Abstract

Results of a study investigating a skew rolling process for elongated axisymmetric parts are presented. Despite the fact that the skew rolling technique for producing such parts was developed and implemented in the mid-twentieth century, there are no studies on this problem. The first part of this paper presents the results of FEM modelling of skew rolling stepped axles and shafts (solid and hollow). The FEM analysis was performed using the MSC Simufact Forming software. The numerical simulation involved the determination of metal flow patterns, the analysis of thermal parameters of the material during rolling, and the prediction of cracking by the Cockcroft-Latham ductile fracture criterion. Force parameters of rolling solid and hollow parts were also determined. The aim of the FEM analysis was to determine initial design assumptions and parameters for the development of the skew rolling mill. Later on in the paper, a design solution of a CNC skew rolling mill for rolling parts based on their envelope profile is proposed. FEM strength test results of a mill stand, obtained with MSC. NASTRAN, are presented. Finally, the performance test results of the constructed rolling mill are presented. The experiments involved rolling real stepped shafts that were modelled numerically. Obtained results show that the proposed skew rolling method has considerable potential. The designed and constructed rolling mill can be used to perform the rolling process according to the proposed method, with the tool and material kinematics being controlled based on the set parameters of a workpiece envelope.

Similar content being viewed by others

1 Introduction

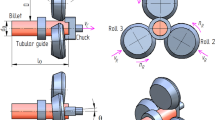

In recent years, the development of energy- and material-saving manufacturing techniques has become one of the top challenges for the global industry. Innovative solutions are sought in practically every branch of the economy to enable reduced energy and material consumption, shorter manufacturing time, and the reduction of harmful substances produced during manufacturing processes. This trend can particularly be observed in the metallurgical and forging industries that by definition are considered to be among the most material- and energy-consuming as well as environment-unfriendly industries. It is also in these industries that one can observe the greatest progress in implementing new cost-effective solutions. A vast volume of forged parts are elongated parts such as stepped axles and shafts. Although they are finished and semi-finished products of relatively simple shapes, their production requires the use of specialist machines and equipment due to large differences between their cross-sectional dimensions and length. Such parts are often produced in several stages, which increases the production cost considerably. Effective manufacturing of elongated axisymmetric parts has become of particular importance in recent years. Increased demand for product quality and repeatability in combination with frequent changes in product assortment create a need for the development of flexible manufacturing techniques for such parts. Nowadays, elongated axisymmetric parts of several hundred millimetres in length are produced by cross wedge rolling [1,2,3] or longitudinal roll forging (predominantly preforms for die forging processes) [4,5,6]. In turn, long parts (of up to several metres in length) are produced by open die forging [7, 8] (they are produced individually or in smaller batches) and rotary forging [9,10,11] (they are higher accuracy parts produced in larger batches). Small elongated parts (with their lengths ranging from dozens to 200 mm) can also be produced by skew rolling in skew rolling mills equipped with rolls having helical impressions [12,13,14]. Parts produced by these methods are usually used as semi-finished products for further processing [15, 16]. They can also be used as semi-finished products for die forging [17]. It is proposed that elongated parts such as stepped shafts be produced by skew rolling using a rolling mill in which the tools are rotated in the same direction and move radially at the same time, and thus change the reduction ratio during the rolling process. Additionally, during rolling, the axial motion of the workpiece is forced by the chuck in which the workpiece is mounted, which makes it possible to correlate the radial displacement of the tools with the axial displacement of the workpiece (Fig. 1). Owing to this kinematics, the process can be used for rolling parts of any shape.

The concept of skew rolling elongated parts was first proposed in the 1960s [18, 19], and the first rolling tests took place at that time, too. However, this rolling technique did not find wide application, which mainly resulted from difficulties with ensuring precise control of the radial displacement of the tools and axial displacement of the workpiece. Usually, three-roller skew rolling mills were used, with their rollers moved radially toward the workpiece by hydraulic servomotors. Rolling mills of this type were equipped with an additional chuck moving along the rolling axis. The radial position of the tools and the axial position of the chuck with workpiece were set using a template whose working part corresponded to the profile of a part rolled. The use of templates for controlling hydraulic distributors of the rolling mill limited the range of possible motions, which led to a reduced accuracy of rolled parts. Furthermore, any change in the type of rolled parts required refurbishing the machine with a suitable set of templates, which was very time-consuming.

Due to the limited availability of skew rolling mills and the problems connected with the rolling accuracy of conventional rolling machines, previous studies on skew rolling processes for stepped parts were solely theoretical. Numerical modelling was employed to investigate skew rolling processes for railway axles [20], multi-stepped main shafts [21] and preforms of crankshafts [22]. Results showed that the 3-roll rolling process is highly universal, which means that it can even be applied in piece production. It was also found that the rolling process is characterized by small loads, which means that the rolling mill used in this process can have a lightweight design. Based on numerical results, an analysis was performed to determine the effect of selected rolling parameters on forces and torques in this process, which was indispensable for launching design works connected with the construction of a rolling test stand [23]. Given its potential benefits, this technique attracted interest from Chinese researchers [24], who also used numerical modelling to investigate force parameters in the skew rolling process for a hollow railway axle. Research was also conducted to model structural changes in the skew rolling of axles [25]. It should be stressed that previous studies have not been verified experimentally, which fully justifies the necessity of designing and constructing a laboratory skew rolling mill.

