Abstract

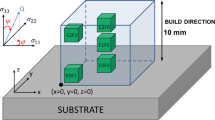

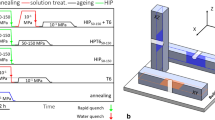

A variety of new materials have been developed during the past two decades in China to support the design and construction of key components for next step fusion devices. Most recently, a domestic project, promoted by the engineering design of China Fusion Engineering Test Reactor (CFETR), has been launched to preliminarily investigate the performance of advanced fusion materials after neutron irradiation. The goal of this paper is to introduce the preparation for the coming neutron irradiation campaign. The development status and acceptance of some outstanding fusion materials are briefly reviewed with the main description focusing on some high-performance 9Cr-ODS steels, Cu–0.3Al2O3 alloys, W-K and W-ZrC alloys for blanket/divertor components. The principles for screening suitable materials out from several candidates are suggested, which consider low activation, sufficient production scale, homogeneous microstructures, safety margin and repeatability of basic properties as the basic requirements. As a recommended approach for neutron irradiation tests, the small sample testing technology (SSTT) is highlighted in this paper. Further development of SSTT using inverse finite element method (FEM) and energy equivalent principle is performed for new designs of small tensile samples.

Similar content being viewed by others

Availability of Data and Material

This paper includes some data not published yet, the authors declare that the release of these data is approved by the material supplier. The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of other ongoing studies.

References

EUROfusion, European Research Roadmap to the Realisation LONG VERSION of Fusion Energy, 2018. https://www.euro-fusion.org/eurofusion/roadmap/

Y. Wan, J. Li, Y. Liu et al., Overview of the present progress and activities on the CFETR. Nucl. Fusion 57(10), 102009 (2017)

J.M. Chen, J.H. Wu, X. Liu, P.H. Wang et al., Materials development for ITER shielding and test blanket in China. J. Nucl. Mater. 417, 81–84 (2011)

Q. Huang, C. Li, Y. Li et al., Progress in development of China low activation martensitic steel for fusion application. J. Nucl. Mater. 367–370, 142–146 (2007)

M. Gussev, J. Busby, K. Field, M. Sokolov, S. Gray, Role of scale factor during tensile testing of small specimens, in Small Specimen Test Techniques, vol 6 (ASTM International, 2015).

P.F. Zheng, T. Nagasaka, T. Muroga, J.M. Chen, Microstructures and mechanical properties of mechanically alloyed V–4Cr–4Ti alloy dispersion strengthened by nano-particles. Fusion Eng. Des. 89, 1648–1652 (2014)

A.-A.F. Tavassoli, J.-W. Rensman, M. Schirra, K. Shiba, Materials design data for reduced activation martensitic steel type F82H. Fusion Eng. Des. 61–62, 617–628 (2002)

M. Rieth, B. Dafferner, Low temperature embrittlement behaviour of different ferritic-martensitic alloys for fusion applications. J. Nucl. Mater. 233–237, 229–232 (1996)

J. Gong, H. Liao, K. Zhang, Heat treatment optimization of China low-activation ferritic/martensitic steel with cerium addition. Fusion Eng. Des. 158, 111696 (2020)

C.Y. Liua, J.D. Tonga, M.G. Jiang et al., Effect of scanning strategy on microstructure and mechanical properties of selective laser melted reduced activation ferritic/martensitic steel. Mater Sci Eng A. 766, 138364 (2019)

M.G. Jiang, Z.W. Chena, J.D. Tonga et al., Strong and ductile reduced activation ferritic/martensitic steel additively manufactured by selective laser melting. Mater. Res. Lett. 710, 426–432 (2019)

X. Chen, Q. Yuan, B. Madigan, WeiXue, Long-term corrosion behavior of martensitic steel welds in static molten Pb–17Li alloy at 550 °C. Corros. Sci. 96, 178–185 (2015)

G. Chen, Y. Lei, Q. Zhu et al., Corrosion behavior of CLAM steel weld bead in flowing Pb-Bi at 550 °C. J. Nucl. Mater. 515, 187–198 (2019)

