Abstract

Background

Developments in digital image correlation (DIC) in the last decade have made it a practical and effective optical technique for displacement and strain measurement at high temperatures.

Objective

This overview aims to review the research progress, summarize the experience and provide valuable references for the high-temperature deformation measurement using DIC.

Methods

We comprehensively summarize challenges and recent advances in high-temperature DIC techniques.

Results

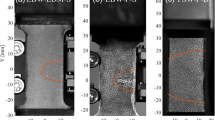

Fundamental principles of high-temperature DIC and various approaches to generate thermal environment or apply thermal loading are briefly introduced first. Then, the three primary challenges presented in performing high-temperature DIC measurements, i.e., 1). image saturation caused by intensified thermal radiation of heated sample and surrounding heating elements, 2) image contrast reduction due to surface oxidation of the heated sample and speckle pattern debonding, and 3) image distortion due to heat haze between the sample and the heating source, and corresponding countermeasures (i.e., the suppression of thermal radiation, fabrication of high-temperature speckle pattern and mitigation of heat haze) are discussed in detail. Next, typical applications of high-temperature DIC at various spatial scales are briefly described. Finally, remaining unsolved problems and future goals in high-temperature deformation measurements using DIC are also provided.

Conclusions

We expect this review can guide to build a suitable DIC system for kinematic field measurements at high temperatures and solve the challenging problems that may be encountered during real tests.

Similar content being viewed by others

References

Sziroczak D, Smith H (2016) A review of design issues specific to hypersonic flight vehicles. Prog Aerosp Sci 84:1–28

Pineau A, Antolovich SD (2009) High temperature fatigue of nickel-base superalloys–a review with special emphasis on deformation modes and oxidation. Eng Fail Anal 16(8):2668–2697

Thornton EA (1996) Experimental Methods for High-Temperature Aerospace Structures. Thermal Stresses IV. North-Holland 1–89

Zhang JS (2010) High temperature deformation and fracture of materials. Elsevier

Kayser P, Godefroy JC, Leca L (1993) High-temperature thin-film strain gauges. Sens Actuators, A 37:328–332

Lei JF, Castelli MG, Androjna D et al (1996) Comparison testings between two high-temperature strain measurement systems. Exp Mech 36(4):430–435

Sharpe WN (1975) Strain gages for long-term high-temperature strain measurement. experimental mechanics 15(12): 482–488

Liu KC, Ding JL (1993) A mechanical extensometer for high-temperature tensile testing of ceramics. J Test Eval 21(5):406–413

Ding JL, Liu KC, More KL et al (1994) Creep and creep rupture of an advanced silicon nitride ceramic. J Am Ceram Soc 77(4):867–874

Ren NF, Yang HM, Yuan SQ et al (2014) High temperature mechanical properties and surface fatigue behavior improving of steel alloy via laser shock peening. Mater Des 53:452–456

Codrington J, Nguyen P, Ho SY et al (2009) Induction heating apparatus for high temperature testing of thermo-mechanical properties. Appl Therm Eng 29(14–15):2783–2789

Cheng X, Qu Z, He R et al (2016) An ultra-high temperature testing instrument under oxidation environment up to 1800 C. Rev Sci Instrum 87(4):045108

Mihailov SJ (2012) Fiber Bragg grating sensors for harsh environments. Sensors 12(2):1898–1918

Lowder TL, Smith KH, Ipson BL et al (2005) High-temperature sensing using surface relief fiber Bragg gratings. IEEE Photonics Technol Lett 17(9):1926–1928

Li Y, Yang M, Wang DN et al (2009) Fiber Bragg gratings with enhanced thermal stability by residual stress relaxation. Opt Express 17(22):19785–19790

Xu P, Ba D, He W et al (2018) Distributed Brillouin optical fiber temperature and strain sensing at a high temperature up to 1000° C by using an annealed gold-coated fiber. Opt Express 26(23):29724–29734