The development of information and electronic technologies in recent years has contributed to the creation of industrial controllers allowing precise control of machine actuators (stepper motors, servo drives, fast hydraulic distributors), and therefore enable accurate control of tool motion based on the trajectory parameters of a workpiece envelope. As a result, the technological capabilities of machines equipped with CNC drive systems have increased significantly. Owing to the material flow pattern in 3-roller skew rolling, this technique can be used to produce parts with high cross-sectional reduction without the risk of material cracking; it is also an effective rolling method for solid and hollow parts. The feasibility of rolling different parts with the use of only one set of tools is of significant importance, too. These advantages prompted the authors to undertake research related to the development of a skew rolling technique for producing elongated stepped axles and shafts [20, 21, 26].

2 FEM analysis of a skew rolling process for stepped axles and shafts

Numerical modelling was performed to determine initial design assumptions for the skew rolling mill in question, as well as to determine the kinematic and force parameters of the rolling process. The first stage of the study was a numerical analysis of a skew rolling process for stepped shafts. The objective of the analysis was to investigate the possibility of skew rolling solid and hollow parts, identify the metal flow pattern in this process, determine force parameters, as well as to identify potential failure modes in skew rolling. Numerical simulations of rolling both solid and hollow shafts were performed by the finite element method using the Simufact Forming 15 software. Shapes and dimensions of the shafts are shown in Fig. 2.

For purposes of the FEM analysis, geometrical models of a skew rolling process for both solid and hollow parts were designed (Fig. 3). Every model consisted of three identical tools—tapered rollers (1, 2, 3), a chuck (4), and a billet (5). The solid part was formed from a bar section of 51 mm in diameter and 320 mm in length, whereas the hollow part was formed from a tube with a diameter of 51 mm, a wall thickness of t = 8 mm and a length of 320 mm. The billets were modelled as rigid-plastic objects made of steel grade S355 using 8-node, first-order cubic elements. The material model of S355 steel was taken from the Simufact Forming material database library and is described by Eq. (1) [27].

where T is the temeprature (ranging from 700 to 1250 °C), ε is the strain, \(\dot{\varepsilon }\) is the strain rate.

The initial diameter of the billet and the type of material were selected based on the available stock of metallurgical materials, as well as due to the fact that S355 is a very popular steel grade, widely used in machine design. It was assumed that the billet material would be thoroughly preheated to 1170 °C and that the temperature of the tools would be maintained constant at 100 °C.

The proposed rolling method is characterized by a relatively long time of process realization and thus a drop in material temperature due to the fact that the heat is carried away to the tools and the environment. To prevent excessive cooling of the material (below the lower limit of the hot forming temperature range), it is recommended that the material be preheated to elevated temperatures. Therefore, it was proposed that the billet should be preheated to 1170 °C, which is a high value, but it is within the hot forming temperature range for the analysed grade of steel. The starting point for selecting the kinematic parameters of the skew rolling process was the determination of the rotational velocity of the tools. It was assumed that the tools would be rotated with a constant velocity of 60 rev/min, in order to ensure that the forming velocity is high enough to prevent the risk of both excessive temperature drop in the workpiece material and stability loss of the rolled parts which—due to their considerable slenderness—exhibit low rigidity and susceptibility to bending and torsion. The tool geometry was selected depending on the type of rolled parts. It was assumed that the diameter of the tools would be equal to D = 150 mm, which makes it possible to roll steps with a minimum diameter of d = 24 mm. Therefore, during the rolling process the tools (rollers) are rotated in the same direction with a velocity of n = 60 rev/min. The chuck, in which the workpiece is mounted, can rotate freely around the rolling axis. The radial motion of the tools and the axial motion of the chuck were defined based on a velocity table to obtain the desired envelope shape of a rolled part. Figure 4 shows the tool and workpiece velocities applied in the simulations. The axial velocity of the chuck with the workpiece was determined based on the vector of the component of the axial tangential velocity of the tools along the axis of rolling and the expected value of workpiece elongation. It was assumed that the axial velocity of the chuck should be similar to the axial velocity of the workpiece (resulting from the tool kinematics and material elongation). The material-tool contact surface was described by a constant friction model, with the friction factor set equal to m = 0.8. Although this value is very high, our previous studies on rotary forming processes have demonstrated that the friction forces in rolling processes are considerably high. This results from the fact that the tools are not lubricated in the rolling process; and what is more, to improve the stability of the process (prevent slip between the tools and the material), the surface of the tools is made rough on purpose to increase friction. Thermal phenomena were considered in the simulations, with the heat exchange coefficient between the material and the tools set equal to 20 kW/m2K, while that between the material and the environment to 0.35 kW/m2K.

