Abstract

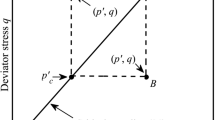

The stress–dilatancy relation is of critical importance for constitutive modelling of geomaterial. A novel fractional-order stress–dilatancy equation had been developed for granular soil, where a nonlinear stress–dilatancy response was always predicted. However, it was experimentally observed that after a certain extent of shearing, an almost linear response between the stress ratio and the dilatancy ratio, rather than the nonlinear response, usually existed. To capture such stress–dilatancy behaviour, a new fractional stress–dilatancy model is developed in this study, where an apparent linear response of the stress–dilatancy behaviour of soil after sufficient shearing is obtained via analytical solution. As the fractional order varies, the derived stress–dilatancy curve and the associated phase transformation state stress ratio keep changing. But, unlike existing researches, no other specific parameters, except the parameter related to fractional order, concerning such shift are required. Then, the developed stress–dilatancy model is applied to constitutive modelling of granular soil and soil–structure interface, for further validation. A series of test results of different granular soils and soil–structure interfaces under different loading conditions are simulated and compared, where a good model performance is observed.

Similar content being viewed by others

References

Been K, Jefferies MG (1985) A state parameter for sands. Géotechnique 35(2):99–112. https://doi.org/10.1016/0148-9062(85)90263-3

Dafalias YF, Manzari MT (2004) Simple plasticity sand model accounting for fabric change effects. J Eng Mech 130(6):622–634. https://doi.org/10.1061/(ASCE)0733-9399(2004)130:6(622)

Dafalias YF, Taiebat M (2016) SANISAND-Z: zero elastic range sand plasticity model. Géotechnique 66(12):999–1013. https://doi.org/10.1680/jgeot.15.P.271

Gao Y, He J, Tang X, Chu J (2019) Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil. Soils Found 59(5):1631–1637. https://doi.org/10.1016/j.sandf.2019.03.014

Hardin BO, Richart JFE (1963) Elastic wave velocities in granular soils. J Soil Mech Found Div ASCE 89(1):33–66

He J, Gao Y, Gu Z, Chu J, Wang L (2020) Characterization of crude bacterial urease for CaCO3 precipitation and cementation of silty sand. J Mater Civil Eng 32(5):04020071. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003100

Hu L, Pu J (2004) Testing and modeling of soil-structure interface. J Geotech Geoenviron Eng 130(8):851–860. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:8(851)

Jefferies M, Been K (2015) Soil liquefaction: a critical state approach. CRC Press, Boca Raton

Jin Y-F, Yin Z-Y (2020) Enhancement of backtracking search algorithm for identifying soil parameters. Int J Numer Anal Meth Geomech 44(9):1239–1261. https://doi.org/10.1002/nag.3059

Jin Y-F, Yin Z-Y, Shen S-L, Hicher P-Y (2016) Selection of sand models and identification of parameters using an enhanced genetic algorithm. Int J Numer Anal Meth Geomech 40(8):1219–1240. https://doi.org/10.1002/nag.2487

Jin Y-F, Yin Z-Y, Zhou W-H, Horpibulsuk S (2019) Identifying parameters of advanced soil models using an enhanced transitional Markov chain Monte Carlo method. Acta Geotech 14(6):1925–1947. https://doi.org/10.1007/s11440-019-00847-1

Kong X, Liu J, Zou D, Liu H (2016) Stress-dilatancy relationship of Zipingpu gravel under cyclic loading in triaxial stress states. Int J Geomech 16(4):04016001. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000584

Lashkari A (2012) A plasticity model for sand-structure interfaces. J Central South Uni 19(4):1098–1108. https://doi.org/10.1007/s11771-012-1115-1

Lashkari A (2017) A simple critical state interface model and its application in prediction of shaft resistance of non-displacement piles in sand. Comput Geotech 88:95–110. https://doi.org/10.1016/j.compgeo.2017.03.008

Lashkari A, Jamali V (2020) Global and local sand geosynthetic interface behaviour. Géotechnique. https://doi.org/10.1680/jgeot.19.P.109

Li X, Dafalias Y (2000) Dilatancy for cohesionless soils. Géotechnique 50(4): 449–460. doi:https://doi.org/10.1680/geot.2000.50.4.449

