Abstract

Laboratory experiments are an important and powerful method for investigating stratified fluid dynamics. Visualising the physics of interest, however, is challenging and often limits the effectiveness of the laboratory approach. Improved techniques and methodologies that simplify visualisation will broaden the application of laboratory experiments with stratified fluid dynamics. Here, we propose a simple variation to the “double-bucket” method, commonly used to generate stratified environments for laboratory experiments, that leads to the formation of robust, discrete, uniformly-spaced double-diffusive layers that are able to be visualised with a shadowgraph. This technique, which we refer to as the “hot double-bucket” method, provides a realtime global shadowgraph view of the movement of isopycnal surfaces throughout the stratified environment. To demonstrate the utility of the hot double-bucket method we visualise the propagation of small-amplitude internal waves and compare our observations with the theoretically derived dispersion relation.

Graphic abstract

Similar content being viewed by others

1 Introduction

Stratification is a leading order governing property of many geophysical fluid dynamics that can fundamentally affect fluid behaviour. Laboratory experiments and demonstrations with stratified fluids play an important role in improving our conceptual understanding of the influence of stratification. While developing a stratified environment in the laboratory setting is relatively simple (e.g., Oster (1965)), qualitatively visualising the stratified dynamics of interest is challenging, and often limits the utility of the experiment, especially as a teaching exercise. Existing methodologies to visualise stratified fluid dynamics typically employ specialised techniques specific to the apparatus, and return an abstract representation of the physics that requires guided interpretation to understand, often rendering them inaccessible for many audiences and applications. New approaches that simplify and improve the visualisation aspect are important steps for enhancing the learning outcomes of laboratory experiments and demonstrations with stratified fluid dynamics (e.g., see Sutherland et al. (2014)).

Optical methods (as opposed to tracer methods; e.g. Merzkirch (1987), Freymuth (1993)) are an effective means to visualising the density and thermodynamic fields of stratified fluids. In terms of its experimental setup, the simplest optical method is the shadowgraph method. The physical basis of the shadowgraph method is that the trajectory of light is deflected when it encounters an along-path change in the refractive index, n. For saltwater, the refractive index is well approximated as a linear function of its density \(\rho \) (kg/m\(^3\)), that is,

where,

and \(\rho _0\) and \(n_0\) are the reference density and its refractive index, respectively Weast (1981). In the case that the angle of deflection is spatially non-uniform, such as when there is curvature to the fluid density field, then light projected through the fluid will cast a shadow that can be visualised on a screen (e.g., Fig. 1). It is important to note that the shadowgraph method visualises the curvature of the density field; linear variations in the density field invoke a uniformly-varying change in the angle of deflection, and thus cast no shadow. The shadowgraph method selectively amplifies signals from small scale structures with high curvature, such as turbulence or density interfaces. Furthermore, the image produced by the shadowgraph method is the result of an integration along the light path, meaning it is best suited to visualise dynamics that can be approximated as two dimensional in the plane normal to the light path. Nevertheless, the simplicity of the shadowgraph method makes it convenient for qualitative depictions of fluid dynamics in environments with heterogenous density.

A standard method for establishing a salinity-stratified environment in the laboratory is known as the “double-bucket” method Oster and Yamamoto (1963). This approach involves two reservoirs, one containing saltwater and the other fresh, connected together in series and each maintained as well-mixed; by draining the system from either of the reservoirs, the salinity of the draining fluid will monotonically change. In its simplest application, the double-bucket method produces a linear density profile, but can be extended to produce more complicated density profiles (e.g., Economidou and Hunt (2009)). For many applications, such as examining the propagation of internal waves, a uniform stratification is preferable, especially for teaching purposes. A uniform stratification has the drawback, however, that it is invisible to the shadowgraph method as there is no curvature to its density field. Thus, fluid dynamics in a uniform stratification are only visible by the shadowgraph method if they generate density structure that has high-curvature, like turbulence, which is not ideal for investigations of linear processes. This constraint has required more sophisticated optical methods, such as Schlieren or interferometry techniques (e.g., Dalziel et al. (2000), Watt and Vest (1987)), be employed to visualise small-amplitude linear dynamics in uniform stratified environments, often limited to a relatively narrow field of view and involving careful calibration steps.