FEM-obtained shapes of stepped shafts as well as distributions of effective strains, temperature and Cockcroft-Latham ductile fracture criterion are shown in Fig. 5 (solid part) and in Fig. 6 (hollow part). The results demonstrate that the metal flow pattern depends on the type of billet used. With a hollow billet, the metal flows radially to the axis of the workpiece, which leads to an increase in the wall thickness of the workpiece and merely a slight elongation of the workpiece. When rolling a solid billet, however, the length of the workpiece is increased to a considerable extent. This material flow pattern affects the distribution of effective strains (Figs. 5a and 6a). In the case of solid parts, the strains in the cross section of rolled steps are highly non-uniform. The maximum values (effective strain is 5) are concentrated in the surface areas and decrease concentrically toward the axis of the workpiece. When hollow parts are rolled, the non-uniformity of strains is much smaller (about 3), and their extreme values are much lower. The observed differences primarily result from the resistance to deformation of the material, which affects the redundant strains generated by the friction forces on the surface of the workpiece.

The type of billet material also affects the distribution of temperature in the rolled part (Figs. 5b and 6b). A higher thermal capacity and strains of the solid billet allow the compensation of heat losses resulting from the contact with the tools and environment, which leads to a significantly higher temperature of the workpiece. This information is vital when rolling semi-finished products for further processing. It can be observed that in solid parts the temperature decrease occurs on the surface, with the temperature dropping to even approx. 980 °C. In the central region of the workpiece the temperature remains high (above 1000 °C). In the case of hollow parts the decrease in temperature is much more considerable (the temperature of the surface of the workpiece drops to approx. 940 °C, while in the region of the hole it drops to approx. 960 °C). This is due to among others, from a smaller thermal capacity of the material and a significantly larger area of heat radiation. However, it should be noted that, in most cases, such parts are already finished products and the temperature of the workpiece is higher than the recrystallization temperature, which should not affect the strength properties of these parts later on. Cracking in the analysed rolling process was predicted with the use of the Cockcroft-Latham ductile fracture criterion. This criterion was primarily selected due to its wide use in the analysis of forming processes, which allows comparison of our results with results obtained by other authors. Moreover, the prediction of cracking based on a given fracture criterion is only possible when one knows the limit values for this criterion. Unfortunately, however, the specialist literature lacks data regarding the limit values for different models of fracture in rotary forming processes. The authors have recently conducted research which resulted in the determination of the limit values of the Cockcroft-Latham damage function in skew and cross rolling processes. Therefore, the Cockcroft –Latham ductile fracture criterion was used in this study. The distribution of the Cockcroft-Latham ductile fracture criterion provides very interesting information (Figs. 5c and 6c). It turns out that performing the rolling process with the use of three tools leads to reducing the value of the Cockcroft-Latham criterion. When parts are skew rolled with two tools [28, 29], the Cockcroft-Latham criterion is very high (above 2), which poses a high risk of material cracking. By changing the rolling pattern (three tools are used), the Cockcroft-Latham criterion can be reduced by several times, and therefore the probability of internal cracking in the steps of rolled shafts can be reduced, too. For solid parts, the Cockcroft-Latham criterion does not exceed the value of 1, whereas for hollow parts it is even lower and does exceed 0.7. In both cases, the limit values of the criterion are concentrated in the surface layers of the tapered section of the workpiece connecting the sections of different diameters. In other regions of the part this criterion is lower, its value not exceeding 0.8 for solid parts and 0.5 for hollow parts. The low limit values of the damage function indicate that the probability of internal crack occurrence in this rolling process is lower than in two-roll skew rolling processes [28].

Apart from the verification of the possibility of rolling parts by the proposed skew rolling process and the identification of phenomena occurring during this process, the main objective of the numerical analysis was to estimate force parameters in this process, on the basis of which the rolling mill design assumptions were made. FEM-modelled radial force of the tools, axial force of the chuck and torque are shown in Fig. 7. Data given in the figure reveal that the forces and torques rapidly increase when the tools cut into the material. After that, the force parameters become stable, and in the steady-state rolling of individual steps on the shaft one can observe a gradual increase in the forces and torques, which can be explained by a drop in the workpiece temperature.

A slightly different behaviour is observed for the axial forces of the chuck. As the tools cut into the material, the forces take negative values (− 2.7 kN for the solid part and − 3.5 kN for the hollow part). This means that the workpiece is pushed by the tools towards the chuck. This is caused by the skew position of the tools (the axes of the rollers are twisted relative to the rolling axis at an angle of γ = 5°), which leads to axial displacement of the workpiece during rolling. During steady-state rolling, the forces become stable too, showing only a slight increase resulting from a drop in the workpiece temperature. The highest forces and torques affecting the magnitude and power of the machine drive system are observed toward the end of rolling steps on the ends of the part (solid and hollow alike). It should also be stressed that the forces and torques are over two times higher when solid parts are rolled than those observed in the rolling of hollow parts. For solid parts, the tool load is 33 kN and the axial load stretching the material on the chuck is 18.5 kN. For hollow parts, the maximum tool load is 26 kN and the axial load on the chuck is 13.5 kN. The maximum torque also depends on the type of rolled part. The maximum torque is measured toward the end of the rolling process, its value being approx. 720 Nm for solid parts and below 270 Nm for hollow parts.

