Composite binders with an SiC content from 10 to 40% are prepared on the basis of high-alumina chamotte and silicon carbide powder previously dispersed in water. Ceramic concretes are prepared based on highly concentrated ceramic binder suspensions (HCBS) and mullite polydispersed filler by vibration casting and their properties are studied. Specimens containing 15% SiC have maximum strength in compression (150 MPa) with a firing temperature of 1200°C. Depending on firing temperature (1200 and 1400°C) and SiC content specimen weight gain specifying the degree of SiC oxidation is in the range 0.2 – 2.6%. Increased heat resistance for specimens containing 10% SiC in the matrix system is established.

Similar content being viewed by others

References

I. S. Kainarskii and É. V. Degtyareva, Carborundum Refractories [in Russian], Metallurgiya, Khar’kov (1063).

Yu. E. Pivinskii, Unmolded Refractories, Vol. 1, Book 1. General Questions of Technology [in Russian], Teploenergetik, Moscow (2003).

J. R. Oliveira and V. C. Pandolfelli, “Deflocculation of Al2O3–SiC suspension,” Am. Ceram. Soc. Bull., 80(2), 47 – 53 (2001).

G. G. Gnesin, Silicon Carbide Material [in Russian], Metallurgiya, Moscow 91977).

I. Allenshtein, et al., G. Ruchka dn Kh. Vutnau (editors), Refractory Materials. Structure, Properties. Testing: handbook (translated from German], Intermet Inzhiniring, Moscow (2010).

E. M. Grishpun, Yu. E. Pivinskii, E. V. Rozhkov, et al., “Production and service of high alumina ceramic castables. 1. Ramming mixtures based on modified bauxite HCBS,” Refract. Ind. Ceram., 41(3/4), 104 – 108 (2000).

E. V. Rozhkov, Yu. E. Pivinskii, and M. Z. Naginskii, “Production and service of high-alumina ceramic castables. 2. Properties and service of vibration-placed castables based on bauxite-modified highly concentrated ceramic binding suspensions (HCBS) for use in blast-furnace runners,” Refract. Ind. Ceram., 42(5/6), 209 – 215 (2001).

Yu. E. Pivinskii, E. M. Grishpun, and A. M. Gorokhovskii, “Engineering, manufacturing and servicing of shaped and unshaped refractories based on highly concentrated ceramic binding suspensions,” Refract. Ind. Ceram., 56(3), 245 – 253 (2015).

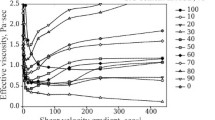

Yu. E. Pivinskii and M. A. Skuratov, “Cast (self-flow) ceramic castables. 3. Rheotechnological properties of molding systems for fabrication of silicon carbide ceramic castables,” Refract. Ind. Ceram., 41(11/12), 401 – 404 (2000).

M. A. Skuratov and Yu. E. Pivinskii, “Cast (self-flow) ceramic castables. 4. Spreadability of molding systems and some properties of mullite-silicon carbide ceramic castables,” Refract. Ind. Ceram., 42(1/2), 23 – 29 (2001).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the field of composite materials based on HCBS and refractory materials based on the system Al2O3–SiO2–SiC. Part 1,” Refract. Ind. Ceram., 59(2), 124 – 133 (2018).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the field of composite materials based on HCBS and refractory materials based on the system Al2O3–SiO2–SiC. Part 2,” Refract. Ind. Ceram., 59(3), 247 – 251 (2018).

P. V. Dyakin, Yu. E. Pivinskii, and A. Yu. Kolobov, “Research in the field of composite materials based on HCBS and refractory materials based on the system Al2O3–SiO2–SiC. Part 3,” Refract. Ind. Ceram., 59(5), 445 – 453 (2019).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the field of composite materials based on HCBS and refractory materials based on the system Al2O3–SiO2–SiC. Part 4,” Refract. Ind. Ceram., 60(2), 142 – 148 (2019).

Yu. E. Pivinskii, P. V. Dyakin, and L. V. Ostryakov, “Research in the field of preparing molded and unmolded refractories based on high-alumina HCBS. Part 14. Composition and some properties of composite composition ceramic concretes in the system Al2O3–SiO2–SiC-C,” Refract. Ind. Ceram., 59(2), 124 – 133 (2018).

P. V. Dyakin, Yu. E. Pivinskii, D. S. Prokhorenkov, et al., “Phase composition, structure and some properyties of materials based on bauxite complex composition HCBS in the Al2O3–SiO2–SiC–C system,” Vestn. BGTU im V. G. Shukhova, No. 2, 115 – 125 (2020).

V. A. Doroganov and Yu. N. Trepalina, “Highly concentrated ceramic binder suspensions based on silicon carbide,” Refract. Ind. Ceram., 51(4), 302 – 304 (2010).

V. A. Doroganov, E. A. Doroganov, E. I. Evtushenko, et al., “Refractory materials based on artificial ceramic binder suspensions of silicon carbide composition,” Vestn. BGTU im V. G. Shukhova, No. 4, 156 – 160 (2013).

V. A. Doroganov, N. A. Peretokina, E. A. Doroganov, et al., “Study of nano-differentiated silicon carbide binders and composites based on them,” Refract. Ind. Ceram., 55(5), 465 – 468 (2015).

S. V. Zaitsev, V. A. Doroganov, E. A. Doroganov, et al., “Study of artificial ceramic binder properties in the system Al2O3–SiO2–SiC,” Refract. Ind. Ceram., 57(5), 526 – 530 (2017).

S. V. Zaitsev, V. A. Doroganov, E. A. Doroganov, et al., “Study of artificial ceramic binders of mullite-silicon carbide composition composites based on them,” Refract. Ind. Ceram., 58(1), 109 – 112 (2017).

S. V. Zaitsev, V. A. Doroganov, E. A. Doroganov, et al., “Artificial ceramic binders based on silicon and silicon carbide for silicon-carbide refractories in a nitride matrix,” Refract. Ind. Ceram., 60(5), 439 – 444 (2020).

Yu. E. Pivinskii and P. L. Mityakin, “Rheological and binding properties of high-alumina suspensions,” Refractories, 22(5/6), 292 – 298 (1981).

Yu. E. Pivinskii, Ceramic Binders and Ceramic Concretes [in Russian], Metallurgiya, Moscow (1990).

Yu. E. Pivinskii, Rheology of Dispersed Systems, HCBS, and ceramic Concretes. Elements of Nanotechnology in Silicate Material Science, Vol. 3 [in Russian] Politekhnika, St. Petersburg (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 16 – 20, November, 2020.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Skuratov, M.A., Doroganov, V.A. et al. Ceramic Composition Binder Suspensions in the Al2O3–SiO2–SiC System and Ceramic Concretes Based Upon Them. Refract Ind Ceram 61, 639–643 (2021). https://doi.org/10.1007/s11148-021-00534-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00534-3