Here we propose a new variation of the double-bucket method that is able to introduce robust, discrete, regularly-spaced instances of nonzero curvature to an otherwise uniform stratified environment. Put simply, we use hot water with the double-buckets instead of room temperature water. This approach, which we refer to as the “hot double-bucket”, still uses salinity to generate the stratification, but double-diffusive convection acts to create discrete layers. This technique permits the use of the shadowgraph visualisation method to obtain a global view of both linear and nonlinear dynamics in a near-uniformly stratified environment. We introduce the method in Sect. 2 and describe the stratification that results in Sect. 3. In Sect. 4 we use it to visualise the propagation of small-amplitude internal waves by way of simple shadowgraph, and summarise our findings in Sect. 5.

A schematic depicting the physical basis of the shadowgraph method. a Light of uniform intensity I (i.e., \(\partial {I}/\partial {z}=0\)) passing through a fluid of uniform refractive index n will remain of uniform intensity. b Uniform intensity light passing through a fluid with linearly varying refractive index will remain of uniform intensity, however the level of intensity will change. c Uniform light passing through a fluid with nonlinearly varying refractive index will not remain of uniform intensity

2 Experimental apparatus & methodology

2.1 Apparatus

We use a tank made of 10 mm thick perspex with internal dimensions of 1.2 \(\times \) 0.65 \(\times \) 0.1 m\(^{3}\) (\(L\times {H}\times {W}\); Fig. 2) in a laboratory maintained at \(T_{lab}=21\pm 0.5^{\circ }\)C. A 250 W Kodak slide projector is positioned approximately 15 m behind the tank and focussed such that it projects approximately collimated light oriented approximately normal to the back face of the tank. The outer surface of the front face of the tank is lined with wax paper, which serves as the screen for the shadowgraph. Note that our use of a relatively narrow tank illuminated through its width is designed to interrogate dynamics that can be approximated as two-dimensional (\(L\times {H}\)); the methods we propose here are not sensitive to the specific dimensions of the tank or lighting configuration.

Two identical 50 L buckets (hence the name “double-bucket”), referred to as the fresh and brine bucket, are positioned on an independent platform approximately 1.4 m above the base of the tank. These two buckets are connected at their bases via a pipe with a closable valve. The brine bucket has a second valved pipe from its base that can be used to drain both buckets when the two valves are open. This drain pipe is connected to a flexible hose that reaches into the perspex tank; the end of this hose opens into a polystyrene float with a porous base. The brine bucket also has an impeller system that maintains the homogeneity of the brine water throughout its volume. When the two valves are open, fresh water enters the brine bucket and is mixed thoroughly, monotonically reducing the salinity of the draining brine water.

Mounted above the centre of the tank is a computer-controlled SmartMotor with linkages that drive a vertically oscillating elliptical cylinder within the stratified fluid. The elliptical cylinder, which has major and minor axes of 50 and 30 mm, respectively, is oriented across the width of the tank, with its major axis in the vertical direction. The frequency of the oscillating elliptical cylinder \(\omega \) (s\(^{-1}\)) and its amplitude \(\lambda \) (m) are imposed. A second SmartMotor drives a conductivity probe vertically through the depth of the fluid to obtain profiles of conductivity-derived density \(\rho _{c}{\left( {z}\right) }\).

2.2 Methodology

We begin each experiment by filling the two buckets with water of a known temperature \(T_{h}\) (\(^{\circ }\)C), with the connecting valve open and the drain valve closed. Ensuring that the bottom pressures of the two buckets have equalised, the connecting valve is closed and a known mass of salt \(M_{s}\) (kg) is added to the brine bucket and dissolved by the impeller. An equal mass \(M_{s}\) of water at temperature \(T_{h}\) is added to the fresh bucket in order to maintain the pressure equilibrium between the two buckets.

Once the salt in the brine bucket has completely dissolved, the density of the water in the brine bucket is recorded. The connecting valve between the buckets is opened; because the bottom pressures of the two buckets are balanced, there is initially no exchange between the buckets. The drain valve is then opened, allowing salty fluid from the brine bucket to drain gently into the polystyrene float and through its porous base, gradually filling the initially empty perspex tank. As salty water drains from the brine bucket, the bottom pressure of the brine bucket reduces, permitting fresh water from the fresh bucket to enter the brine bucket. While this fresh water is steadily entering the brine bucket, the impeller keeps the water in the brine bucket homogenous. In time, as more salty water drains into the perspex tank and more fresh water is mixed through the brine bucket, the salinity (and hence, density) of the brine bucket water decreases. Providing that the polystyrene float sufficiently damps the momentum and disturbances of the draining brine bucket waters, this double-bucket system establishes a uniform stratification in the perspex tank.