3 Design of a CNC skew rolling mill

A CNC skew rolling mill was designed and constructed at the Lublin University of Technology for the purpose of research on rotary forming processes for axisymmetric semi-finished products [30]. The machine can be used to produce elongated axisymmetric parts according to the proposed skew rolling process. A fundamental element of the developed machine is its computerized control of rolling, which makes it possible to perform any sequence of tool and workpiece motion.

The developed skew rolling mill has a segment structure and comprises 9 basic units: a support frame—1, a power unit—2, mill stand—3, axial displacement unit—4, a drive unit—5, workpiece holding unit—6, a chuck unit—7, product holding unit—8, and power and control system (not shown in Fig. 8). A 3D model of the rolling mill is shown in Fig. 8. In the rolling process, a bar is placed in the head of the workpiece support unit. The bar is mounted by one end in a four-jaw chuck of the chuck unit. It is moved together with the chuck unit by means of an axial displacement servomotor to the initial position. Then, three rollers mounted on tool shafts are rotated by three electric engines and planetary gears. After that, three slides begin to move in a radial direction, their translational motion being generated by the servomotor spindles. Simultaneously, in accordance with the adopted control algorithm, translational motion of the axial displacement servomotor spindle is started, causing axial displacement of the workpiece-holding chuck unit.

The workpiece is rotated by the rollers that rotate in the same direction. At the same time these radially moving tools reduce the cross-section of the workpiece. As the tools cut into the material, the workpiece is moved axially by the chuck unit between the rotating tools, which leads to the formation of successive steps on the shaft. The radial motion of three slides with the tools is correlated with the translational motion of the chuck in such a way that a resulting trajectory of the tool motion and chuck axial displacement corresponds to the envelope profile of a part rolled. Toward the end of the rolling process, the product holding head moves towards the rolling axis; the head holds the rolled part and thus prevents it from bending. Torque is measured by a torque gauge located in front of one of the jointed shafts. In addition, tool load is measured using a load gauge located in one of the slides. In addition to that, chuck load is measured with a strain gauge mounted on the servomotor spindle. Technical specifications of the CNC skew rolling mill are listed in Table 1.

The rolling process is performed in a mill stand (Fig. 9) whose frame consists of two pillar plates 1 in which mounting holes are made. Three sets of slides 2 are mounted in these holes every 120° symmetrically to the rolling axis. Every set of the working slides consists of an outer frame 3, inside which an inner slide body 4 with the slide 5 is mounted rotationally.

In the upper part of the slide is mounted a load gauge 6 connecting the slide with a servomotor spindle 7. During rolling this gauge measures the tool load on the workpiece. In their lower part, perpendicular to their axis, the slides have holes in which tool shafts 8 are bearing-mounted. Working rollers 9 are mounted on shaft necks. The angular position of the tools in the mill stand can be adjusted using a screw mechanism 10 which is located in the outer slide frame 3; this mechanism allows rotation of the inner slide frame with the slide and the tool shaft in a range ± 10°. Once the angular position of the tools is set, the inner frame of the slide is prevented from automatic rotation by a clamping eccentric mandrel 11.

The desired tool and chuck motion is ensured by servo drives. This solution allows the precise identification of tool and workpiece position at any moment of the process. The servo drives are powered and controlled by an electronic system. The power and control system consists of 4 servomotors (KOMPAX), an industrial automation controller PAC, a personal computer and devices preventing overload of the system components. A scheme illustrating the control and management of the rolling process is shown in Fig. 10. The most important element of the system is the industrial controller PAC that communicates with the servomotors and controls their operation based on the defined envelope of a rolled part. For a precise definition of the current position of the tools and workpiece, the servomotors are in a coupling loop with the servo drives and the PAC controller. Data loading to the PAC controller and process visualisation are made by a PC computer that is used as the control system operator’s panel. Force parameters during rolling are measured by a torque gauge installed on one of the tool rotating output shafts of the moto reducer and by the load gauges located in one of the slides in the mill stand, in front of the workpiece holding chuck. Signals recorded by the gauges are uploaded to the computer using a measuring system based on the National Instruments USB-6008 measuring card. This special control and measuring application was developed in the LabVIEW environment. A scheme illustrating the drive and servomotor control systems in the rolling mill is given in Fig. 10.

