Abstract

The world energy consumption is going to rise by nearly 50% in 2050 when compared to 2010. With conventional and unconventional reserves depleting, demand for energy supply is rising. The feasibility and the current efficiency of renewable energy sources may not be capable of satisfying the world energy demand by themselves. Increase in production of non-renewable energy source, i.e., the fossil fuels may help to fulfill the energy requirement of future generations. Shale gas is one of the unconventional sources of energy. Shale gas deposits are scattered all over the planet in low-permeability and low porosity reservoirs. India has overall reserves of shale gas between 600 and 2000 TCF, of which 63 TCF is of recoverable shale gas (Pradhan and Prakash 2000). Shale production depends on many factors such as political matters, wars, social and economic aspects, and exploration techniques. Depending on the recoverable reserve (RR), production of shale gas entails different methods and with a different method, comes different problems described and discussed in this manuscript. Along with the problems, the technically recoverable reserves of different countries, different production mechanisms, and economic aspects of shale gas are also discussed.

Similar content being viewed by others

Introduction

The non-renewable fuels (natural gas, oil, and coal) right after their discovery have controlled the world energy supplies finding a place in residential, commercial, industrial, and even transportation sector. It is perhaps impossible to imagine a world where there were no fossil fuels. Over the past few decades, global demand for energy has multiplied. There is a significant rise in energy usage as the population continues to grow. Global development, following the developing world, suggests household income increase, which requires more energy use, greater access to transport networks and services (Wolfram et al. 2012). Now, as the demand keeps on increasing the energy supply too needs to upsurge in coherence. That is one aspect. Another critical factor is the environmental aspect. There are significant consequences of the energy usage on the local pollutants and the emission of greenhouse gases. The inclination toward using more sustainable forms of energy is undeniable. While there is an enormous amount of research and development put into renewable sources of energy like solar, wind, and hydropower, one common problem that exists with these is feasibility and efficiency. One can easily understand that it is not possible to harness wind energy in every part of the world. The same may be the case with hydropower or ocean thermal energy.

Not only this but, with current technological advancements, it is not easy to extract the maximum amount of energy contained in these sources. Even if it was possible, the costs would be so high that they cannot be afforded at every place. It is also clear that while these resources have great potential to meet global energy needs, there is still a long way to go to capture full advantage of these resources (Ellabban et al. 2014). An energy resource is required, which is much less damaging to the environment and can meet the high energy requirements simultaneously. Natural gas extracted from shale nowadays is a much sought-after resource that has a possibility of meeting such needs.

Natural gas, when compared to other fuels, is much more eco-friendly. Getting such a fuel extracted from a new unconventional source can help in meeting the high energy demands all over the world. Initially, the production of natural gas from these lesser-known reservoirs was not considered profitable due to the low permeability issues. However, the technological advancements that have taken place in the past few decades have led to an increased reliability on taking production from these unconventional resources (Sunjay and Kumar 2014). Thus, shale gas can be seen as a new unconventional source of energy (Kok and Merey 2014; Shar et al. 2017). This paper discusses shale gas power as a primary source of energy by extending the shale gas production process, the challenges it faces in its production, and its environmental impacts. This paper also discusses the number of gas occurrences spread in different parts of the world and the numerous factors that can influence production performance from a financial perspective.

Shale gas production process

Over the past few decades, gas production from unconventional shale gas deposits has become very common, as a result, the demand to understand the petrophysical properties of these rocks is growing. But characterizing these reservoirs is extremely difficult because of its uncertain reservoir properties which have a significant effect on the production of shale gas making the process of hydraulic fracturing which is the primary process for the production of gas from shale reservoirs even more complicated (Speight 2013).

So, the evaluation of the shale reservoir is done by taking geology and geochemistry together into consideration to achieve extremely low shale matrix permeability (Guo et al. 2017). In general, the extraction of shale gas depends on the amount of gas in place which is affected by the following four key parameters:

-

Thermal maturity, expressed as reflection of vitrinite

-

Total organic carbon content (TOC)

-

The thickness of a reservoir

-

Fractional adsorbed gas

The degree of natural fracture growth or low matrix permeability of the shale reservoir also serves as a crucial factor impacting the production of shale gas. The production of shale gas is carried out by four basic processes:

-

Pad preparation

-

Drilling

-

Well cementation

-

Hydraulic fracturing and well completion (Chang et al. 2014) (Fig. 1).

Shale gas production process module (Chang et al. 2014)

Pad preparation

The process of pad preparation consists of site cleansing and construction of various site features shown in Fig. 2. In this process, the well site is prepared from the layout; the technical specifications and productivity of the equipment are also estimated in this process (Chang et al. 2014). The pad is generally rectangular covering nearly 4-5acres of land over which the drilling activities are conducted. The site is paved, surfaced, and leveled to position drilling rigs and rig trucks. Various activities, such as the drilling and the completion of the well, are carried out with the rig installed (Speight 2013). In shale gas production, it is becoming a common practice to use a single drill pad which is developed over a large area of the subsurface which can be used to drill multiple wells. Decreased infrastructure cost and land use with increased operational efficiency are observed by pad preparation. In this way, it also does not have any adverse effect on the environment (Ogoke et al. 2014).