Petrie CM, Sridharan N, Hehr A et al (2019) High-temperature strain monitoring of stainless steel using fiber optics embedded in ultrasonically consolidated nickel layers. Smart Mater Struct 28(8):085041

Cavillon M, Lancry M, Poumellec B et al (2019) Overview of high temperature fibre Bragg gratings and potential improvement using highly doped aluminosilicate glass optical fibres. Journal of Physics: Photonics 1(4):042001

Lei JF, Will HA (1998) Thin-film thermocouples and strain-gauge technologies for engine applications. Sens Actuators, A 65(2–3):187–193

Gregory OJ, Luo Q (2001) A self-compensated ceramic strain gage for use at elevated temperatures. Sens Actuators, A 88(3):234–240

Hoffmann K (1989) An introduction to measurements using strain gages. Hottinger Baldwin Messtechnik, Darmstadt

Pan B, Tian L (2016) Advanced video extensometer for non-contact, real-time, high-accuracy strain measurement. Opt Express 24(17):19082–19093

Sharpe WN (2010) A high-frequency high-temperature optical strain/displacement gage. Exp Mech 50(2):227–237

Løkberg OJ, Malmo JT, Slettemoen GÅ (1985) Interferometric measurements of high temperature objects by electronic speckle pattern interferometry. Appl Opt 24(19):3167–3172

Malmo JT, Jøkberg OJ, Slettemoen GA (1988) Interferometric testing at very high temperatures by TV holography (ESPI). Exp Mech 28(3):315–321

James JD, Spittle JA, Brown SGR et al (2001) A review of measurement techniques for the thermal expansion coefficient of metals and alloys at elevated temperatures. Meas Sci Technol 12(3):R1

Post D, Wood JD (1989) Determination of thermal strains by moiré interferometry. Exp Mech 29(3):318–322

Han B, Guo Y (1995) Thermal deformation analysis of various electronic packaging products by moiré and microscopic moiré interferometry

Guo Y, Lim CK, Chen WT et al (1993) Solder ball connect (SBC) assemblies under thermal loading: I. deformation measurement via moiré interferometry, and its interpretation. IBM J Res Development 37(5): 635–648

Anwander M, Zagar BG, Weiss B et al (2000) Noncontacting strain measurements at high temperatures by the digital laser speckle technique. Exp Mech 40(1):98–105

Völkl R, Fischer B (2004) Mechanical testing of ultra-high temperature alloys. Exp Mech 44(2):121–127

Jenner F, Walter ME, Iyengar RM et al (2014) Application of high-speed video extensometry for high-temperature tensile characterization of boron heat-treated steels. The Journal of Strain Analysis for Engineering Design 49(6):378–387

Du Y, Gou Z (2019) Application of the Non-Contact Video Gauge on the Mechanical Properties Test for Steel Cable at Elevated Temperature. Appl Sci 9(8):1670

Turner JL, Russell SS (1990) Application of digital image analysis to strain measurement at elevated temperature. Strain 26(2):55–59

Lyons JS, Liu J, Sutton MA (1996) High-temperature deformation measurements using digital-image correlation. Exp Mech 36(1):64–70

Grant BMB, Stone HJ, Withers PJ et al (2009) High-temperature strain field measurement using digital image correlation. The Journal of Strain Analysis for Engineering Design 44(4):263–271

Pan B, Wu D, Wang Z et al (2010) High-temperature digital image correlation method for full-field deformation measurement at 1200 C. Meas Sci Technol 22(1):015701

Chu TC, Ranson WF, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25(3):232–244

Bruck HA, McNeill SR, Sutton MA et al (1989) Digital image correlation using Newton-Raphson method of partial differential correction. Exp Mech 29(3):261–267

Luo PF, Chao YJ, Sutton MA et al (1993) Accurate measurement of three-dimensional deformations in deformable and rigid bodies using computer vision. Exp Mech 33(2):123–132

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer Science & Business Media

Pan B, Qian K, Xie H et al (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):062001