The design process of a rolling mill involved a comprehensive analysis of the strength of the main units of this machine. This was done using engineering methods based on fundamental principles of materials strength to determine the minimum sections of critical members of the machine. Next, numerical methods were applied to verify the developed design with respect to its strength and rigidity. Numerical calculations were performed for linear strength characteristics of the material in the NX Nastran environment by the finite element method. Initial results demonstrate that the mill stand is the most loaded unit of the machine and that its rigidity and strength are of key importance for the reliable operation of the rolling mill and the dimensional accuracy of rolled parts. For this reason, this paper will focus on presenting the strength analysis results of this particular unit. All parts of the mill stand were assigned the following material properties: Poisson’s ratio ν = 0.3, Young’s modulus E = 2.1 × 105 MPa. The boundary conditions between the mill stand plates, servomotors and slide components were described by a default function for screw joints, which corresponded to real screw joints of these members. Other joints were described by linear contact without penetration and distance. A discrete model of the mill stand for FEM analysis was created using 4-node elements of 2 mm in size. The size of the structure-describing elements depended on the dimensions of the discretized members. The accuracy of this method greatly depends on the finite element size. Given its dimensions and shape, the analysed structure was initially discretized using 4-node finite elements of 5 mm in size. After that, the calculations were repeated for the twice smaller elements (2.5 mm), and then the size of the mesh elements was again reduced to 2 mm. Results obtained for the two last repetitions are similar, which demonstrates that both quality and accuracy of the calculations are satisfactory for the structure under analysis. The numerical analysis was performed for maximum loads (pre-estimated in the FEM simulation of the rolling process and increased by 50%). The concentrated forces of Fr = 50 kN were applied axially to the three rollers mounted on the working shafts, in compliance with the direction of motion of the slides. These forces were applied to the surfaces of the sizing shafts, and their sense corresponded to the resistance of metal during the rolling process. In addition to that, concentrated axial forces of Fz = 16.5 kN were applied to the surfaces of the sizing of three tools; the forces were applied in accordance with the rolling direction. Additionally, each of the rollers was loaded a torque of Mo = 1200 Nm applied to the mill shafts that was counterbalanced by the circumferential force Fo = 16 kN and Fr = 50 kN applied to the surface of every roller. The load scheme of the rolling stand is shown in Fig. 11.

FEM results served for determining the distributions of reduced stresses according to the Huber–Mises hypothesis and the displacement of the mill stand components under the applied external loading. Obtained stress and displacement results are plotted in Fig. 12. The distributions of reduced stress were used to evaluate the degree of material effort in critical members of the structure; primarily, the yield point of the most loaded mill stand components was determined. Results of the mill stand component displacement were used to evaluate the machine’s rigidity, as this parameter affects the accuracy of rolled parts. An analysis of the results reveals that the working shafts on which the rollers are mounted are the most loaded members of the structure. The reduced stresses at their support reach 100 MPa. These values are acceptable (the yield point of 42CrMo4 is about Re = 900 MPa) because they will not cause any permanent strains in these elements. The effort of other components of the mill stand, including the support plates, slide housings and slides, is considerably lower. The maximum reduced stresses in the support plates of the mill stand are below 30 MPa. In contrast, the loading of the slide housings and slides is higher than that of the support plates, with the maximum stress amounting to 70 MPa. Nevertheless, these values are several-fold lower than the yield stress of their material (it was assumed that the slide housing would be made of S355 steel, the yield stress of this steel grade being equal to 355 MPa), which indicates that there is no risk of damage of the machine components if the rolling process is conducted with the assumed technological parameters. It turns out that the key parameter ensuring the correct operation of the rolling mill is the rigidity of the mill stand. This is confirmed by quite high elastic strains identified in displacement analysis. It can be observed that the main shaft necks in the mill stand travel by approx. 0.3 mm. This is the total value of tool travel connected with the elastic strain of the support plates (by approx. 0.05 mm), the slides and their housings (by approx. 0.15 mm), and the main shafts with tools (that move by a total of 0.3 mm). It should, however, be stressed that in the case of hot rolling, the FEM deflection is within the manufacturing tolerance range for semi-finished products and will have no significant effect on the accuracy of rolled parts (only finish allowance may be higher). The relatively high elastic deflection of the shafts results, among others, from the applied pattern of tool support (the type of tool mounting). In the mill stand, the necks on which the shafts are mounted are supported on one side. This solution considerably improves the functional properties of the machine and facilitates frequent tool exchange when testing new solutions. Nevertheless, it has a negative effect on the rigidity of the entire system. The industrial version of the machine should be provided with a two-side support of the working shafts, which will allow reducing elastic deflection of the rollers by several times while at the same time maintaining the cross sections of the working shafts identical. The effect of elastic strains of the mill stand components on the accuracy of rolled parts can be minimized by correcting tool displacement to consider the frame’s elastic strain caused by the rolling forces, which is relatively easy to implement in the case of the employed control system.