Module for pad preparation (Chang et al. 2014)

Well drilling

Shale gas extraction is generally carried out by horizontal drilling which is a relatively recent innovation. And, oil-based mud (OBM) is typically used as the drilling fluid. The drilling process is carried out from surface to the shoe, i.e., total depth (TD). Water-based mud (WBM) is not used as it causes various problems like tight spots, packoffs, and stuck pipe while drilling through the curved and lateral sections. Due to this, the amount of time spent on drilling process increases as compared to that of oil-based muds (OBM) (Guo et al. 2012). A larger area of reservoir rock is encountered while horizontal drilling when compared to vertical drilling and a larger area of contact results in higher recovery factors and increased production rate. In this way, horizontal drilling plays a vital role in the development of shale gas reservoirs (Speight 2013) (Fig. 3).

Module for well drilling (Chang et al. 2014)

Well cementation

This procedure involves well casing, followed by cement slurry placement. Three kinds of casings are commonly used.

-

Surface casing

-

Intermediate casing

-

Production casing

Based upon the depth of operation, different classes of cement can be used. For example, for the formation of cement slurry, for from 1830 to3050 m depth, class ‘D’ cement is generally used. The water to cement ratio is decided by considering the reservoir properties into account (Chang et al. 2014) (Fig. 4).

Module for well cementation (Chang et al. 2014)

Hydraulic fracturing and well completion

Hydraulic fracturing has enabled a number of oil and gas producers in the world to gain access to areas that would not otherwise exist.The hydraulic fracturing process, also commonly called fracking, is used to release the natural gas from the low-permeable shale rock formations (Carter et al. 2013). In this procedure, the formation of shale rock is broken using a pressurized fluid often known as fracturing fluid. The fracking liquid primarily consists of water, sand, and thickening agents. The sand particles keep the fracture open hence allowing the gas to propagate continuously (Osborn et al. 2011). The method involves the injection of fracking fluid into the well at high pressure to create gaps in the rock layers from which natural gas can pass freely. After the hydraulic fracturing is completed, and all the natural gas from the shale rock deposits is extracted, the well-completion process is completed, and the well is abandoned (Rahm 2011) (Fig. 5).

Hydraulic fracturing and well-completion module (Chang et al. 2014)

Problems faced during fracturing of gas bearing formations

With the production of shale gas using the methods mentioned above, challenges are also involved in these methods. The risk analysis of these methods is essential because these risks can cause big issues. Some of the challenges faced by these methods are mentioned below:

Groundwater contamination

The fracking operations use different fracking fluids which may cause the contamination of the underground aquifers if the well is not constructed correctly. The fracking process creates fractures which can propagate vertically through the shale formations, which might lead to leakage of shale gas or the fracking fluid to the shallow aquifer. The leakage of methane at the well site may also take place due to the poor well design or construction. Groundwater may be contaminated due to the poor well integrity, which may lead to leakage and spills of fracking chemicals and contaminants in groundwater. Aquifers in shale deposits in Northeast Pennsylvania and Upstate New York were determined to be polluted with methane from studies of Osborn et al. (2011). 19.2–64 mg L−1 of concentration of methane was found in the drinking water wells which were present nearby the gas-producing wells. There are two ways for shallow groundwater contamination (a) over ground accidental spills (b) well integrity failure and upward fluid migration (Jabbari et al. 2017). Such channels are more likely to contaminate groundwater than the direct injection of contaminants into the formations (Jackson et al. 2013; Jasechko and Perrone 2017).

Case study

Research done by Vengosh et al. (2013) on various shale wells shows that the extraction of natural gas from shale basins may have environmental consequences, in particular the contamination of shallow drinking water aquifers from groundwater. The experiment found that water wells located close (less than 1 km) shale gas drilling sites have a higher concentration of methane gas than wells located (more than 1 km) away from the drilling sites. Scientists debated the fact that methane found in these water wells could be from the basin and not from the drilling activities. But the isotope of methane found in these water wells was of thermogenic composition. Yet the well that was situated away from the drilling sites had a biogenic composition of methane isotopes that clearly showed that the higher levels of methane in water wells near the drilling sites were due to the pollution of the stray gas. It is widely believed that inadequate cement around casing causes leakage which contaminates the stray gas, leakage may also take place through annulus from the intermediate formation.

Also, the wastewater generated due to the production of natural gas has very high salinity, toxic elements, and radioactive materials, and even after disposing of this water through brine treatment facilities, highly saline plume forms which still consists of radioactive materials. So, the management and disposal of wastewater associated with natural gas production are becoming a big problem. With the rise in the use of hydraulic fracturing techniques for the production of natural gas, the amount and types of wastewater are also expected to increase.