The extension we propose as the “hot double-bucket” method begins with ensuring the water temperature \(T_{h}\) is hotter than the laboratory temperature, \(T_{lab}\). We use this hot water to fill both the buckets and to pre-fill the perspex tank; this pre-fill of the perspex tank brings the temperature of the tank and apparatus as close as possible to \(T_{h}\). The salt is dissolved into the brine bucket fluid as described above; once this is complete, the perspex tank, now warm, is rapidly emptied. The valves are then opened, and the warmed perspex tank is filled with water draining from the brine bucket. When the tank is filled to a suitable depth, the drain valve is closed and the stratified fluid in the tank is left for \(\sim \)10 minutes to allow any disturbances to settle. Vertical profiles of the conductivity are then obtained along with the densities of fluid samples extracted from different depths, allowing the vertical density gradient \({\text {d}{\rho }/\text {d}z}\) (kg/m\(^4\)) to be calculated.

3 Hot double-bucket stratification

The progression of a typical fill with the “hot double-bucket” is shown in the sequence of shadowgraph images in Fig. 3. The warm salty fluid enters the perspex tank as surface fluid, where it is able to lose some of its heat to the laboratory, predominantly via convection of the warm air above the water. In practice, this warm convecting air subsequently acts to maintain the temperature of the preheated tank as greater than that of the laboratory. The surface fluid is rapidly replaced by relatively fresher fluid, which caps the previous surface fluid and confines its heat loss to the laboratory through the sidewalls of the tank. This process of surface fluid replacement and capping of the underlying waters continues until the tank is full.

Snapshots of the tank being filled with the hot double-bucket method. This experiment has \(\varDelta {T}=30.6^{\circ }\)C and \(\text {d}\rho /\text {d}z=108.1\)kg/m\(^4\). These are taken at a 5, b 15, c 25 and d 40 minutes after the filling began. Double-diffusive layers are evident in fluid that has been in the tank for longer than \(\sim \)5 minutes. A video of this filling process is available here: https://www.youtube.com/watch?v=j9UbaKuNZ_c

In the case presented here, approximately 5 minutes after entering the tank (Fig. 3a), distinct, regularly-spaced layers are observed to develop in shadowgraph of the water. These layers continue to develop in the shadowgraph from the bottom upwards throughout the fluid at depths that have been in the tank for at least \(\sim \)5 minutes (Figs. 3b,c). Note that the time taken to develop these layers is observed to be inversely dependent on the water-to-laboratory temperature difference, although this timescale is not quantified here. Also, the timescale to develop the layers increases if the sidewalls of the tank are insulated, however the shadowgraph is then obscured. Once the tank is full, these layers occupy the entire depth of the stratified fluid, up to a relatively thicker surface convective boundary layer, in which active convection is observed in the shadowgraph (Fig. 3d). Video footage of the filling process show slight disturbances and turbulence evident in the movement of shadows, which give the impression of the propagation of internal waves throughout the fluid.

The images of the stratified environment resulting from the hot double-bucket and visualised with the shadowgraph method are reminiscent of those obtained by the “Fluo-line techinque” Hopfinger et al. (1991). This technique involves the careful dragging of thin cotton wires, pre-soaked in a highly-concentrated fluorescein solution and allowed to dry, throughout the stratified environment at regularly spaced vertical levels, and visualised with a vertical laser sheet. The fluorescein lines mark isopycnals, and the vertical displacement of these can indicate the presence of internal waves, for instance. Recent efforts employing the Fluo-line technique make use of image processing software to identify light intensity variations, thereby allowing the fluorescein-marked isopycnal dynamics to be captured digitally and analysed, such as Voisin et al. (2010). A similar quantitative analysis can, in principle, be extended to the light intensity variations of the shadowgraph images here, but is not necessary here for our relatively simple demonstration of the hot double-bucket method. In addition, the layered nature of the hot double-bucket stratification is comparatively more robust than techniques that dye-mark isopycnals, as unintentional disturbances of the stratification (that would otherwise lead to an irreversible diffusion and blurring of dye-lines) eventually settle such that the layers return to rest horizontal and, importantly, remain visible with the shadowgraph method. Furthermore, as the hot double-bucket method does not require any subsequent delicate dye distribution techniques, the time it takes to repeatedly fill, run, and refill experiments is relatively shorter (a single researcher could manage 1 experiment per hour with our apparatus), allowing us to span a wider range of parameter space for the same amount of effort.