Pan B (2018) Digital image correlation for surface deformation measurement: historical developments, recent advances and future goals. Meas Sci Technol 29(8):082001

Liu J, Lyons J, Sutton M et al (1998) Experimental characterization of crack tip deformation fields in alloy 718 at high temperatures

Liu J, Sutton M, Lyons J et al (1998) Experimental investigation of near crack tip creep deformation in alloy 800 at 650^ C. Int J Fract 91(3):233–268

Zhang J, Li M, Xiong C Y et al (2005) Thermal deformation analysis of BGA package by digital image correlation technique. Microelectronics international

Sun Y, Pang J H L, Shi X et al (2006) Thermal deformation measurement by digital image correlation method. Thermal and Thermomechanical Proceedings 10th Intersociety Conference on Phenomena in Electronics Systems, 2006. ITHERM 2006. IEEE, 2006: 921–927

Berfield TA, Carroll Iii JF, Payne DA et al (2009) Thermal strain measurement in sol-gel lead zirconate titanate thin films. J Appl Phys 106(12):123501

Bing P, Hui-min X, Tao H et al (2009) Measurement of coefficient of thermal expansion of films using digital image correlation method. Polym Testing 28(1):75–83

Dudescu C, Botean A, Hardau M (2013) Thermal expansion coefficient determination of polymeric materials using digital image correlation. Materiale plastice 50(1):55–59

Wang YG, Tong W (2013) A high resolution DIC technique for measuring small thermal expansion of film specimens. Opt Lasers Eng 51(1):30–33

Lee TI, Kim MS, Kim TS (2016) Contact-free thermal expansion measurement of very soft elastomers using digital image correlation. Polym Testing 51:181–189

Graciani E, Justo J, Zumaquero PL (2020) Determination of in-plane and through-the-thickness coefficients of thermal expansion in composite angle brackets using digital image correlation. Compos Struct 238:111939

Berke RB, Lambros J (2014) Ultraviolet digital image correlation (UV-DIC) for high temperature applications. Rev Sci Instrum 85(4):045121

Dong Y, Kakisawa H, Kagawa Y (2013) Optical system for microscopic observation and strain measurement at high temperature. Meas Sci Technol 25(2):025002

Novak MD, Zok FW (2011) High-temperature materials testing with full-field strain measurement: experimental design and practice. Rev Sci Instrum 82(11):115101

Dong Y, Pan B (2019) In-situ 3D shape and recession measurements of ablative materials in an arc-heated wind tunnel by UV stereo-digital image correlation. Opt Lasers Eng 116:75–81

Wang W, Xu C, Jin H et al (2017) Measurement of high temperature full-field strain up to 2000 C using digital image correlation. Meas Sci Technol 28(3):035007

Guo X, Liang J, Tang Z et al (2014) High-temperature digital image correlation method for full-field deformation measurement captured with filters at 2600 C using spraying to form speckle patterns. Opt Eng 53(6):063101

Pan Z, Huang S, Su Y et al (2020) Strain field measurements over 3000°C using 3D-Digital image correlation. Opt Lasers Eng 127:105942

Zheng Q, Mashiwa N, Furushima T (2020) Evaluation of large plastic deformation for metals by a non-contacting technique using digital image correlation with laser speckles. Mater Des 191:108626

Meyer P, Waas AM (2015) Measurement of in situ-full-field strain maps on ceramic matrix composites at elevated temperature using digital image correlation. Exp Mech 55(5):795–802

Song J, Yang J, Liu F et al (2018) High temperature strain measurement method by combining digital image correlation of laser speckle and improved RANSAC smoothing algorithm. Opt Lasers Eng 111:8–18

Song J, Yang J, Liu F et al (2019) Ultra-high temperature mechanical property test of C/C composites by a digital image correlation method based on an active laser illumination and background radiation suppressing method with multi-step filtering. Appl Opt 58(24):6569–6580

