Abstract

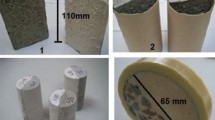

The increase in the corrosion rate around a repair area caused by the formation of a galvanic cell between the substrate concrete and the repair mortar is known as the incipient anode. The current study is aimed at investigating the effects of repair dimensions on the corrosion rate of the macrocell created by the patch repair. To do so, repair slabs were manufactured with different repair dimensions and repair mortars containing ordinary Portland cement (OPC), 5% microsilica, and 9% microsilica. The half-cell potential and macrocell current of the experimental specimens were measured, and the electrochemical parameters (i.e., Tafel slope and macrocell corrosion rate) of the repair mortar and the substrate concrete were determined. The effects of repair dimensions and the driving force were evaluated in a wider range using a numerical model. The results showed that compared to OPC, the repair mortar containing 9% microsilica significantly reduced the maximum macrocell corrosion (MMC) and the average macrocell corrosion (AMC) rates. The effects of the repair dimensions are not significant and there is only a slight increase of 30% in the MMC rate when the repair dimension is less than 30 cm, while this rate remains constant in repair dimensions higher than 30 cm. The effect of the repair dimension on the AMC is more significant than its effect on the MMC, i.e., as the repair dimension increases to 100 cm, the AMC increases by at least 130%, and then, it remains constant. Moreover, the reduction in the driving force considerably decreased the MMC and AMC rates.

Similar content being viewed by others

References

Bertolini L, Elsener B, Pedeferri P, Redaelli E, Polder R (2013) Corrosion of steel in concrete, vol 392. Wiley Online Library, Hoboken

Raupach M, Büttner T (2014) Concrete repair to EN 1504: diagnosis, design, principles and practice. CRC Press, Boca Raton

Rilem (1994) Draft recommendation for repair strategies for concrete structures damaged by reinforcement corrosion. Mater Struct 27:415–436

Zhang J, Mailvaganam NP (2006) Corrosion of concrete reinforcement and electrochemical factors in concrete patch repair. Can J Civ Eng 33(6):785–793

Page CL (1982) Aspects of the electrochemistry of steel in concrete. Nature 297:109–115

Raupach M (1996) Chloride-induced macrocell corrosion of steel in concrete—theoretical background and practical consequences. Constr Build Mater 10(5):329–338

Barkey DP (2004) Corrosion of steel reinforcement in concrete adjacent to surface repairs. Mater J 101(4):266–272

Raupach M (2006) Patch repairs on reinforced concrete structures–Model investigations on the required size and practical consequences. Cem Concr Compos 28(8):679–684

Hanley B, Coverdale T, Miltenberger M, Nmai C (1998) Electrochemical compatibility in concrete repair. ICRI Workshop Man Houst 3:21–98

Grantham M, Gray A (1997) Patch repairs and cathodic protection. Constr Repair 11(2)

Wheat HG, Harding KS (1993) Galvanic corrosion in repaired reinforced concrete slabs: an update. Mater Perform 32(5):58–62

Emberson NK, Mays GC (1990) Significance of property mismatch in the patch repair of structural concrete part 1: properties of repair systems. Mag Concr Res 42(152):147–160

Raupach M, Schießl P (2001) Macrocell sensor systems for monitoring of the corrosion risk of the reinforcement in concrete structures. NDT E Int 34(6):435–442

Gu P, Beaudoin JJ, Tumidajski PJ, Mailvaganam NP (1997) Electrochemical incompatibility of patches in reinforced concrete. Concr Int 19(8):68–72

Emmons PH, Vayasburd AM, McDonald JE (1994) Concrete repair in the future turn of the century-any problems? Concr Int 16(3):42–49

McDonald JE, Vaysburd AM, Emmons PH, Poston RW, Kesner K (2002) Selecting durable repair materials: performance criteria—Summary. Concr Int 24(1):37–44

Soleimani S, Ghods P, Isgor OB, Zhang J (2010) Modeling the kinetics of corrosion in concrete patch repairs and identification of governing parameters. Cem Concr Compos 32(5):360–368

Pruckner F, Gjørv OE (2002) Patch repair and macrocell activity in concrete structures. Mater J 99(2):143–148

Eldho CA, Nanayakkara O, Xia J, Jones SW (2016) Macrocell corrosion formation in concrete patch repairs—a laboratory study. Key Eng Mater 711:68–75

Warkus J, Raupach M (2010) Modelling of reinforcement corrosion—geometrical effects on macrocell corrosion. Mater Corros 61(6):494–504

Warkus J, Raupach M (2008) Numerical modelling of macrocells occurring during corrosion of steel in concrete. Mater Corros 59(2):122–130