4 Rolling stepped shafts (solid and hollow) in a CNC skew rolling mill

Given the satisfactory results of both FEM modelling of the proposed skew rolling process and strength analysis of the designed machine, the authors decided to construct a CNC skew rolling mill based on the developed design. Shown in Fig. 13, the constructed rolling mill can be used under real conditions.

To validate the FEM numerical models and to verify the technological capabilities of the skew rolling method and rolling mill, experimental rolling tests were conducted. Solid and hollow stepped shafts were rolled, their parameters being identical to those applied in the FEM modelling. Billet materials for the experiments were S355 steel bars and tubes with the same dimensions as those applied in the FEM analysis (Fig. 4). The billet material was first preheated to 1170 °C in a chamber furnace and then mounted in the chuck of the machine. On transferring the billet from the furnace to the rolling mill, the temperature of the material was measured with an infrared camera. The temperature results obtained at the beginning of the rolling process demonstrate that the temperature drop is insignificant (it does not exceed 10 degrees Fig. 14a), which can be explained by the presence of scale and its insulating role. Next, it was fed between the tools that were rotated in the same direction. The rolling process was started once the billet assumed its initial position. During the rolling process, the radial motion of the tools and the axial motion of the chuck and workpiece are controlled based on the workpiece envelope that was introduced earlier via the operator’s pulpit (laptop) to the PLC controller. Successive stages of rolling parts in a CNC skew rolling mill are shown in Fig. 14.

Once all steps are formed, the rolled part in the chuck is taken beyond the forming zone, removed from the chuck and subjected to low-rate air cooling. Rolled parts are cleaned; their longitudinal and cross sections are made and visually inspected for any internal defects. Shapes of the experimental solid and hollow parts (together with their longitudinal and cross sections) are shown in Fig. 15. The experimental parts show a good geometrical and dimensional agreement with the initial assumptions and FEM results. Although the cylindrical surfaces of the rolled parts are free from defects, on the tapered surfaces between the steps one can observe spiral grooves that are characteristic of this process and result from the specific motion of the tools and workpiece.

The axial sections are free from internal cracks, while the cross sections show a high geometrical accuracy of the circular profiles of individual steps on the rolled parts. When rolling a solid part, there occurs some material pile-up and a local increase in the workpiece diameter in the vicinity of the step rolled, which results from an axial flow of the material. The phenomenon of material pile-up is not observed in the hollow parts, which can be explained by the fact that the material predominantly flows radially when the tools cut into the workpiece. Obviously, the cross-sectional reduction causes the material to flow axially, which—in turn—causes an increase in the length of the workpiece. The length increase when rolling solid parts is easy to calculate and results from the constant volume principle. When hollow parts are rolled, the material predominantly flows radially, and thus increases the workpiece wall thickness, which leads to a relatively small elongation of the workpiece. This is characteristic of this type of process. It must be stressed that the wall thickness increase is quite homogenous over the length of individual shaft steps, which is beneficial and ensures obtaining parts with the desired shape. The inspection of the rolled parts reveals the presence of cavities on the end faces of both solid and hollow parts. The end-face cavities results from a non-homogenous flow of the material in an axial direction. The surface metal layers flow more rapidly than the central layers, which causes the formation of end-face cavities. The rate of cavity formation greatly depends on the rolled part type (solid or hollow) and the cross-sectional reduction ratio. Solid parts are rolled with the metal flow being primarily axial, and the highest strain rate is observed in the surface layers, which leads to the formation of quite deep cavities on the end face of the workpiece. Hollow parts are rolled with a predominantly radial material flow and relatively small workpiece elongation. It can be observed that the strains are concentrated in the surface layers; however, these strains are several times lower than those observed in the solid parts. Consequently, the depth of the end-face cavities is definitely smaller.

Steps on the rolled parts were examined for dimensional accuracy. Diameter measurements were made in three sections over the length of the formed steps. Additionally, to estimate shape accuracy, measurements were made in two mutually perpendicular planes for every analysed cross section. The way in which the measurements were made is shown in Fig. 16, and obtained results are listed in Table 2. Surface roughness was measured on the formed steps. The results show high dimensional and geometric accuracy. Manufacturing deviations from the nominal dimension for individual steps do not exceed 0.3 mm for solid parts and 0.45 mm for hollow parts. The mean deviation from the circularity of the cross sections for individual steps does not exceed 0.10 mm for solid steps and 0.2 mm for hollow steps. In addition, the profilometry results of surface roughness point to the high surface quality of the rolled steps. For solid parts, the surface roughness is approx. 29 µm for the 43 mm diameter step and 25 µm for the 38 mm diameter step. The surface quality of hollow parts is slightly lower. The surface roughness is 29 µm for the bigger diameter step and 35 µm for the smaller diameter step. The reduced surface quality of hollow parts can be explained by predominantly radial flow of the material and lower elongation of the material. As a result, in spite of the same axial velocity in rolling solid and hollow parts, the quality of hollow steps is reduced. Manufacturing accuracy also depends on the rigidity of a rolled part (this rigidity being lower for hollow parts), which leads to reduced quality of hollow parts. It should, however, be stressed that in both cases the quality of parts produced by this analysed process is significantly higher than that obtained with other hot forming processes. Consequently, it can be claimed that the proposed technique can be used to produce parts by the near net shape method, leaving minimal finishing allowance.