Given its potential as a diagnostic tool, the layered structure is of interest; specifically, what physics govern the layer thickness, and are we able to approximate this layered system as uniformly stratified?

3.1 Layer thickness

To understand the layer thickness, we begin by taking the simplified equation of state for density \(\rho \) as a function of temperature T (\(^\circ \)C) and salinity S (g/kg),

where \(T_{0}\) and \(S_{0}\) are reference temperatures and salinities, respectively, and \(\alpha \) (\(^{\circ }\)C\(^{-1}\)) and \(\beta \) (kg/g) are the thermal expansion and haline contraction coefficients, respectively, taken as,

and \(\beta =0.7\), where the former is the quadratic fit of \(\alpha \) as a function of temperature between 10–60\(^\circ \)C Elert (2020). Considering the hot double-bucket system setup, the salinity of the water entering the tank reduces monotonically as the system drains and the tank fills. The temperature of the water entering the tank, which is initially the temperature of the water in the hot double-bucket \(T_{h}\), is monitored throughout the duration of the fill (approximately 30 minutes), and is observed to decrease from \(T_{h}\) by at most 1\(^\circ \)C, meaning the tank can be considered initially isothermal. Therefore, the initial stratification of the tank can be approximated by the vertical gradient of salinity alone, that is,

The stratified water in the tank is of temperature \(T_{h}>T_{lab}\), and therefore loses some of its heat to the laboratory through the sidewalls of the tank. This cooling increases the density of the fluid that is close to the tank walls, causing it to sink through the stratification to its level of neutral buoyancy. This cooled fluid intrudes from the tank walls into the interior of the tank, diffusively warming by way of the surrounding fluid and rising back through the stratification. In this way, a gradual convective overturning circulation that is confined to a finite layer depth is established. The physical processes governing this phenomenon, referred to as double-diffusive convection, have been widely reported (see, e.g., Thorpe et al. (1969), Chen et al. (1971), Kranenborg (1996)). The effect of the double-diffusive convection on the stratification is to introduce relatively small, regularly-spaced anomalies to the otherwise uniform stratification. These stratification anomalies are instances of nonzero density curvature, so that they are visible with the shadowgraph method.

Following Kranenborg (1996), the theoretical lengthscale of the layer thickness, \(\eta \) (m), primarily depends on two factors: the initial strength of the stratification, and the temperature anomaly available to the fluid,

where \(\varDelta {T_t}\,=\,T_{h}\,-\,T_{t}\) is the temperature difference between the bulk water temperature \(T_{h}\) and the inner wall of the tank \(T_{t}\). By ensuring that the inner wall temperature is as uniform as possible (which we achieve by preheating the tank) we are able to produce layers of uniform thickness throughout the full depth of the tank. Interestingly, if tank is not preheated, the layer thickness tends to decrease as the tank becomes more full; this is because the upper regions of the tank are heated by the warm air convecting from the water surface, thereby reducing \(\varDelta {T_t}\).

The visibility of the layers by the shadowgraph method relies on the existence of small-scale nonlinear features in the vertical density gradient. So while these nonlinear features exist, the layers will remain visible. The double-diffusive convection within each layer reinforces the nonlinear density gradient, while diffusion operates to erode the gradient. By considering only the diffusive erosion of the layers, we can estimate a lower-bound of the timescale for which the layers will remain visible. Taking the diffusivity of salt as \(\kappa _{s}=1.39\times 10^{-9}\)m\(^2\)/s, and the finite thickness of the density interfaces between layers to be approximately half the layer thickness \(\eta =10^{-2}\)m, the timescale for diffusion to erode the visibility of the layers is,

However, the double-diffusive convection within each layer operates to continually sharpen the interfaces between layers, meaning that in practice the layers remain visible with the shadowgraph method for much longer than this lower-bound estimate.