Ji Y, Hu Y, Zhang L, Bao Z (2016) Laboratory studies on influence of transverse cracking on chloride-induced corrosion rate in concrete. Cem Concr Compos 69:28–37

Feliu C, Gonzalez S, Feliu JA, Andrade S (1989) Relationship between conductivity of concrete and corrosion of reinforcing bars. Corrosion 24(3):195–198

Bertolini L, Polder R (1997) Concrete resistivity and reinforcement corrosion rate as a function of temperature and humidity of the environment, TNO report-97-bt-R 0574. Technical report, TNO Building and Construction Research

Elsener B, Gulikers J, Polder R, Raupach M (2003) Half-cell potential measurements-Potential mapping on reinforced concrete structures. Mater Struct 36:461–471

Andrade C (2019) Propagation of reinforcement corrosion: principles, testing and modelling. Mater Struct 52(1):2

Hornbostel K (2015) The role of concrete resistivity in chloride-induced macro-cell corrosion of reinforcement. NTNU

Castro P, Pazini E, Andrade C, Alonso C (2003) Macrocell activity in slightly chloride-contaminated concrete induced by reinforcement primers. Corrosion 59(6):535–546

Hornbostel K, Angst UM, Elsener B, Larsen CK, Geiker MR (2015) On the limitations of predicting the ohmic resistance in a macro-cell in mortar from bulk resistivity measurements. Cem Concr Res 76:147–158

Hiemer F, Jakob D, Keßler S, Gehlen C (2018) Chloride induced reinforcement corrosion in cracked and coated concrete: from experimental studies to time-dependent numerical modeling. Mater Corros 69(11):1526–1538

ASTM (2007) G109–07: Standard test method for determining effects of chemical admixtures on corrosion of embedded steel reinforcement in concrete exposed to chloride environments. ASTM International, West Conshohocken, PA

ASTM-C876 (1999) Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in concrete, ASTM International. West Conshohocken, PA, USA

BSI (2012) BS EN ISO 12696: 2012: Cathodic protection of steel in concrete. BSI London, UK

NACE RP0290: Impressed current cathodic protection of reinforcing steel in atmospherically exposed concrete structures, NACE International, Houston, TX, USA, 2007.

Andrade C, Maribona IR, Feliu S, González JA, Feliu S (1992) The effect of macrocells between active and passive areas of steel reinforcements. Corros Sci 33(2):237–249

Hornbostel K, Angst UM, Elsener B, Larsen CK, Geiker MR (2016) Influence of mortar resistivity on the rate-limiting step of chloride-induced macro-cell corrosion of reinforcing steel. Corros Sci 110:46–56

Kaesche H (2012) Corrosion of metals: physicochemical principles and current problems. Springer Science & Business Media, Berlin

Larbi JA (1993) Microstructure of the interfacial zone around aggregate particles in concrete. STIN 94:19322

Kim C-Y, Kim J-K (2008) Numerical analysis of localized steel corrosion in concrete. Constr Build Mater 22(6):1129–1136

Valipour M, Shekarchi M, Ghods P (2014) Comparative studies of experimental and numerical techniques in measurement of corrosion rate and time-to-corrosion-initiation of rebar in concrete in marine environments. Cem Concr Compos 48:98–107

Chalhoub C, François R, Garcia D, Laurens S, Carcasses M (2020) Macrocell corrosion of steel in concrete: Characterization of anodic behavior in relation to the chloride content. Mater Corros 71:1424–1441

Yu B, Yang L, Wu M, Li B (2014) Practical model for predicting corrosion rate of steel reinforcement in concrete structures. Constr Build Mater 54:385–401

Broomfield JP (1997) Corrosion of steel in concrete: understanding. Investig Repair, E&FN, London, p 1–15

Bungey JH, Grantham MG (2006) Testing of concrete in structures. CRC Press, Boca Raton

Gonzalez JA, Miranda JM, Feliu S (2004) Considerations on reproducibility of potential and corrosion rate measurements in reinforced concrete. Corros Sci 46(10):2467–2485

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors of study entitled " Experimental and Numerical Investigation of Repair Dimensions Effect on Macro-cell Corrosion Induced by concrete Slabs Patch Repair " certify that they have NO affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent-licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

Rights and permissions

About this article

Cite this article

Ghoddousi, P., Haghtalab, M. & Shirzadi Javid, A. Experimental and Numerical Investigation of Repair Dimensions Effect on Macro-cell Corrosion Induced by Concrete Slabs Patch Repair. Int J Civ Eng 19, 1091–1110 (2021). https://doi.org/10.1007/s40999-021-00620-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-021-00620-0