Pang Y, Chen BK, Liu W et al (2020) Development of a non-contact and non-destructive laser speckle imaging system for remote sensing of anisotropic deformation around fastener holes. NDT and E Int 111:102219

Brillaud J, Lagattu F (2002) Limits and possibilities of laser speckle and white-light image-correlation methods: theory and experiments. Appl Opt 41(31):6603–6613

Pan B, Wu D, Xia Y (2010) High-temperature deformation field measurement by combining transient aerodynamic heating simulation system and reliability-guided digital image correlation. Opt Lasers Eng 48(9):841–848

Berny M, Archer T, Mavel A et al (2018) On the analysis of heat haze effects with spacetime DIC. Opt Lasers Eng 111:135–153

Archer T, Beauchene P, Huchette C et al (2019) Global digital image correlation up to very high temperatures with grey level corrections. Meas Sci Technol 31(2):024003

Pan B, Wu D, Yu L (2012) Optimization of a three-dimensional digital image correlation system for deformation measurements in extreme environments. Appl Opt 51(19):4409–4419

Chen X, Xu N, Yang L et al (2012) High temperature displacement and strain measurement using a monochromatic light illuminated stereo digital image correlation system. Meas Sci Technol 23(12):125603

Sutton MA, Yan JH, Tiwari V et al (2008) The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt Lasers Eng 46(10):746–757

Pan B, Yu L, Wu D (2013) High-accuracy 2D digital image correlation measurements with bilateral telecentric lenses: error analysis and experimental verification. Exp Mech 53(9):1719–1733

Pan B, Yu LP, Zhang QB (2018) Review of single-camera stereo-digital image correlation techniques for full-field 3D shape and deformation measurement. SCIENCE CHINA Technol Sci 61(1):2–20

Chi Y, Yu L, Pan B (2018) Low-cost, portable, robust and high-resolution single-camera stereo-DIC system and its application in high-temperature deformation measurements. Opt Lasers Eng 104:141–148

Wu LF, Yin YJ, Zhang Q et al (2018) Bi-prism-based single-lens three dimensional digital image correlation system with a long working distance: methodology and application in extreme high temperature deformation test. SCIENCE CHINA Technol Sci 61(1):37–50

Sun Y, Pang JHL, Wong CK et al (2005) Finite element formulation for a digital image correlation method. Appl Opt 44(34):7357–7363

Sutton MA, Turner JL, Bruck HA et al (1991) Full-field representation of discretely sampled surface deformation for displacement and strain analysis. Exp Mech 31(2):168–177

Pan B, Xie H, Guo Z et al (2007) Full-field strain measurement using a two-dimensional Savitzky-Golay digital differentiator in digital image correlation. Opt Eng 46(3):033601

Pan B, Asundi A, Xie H et al (2009) Digital image correlation using iterative least squares and pointwise least squares for displacement field and strain field measurements. Opt Lasers Eng 47(7–8):865–874

Leplay P, Réthoré J, Meille S et al (2012) Identification of asymmetric constitutive laws at high temperature based on Digital Image Correlation. J Eur Ceram Soc 32(15):3949–3958

Mao W, Wang Y, Huang H et al (2020) In situ characterizations of mechanical behaviors of freestanding (Gd0. 9Yb0. 1) 2Zr2O7 coatings by bending tests under different temperatures based on digital image correlation. J Eur Ceram Soc 40(2): 491–502

van Rooyen M, Becker TH (2018) High-temperature tensile property measurements using digital image correlation over a non-uniform temperature field. J Strain Anal Eng Des 53(3):117–129

Vautrot M, Balland P, Hopperstad OS et al (2014) Experimental technique to characterize the plastic behaviour of metallic materials in a wide range of temperatures and strain rates: application to a high-carbon steel. Exp Mech 54(7):1163–1175

Casperson MC, Carroll JD, Lambros J et al (2014) Investigation of thermal effects on fatigue crack closure using multiscale digital image correlation experiments. Int J Fatigue 61:10–20