Liu J, Zou D, Kong X (2014) A three-dimensional state-dependent model of soil–structure interface for monotonic and cyclic loadings. Comput Geotech 61:166–177. https://doi.org/10.1016/j.compgeo.2014.05.012

Lu D, Liang J, Du X, Ma C, Gao Z (2019) Fractional elastoplastic constitutive model for soils based on a novel 3D fractional plastic flow rule. Comput Geotech 105:277–290. https://doi.org/10.1016/j.compgeo.2018.10.004

Mortara G, Mangiola A, Ghionna VN (2007) Cyclic shear stress degradation and post-cyclic behaviour from sand–steel interface direct shear tests. Can Geotech J 44(7):739–752. https://doi.org/10.1139/t07-019

Pain A, Nimbalkar S, Hussain M (2020) Applicability of bouc-wen model to capture asymmetric behavior of sand at high cyclic shear strain. Int J Geomech 20(6):06020009. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001671

Rui S, Wang L, Guo Z, Cheng X, Wu B (2020) Monotonic behavior of interface shear between carbonate sands and steel. Acta Geotech. https://doi.org/10.1007/s11440-020-00987-9

Rui S, Wang L, Guo Z, Zhou W, Li Y (2020) Cyclic behavior of interface shear between carbonate sand and steel. Acta Geotech. https://doi.org/10.1007/s11440-020-01002-x

Saberi M, Annan C-D, Konrad J-M, Lashkari A (2016) A critical state two-surface plasticity model for gravelly soil-structure interfaces under monotonic and cyclic loading. Comput Geotech 80:71–82. https://doi.org/10.1016/j.compgeo.2016.06.011

Saberi M, Annan C-D, Konrad J-M (2018) A unified constitutive model for simulating stress-path dependency of sandy and gravelly soil–structure interfaces. Int J Non-Linear Mech 102:1–13. https://doi.org/10.1016/j.ijnonlinmec.2018.03.001

Saberi M, Annan C-D, Konrad J-M (2020) Three-dimensional constitutive model for cyclic behavior of soil-structure interfaces. Soil Dyn Earthq Eng 134:106162. https://doi.org/10.1016/j.soildyn.2020.106162

Saberi M, Annan C-D, Konrad J-M (2020) A non-linear interface model for monotonic shear coupling in granular soil–structure interaction problems. Geotech Lett 10(2):1–10. https://doi.org/10.1680/jgele.19.00041

Schofield A, Wroth P (1968) Critical state soil mechanics. McGraw-Hill London, New York

Shi XS, Yin J, Zhao J (2019) Elastic visco-plastic model for binary sand-clay mixtures with applications to one-dimensional finite strain consolidation analysis. J Eng Mech 145(8):04019059. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001623

Stutz H, Mašín D (2017) Hypoplastic interface models for fine-grained soils. Int J Numer Anal Meth Geomech 41(2):284–303. https://doi.org/10.1002/nag.2561

Stutz HH, Wuttke F (2018) Hypoplastic modeling of soil-structure interfaces in offshore applications. J Zhejiang Uni SCi A 19(8):624–637. https://doi.org/10.1631/jzus.A1700469

Sumelka W, Nowak M (2016) Non-normality and induced plastic anisotropy under fractional plastic flow rule: a numerical study. Int J Numer Anal Meth Geomech 40(5):651–675. https://doi.org/10.1002/nag.2421

Sun Y, Nimbalkar S (2019) Stress-fractional soil model with reduced elastic region. Soils Found 59(6):2007–2023. https://doi.org/10.1016/j.sandf.2019.10.001

Sun Y, Gao Y, Shen Y (2019) Mathematical aspect of the state-dependent stress-dilatancy of granular soil under triaxial loading. Géotechnique 69(2):158–165. https://doi.org/10.1680/jgeot.17.t.029

Sun Y, Gao Y, Chen C (2019) Critical-state fractional model and its numerical scheme for isotropic granular soil considering state-dependence. Int J Geomech 13(9):04018202. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001353

Sun Y, Sumelka W, Gao Y (2020) Reformulated fractional plasticity for soil-structure interface. Mech Res Commun 108:103580. https://doi.org/10.1016/j.mechrescom.2020.103580