3.2 Uniformity of stratification

Our next task is to confirm that this layered system is suitable for approximating a uniformly stratified environment. We do this by way of vertical profiles of the fluid conductivity, which is representative of its salinity, and therefore density (assuming negligible \(T_{h}\) variations). The conductivity (S/m; siemens per metre) is converted to voltage (V) by a bridge unit and logged. The recorded voltage, once calibrated with samples of known salinities, is approximately linearly dependent on the salinity of the water, from which we can calculate the conductivity-derived density, \(\rho _{c}\). That is, the vertical profile of conductivity-derived density is approximated as,

where \(V_{0}\) is a known reference voltage, and \(C_{0}\) and \(C_{1}\) are calibration coefficients. Note that this conductivity-derived density does not reflect the thermal contribution to density (which are assumed to be negligible given the small \(T_{h}\) variations), only the salinity contribution.

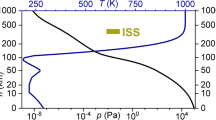

Figure 4a depicts vertical profiles of the conductivity-derived density \(\rho _{c}\), and the linear least-squares best fit for this, \(\overline{\rho _{c}}\), for a typical experiment. The layered structure is clearly evident, as is the bulk stratification. These profiles demonstrate that the density differences that arise from the layered environment are small relative to the bulk uniform stratification; for reference, the range of uniform stratifications that envelope the layered structures are ±4%. Noting that within each layer the density field is gravitationally stable, we are able to estimate the temperature anomaly required to ensure this stability, which we refer to as the conductivity-derived temperature anomaly, \(\delta {T_{c}}\). The vertical profile of the conductivity-derived temperature anomaly is then given by,

Figure 4b shows the vertical profile of \(\delta {T_{c}}\) for the same typical experiment. The conductivity-derived temperature anomaly within each layer is on the order of 2\(^\circ \)C, and throughout the depth \(\delta {T_{c}}\) is less than \(\pm 3^\circ \)C. Thus, considering the absence of substantial discontinuities in the density field, the small temperature anomalies that are essentially confined within each layer, and the regularity of the layer thickness, we have confidence that the layered system approximates a uniformly stratified environment for dynamics with vertical scales larger than the layer thickness. Indeed, spontaneous double-diffusive layers of this exact origin have been noted in experiments investigating internal wave dynamics, and were observed to have no visible impact on the dynamics of interest Dossmann et al. (2020).

3.3 Stratification experiments

Table 1 and Fig. 5 details the set of experiments performed to investigate the predictability of the layer thicknesses obtained from the hot double-bucket system. Due to the practical difficulty of measuring the temperature of inner wall of the tank \(T_{t}\), the temperature difference \(\varDelta {T}\) presented here is between the temperature of the water \(T_{h}\) and that of the laboratory \(T_{lab}\). It is expected that \(\varDelta {T}\) will certainly be larger than \(\varDelta {T_{t}}\), which governs the layer thickness. However, these can be approximately related by the ratio r,

which for \(\varDelta {T}>>\varDelta {T_{t}}\) can be expressed in terms of the thermal properties of the tank and laboratory as,

where \(c_{conv}\) is the convective heat transfer coefficient from the outer tank wall to the laboratory (taken as \(c_{conv}\approx 2.5\)W/m\(^2\) \(^{\circ }\)C), w is the width of the tank wall (\(w=10\) mm), and \(k_{tank}\) is the thermal conductivity of the tank (\(k_{tank}=0.2\)W/m\(^{\circ }\)C for perspex). This approach returns an approximate scaling for the ratio \({\varDelta {T_{t}}}/{\varDelta {T}}=0.125\).

a Vertical profiles of the conductivity-derived density \(\rho _{c}\)(z) and its linear best-fit \(\overline{\rho _{c}}\)(z), for a typical experiment with the hot double-bucket system (\(\varDelta {T} = 27.8^{\circ }\)C, \(\text {d}\rho /\text {d}z=91.7\)kg/m\(^4\)). Also included are the envelope of profiles with uniform stratifications that are ±4% of that for \(\overline{\rho _{c}}\)(z). b Vertical profiles of the conductivity-derived temperature anomaly \(\delta {T_{c}}\); that is, the temperature anomaly required at some depth z to account for the difference between \(\rho _{c}\)(z) and \(\overline{\rho _{c}}\)(z)

