Abstract

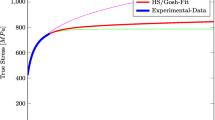

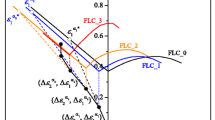

Failure in sheet metal forming can occur by necking, fracture or wrinkling. By using a forming limit diagram (FLD) as a powerful tool to prevent sheets metal failures in the forming process, provides parameters controlling throughout forming. There are different developed methods for predicting FLDs, which estimate sheet metal forming strains limits. Assessment of FLD estimation reveals that there is a dependency between the effect of several factors containing normal stress, shear stress, sheet thickness, mechanical properties, metallurgical properties, yield function, strain path, and bending with formability. In this research, the effects of bending via two finite element models are investigated. In the first method, the out-of-plane deformation is applied by increasing punch displacement to study the effects of bending. In the second method, the effect of bending is investigated via changing punch diameter (25, 50, 70 and, 100 mm). The Marciniak–Kuczynski (M–K) theory is used to predict the time of localized necking in finite element simulations. Furthermore, a novel method for the determination of the inhomogeneity coefficient is presented in M–K model to simulate the groove width for M–K model. To verify finite element simulation results, Nakazima tests with 50 and 100 mm punch diameters were done as experimental studies. The comparison of experimental results and finite element analysis illustrates that the increasing bending or the out-of-plane loading can improve formability. At the end, the effect of bending on FLD is reported as an equation based on minor and major strains.

Similar content being viewed by others

Abbreviations

- E :

-

Modulus of elasticity (MPa)

- f :

-

M–K model defect coefficient

- K :

-

Hardness coefficient (MPa)

- n :

-

Hardness index

- \({r}_{0}\) :

-

Anisotropy in the rolling direction

- \({r}_{45}\) :

-

Anisotropy in 45-degree direction

- \({r}_{90}\) :

-

The anisotropy in a perpendicular direction

- \({\varepsilon }_{1}\) :

-

Major strain

- \({\varepsilon }_{2}\) :

-

Minor strain

- \({\varepsilon }_{e}\) :

-

Equivalent strain

- \({\sigma }_{e}\) :

-

Equivalent stress

- \({\sigma }_{y}\) :

-

Yield stress

References

Paul SK, Manikandan G, Verma RK. Prediction of entire forming limit diagram from simple tensile material properties. J Strain Anal Eng Des. 2013;48:386–94. https://doi.org/10.1177/0309324713488886.

Habibi M, Ghazanfari A, Assempour A, Naghdabadi R, Hashemi R. Determination of forming limit diagram using two modified finite element models. Asjr-Me. 2017;48:141–3.

Habibi M, Hashemi R, Sadeghi E, et al. Enhancing the mechanical properties and formability of low carbon steel with dual-phase microstructures. J Mater Eng Perform. 2016;25:382–9. https://doi.org/10.1007/s11665-016-1882-1.

Backhofen SPK and WA. Plastic instability and fracture in sheet stretched over rigid punches. ASM Trans Q 1963;56:25–48.

Goodwin GM. Application of strain analysis to sheet metal forming problems in the press shop. SAE Tech Pap 1968:380–7. https://doi.org/10.4271/680093.

Swift HW. Plastic instability under plane stress. J Mech Phys Solids. 1952;1:1–18. https://doi.org/10.1016/0022-5096(52)90002-1.

Hill R. On discontinuous plastic states, with special reference to localized necking in thin sheets. J Mech Phys Solids. 1952;1:19–30. https://doi.org/10.1016/0022-5096(52)90003-3.

Marciniak Z, Kuczyński K. Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci. 1967;9:609–20. https://doi.org/10.1016/0020-7403(67)90066-5.

Ghazanfari A, Assempuor A, Habibi M, Hashemi R. Investigation on the effective range of the through thickness shear stress on forming limit diagram using a modified Marciniak–Kuczynski model. Modares Mech Eng. 2016;16(1):137–43.

Darabi R, Azodi HD, Bagherzadeh S. Investigation into the effect of material properties and arrangement of each layer on the formability of bimetallic sheets. J Manuf Process. 2017;29:133–48. https://doi.org/10.1016/j.jmapro.2017.07.022.

Hashemi R, Abrinia K. Analysis of the extended stress-based forming limit curve considering the effects of strain path and through-thickness normal stress. Mater Des. 2014;54:670–7. https://doi.org/10.1016/j.matdes.2013.08.023.

Allwood JM, Shouler DR. Generalised forming limit diagrams showing increased forming limits with non-planar stress states. Int J Plast. 2009;25:1207–30. https://doi.org/10.1016/j.ijplas.2008.11.001.

Assempour A, Nejadkhaki HK, Hashemi R. Forming limit diagrams with the existence of through-thickness normal stress. Comput Mater Sci. 2010;48:504–8. https://doi.org/10.1016/j.commatsci.2010.02.013.