Water sourcing and disposal

Porosity and depth of shale are the factors which control the amount of water required for extraction of shale gas. Places, where there is a shortage of freshwater the extraction of freshwater, may cause an even bigger issue. From different studies, it has been found that an average of 20 million liters of water with additional 2,00,000 L of different fracking fluids is pushed under pressure at each well. A large volume of some solid particles such as sand which is acting as proppants is also pushed with the fluids to keep the fractures open (Howarth and Ingraffea 2011). Disposal of the used water is also an issue because mainly 80% of water flows back to the surface. If the used water is in small amounts, it can be sent to the water treatment plants to purify the water and use it again. Still, a large amount of water is generally reused without purifying or disposing of the water. Another issue of water management is that the water that returns from the downhole may also contain naturally occurring radioactive materials (NORM) in small quantities. Practical procedures for water management should be taken with the help of governmental water authorities (Geological Society of London 2012).

Case study

Warner et al. (2013) conducted a study to analyze the impact of wastewater that is released from the brine treatment facilities into the stream. The disposal of this wastewater which is formed during the production of natural gas from shale reservoir is becoming a significant problem as it consists of high salinity, toxic and radioactive elements. Some of the disposal options for these waters are, injection in a disposal well or spreading on the roads for dust suppression and de-icing. But such disposal methods entail environmental risks. They are therefore not permitted to be applied in some areas that lack adequate geology or if the laws of the government do not require the water to be sprayed on the roads. This water is made up of drilling fluids, flow-back fluids, and water produced. It is collectively referred to as wastewater.

Due to the poor quality of water flow and water generated, the options for disposal and management of such wastewater are constrained. The water's salinity ranges from 5000 to > 200,000 mg/L. Its high salinity is due to the presence of chlorides and bromides of metals like barium and strontium. It also consists of isotopes of radium which are also known as naturally occurring radioactive materials (NORM). Their radioactivity varies from 185 to 592 Bq/L. Generally, these wastewaters are treated in brine treatment facilities and are discharged into the surface water. But the disposal of these wastewater through treatment facilities still causes an increase in the chloride concentration at the downstream surface water. Even after the water is treated from the brine treatment facilities, it is still highly saline and, hence increases the salinity of our downstream surface water.

Induced seismicity

Human activities such as mining, deep quarrying, and geothermal energy production mainly cause a release of energy stored inside the earth's crust; this process of release of energy is called induced seismicity. Due to this, there have been earthquakes in the past. The mechanical strength of the rock determines the maximum frequency of that seismic event. Drilling through near faults should be avoided to minimize the risk of this seismic activity. Active management should be in place, and micro-seismicity readings must be monitored before, during, and after every process (Geological Society of London 2012). The 'Denver Earthquakes' caused in the 1960s were because of the military fluid being disposed of in the Rocky Mountain Arsenal, Colorado at a depth of 3671 m (Davies et al. 2013). Another example of this problem was mentioned by (Frohlich et al. 2011), which said that the Dallas–Fort Worth (DFW) region experienced many earthquakes of magnitude between 2.2 and 3.3. It was found from the seismograms that the epicenter was nearby to a closed well which was drilled up to a depth of 4.2 km to dispose of the hydraulic fracturing fluid which was associated with natural gas production (Geological Society of London 2012).

Case study

Rutqvist et al. (2013) conducted various studies for understanding the seismic events the hydraulic fracturing during the production of natural gas from shale reservoirs. The data showed that the seismicity caused by injection could always move upwards by around 1000 feet due to the activation of pre-existing faults caused by the poroelastic effect of the rock matrix and the diffusion of fluid. Das and Zoback (2011) indicated the presence of injection-induced shear reactivation along minor faults within the shale reservoirs. Yet because they are of minimal size, it is highly likely that pre-existing fractures and minor faults in the shale reservoir are due to increased productivity. These frequent micro-seismic events are of such a low magnitude that humans cannot detect them. Structural geology, stress factors, rock mass properties (e.g., soft and ductile v/s hard and brittle or fractured), and injection operating procedures can contribute to significant seismic events. Thus, it can be inferred that a fault can effectively control the growth of the fracture and can thus channel the energy into the fault network, causing fractures along the fault. And that might cause an earthquake. The resulting earthquake may go up to 5 km from the injection well and to a depth of 6 km.