Y.A.N.G. Ke, Y.A.N. Wei, W.A.N.G. Zhiguang et al., Development of a novel structural material (SIMP steel) for nuclear equipment with balanced resistances to high temperature, radiation and liquid metal corrosion. Acta Metall. Sin. 11, 0788 (2016). ((in Chinese))

X. Xiong, F. Yang, X. Zou, J. Suo, Effect of twice quenching and tempering on the mechanical properties and microstructures of SCRAM steel for fusion application. J. Nucl. Mater. 430, 114–118 (2012)

J. Pamela, A. Bécoulet, D. Borbaa et al., Efficiency and availability driven R&D issues for DEMO. Fusion Eng. Des. 84, 194–204 (2009)

Z. Hong, X. Zhang, Q. Yan et al., A new method for preparing 9Cr-ODS steel using elemental yttrium and Fe2O3 oxygen carrier. J. Alloy. Compd. 770, 831–839 (2019)

J. Feng, Q. Yan, X. Zhang et al., Characterization of Y-bearing particles in CNS-I-ODS steel fabricated by vacuum induction melting & casting technique. J. Mater. Res. Technol. 8, 3859–3871 (2019)

Y. Chen, F. Zhang, Q. Yan et al., Microstructure characteristics of 12Cr ferritic/martensitic steels with various yttrium. J. Rare Earths 37, 547–554 (2019)

G. Wang, Y. Li, J. Zhang et al., Design and preliminary characterization of a novel carbide-free 9Cr-ODS martensitic steel. Fusion Eng. Des. (these proceedings).

M. Li, Z. Zhou et al., Microstructure and mechanical property of 12Cr oxide dispersion strengthened ferritic steel for fusion application. Fusion Eng. Des. 85, 1573–1576 (2010)

Z. Li, Z. Lu, R. Xie et al., Effects of Y2O3, La2O3 and CeO2 additions on microstructure and mechanical properties of 14Cr-ODS ferrite alloys produced by spark plasma sintering. Fusion Eng. Des. 121, 159–166 (2017)

C. Lu, Z. Lu, R. Xie et al., Microstructure of a 14Cr-ODS ferritic steel before and after helium ion implantation. J. Nucl. Mater. 455, 366–370 (2014)

Y. Li, J. Zhang, W. Yan et al., Anisotropy in creep properties and its microstructural origins of 12Cr oxide dispersion strengthened ferrite steels. J. Nucl. Mater. 517, 307–314 (2019)

Z. Hong, X. Zhang, Q. Yan, Y. Chen, A new method for preparing 9Cr-ODS steel using elemental yttrium and Fe2O3 oxygen carrier. J. Alloys Compd. 770, 831–839 (2019)

Q. Yan, M. Xia et al., Vacuum casted F/M steels containing a dense uniform dispersion of oxides nanoclusters with high strength and irradiation resistance stability, in The 18th International Conference on Fusion Reactor Materials (ICFRM-18). Aomori, Japan, 2017.

H.J. Xu, Z. Lu, D.M. Wang et al., Structure and composition of oxides in FeCrAl ODS alloy with Zr addition. Mater. Sci. Tech-Lond. 33, 1790–1795 (2017)

Y. Shi, Lu. Zheng et al., Microstructure and tensile properties of Zr-containing ODS-FeCrAl alloy fabricated by laser additive manufacturing. Mater. Sci. Eng. A 774, 138937 (2020)

Z.-q Xiang, Z. Li, Q. Lei et al., High temperature mechanical behavior of alumina dispersion strengthened copper alloy with high content of alumina. Trans. Nonferrous Met. Soc. China 25, 444–450 (2015)

X. Zhang, C. Lin, S. Cui et al., Characteristics of nano-alumina particles dispersion strengthened copper fabricated by reaction synthesis. Rare Metal Mater. Eng. 45, 893–896 (2016)

M. Li, H. Wang, Y. Guo et al., Microstructures and mechanical properties of the novel CuCrZrFeTiY alloy for fusion reactor. J. Nucl. Mater. 532, 152063 (2020)

E.A. Lazarus et al., Confinement in beam-heated plasmas: the effects of low-Z impurities. Nucl. Fusion 25, 135 (1985)

Y. Lian et al. Mechanical properties and thermal shock performance of W-Y2O3 composite prepared by high-energy-rate forging. Physica Scripta T170.T170(2017):014044.