Sun Y, Wichtmann T, Sumelka W, Kan M (2020) Karlsruhe fine sand under monotonic and cyclic loads: modelling and validation. Soil Dyn Earthq Eng 133:106119. https://doi.org/10.1016/j.soildyn.2020.106119

Verdugo R, Ishihara K (1996) The steady state of sandy soils. Soils Found 36(2):81–91. https://doi.org/10.3208/sandf.36.2_81

Wan R, Guo P (1998) A simple constitutive model for granular soils: modified stress-dilatancy approach. Comput Geotech 22(2):109–133. https://doi.org/10.1016/S0266-352X(98)00004-4

Wang R, Dafalias YF, Fu P, Zhang J-M (2019) Fabric evolution and dilatancy within anisotropic critical state theory guided and validated by DEM. Int J Solids Struct. https://doi.org/10.1016/j.ijsolstr.2019.10.013

Wichtmann T, Triantafyllidis T (2016) An experimental database for the development, calibration and verification of constitutive models for sand with focus to cyclic loading: part I—tests with monotonic loading and stress cycles. Acta Geotech 11(4):739–761. https://doi.org/10.1007/s11440-015-0402-z

Xiao Y, Liu H, Chen Y, Jiang J, Zhang W (2014) Testing and modeling of the state-dependent behaviors of rockfill material. Comput Geotech 61:153–165. https://doi.org/10.1016/j.compgeo.2014.05.009

Yang J, Li X (2004) State-dependent strength of sands from the perspective of unified modeling. J Geotech Geoenviron Eng 130(2):186–198. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:2(186)

Yang J, Yin Z-Y, Laouafa F, Hicher P-Y (2019) Hydromechanical modeling of granular soils considering internal erosion. Can Geotech J. https://doi.org/10.1139/cgj-2018-0653

Yao Y, Hou W, Zhou AN (2009) UH model: three-dimensional unified hardening model for overconsolidated clays. Géotechnique 59(5):451–469. https://doi.org/10.1680/geot.2007.00029

Yin ZY, Li J, Jin YF, Liu FY (2019) Estimation of Robustness of Time Integration Algorithms for Elasto-Viscoplastic Modeling of Soils. Int J Geomech 19(2):04018197. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001351

Zhang G, Zhang J (2006) Monotonic and cyclic tests of interface between structure and gravelly soil. Soils Found 46(4):505–518. https://doi.org/10.3208/sandf.46.505

Zhang G, Zhang J (2008) Unified modeling of monotonic and cyclic behavior of interface between structure and gravelly soil. Soils Found 48(2):231–245. https://doi.org/10.3208/sandf.48.231

Zhang G, Zhang J-M (2009) Constitutive rules of cyclic behavior of interface between structure and gravelly soil. Mech Mater 41(1):48–59. https://doi.org/10.1016/j.mechmat.2008.08.003

Zhang G, Wang L, Zhang JM (2011) Dilatancy of the interface between a structure and gravelly soil. Géotechnique 61(1):75–84. https://doi.org/10.1680/geot.9.P.051

Zhang P, Yin Z-Y, Jin Y-F, Ye G-L (2020) An AI-based model for describing cyclic characteristics of granular materials. Int J Numer Anal Meth Geomech 44(9):1315–1335. https://doi.org/10.1002/nag.3063

Zhou Y (2016) Chapter preliminaries. In: Zhou Y (ed) Fractional evolution equations and inclusions. Academic Press, Cambridge, pp 1–39. https://doi.org/10.1016/B978-0-12-804277-9.50001-8

Acknowledgement

The first author would like to thank Prof. Wen Chen for the invaluable inspiration. The financial support from the National Natural Science Foundation of China (Grant No. 51890912) and the National Science Centre, Poland (Grant No. 2017/27/B/ST8/00351), is appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Constitutive modelling of granular soil