Force parameters (torque, radial and axial forces) were measured during the rolling tests. The results are plotted in Fig. 17. As expected, the forces and torques are higher when solid parts are rolled, which results from a higher material flow resistance than in the rolling of hollow parts. It is worth emphasizing that the radial forces and torques in all analysed cases rapidly increase as the tools cut into the material. At the same time, the axial force on the chuck decreases. The axial force decrease results from a higher rate of workpiece elongation compared to the chuck velocity, which even leads to the occurrence of negative force values indicating material compression. Next, in the steady-state process stage when the tools do not change their radial position, the forces and torques become stable.

A comparison of the FEM and experimental results shows their relatively high qualitative and quantitative agreement with respect to the shape of rolled parts. As for the force parameters, small differences can be observed regarding the FEM (Fig. 7) and experimental results (Fig. 17). The experimental maximum forces and torques are about 15% higher than the FEM results. It is also worth stressing the different behaviour patterns of the forces and torque. One can observe that the experimental forces and torques are on a similar level when parts are rolled without changing the reduction ratio (steady-state rolling). In contrast, the forces and torques obtained by FEM are higher. This can be explained by the resistance to the motion of the machine components that was not considered in numerical modelling. In effect, the force and torque measurement sensitivity is reduced, which may affect their results. Importantly, this trend is not observed for the axial force of the chuck. It should be emphasized that the obtained maximum forces and torques are lower than the nominal parameters of the machine, which confirms the correctness of the applied design assumptions.

The technological capability of the CNC skew rolling mill is not limited to producing simple parts. Positive results were obtained when rolling more complex parts, too. Examples of parts rolled in this CNC skew rolling mill are shown in Fig. 18. An analysis of the produced parts and semi-finished products indicates that the proposed skew rolling method can be used to produce elongated axisymmetric parts with practically any shape of the envelope. The rolled parts have a relatively good surface quality and high dimensional accuracy. In addition, they are free from internal cracks in spite of the application of a very high reduction ratio, with its value exceeding 2.

5 Summary and conclusions

The results of this study have shown the vast potential of rolling elongated stepped axles and shafts as well as preforms in a CNC rolling mill. The main advantage of the proposed skew rolling technique is its high versatility allowing the production of parts with different profiles with the use of only one set of tools (rollers). Owing to this feature, the proposed technique is very attractive to smaller forging plants that manufacture small batches of products, infrequently on an alternate basis. Another advantage of the proposed process is the possibility of rolling both solid and hollow parts, which—in the case of conventional rolling methods—requires the use of additional machines and specialist tooling. The skew rolling mill developed for the purpose of this study has a simple and compact design, which means that it can be used to produce parts having a wide dimensional range. The applied machine design solutions such as the use of electronically controlled servomotors for driving the slides and controlling the chuck make it possible to perform any motion of the tools and material, which adds up to a higher technological potential of the rolling mill. This solution is an attractive alternative to conventional solutions based on the use of template systems.

The results of this study lead to the following conclusions:

-

CNC skew rolling mills make it possible to produce elongated stepped axles and shafts using only one set of tools.

-

The performance tests of the machine have confirmed that the proposed design solutions can be implemented in industrial machines.

-

The developed skew rolling mill can be used for skew rolling elongated solid and hollow parts in compliance with the process design assumptions.

-

The strength test results of the mill stand have shown that there is no risk of failure of the structure or deformation of its critical components under the assumed loading.

-

The mill stand components may undergo quite high elastic strains during operation. Nevertheless, these strains should not have a negative effect on the accuracy of rolled parts because the machine control system is capable of compensating for elastic deflection.

-

The machine performance tests have confirmed the correctness of both design and technological assumptions, as well as the suitability of the PAC control system used in the rolling mill for performing any sequence of tool motion.

-

Given a growing interest of forging plants in this relatively cost-effective rolling method, it is justified to conduct further studies on the development of the skew rolling technique and skew rolling mills that can be implemented in the industry.

References

Shu X, Wei X, Li C, Hu Z. The influence rules of stress about technical parameters on synchronous rolling railway axis with multi-wedge cross-wedge rolling. Appl Mech Mater. 2010;37–38:1482–8.

Pater Z. Cross wedge rolling. In: Button ST, editor. Comprehensive materials processing. Berlin: Elsevier Ltd.; 2014. p. 211–79.

Zhou J, Yu Y, Zeng Q. Analysis and experimental studies of internal voids in multi-wedge cross wedge rolling stepped shaft. Int J Adv Manuf Technol. 2014;72:1559–66.

Tofil A, Pater Z. Overview of the research on roll forging processes. Adv Sci Technol Res J. 2017;11:72–86.