Berke RB, Sebastian CM, Chona R et al (2016) High temperature vibratory response of Hastelloy-X: stereo-DIC measurements and image decomposition analysis. Exp Mech 56(2):231–243

Blaber J, Adair BS, Antoniou A (2015) A methodology for high resolution digital image correlation in high temperature experiments. Rev Sci Instrum 86(3):035111

Valeri G, Koohbor B, Kidane A et al (2017) Determining the tensile response of materials at high temperature using DIC and the virtual fields method. Opt Lasers Eng 91:53–61

Su Y, Pan Z, Peng Y et al (2019) Creep of stainless steel under heat flux cyclic loading (500–1000 C) with different mechanical preloads in a vacuum environment using 3D-DIC. Smart Struct Syst 24(6):759–768

Yuan W, Wang J, Song H et al (2018) Full-field deformation and temperature measurement for CW laser irradiated structures. Opt Lasers Eng 110:244–252

Archer T, Berny M, Beauchêne P et al (2020) Creep behavior identification of an environmental barrier coating using full-field measurements. J Eur Ceram Soc

Chen X, Yang L, Xu N et al (2014) Cluster approach based multi-camera digital image correlation: Methodology and its application in large area high temperature measurement. Opt Laser Technol 57:318–326

Pan B, Yu L, Wu D (2015) Thermo-mechanical response of superalloy honeycomb sandwich panels subjected to non-steady thermal loading. Mater Des 88:528–536

Koyanagi J, Fukuda Y, Yoneyama S et al (2017) Local out-of-plane deformation of CFRP ablator subjected to rapid heating. Adv Compos Mater 26(1):23–34

Le VT, San Ha N, Jin T et al (2016) Thermal interaction of a circular plate-ring structure using digital image correlation technique and infrared heating system. J Mech Sci Technol 30(9):4363–4372

Xu Y, Ren S, Zhang W et al (2018) Study of thermal buckling behavior of plain woven C/SiC composite plate using digital image correlation technique and finite element simulation. Thin-Walled Structures 131:385–392

Wu D, Lin L, Ren H et al (2019) High-temperature deformation measurement of the heated front surface of hypersonic aircraft component at 1200° C using digital image correlation. Opt Lasers Eng 122:184–194

Riley ZB, Perez RA, Bartram GW et al (2019) Aerothermoelastic experimental design for the AEDC/VKF Tunnel C: Challenges associated with measuring the response of flexible panels in high-temperature, high-speed wind tunnels. J Sound Vib 441:96–105

Abotula S, Heeder N, Chona R et al (2014) Dynamic thermo-mechanical response of Hastelloy X to shock wave loading. Exp Mech 54(2):279–291

Yang X, Liu Z, Xie H (2012) A real time deformation evaluation method for surface and interface of thermal barrier coatings during 1100° C thermal shock. Meas Sci Technol 23(10):105604

Thornton EA (1997) Aerospace thermal-structural testing technology. Appl Mech Rev 50(9):477–498

Rudnev V, Loveless D, Cook RL (2017) Handbook of induction heating. CRC press

Pan B, Wu D, Gao J (2014) High-temperature strain measurement using active imaging digital image correlation and infrared radiation heating. J Strain Anal Eng Des 49(4):224–232

Rybicki GB, Lightman AP (2008) Radiative processes in astrophysics. John Wiley & Sons

Pan B, Wu D, Xia Y (2012) An active imaging digital image correlation method for deformation measurement insensitive to ambient light. Opt Laser Technol 44(1):204–209

Hu Y, Bao S, Dan X et al (2018) Improvement of high-temperature deformation measurement accuracy based on image restoration method. Meas Sci Technol 29(9):094003

Dong YL, Zhao JQ, Pan B (2020) Ultraviolet 3D digital image correlation applied for deformation measurement in thermal testing with infrared quartz lamps. Chin J Aeronaut 33(3):1085–1092