Table 1 also lists the stratifications obtained from the measured densities of water samples withdrawn from a range of depths for each experiment. The theoretical scaling for the layer thickness \(h_{t}\) is calculated by Eq. 6 using \(\varDelta {T}\,=\,T_{h}\,-\,T_{lab}\); \(h_{t}\) is expected to be larger than \(\eta \) because \(\varDelta {T}\) should ideally use \(T_{t}\) rather than \(T_{lab}\). The measured layer thickness \(h_{m}\) is that which is observed for each experiment. Figure 5b clearly demonstrates that the layer thickness is predictable and robust spanning the stratification and temperature anomaly space that we cover. The righthand column of Table 1 lists the theoretically-derived dynamical temperature difference experienced by the water, \(\varDelta {T_{t}}\,=\,T_{h}\,-\,T_{t}\), where \(T_{t}\) is the temperature of the inner tank wall, given by,

Note that the average of this quantity across all the experiments (\(\overline{\varDelta {T_{t}}} = 3.0^\circ \)C) is consistent with the conductivity-derived temperature anomaly \(\delta {T_{c}}\) variation within each layer. Finally, the ratio \({\varDelta {T_{t}}}/{\varDelta {T}}\) is listed; the average value of this ratio for the 14 experiments with \({\varDelta {T}}-{\varDelta {T_{t}}}>10^{\circ }\)C is \(r=0.124\), which agrees with the value \(r=0.125\) derived from the thermal properties of the tank and laboratory.

The set of experiments performed to investigate the behaviour of the layer thickness in response to temperature difference \(\varDelta {T}=T_{h}-T_{lab}\) and stratification strength. a The parameter space covered here; the colour each data point represents the temperature difference \(\varDelta {T}\) for that experiment, and the size of the data point represents its stratification. The general behaviour of the layer thickness is indicated; the layer thickness decreases as the stratification strengthens, and increases as the temperature difference increases. b The measured layer thickness \(h_{m}\) is well represented by the theoretically predicted layer thickness \(h_{t}\) (with a correlation coefficient r=0.992) despite the predicted value using the temperature of the laboratory rather than the temperature of the inner tank wall

4 Visualising internal waves with a shadowgraph

The hot double-bucket system provides an environment that is of approximately uniform stratification, with well-behaved, regularly-spaced layers that are globally visible with the shadowgraph method. Here we demonstrate that this methodology is suitable for visualising small-amplitude, linear internal waves. We begin with our tank filled with a stratification by the hot double-bucket system. We carefully position an elliptical cylinder near the centre of the stratified environment; this cylinder is connected to a computer controlled SmartMotor that is able to vertically oscillate the cylinder at a precise frequency \(\omega \) and amplitude \(\lambda \). The amplitude is held constant at \(\lambda =16\) mm throughout the experiments; this amplitude is set so as to be at least of similar magnitude to the measured layer thickness scale (O(1)cm), yet small enough to minimise local turbulence generated by the elliptical cylinder.

The measured stratification \({\text {d}{\rho }}/{\text {d}z}\) is used to calculate the characteristic Brunt–Väisälä frequency N (s\(^{-1}\)), defined as,

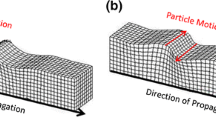

where g is gravitational acceleration. This value of N provides an upper bound of \(\omega \) for which linear internal waves are able to propagate, with their angle of propagation given by the dispersion relation,

where \(\varTheta \) is the angle of propagation of the group velocity relative to the horizontal. For a given experiment, we span a range of \(\omega \) that increases up to \(\omega >N\), at which point the internal wave propagation ceases; for each value of \(\omega \), we record the angle \(\varTheta \) at which the group velocity propagates. From the dispersion relation for internal waves (Eq. 14), when \(\omega <N\), the angle \(\varTheta \) is such that \(\omega =N\text {cos}\varTheta \) is satisfied.

