, 1962; Khimiya, Leningrad, 1966; Pergamon, Oxford, 1971).

L. Han, X. Jia, Z. Li, Z. Yang, G. Wang, and G. Ning, “Effective encapsulation of paraffin wax in carbon nanotube agglomerates for a new shape-stabilized phase change material with enhanced thermal-storage capacity and stability,” Ind. Eng. Chem. Res. 57, 13026–13035 (2018). https://doi.org/10.1021/acs.iecr.8b02159

G. Fredi, A. Dorigato, L. Fambri, and A. Pegoretti, “Wax confinement with carbon nanotubes for phase changing epoxy blends,” Polymers 9, 405 (2017). https://doi.org/10.3390/polym9090405

J. F. Wang, H. Q. Xie, and Z. Xin, “Thermal properties of paraffin based composites containing multi-walled carbon nanotubes,” Thermochim. Acta 488, 39–42 (2009). https://doi.org/10.1016/j.tca.2009.01.022

B. W. Xu and Z. J. Li, “Paraffin/diatomite/multi-wall carbon nanotubes composite phase change material tailor-made for thermal energy storage cement-based composites,” Energy 72, 371–380 (2014). https://doi.org/10.1016/j.energy.2014.05.049

Y. J. Zhong, Q. G. Guo, S. Z. Li, J. L. Shi, and L. Liu, “Heat transfer enhancement of paraffin wax using graphite foam for thermal energy storage,” Sol. Energy Mater. Sol. Cells 94, 1011–1014 (2010). https://doi.org/10.1016/j.solmat.2010.02.004

M. Mehrali, S. T. Latibari, M. Mehrali, H. S. C. Metselaar, and M. Silakhori, “Shape-stabilized phase change materials with high thermal conductivity based on paraffin/graphene oxide composite,” Energy Convers. Manage. 67, 275–282 (2013). https://doi.org/10.1016/j.enconman.2012.11.023

T. Y. Wang, S. F. Wang, L. X. Geng, and Y. T. Fang, “Enhancement on thermal properties of paraffin/calcium carbonate phase change microcapsules with carbon network,” Appl. Energy 179, 601–608 (2016). https://doi.org/10.1016/j.apenergy.2016.07.026

J. L. Xiang and L. T. Drzal, “Investigation of exfoliated graphite nanoplatelets (xGnP) in improving thermal conductivity of paraffin wax-based phase change material,” Sol. Energy Mater. Sol. Cells. 95, 1811–1818 (2011). https://doi.org/10.1016/j.solmat.2011.01.048

Z. G. Zhang, N. Zhang, J. Peng, X. M. Fang, X. N. Gao, and Y. T. Fang, “Preparation and thermal energy storage properties of paraffin/expanded graphite composite phase change material,” Appl. Energy 91, 426–431 (2012). https://doi.org/10.1016/j.apenergy.2011.10.014

Z.-P. Liu and R. Yang, “Synergistically-enhanced thermal conductivity of shape-stabilized phase change materials by expanded graphite and carbon nanotube,” Appl. Sci. 7, 574 (2017). https://doi.org/10.3390/app7060574

M. AlMaadeed, S. Labidi, I. Krupa, and M. Karkri, “Effect of expanded graphite on the phase change materials of high density polyethylene/wax blends,” Thermochim. Acta 600, 35–44 (2015). https://doi.org/10.1016/j.tca.2014.11.023

P. Sobolciak, M. Karkri, M. A. Al-Maadeed, and I. Krupa, “Thermal characterization of phase change materials based on linear low-density polyethylene, paraffin wax and expanded graphite,” Renewable Energy 88, 372–382 (2016). https://doi.org/10.1016/j.renene.2015.11.056

W.-L. Cheng, R.-M. Zhang, K. Xie, N. Liu, and J. Wang, “Heat conduction enhanced shape-stabilized paraffin/HDPE composite PCMs by graphite addition: Preparation and thermal properties,” Sol. Energy Mater. Sol. Cells 94, 1636–1642 (2010). https://doi.org/10.1016/j.solmat.2010.05.020

M. Xiao, B. Feng, and K. Gong, “Preparation and performance of shape stabilized phase change thermal storage materials with high thermal conductivity,” Energy Convers. Manage. 43, 103–108 (2002). https://doi.org/10.1016/S0196-8904(01)00010-3

Y. Zhang, J. Ding, X. Wang, R. Yang, and K. Lin, “Influence of additives on thermal conductivity of shape-stabilized phase change material,” Sol. Energy Mater. Sol. Cells 90, 1692–1702 (2006). https://doi.org/10.1016/j.solmat.2005.09.007

Funding

The work was performed under State Assignment no. FSWF-2020-0023.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Krasnoshchekova

Rights and permissions

About this article

Cite this article

Grigor’ev, I.S., Dedov, A.V. & Eletskii, A.V. Phase Change Materials and Power Engineering. Therm. Eng. 68, 257–269 (2021). https://doi.org/10.1134/S0040601521040029

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601521040029