Indian reserves

India has a shortage of natural gas. In India, the demand for natural gas is very high, but we do not have a high amount of production and functional techniques to increase production. India is not able to match the required natural gas with produced natural gas. So the gap between supply and demand is approximately 40% (Bhushan 2016). India imports most of the natural gas from Qatar and LNG from Russia at a high cost. To provide an economical supply of natural gas, India is working out on the plan to bring out natural gas from Turkmenistan by pipeline (Bhushan 2016). The energy demand in India is increasing continuously, and energy production is mainly dependent on natural gases. But we cannot rely only on conventional sources, so we have to move toward some unconventional source to reduce the import of natural gases (Brennan and Pastorelli 2013). All countries are focusing on the exploration and production of shale gas to meet energy demand in the future. Shale gas is a distributed resource, but it is challenging to find out reserves and resources. In the case of conventional resources, estimation is easy, but shale gas reserves estimation is difficult because, to estimate the exact amount, well has to be a drill. India has been active in the discovery of natural gas deposits. India can get shale gas reserves from the Gujarat, Jharkhand, West Bengal, Andhra Pradesh, Tamil Nadu, Rajasthan, and other areas. India has 26 sedimentary basins, from which 6 basins have prospects of shale gas (Petroleum & Natural Gas Regulatory Board 2013). There has been limited exploration in India, and according to EIA, we have the majority of shale gas opportunities in Cambay, Krishna-Godavari, Cauvery, and Damodar Valley. Karthikeyan et al. (2018). EIA reports that there is a total of 584 TCF of risked shale gas in India and 96 TCF of technically recoverable shale gas. EIA estimated that in 2011, 4 out of 6 basins have 1170 TCF risked shale gas and 63 TCF of recoverable shale gas is present in India (Petroleum & Natural Gas Regulatory Board 2013). 20 TCF of extractable shale gas could be found in Gujarat's Cambay Basin with a prospective area of 1940 square miles. Whereas in Eastern India, the Krishna-Godavari basin might have 27–30 TCF of extractable shale gas with a prospective area of 4350 square miles. Also, the process of finding shale gas reserves in 11 additional basins was initiated (Karthikeyan et al. 2018).

Comparison of Indian reserves with the US

The US is the largest producer of shale gas in the world. The US has a total of 750.38 TCF, risked technically recoverable shale gas from which 472.05 TCF is recoverable in the northeast. The Gulf Coast has 99.99 TCF of recoverable shale gas, the southwest has 75.52 TCF of recoverable shale gas, and the rocky mountain range has 43.03 TCF of recoverable shale gas (EIA 2011). India has 0.128% of shale gas recoverable compared to the US. In terms of production, India has 0% as compared to the US because in India production of shale gas has not started because first of all India does not have proven recoverable shale gas these data were estimates of EIA/ARI and USGS. India is facing problems in hydraulic fracking, resource evaluation, resource management, specialized technical interventions, environmental system, open land availability, water availability, seismic as well as promoting shale gas regime, following the current oil and gas exploration strategy (Bhushan 2016) (Fig. 6).

Shale gas reserves in the USA (Parraguez Kobek et al. 2015)

EIA/ARI and USGS estimated that India has technically recoverable shale gas, but no commercial exploitation of shale gas reserves has been taken place till yet. India has not able to exploit shale gas from recoverable resources because of some government, technical, economic, and environmental problems. Shale gas exploration starts with a wide range of problems, including fracking technology, drilling costs, land availability, water availability, more people, and the danger of seismic activity (Jain et al. 2016).

Recoverable shale gas reserves around the world

Shale gas is an unconventional resource. It is also called as tight gas because we get it from tight formations. Tight formations have always existed in the world. From the last half, a century shale rock formation has been avoided by the engineers. The tight formation has low permeability. So, production from the tight formation is hard, and then, we have to work on less margin due to high production cost and less production as compared to the conventional source. Initially, when tight gas was found investment in that tight gas production was excellent. Then, it decreased with time due to less profit. But still, geological exploration of recoverable shale gas has been taking place in the world, and also in some countries, production has been taking place (Reynolds and Umekwe 2019).

There are varying estimates of shale gas reserves in the world, and exploration of shale gas has taken place at limited locations. According to EIA estimates the world's unconventional gas amount is approximately equal to the remaining conventional gas amount. EIA/ARI analyzed 26 regions, including 41 individual countries, and estimated 35,782 TCF of overall risky shale gas on site and 7795 TCF of theoretically recoverable shale gas on site (Bhushan 2016; Iea 2012).

Many factors are taken into consideration for the estimation of technically recoverable resource, such as gas in place (GIP), recovery factor that deals with various aspects of shale geology and some more. The recovery factor also takes the mineralogy of the shale into consideration to know if the given shale is favorable for the process of hydraulic fracturing or not. Surroundings such as micro-scale natural fractures, lack of deep cutting faults, stress status for shale formations, relative volumes of free and adsorbed gas concentrations, and reservoir pressure may also affect the recovery factor of the shale gas reservoir.

Shale gas reservoirs with a very high geological complexity and a very high volume of clay are removed from shale gas resources evaluation and classified as non-perspective. The regional-scale assessments which are given the category of non-perspective can be identified and can be added to the resource assessment by small-scale resource assessment (EIA 2011).

Above Fig. 7 does not include the changes in shale gas reserves of Venezuela because of the limitation of graph range. Venezuela has 1418% increase in its TRR as described in Table 1.

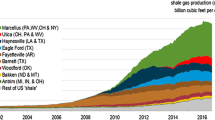

The US is the highest producer of shale gas in the world. It has a high amount of recoverable proved shale gas. In 2015, it produced 13 TCF of tight gas and now wants to be the exporter from an importer in upcoming years by using this unconventional resource. In the US shale gas is full production in reserves across the country Pennsylvania, Louisiana, and Texas and also started production from the newly discovered reserves across the country Marcellus, Eagle Ford, and Utica (Fig. 8).