R. Liu et al., Nanostructured yttria dispersion-strengthened tungsten synthesized by sol–gel method. J. Alloy. Compd. 657, 73–80 (2016)

Z.M. Xie et al., High thermal shock resistance of the hot rolled and swaged bulk W-ZrC alloys. J. Nucl. Mater. 469, 209–216 (2016)

Z.M. Xie et al., Extraordinary high ductility/strength of the interface designed bulk W-ZrC alloy plate at relatively low temperature. Sci. Rep. 5, 16014 (2015)

Y. Lv et al., The influence of modification route on the properties of W-0.3 wt% Y2O3 powder and alloy prepared by nano-in-situ composite method. J. Alloys Compd 774, 1140–1150 (2019)

L. Luo et al., Preparation and characteristics of W-1 wt.% TiC alloy via a novel chemical method and spark plasma sintering. Powder Technol 273, 8–12 (2015)

X. Tan et al., Mechanical properties and microstructural change of W-Y2O3 alloy under helium irradiation. Sci. Rep. 5, 12755 (2015)

Bo. Huang, Ye. Xiao, Bo. He et al., Effect of potassium doping on the thermal shock behavior of tungsten. Int. J. Refract. Metals Hard Mater. 51, 19–24 (2015)

K. Broden, M. Lindberg, G. Olsson, Management of waste from six potential fusion power plant models. Fusion Eng. Des. 54, 349–352 (2001)

E.A. Hoffman, W.M. Stacey, N.E. Hertel, Radioactive waste disposal characteristics of candidate demonstration reactors. Fusion Eng. Des. 31, 35–62 (1997)

AFCEN Code RCC-MRx, Design and construction rules for mechanical components of nuclear installations, 2012 edition.

H. Liu, Y. Shen, S. Yang, P. Zheng, L. Zhang, A comprehensive solution to miniaturized tensile testing: Specimen geometry optimization and extraction of constitutive behaviors using inverse FEM procedure. Fusion Eng. Des. 121, 188–197 (2017)

H. Chen, L. Cai, Unified elastoplastic model based on a strain energy equivalence principle. Appl. Math. Model. 52, 664–671 (2017)

H. Chen, L. Cai, Theoretical model for predicting uniaxial stress-strain relation by dual conical indentation based on equivalent energy principle. Acta Mater. 121, 181–189 (2016)

Z. Zhang, X. Liu, P. Zheng, et al. A small specimen testing method to determine tensile properties of metallic materials[J]. Fusion Engineering and Design 164(1):112148 (2021)

Acknowledgements

This work is supported by the National Key Research and Development Program of China (Grant Nos.: 2018YFE0307101, 2018YFE0307102) and Sichuan Science and Technology Program (No. 2018JZ0070). The auhors are grateful to Prof. Yanfen Li at Institute of Metal Research Chinese Academy of Sciences (IMR) for releasing some data not yet published.

Author information

Authors and Affiliations

Contributions

Pengfei Zheng: formal analysis, data curation, writing—original draft. Xing Liu: resources, data collection—review and editing. Zhijie Zhang: investigation, methodology. Jiming Chen: funding acquisition, supervision, project administration. Shouhua Sun: supervision, validation, conceptualization—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, P., Liu, X., Zhang, Z. et al. A Preliminary Work on the Preparation for Neutron Irradiation of Advanced Fusion Materials Using Small Samples in China. J Fusion Energ 40, 11 (2021). https://doi.org/10.1007/s10894-021-00296-3

Accepted:

Published:

DOI: https://doi.org/10.1007/s10894-021-00296-3