Figure 6 contains a set of frames showing the group velocity propagation for a range of imposed \(\omega \), where \(\omega <N\). Superimposed on the frames are arrows to indicate this direction; it appears relatively less clear in this static view than is does in reality or in videos (e.g., see https://www.youtube.com/watch?v=fc-emxoodas). Also included is a panel relating the imposed oscillation frequency \(\omega \) to the quantity \(N\text {cos}\varTheta \) (Fig. 6f). Note that the largest source of uncertainty here is in the measurement of the propagation angle, which is best performed on video footage replayed in timelapse. Nevertheless, it is clearly evident that the hot double-bucket system is able to provide a stratified environment that is suitable for visualising the dynamics of small-amplitude linear internal waves with the simple shadowgraph method.

a–e The group velocity propagation for a range of \(\omega \), where \(\omega <N\). The superimposed arrows are indicative of the group velocity propagation direction; this is relatively clearer in reality or video footage (https://www.youtube.com/watch?v=fc-emxoodas) rather than these static images. f A comparison of the driving frequency \(\omega \) with the quantity \(N\text {cos}\varTheta \)

5 Conclusions

The effective visualisation of stratified fluid dynamics in laboratory experiments is challenging. Simple optical methods, such as the shadowgraph method, are not well-suited to visualise many basic physics of a uniformly stratified environment. Here we have proposed a simple variation to an established method for developing a stratified environment that allows isopycnals to be globally visible with shadowgraph. This proposed method, the hot double-bucket, uses no additional experimental apparatus. We demonstrate this new approach through the successful evaluation of the dispersion relation for small-amplitude linear internal waves visualised by way of shadowgraph. The hot double-bucket method allows fundamental stratified fluids dynamics to be visible with a shadowgraph, thereby greatly increasing the utility of laboratory experiments in stratified environments.

References

Chen CF, Briggs DG, Wirtz RA (1971) Stability of thermal convection in a salinity gradient due to lateral heating. Int J Heat Mass Transf 14:57–65

Dalziel SB, Hughes GO, Sutherland BR (2000) Whole-field density measurements by ‘synthetic schlieren’. Exp Fluids 28:322–335

Dossmann Y, Shakespeare CJ, Stewart KD, Hogg AMcC (2020) Asymmetric internal tide generation in the presence of a steady flow. J Geophys Res: Oceans 125:e2020JC016503

Economidou M, Hunt GR (2009) Density stratified environments: the double-tank method. Exp Fluids 46:453–466

Elert G (2020) The Physics Hypertextbook, https://physics.info/

Freymuth P (1993) Flow visualization in fluid mechanics. Rev Sci Instrum 64:1–18

Hopfinger EJ, Flór J-B, Chomaz J-M, Bonneton P (1991) Internal waves generated by a moving sphere and its wake in a stratified fluid. Exp Fluids 11:255–261

Kranenborg J (1996) Double-Diffusive Convection Due to Lateral Thermal Forcing, Ph.D Thesis, Utrecht University

Merzkirch W (1987) Flow visualization, 2nd edn. Academic, Orlando

Oster G, Yamamoto M (1963) Density gradient techniques. Chem Rev 63:257–268

Oster G (1965) Density gradients. Sci Am 213:70–76

Sutherland B, Dauxois T, Peacock T (2014) Internal waves in laboratory experiments. In: von Larcher T, Williams PD (eds) Modeling atmospheric and oceanic flows: insights from laboratory experiments and numerical simulations. American Geophysical Union, Washington DC, pp 193–212

Thorpe SA, Hutt PK, Soulsby R (1969) The effect of horizontal gradients on thermohaline convection. J Fluid Mech 38:375–400

Voisin B, Ermanyuk EV, Flór J-B (2010) Internal wave generation by oscillation of a sphere, with application to internal tides. J Fluid Mech 666:308–357

Watt DW, Vest CM (1987) Digital interferometry for flow visualization. Exp in Fluids 5:401–406

Weast RC (1981) Handbook of chemistry and physics, 62nd edn. C.R.C. Press, Boca Raton

Acknowledgements

Many thanks to Angus Rummery and Anthony Beasley for their technical expertise and laboratory assistance. This work was supported by the Australian National University Vice-Chancellor’s Teaching Enhancement Grant, Fluids in 4K. CJS acknowledges support from an ARC Discovery Early Career Researcher Award DE180100087 and ANU Futures Scheme award. YD acknowledges support from the Embassy of France in Australia, and the French PIA project Lorraine Université d’ Excellence (ANR-15-IDEX-04-LUE).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Stewart, K.D., Shakespeare, C.J., Dossmann, Y. et al. A simple technique for developing and visualising stratified fluid dynamics: the hot double-bucket. Exp Fluids 62, 103 (2021). https://doi.org/10.1007/s00348-021-03190-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-021-03190-y