Eyckens P, Van Bael A, Van Houtte P. Marciniak-Kuczynski type modelling of the effect of through-thickness shear on the forming limits of sheet metal. Int J Plast. 2009;25:2249–68. https://doi.org/10.1016/j.ijplas.2009.02.002.

Ravi KD. Formability analysis of extra-deep drawing steel. J Mater Process Technol. 2002;130–131:31–41. https://doi.org/10.1016/S0924-0136(02)00789-6.

Neale KW, Chater E. Limit strain predictions for strain-rate sensitive anisotropic sheets. Int J Mech Sci. 1980;22:563–74. https://doi.org/10.1016/0020-7403(80)90018-1.

Yun W, Peilong D, Zhenying X, Hua Y, Jiangping W, Jingjing W. A constitutive model for thin sheet metal in micro-forming considering first order size effects. Mater Des. 2010;31:1010–4. https://doi.org/10.1016/j.matdes.2009.07.037.

Hollomon H. Tensile deformation. Aime Trans. 1945;12:1–22.

Ghazanfari A, Soleimani SS, Keshavarzzadeh M, Habibi M, Assempuor A, Hashemi R. Prediction of FLD for sheet metal by considering through-thickness shear stresses. Mech Based Des Struct Mach. 2019. https://doi.org/10.1080/15397734.2019.1662310.

Butuc MC, Banabic D, Barata da Rocha A, Gracio JJ, Ferreira Duarte J, Jurco P, et al. The performance of Yld96 and BBC2000 yield functions in forming limit prediction. J Mater Process Technol. 2002;125126:281–6. https://doi.org/10.1016/S0924-0136(02)00399-0.

Stoughton TB. General forming limit criterion for sheet metal forming. Int J Mech Sci. 2000;42:1–27. https://doi.org/10.1016/S0020-7403(98)00113-1.

Sing WM, Rao KP. Influence of material properties on sheet metal formability limits. J Mater Process Tech. 1995;48:35–41. https://doi.org/10.1016/0924-0136(94)01630-J.

Rees DWA. Plastic instability. Basic Eng Plast. 2006;20:371–410. https://doi.org/10.1016/b978-0-7506-8025-7.50017-9.

Shi MF, Gerdeen JC. Effect of strain gradient and curvature on forming limit diagrams for anisotropic sheets. J Mater Shap Technol. 1991;9:253–68. https://doi.org/10.1007/BF02833650.

Fictorie E, van den Boogaard AH, Atzema EH. Influence of punch radius in a Nakazima test for mild steel and aluminium. Int J Mater Form. 2010;3:1179–82. https://doi.org/10.1007/s12289-010-0983-x.

American Society for Testing and Materials Annual. Annual book of ASTM standards. vol. Sec., 4. 1992. https://doi.org/https://doi.org/10.1520/C1530_C1530M-04R10E01.

Habibi M, Hashemi R, Ghazanfari A, Naghdabadi R, Assempour A. Forming limit diagrams by including the M–K model in finite element simulation considering the effect of bending. Proc Inst Mech Eng Part L J Mater Des Appl. 2018;232:625–36. https://doi.org/10.1177/1464420716642258.

Rahmatabadi D, Tayyebi M, Najafizadeh N, Hashemi R, Rajabi M. The influence of post-annealing and ultrasonic vibration on the formability of multilayered Al5052/MgAZ31B composite. Mater Sci Technol (United Kingdom). 2020. https://doi.org/10.1080/02670836.2020.1867784.

Roostaei M, Darabi R. Investigation on formability of three-layer joined Al/Cu/Al sheets annealed at different temperature. Mater Sci Technol (United Kingdom). 2020. https://doi.org/10.1080/02670836.2020.1792637.

Aghchai AJ, Shakeri M. Theoretical and experimental formability study of two-layer metallic sheet (Al1100/St12). Proc Inst Mech Eng Part B J Eng Manuf. 2008;222:1131–8. https://doi.org/10.1243/09544054JEM1140.

Darabi R, Azodi HD, Bagherzadeh S. Investigation into the effect of material properties and arrangement of each layer on the formability of bimetallic sheets. J Manuf Process. 2017. https://doi.org/10.1016/j.jmapro.2017.07.022.

Producers BR, Bureau N. A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond Ser A Math Phys Sci. 1948;193:281–97. https://doi.org/10.1098/rspa.1948.0045.

Assempour A, Hashemi R, Abrinia K, Ganjiani M, Masoumi E. A methodology for prediction of forming limit stress diagrams considering the strain path effect. Comput Mater Sci. 2009;45:195–204. https://doi.org/10.1016/j.commatsci.2008.09.025.

Funding

There is no funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Peng, D., Chen, S., Darabi, R. et al. Prediction of the bending and out-of-plane loading effects on formability response of the steel sheets. Archiv.Civ.Mech.Eng 21, 74 (2021). https://doi.org/10.1007/s43452-021-00227-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00227-1