Hansen RS, Bird TJ, Voie R et al (2019) A high magnification UV lens for high temperature optical strain measurements. Rev Sci Instrum 90(4):045117

Leplay P, Lafforgue O, Hild F (2015) Analysis of asymmetrical creep of a ceramic at 1350 C by digital image correlation. J Am Ceram Soc 98(7):2240–2247

Doitrand A, Estevez R, Thibault M et al (2020) Fracture and Cohesive Parameter Identification of Refractories by Digital Image Correlation Up to 1200 °C. Exp Mech 1–14

Thai TQ, Hansen RS, Smith AJ et al (2019) Importance of exposure time on DIC measurement uncertainty at extreme temperatures. Exp Tech 43(3):261–271

Thai TQ, Smith AJ, Rowley RJ et al (2020) Change of exposure time mid-test in high temperature DIC measurement. Meas Sci Technol 31(7):075402

Tang Y, Yue M, Fang X et al (2019) Overcoming high luminance gradient using serial exposure time method for synchronous full-field measurement of temperature and deformation. Appl Opt 58(25):6966–6974

Pan B, Lu Z, Xie H (2010) Mean intensity gradient: an effective global parameter for quality assessment of the speckle patterns used in digital image correlation. Opt Lasers Eng 48(4):469–477

Dong YL, Pan B (2017) A review of speckle pattern fabrication and assessment for digital image correlation. Exp Mech 57(8):1161–1181

Su YQ, Yao XF, Wang S et al (2015) Improvement on measurement accuracy of high-temperature DIC by grayscale-average technique. Opt Lasers Eng 75:10–16

Su H, Fang X, Qu Z et al (2016) Synchronous full-field measurement of temperature and deformation of C/SiC composite subjected to flame heating at high temperature. Exp Mech 56(4):659–671

De Strycker M, Lava P, Van Paepegem W et al (2011) Measuring welding deformations with the digital image correlation technique. Weld J 90(6):107S-112S

Le DB, Tran SD, Torero JL et al (2019) Application of digital image correlation system for reliable deformation measurement of concrete structures at high temperatures. Eng Struct 192:181–189

Rossmann L, Sarley B, Hernandez J et al (2020) Method for conducting in situ high-temperature digital image correlation with simultaneous synchrotron measurements under thermomechanical conditions. Rev Sci Instrum 91(3):033705

Tracy J, Waas A, Daly S (2015) A new experimental approach for in situ damage assessment in fibrous ceramic matrix composites at high temperature. J Am Ceram Soc 98(6):1898–1906

Pan B, Jiang T, Wu D (2014) Strain measurement of objects subjected to aerodynamic heating using digital image correlation: experimental design and preliminary results. Rev Sci Instrum 85(11):115102

Yuile A, Schwerz R, Roellig M et al (2018) Heat haze effects in thermal chamber tensile tests on Digital Image Correlation. 2018 19th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE). IEEE, 1–7

Jian Z, Dong Z, Zhe Z (2016) A non-contact varying temperature strain measuring system based on digital image correlation. Exp Tech 40(1):101–110

Su Y, Yao X, Wang S et al (2017) Refraction error correction for deformation measurement by digital image correlation at elevated temperature. Opt Eng 56(3):034106

Jones EMC, Reu PL (2018) Distortion of digital image correlation (DIC) displacements and strains from heat waves. Exp Mech 58(7):1133–1156

Jones EMC, Quintana EC, Reu PL et al (2020) X-Ray stereo digital image correlation. Exp Tech 44(2):159–174

Liang J, Wang Z, Xie H et al (2018) In situ scanning electron microscopy-based high-temperature deformation measurement of nickel-based single crystal superalloy up to 800°C. Opt Lasers Eng 108:1–14

Walley JL, Wheeler R, Uchic MD et al (2012) In-situ mechanical testing for characterizing strain localization during deformation at elevated temperatures. Exp Mech 52(4):405–416