World map showcasing technically recoverable shale gas of different countries according to the data provided by (Statistics 2013)

The US imports its natural gas from Canada. Canada has a high amount of conventional gas resources, so Canada has not more interest in investing in shale gas production. As US production rises, Canada will need to establish other markets for its excess supply of natural gas, but Canada still has far less shale gas output. Argentina is showing more room for the development of shale gas because Argentina wants to decrease the number of natural gas imports, which is advantageous to the country's economy. Preliminary research in South America indicates that vast reserves of shale gas lie below many countries, including Argentina, Brazil, Colombia, and others. This research found that shale gas reserves in Brazil are the second largest after the US. Argentina has the production of shale gas from the Neuquén Basin. In Western European countries UK, Netherland, Germany, France, Scandinavia, and Norway, exploring shale gas is occurring, but shale gas production is still doubtful. Poland has a high potential to produce shale gas in Western Europe, while Turkey and Ukraine have some potential for shale gas production. But Russia does not have any interest in shale gas development because it has significant conventional sources for natural gas. Australia has a very high amount of conventional gas resources. Australia's shale gas reserves are typically located in remote areas, and extraction is difficult both economically and politically, which is why Australia currently has no commercial shale gas extraction.China has found some reserves of shale gas and started to produce shale gas and is estimated to have around 1275 TCF of recoverable shale gas.China's shale gas reserves are geographically different than US (International 2012).

Shale gas producer countries around the world have an advantage in other countries because by shale gas production these countries can fulfill their energy demands and also probably these countries can be exporters of natural gas in the future.

Factors affecting economics of shale gas exploitation

The discovery in many countries of shale gas reserves has shown considerable independence both in terms of energy and energy resources.The shale gas revolution in the USA has contributed significantly to the reduction in imports of natural gas, and this is one of the key reasons for such tremendous progress in the energy sector in the US. (Statistics 2013). In the past few years, it has been quite challenging to assess the cost implications and the impacts of shale gas exploitation on the environment and economy. As discussed in the previous sections, it is clear that the exploitation of shale gas can have several impacts on the environment as well as on the economy, it is difficult to substantiate the potential costs and benefits accompanying shale gas exploitation (Sovacool 2014). A cost–benefit analysis of shale gas production is essential as it takes into account many variables, including social, environmental, and cultural. Hence, it is crucial in terms of financial aspects and also brings out the positive and negative effects of shale gas exploitation (Grecu et al. 2018).

Technology is one of the essential factors in the exploitation of shale gas. Technology not only affects the costs of exploitation but also as a massive impact on gas production, which again has implications on the net profit in the production of shale gas. Using better and technically advanced equipment costs high but can help increase gas production. Whereas using the older generation of paraphernalia, the equipment may cost less but can also affect gas production negatively (Yunna et al. 2015). Another critical factor affecting the economies of shale gas production is volatility in the international market for natural gas prices. It is highly recommended that the costs of producing the shale should be estimated and planned, keeping in mind the high uncertainties in the prices of shale gas overseas. The extraction and development of shale gas are only possible when the market prices can counterbalance the production expenses which is not an easy task since the forecasts must be exact and reliable (Ahmed and Rezaei-Gomari 2019).

The investments in shale gas can also be affected by the occurrence of supercycles. A supercycle can be defined as an increase in the prices for an extended time (or decades). It is affected by the geopolitical insecurities prevailing in that particular region. As the administration introduces new policies, this can lead to political and economic turmoil. Therefore, widespread corruption, weak institutional and government support, political intervention, and lack of accountability can have a significant effect on shale gas projects investments.

Moreover, environmental regulations involving hydraulic fracturing can dampen the possibility for investments in the exploration of the shale gas reservoirs and the development of possible reserves (Vásquez Cordano and Zellou 2020). An important point to note about the exploitation of shale gas is that the economic viability of shale gas may not be the same as the US. Considering the case study of the UK, shale gas exploitation does not seem to be very profitable as the costs of extraction and production seem to be very high. The impact of shale gas in the domestic market too seems to be negligible for now (Cooper et al. 2018). Hence, shale gas can be considered as a future energy resource only when there lie suitable technology and equipment, satisfactory analysis of the national and international market prices, and proper implementation of policies by the administration. In addition to this, if a commercial shale gas deposit is found, a rigorous cost–benefit analysis is a must before continuing with the production phase.

Challenges and future scope

It is evident that in the coming future, shale gas has enormous potential of taking over many of the energy requirement of the world. Natural gas, if not the best fossil fuel, releases much less amount of greenhouse gases when compared to other energy sources. But there are still some environmental concerns that need to be considered upon in the coming years before totally relying upon shale gas as an unconventional fuel. These issues have not been discussed much, and a proper discussion and justification are needed. The fracturing of the reservoir is said to induce seismicity and contamination of the aquifers discussed earlier in this paper. The requirement of large amounts of freshwater for fracking creates a problem as it can affect the local water system (Wang et al. 2014).

