Abstract

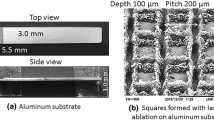

To improve the adhesive strength between metal and acrylonitrile butadiene styrene (ABS) resin, a metal surface was embossed with an irregular shape, and then we studied the bonding between different materials by insert molding. The irregular embossing of the metal surface was completed by nickel plating using micro particles of artificial diamond and aluminum oxide. Particles of various sizes were used, and the plating height was set at 1/2, 1/3, and 1/4 of the particle size. When the embossed surface was implemented on the metal surface through the particles, an undercut area was formed on the metal surface. During insert molding, the resin solidified in the undercut area, which increased the adhesive force. As the undercut size was different depending on the plating height and particle size, the adhesive strength varied, and as the particle size increased, the adhesive strength increased. The adhesion strength was higher in the plated specimens using aluminum oxide particles than those with artificial diamond particles. Moreover, the adhesive strength was better with ABS resin containing glass fiber than with pure ABS resin.

Similar content being viewed by others

References

Y. Zhang, P. Zhu, and G. Chen, Thin Walled Struct., 45, 670 (2007).

A. Kastensson, J. Clean. Prod., 66, 337 (2014).

G. V. Mahajan and V. S. Aher, IJSRP, 2, 1 (2012).

H.-X. Huang, J.-D. Tian, and W.-S. Guan, Polym. Eng. Sci., 54, 327 (2014).

W. Zhai, Y.-W. Kim, D. W. Jung, and C. B. Park, Ind. Eng. Chem. Res., 50, 5523 (2011).

K. H. Seo, J. C. Lim, and H. S. Lim, Elastom. Compos., 35, 132 (2000).

R. Stewart, Reinf. Plast., 54, 22 (2010).

Y. Kim and S. Kil, J. Weld. Join., 34, 31 (2016).

Y. Kim and H. Bang, J. Weld. Join., 36, 27 (2018).

S. T. Amancio-Filho and J. F. Santos, Polym. Eng. Sci., 49, 1461 (2009).

N.-H. Kim and J. Kim, J. Adhes. Interface, 19, 173 (2018).

D. A. Norman, Interactions, 9, 36 (2002).

S. L. Kim, M.-Y. Lyu, and S. W. Jang, Polym. Korea, 41, 727 (2017).

S. L. Kim and M.-Y. Lyu, Polym. Eng. Sci., 59, E93 (2019).

G. Potsch and W. Michaeli, in Injection Molding: An Introduction, Hanser, Munich, 2007, pp 180–181.

M. Honkanen, M. Hoikkanen, M. Vippola, J. Vuorinen, and T. Lepistö, J. Adhes. Sci. Technol., 23, 1747 (2009).

T. J. Lho, J. Y. Kim, D. J. Kang, J. H. Kim, and G. Y. Kim, J. KSPE, 25, 43 (2008).

N. M. Zain, S. H. Ahmad, and E. S. Ali, Int. J. Adhes. Adhes., 55, 43 (2014).

P. Fabrin, M. Hoikkanen, and J. Vuorinen, in Proceedings of SPE Annual Technical Conference (ANTEC 2007), Cincinnati, OH, 2007, pp 2528–2532.

P. K. Ghosh, A. Patel, and K. Kumar, Polymer, 87, 159 (2016).

M. Tahara N.K. Cuongand Y. Nakashima Surf. Coat. Techl. 173/174, 826 (2003

R. Prat, T. Suwa, M. Kogoma, and S. Okazaki, J. Adhes., 66, 163 (1998).

Acknowledgments

This work was supported by Korea Environment Industry & Technology Institute (KEITI) through R&D Project for recyclability of non-recyclable products, funded by Korea Ministry of Environment (MOE) (2020003080006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Woo, I.Y., Lyu, MY. Adhesive Strength Between Metal Sheet Plated Using Micro Particles and ABS Resin. Macromol. Res. 29, 297–305 (2021). https://doi.org/10.1007/s13233-021-9036-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-021-9036-1