Cai Z. Precision design of roll-forging die and its application in the forming of automobile front axles. J Mater Process Technol. 2005;168:95–101.

Zhuang W, Hua L, Wang X, Liu Y, Han X, Dong L. Numerical and experimental investigation of roll-forging of automotive front axle beam. Int J Adv Manuf Technol. 2015;79:1761–77.

Franzke M, Recker D, Hirt G. Development of a process model for online-optimization of open die forging of large workpieces. Steel Res Int. 2008;79:753–7.

Groche P, Fritsche D, Tekkaya EA, Allwood JM, Hirt G, Neugebauer R. Incremental bulk metal forming. Ann CIRP. 2007;56:635–56.

Şchiopu V, Luca D. A new net-shape plating technology for axisymmetric metallic parts using rotary swaging. Int J Adv Manuf Technol. 2016;85:2471–82.

Gronostajski Z, Pater Z, Madej L, Gontarz A, Lisiecki L, Lukaszek-Solek A, Luksza J, Mróz S, Muskalski Z, Muzykiewicz W, Pietrzyk M, Sliwa RE, Tomczak J, Wiewiórowska S, Winiarski G, Zasadzinski J, Ziólkiewicz S. Recent development trends in metal forming. Arch Civ Mech Eng. 2019;19:898–941.

Groche P, Krech M. Efficient production of sensory machine elements by a two-stage rotary swaging process—relevant phenomena and numerical modelling. J Mater Process Technol. 2017;242:205–17.

Tomczak J, Pater Z, Bulzak T. A helical rolling process for producing ball studs. Arch Civ Mech Eng. 2019;19:1316–26.

Hu Z, Wang B, Liu J, et al. Technology of skew rolling. Beijing: Chemical Industry Press; 2014. p. 4–5.

Pater Z, Tomczak J, Bartnicki J, Lovell MR, Menezes PL. Experimental and numerical analysis of helical-wedge rolling process for producing steel balls. Int J Mach Tools Manuf. 2013;67:1–7.

Tofil A. The rolling processes of semifinished in a universal forging mill. Lublin: Lublin University of Technology Press; 2016.

Pater Z. Cross wedge rolling. Lublin: Lublin University of Technology Press; 2009.

Li R, Jiao S, Wang J. Roll—forging technology of automotive front axle precision performing and die design. IERI Procedia Vol. 2012;1:166–71.

Smirnov VZ, Anisiforov VP, Vasilchikov MV et al (1957) Poperechnaya prokatka v mashinostroyenii, GNTIML, Moskva

Gronovskij SP. Novye procesy i stany dla prokatki izdelij v vintovych kalibrach. Moscow: Mietalurgija; 1980. ((in Russian)).

Pater Z, Tomczak J, Bulzak T. Numerical analysis of the skew rolling process for rail axles. Arch Metall Mater. 2015;60:415–8.

Pater Z, Tomczak J, Bulzak T. Numerical analysis of the skew rolling process for main shafts. Metalurgija. 2015;54(4):627–30.

Lis K, Wójcik Ł, Pater Z. Numerical analysis of a skew rolling process for producing a cranckshaft preform. Open Eng. 2016;6:581–4.

Pater Z, Tomczak J, Bulzak T. FEM simulation of the cross-wedge rolling process for a stepped shaft. Strength Mater. 2017;49(4):521–7.

Xu C, Shu XD. Influence of process parameters on the forming mechanics parameters of the three-roll skew rolling forming of the railway shaft with 1:5. Metalurgija. 2018;57(3):153–6.

Wang JT, Shu XD, Zhang S. Effect of process parameters on average grain size and microscopic uniformity of the three-roll skew rolling forming of the railway hollow shaft. Metalurgija. 2020;59(1):47–50.

Pater Z, Tomczak J, Bulzak T. Numeral analysis of a skew rolling process for producing axle shafts. Comput Methods Mater Sci. 2016;16:63–9.

Simufact Material (2018) (v2018.0.60847), Material database. Simufact engineering gmbh, Hamburg

Pater Z, Tomczak J, Bulzak T. Rotary compression as a new calibration test for prediction of a critical damage value. J Mater Res Technol. 2020;9:5487–98.

Pater Z, Tomczak J, Bulzak T, Wójcik Ł, Walczuk P. Assessment of ductile fracture criteria with respect to their application in the modeling of cross wedge rolling. J Mater Process Technol. 2020;278:1–11.

Tomczak J, Pater Z, Bulzak T (2018) Skew rolling mill. Patent application: no P.427770

Acknowledgements

The research was financed in the framework of the project Lublin University of Technology -Regional Excellence Initiative, funded by the Polish Ministry of Science and Higher Education (contract no. 030/RID/2018/19).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tomczak, J., Pater, Z., Bulzak, T. et al. Design and technological capabilities of a CNC skew rolling mill. Archiv.Civ.Mech.Eng 21, 72 (2021). https://doi.org/10.1007/s43452-021-00205-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00205-7