Moreover, many of the shale gas reservoirs are located in remote and arid locations which can again produce a problem of availability of large amounts of water. A large number of chemicals and additives are added to the fracking fluid to create fractures in the shale rock and produce gas from the reservoir. Several new additives need to be studied to enhance the property of the fracking fluid. These new additives should be cheaper, environment friendly, and should be able to enhance gas production. Alternative fracking fluids which can replace water and serve these purposes need to be studied, and more number of experiments need to be carried out (Li et al. 2018, 2019; Lv et al. 2017; Zhao et al. 2015). The water that has been used already in fracking fluid gets contaminated, and thoughtless disposal of this water can pose much threat to the marine ecosystem. Hence, the purification and sustainable reuse of such wastewater need to be studied in the future studies (Cheng et al. 2016; Tang et al. 2020, 2017).

Conclusion

From the above discussion, it is clear that the hunt for shale gas is not just the hunt for energy but a new and better energy resource which can transform the future energy requirements of the world. There is a long way to go for the world to depend upon renewable energy resources entirely. Hence, shale gas can be the "transition fuel" which can help in shifting from non-renewable resources to renewable sources of energy and has much fewer carbon emissions than any other fossil fuel. Since India has a very high energy demand, it has started an exploration of shale gas. Still, the production is very less as compared to other shale gas-producing countries. The technically recoverable shale gas content is high in countries like China and Argentina. However, there are various other countries which have a low content of shale gas. These data keep on changing with the discovery of new reserves. The production of shale gas is a very complicated process that has been made possible by hydraulic fracturing.

Nevertheless, the production is costly as compared to conventional gas. But this process cannot be carried out everywhere as it has various effects on the environment like groundwater contamination, water sourcing and disposal, and induced seismicity. These issues have been present in the process of production of shale gas since the beginning. However, in case of induced seismicity, the magnitude is such ow that they do not seem to pose any threat to the surrounding areas. With the use of proper precautions, problems like these can be avoided, and production can be carried out efficiently making very less impact on the environment. The economic aspects of exploitation of shale gas involve several factors which include technology, geopolitical situations prevailing in that region, environmental impacts of the production mechanism used, etc. Conducting a detailed cost–benefit analysis is a crucial step toward projecting the scope of shale gas reserves in that region. There are several aspects which require attention to substantiate the viability of shale gas as an energy resource. They have not been addressed or have been partially addressed so far. Problems related to contamination of aquifers, use of different types of fracking fluid, disposal of wastewater need to be reflected. The danger of induced seismicity has been in debate for long, which needs to be studied in depth to materialize safety and environmental concerns related to shale gas production.

Availability of data and materials

All relevant data and material are presented in the main paper.

References

Ahmed M, Rezaei-Gomari S (2019) Economic feasibility analysis of shale gas extraction from UK’s carboniferous bowland-hodder shale unit. Resources 8(1):5

Bhushan C (2016) To frac or not to frac shale gas in India—prospects and risks. Heinrich Böll Foundation

Brennan E, Pastorelli S (2013) India’s shale gas boom: dream or reality? The Diplomat. https://thediplomat.com/2013/06/indias-shale-gas-boom-dream-or-reality/

Carter KE, Hakala JA, Hammack RW (2013) Hydraulic fracturing and organic compounds—uses, disposal and challenges. In: SPE Eastern Regional Meeting, Rahm 2011, pp 287–297. https://doi.org/10.2118/165692-ms

Chang Y, Huang R, Ries RJ, Masanet E (2014) Shale-to-well energy use and air pollutant emissions of shale gas production in China. Appl Energy 125:147–157. https://doi.org/10.1016/j.apenergy.2014.03.039

Cheng X, Liang H, Ding A, Qu F, Shao S, Liu B, Wang H, Wu D, Li G (2016) Effects of pre-ozonation on the ultrafiltration of different natural organic matter (NOM) fractions: membrane fouling mitigation, prediction and mechanism. J Membr Sci 505:15–25. https://doi.org/10.1016/j.memsci.2016.01.022

Cooper J, Stamford L, Azapagic A (2018) Economic viability of UK shale gas and potential impacts on the energy market up to 2030. Appl Energy 215(December 2017):577–590. https://doi.org/10.1016/j.apenergy.2018.02.051

Das I, Zoback M (2011) Long-period, long-duration seismic events during hydraulic fracture stimulation of a shale gas reservoir. Lead Edge. https://doi.org/10.1190/1.3609093

Davies R, Foulger G, Bindley A, Styles P (2013) Induced seismicity and hydraulic fracturing for the recovery of hydrocarbons. Mar Pet Geol 45:171–185. https://doi.org/10.1016/j.marpetgeo.2013.03.016