Liang J, Wang Z, Xie H et al (2019) In situ scanning electron microscopy analysis of effect of temperature on small fatigue crack growth behavior of nickel-based single-crystal superalloy. Int J Fatigue 128:105195

Wang Z, Wu W, Liang J et al (2020) Creep–fatigue interaction behavior of nickel-based single crystal superalloy at high temperature by in-situ SEM observation. Int J Fatigue 141:105879

Li N, Sutton MA, Li X et al (2008) Full-field thermal deformation measurements in a scanning electron microscope by 2D digital image correlation. Exp Mech 48(5):635–646

Pataky GJ, Sehitoglu H (2015) Experimental methodology for studying strain heterogeneity with microstructural data from high temperature deformation. Exp Mech 55(1):53–63

Martin G, Caldemaison D, Bornert M et al (2013) Characterization of the high temperature strain partitioning in duplex steels. Exp Mech 53(2):205–215

Bumgardner C, Croom B, Li X (2017) High-temperature delamination mechanisms of thermal barrier coatings: in-situ digital image correlation and finite element analyses. Acta Mater 128:54–63

Stinville JC, Echlin MP, Callahan PG et al (2017) Measurement of strain localization resulting from monotonic and cyclic loading at 650∘C in nickel base superalloys. Exp Mech 57(8):1289–1309

Edwards TEJ, Di Gioacchino F, Clegg WJ (2021) High resolution digital image correlation mapping of strain localization upon room and high temperature, high cycle fatigue of a TiAl intermetallic alloy. Int J Fatigue 142:105905

Edwards TEJ, Di Gioacchino F, Springbett HP et al (2017) Stable speckle patterns for nano-scale strain mapping up to 700 C. Exp Mech 57(9):1469–1482

Kammers AD, Daly S (2011) Small-scale patterning methods for digital image correlation under scanning electron microscopy. Meas Sci Technol 22(12):125501

Li YJ, Xie HM, Luo Q et al (2012) Fabrication technique of micro/nano-scale speckle patterns with focused ion beam. Science China Physics, Mechanics and Astronomy 55(6):1037–1044

Montgomery CB, Koohbor B, Sottos NR (2019) A robust patterning technique for electron microscopy-based digital image correlation at sub-micron resolutions. Exp Mech 59(7):1063–1073

Dahdah N, Limodin N, El Bartali A et al (2016) Influence of the Casting Process in High Temperature Fatigue of A319 Aluminium Alloy Investigated By In-Situ X-Ray Tomography and Digital Volume Correlation. Procedia Structural Integrity 2:3057–3064

Khoshkhou D, Mostafavi M, Reinhard C et al (2016) Three-dimensional displacement mapping of diffused Pt thermal barrier coatings via synchrotron X-ray computed tomography and digital volume correlation. Scripta Mater 115:100–103

Bale HA, Haboub A, MacDowell AA et al (2013) Real-time quantitative imaging of failure events in materials under load at temperatures above 1,600 C. Nat Mater 12(1):40–46

Haboub A, Bale HA, Nasiatka JR et al (2014) Tensile testing of materials at high temperatures above 1700 C with in situ synchrotron X-ray micro-tomography. Rev Sci Instrum 85(8):083702

Maynadier A, Poncelet M, Lavernhe-Taillard K et al (2012) One-shot measurement of thermal and kinematic fields: infrared image correlation (IRIC). Exp Mech 52(3):241–255

Wang XG, Liu CH, Jiang C (2017) Simultaneous assessment of Lagrangian strain and temperature fields by improved IR-DIC strategy. Opt Lasers Eng 94:17–26

Tang Y, Yue M, Fang X et al (2019) Synchronous full-field measurement of temperature and deformation based on separated radiation and reflected light. Opt Lasers Eng 116:94–102

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant nos. 11925202, 11872009, and 11632010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, L., Pan, B. Overview of High-temperature Deformation Measurement Using Digital Image Correlation. Exp Mech 61, 1121–1142 (2021). https://doi.org/10.1007/s11340-021-00723-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00723-8