EIA U (2011) World shale gas resources: an initial assessment of 14 regions outside the United States. U.S. Energy Information Administration, April, 365. http://cdm16064.contentdm.oclc.org/cdm/ref/collection/p266901coll4/id/3447

Ellabban O, Abu-Rub H, Blaabjerg F (2014) Renewable energy resources: current status, future prospects and their enabling technology. Renew Sustain Energy Rev 39:748–764. https://doi.org/10.1016/j.rser.2014.07.113

Frohlich C, Hayward C, Stump B, Potter E (2011) The Dallas-Fort Worth earthquake sequence: October 2008 through May 2009. Bull Seismol Soc Am 101(1):327–340. https://doi.org/10.1785/0120100131

Geological Society of London (2012) Shale gas: challenges and opportunities. June, 4

Grecu E, Aceleanu MI, Albulescu CT (2018) The economic, social and environmental impact of shale gas exploitation in Romania: a cost-benefit analysis. Renew Sustain Energy Rev 93(2):691–700. https://doi.org/10.1016/j.rser.2018.05.026

Guo, Q., Ji, L., Rajabov, V., Friedheim, J., Portella, C., & Wu, R. (2012). Shale gas drilling experience and lessons learned from Eagle Ford. In: Society of Petroleum Engineers - SPE Americas Unconventional Resources Conference 2012, 381–388. https://doi.org/10.2118/155542-ms

Guo X, Hu D, Li Y, Wei Z, Wei X, Liu Z (2017) Geological factors controlling shale gas enrichment and high production in Fuling shale gas field. Pet Explor Dev 44(4):513–523. https://doi.org/10.1016/S1876-3804(17)30060-5

Howarth RW, Ingraffea A (2011) Natural gas: should fracking stop? Nature 477(7364):271–273. https://doi.org/10.1038/477271a

Iea (2012) Golden rules for a golden age of gas. World Energy Outlook Special Report, 155

International K (2012) Shale gas—a global perspective. https://home.kpmg/ru/en/home/insights/2012/01/shale-gas-a-global-perspective.html

Jabbari N, Aminzadeh F, de Barros FPJ (2017) Hydraulic fracturing and the environment: risk assessment for groundwater contamination from well casing failure. Stoch Environ Res Risk Assess 31(6):1527–1542. https://doi.org/10.1007/s00477-016-1280-0

Jackson RE, Gorody AW, Mayer B, Roy JW, Ryan MC, Van Stempvoort DR (2013) Groundwater protection and unconventional gas extraction: the critical need for field-based hydrogeological research. Groundwater. https://doi.org/10.1111/gwat.12074

Jain AK, Aayog NITI, Ram R (2016) Shale gas in India: challenges and prospects

Jasechko S, Perrone D (2017) Hydraulic fracturing near domestic groundwater wells. Proc Natl Acad Sci USA 114(50):13138–13143. https://doi.org/10.1073/pnas.1701682114

Karthikeyan S, Vijay Prabhu M, Kumar A, Kumar S, Kumar K (2018) Shale Oil & Gas as an Alternative Source of Energy Management Strategy in Modern Industrial Development. Mod Approach Oceanogr Petrochem Sci 1(4):58–64. https://doi.org/10.32474/maops.2018.01.000118

Kok MV, Merey S (2014) Shale gas: current perspectives and future prospects in Turkey and the world. Energy Sources A Recov Util Environ Eff 36(22):2492–2501. https://doi.org/10.1080/15567036.2014.943854

Li B, Zheng C, Xu J, Lv Q, Shi D, Li Z (2018) Experimental study on dynamic filtration behavior of liquid CO2 in tight sandstone. Fuel 226(March):10–17. https://doi.org/10.1016/j.fuel.2018.03.163

Li Q, Wang Y, Wang F, Wu J, Usman Tahir M, Li Q, Yuan L, Liu Z (2019) Effect of thickener and reservoir parameters on the filtration property of CO2 fracturing fluid. Energy Sources A Recov Util Environ Eff 42(14):1705–1715. https://doi.org/10.1080/15567036.2019.1604880

Lv Q, Li Z, Li B, Zhang C, Shi D, Zheng C, Zhou T (2017) Experimental study on the dynamic filtration control performance of N2/liquid CO2 foam in porous media. Fuel 202:435–445. https://doi.org/10.1016/j.fuel.2017.04.034

Ogoke VC, Schauerte LJ, Bouchard G, Inglehart SC (2014) Simultaneous operations in multi-weil pad: a cost effective way of drilling multi wells pad and deliver 8 Fracs a day. Proc SPE Annu Techn Conf Exhib 3(2001):2234–2244

Osborn SG, Vengosh A, Warner NR, Jackson RB (2011) Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing. Proc Natl Acad Sci USA 108(20):8172–8176. https://doi.org/10.1073/pnas.1100682108

Parraguez Kobek ML, Ugarte A, Campero Aguilar G (2015) Shale Gas in the United States: transforming energy security in the twenty-first century. Norteamérica 10(1):7–38. https://doi.org/10.20999/nam.2015.a001

Petroleum & Natural Gas Regulatory Board (2013) Vision 2030. Natural gas infrastructure in India report by Industry Group For Petroleum & Natural Gas Regulatory Board. 1–99

Pradhan S, Prakash O (2000) Shale gas play: possibility and challenges in India as an unconventional energy resource. September 2016, 4

Rahm D (2011) Regulating hydraulic fracturing in shale gas plays: the case of Texas. Energy Policy 39(5):2974–2981. https://doi.org/10.1016/j.enpol.2011.03.009

Reynolds DB, Umekwe MP (2019) Shale-oil development prospects: the role of shale-gas in developing shale-oil. Energies. https://doi.org/10.3390/en12173331

Rutqvist J, Rinaldi AP, Cappa F, Moridis GJ (2013) Modeling of fault reactivation and induced seismicity during hydraulic fracturing of shale-gas reservoirs. J Pet Sci Eng 107:31–44. https://doi.org/10.1016/j.petrol.2013.04.023

Shar AM, Mahesar AA, Memon KR (2017) Could shale gas meet energy deficit : its current status and future prospects. J Pet Explor Prod Technol. https://doi.org/10.1007/s13202-017-0399-y

Sovacool BK (2014) Cornucopia or curse? Reviewing the costs and benefits of shale gas hydraulic fracturing (fracking). Renew Sustain Energy Rev 37:249–264. https://doi.org/10.1016/j.rser.2014.04.068

Speight J (2013) Shale gas production processes. Gulf Professional Publishing, Houston. https://doi.org/10.1016/B978-0-12-404571-2.00001-7

Statistics I (2013) Technically recoverable shale oil and shale gas resources: an assessment of 137 shale formations in 41 countries outside the United States. 2013 (June 13, 2013-Corrected Executive Summary, Table 5))

Sunjay S, Kumar S (2014) Shale gas: an unconventional gas reservoir. In: Offshore Mediterranean Conference and Exhibition, December. https://doi.org/https://doi.org/10.13140/RG.2.1.1975.2805

Tang P, Liu B, Zhang Y, Chang H, Zhou P, Feng M, Sharma VK (2020) Sustainable reuse of shale gas wastewater by pre-ozonation with ultrafiltration-reverse osmosis. Chem Eng J 392(October):123743. https://doi.org/10.1016/j.cej.2019.123743

Tang S, Zhang Z, Zhang X (2017) New insight into the effect of mixed liquor properties changed by pre-ozonation on ceramic UF membrane fouling in wastewater treatment. Chem Eng J 314:670–680. https://doi.org/10.1016/j.cej.2016.12.032

Vásquez Cordano AL, Zellou AM (2020) Super cycles in natural gas prices and their impact on Latin American energy and environmental policies. Resour Policy. https://doi.org/10.1016/j.resourpol.2019.101513

Vengosh A, Warner N, Jackson R, Darrah T (2013) The effects of shale gas exploration and hydraulic fracturing on the quality of water resources in the United States. Procedia Earth Planet Sci 7:863–866. https://doi.org/10.1016/j.proeps.2013.03.213

Wang Q, Chen X, Jha AN, Rogers H (2014) Natural gas from shale formation—the evolution, evidences and challenges of shale gas revolution in United States. Renew Sustain Energy Rev 30:1–28. https://doi.org/10.1016/j.rser.2013.08.065

Warner NR, Christie CA, Jackson RB, Vengosh A (2013) Impacts of shale gas wastewater disposal on water quality in Western Pennsylvania. Environ Sci Technol 47(20):11849–11857. https://doi.org/10.1021/es402165b

Wolfram C, Shelef O, Gertler P (2012) How will energy demand develop in the developing world? J Econ Perspect 26(1):119–138. https://doi.org/10.1257/jep.26.1.119

Yunna W, Kaifeng C, Yisheng Y, Tiantian F (2015) A system dynamics analysis of technology, cost and policy that affect the market competition of shale gas in China. Renew Sustain Energy Rev 45:235–243. https://doi.org/10.1016/j.rser.2015.01.060

Zhao F, Hao H, Hou J, Hou L, Song Z (2015) CO2 mobility control and sweep efficiency improvement using starch gel or ethylenediamine in ultra-low permeability oil layers with different types of heterogeneity. J Pet Sci Eng 133:52–65. https://doi.org/10.1016/j.petrol.2015.05.014

Acknowledgements

The authors are grateful to School of Petroleum Technology and Department of Chemical Engineering, School of Technology Pandit Deendayal Energy University for the permission to publish this research.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All the authors make substantial contribution in this manuscript. JB, HKV DK, DM, and MS participated in drafting the manuscript. JB, HKV DK, and DM wrote the main manuscript, all the authors discussed the results and implication on the manuscript at all stages.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bellani, J., Verma, H.K., Khatri, D. et al. Shale gas: a step toward sustainable energy future. J Petrol Explor Prod Technol 11, 2127–2141 (2021). https://doi.org/10.1007/s13202-021-01157-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01157-7