To demonstrate the performance of the developed stress–dilatancy equation, the elegant work by Dafalias and Manzari [2] is employed and modified here, by incorporating the fractional-order stress–dilatancy equation. Accordingly, the general constitutive relation for granular soils under triaxial loading can be provided as:

where the incremental strain vector \({\dot{\mathbf{\varepsilon }}} = \left[ {\dot{\varepsilon }_{v} ,\dot{\varepsilon }_{s} } \right]^{T}\), in which the superimposed dot (∙) indicates increment; the incremental stress vector \({\dot{\mathbf{\sigma }}}{^{\prime}} = \left[ {\dot{p}{^{\prime}} ,\dot{q}} \right]^{T}\); \({\mathbf{C}}^{e}\) is the elastic compliance vector, which can be expressed as:

where the bulk modulus and shear modulus can be, respectively, defined as [5]:

where \(\nu\) is the Poisson’s ratio, defining the lateral deformation ability of the material, which can be determined by fitting the relation between the first and third principal strains; \(p_{a} = 100{\text{ kPa}}\) is the atmospheric pressure; \(G_{0}\) is the elastic constant, which can be determined by fitting the initial stress–strain curve of sand. \(G_{0}\) determines the elastic behaviour of the material.

Moreover, n and m in Eq. (27) are the plastic flow and loading vectors, respectively. n can be defined by using the fractional-order stress–dilatancy equation (21), such that:

The plastic loading/unloading vector m can be defined by following Dafalias and Manzari [2], such that:

\(\alpha_{r}\) is the back stress ratio defined by Dafalias and Manzari [2], which determines the kinematic hardening of the loading surface of granular soil (\(\dot{\alpha }_{r} = \dot{\eta }\)); m defines the size of the elastic region of the loading surface, which is set as zero in this study for the sake of simplicity [3]. Therefore, the monotonic loading vector at compression and extension can be derived as:

while for cyclic unloading from compression and extension, Eq. (32) can be derived as:

Furthermore, in Eq. (27), H is the hardening modulus. The hardening modulus describes a criterion to determine the incremental plastic strains induced by the particle rearrangement and even particle degradation, i.e. the change of phase position between particles and the amount of particle breakage, at a given stress level. The hardening function in the constitutive model represents the increment of yield surface under certain loading conditions, and is generally a function of the plastic strain, stress level, material state and even fabric [39]. For the sake of simplicity, the following formula for H is defined:

where \(h_{0}\),\({ }c_{l}\) and k are the material constants, in which \(h_{0}\) captures the influence of void ratio on the plastic hardening modulus, while \(c_{l}\) reflects the impact of reloading on the hardening behaviour of granular soil. \(h_{0}\) and \(c_{l}\) can be determined by fitting the \(q - \varepsilon_{1}\) relationship during virgin loading and first reloading, respectively. The role of \(c_{l}\) is only activated for reloading, in other words, \(c_{l} = 1\) when unloading takes place. Furthermore, \(M_{p} = M\exp \left( { - k\Psi } \right)\) is the peak stress ratio, in which k can be determined by fitting the peak stress ratio points, as comprehensively discussed in Sun et al. [36]. Note that k defines the dependence of peak failure state on material state. \(\alpha_{in}\) is the stress ratio at the last stress reversal; therefore, \(\alpha_{in} = 0\) for the initial loading case. Therefore, in Eq. (35), the effects of plastic strain level (e), stress level (\(\alpha_{r}\)) and material state (\(\Psi\)) are all considered. However, the material fabric is not taken into account in the current study and needs further comprehensive investigation.

1.2 Constitutive modelling of soil–structure interface

To model the stress–displacement behaviour of soil–structure interface, the constitutive relation should be reformulated in terms of the incremental normal/tangential stress and the incremental normal/tangential displacement. Accordingly, the constitutive relation for soil–structure interface under monotonic and cyclic loads can be reformulated as [13, 23]:

where \({\dot{\mathbf{\sigma }}} = {[}\dot{\sigma }_{n} ,\dot{\tau }{]}^{T}\) is the incremental stress vector, in which \(\sigma_{n}\) and \(\tau\) are the normal and tangential stresses, respectively; \({\dot{\mathbf{U}}} = \left[ {u,v} \right]^{T}\) is the displacement vector, in which \(u\) and \(v\) are the normal and tangential displacements, respectively; \(t_{n}\) is the thickness of the interface, which is 5–10 times of the median particle size of the interface material; following Saberi et al. [23], \(t_{n} = 5d_{50}\) is used in this study. The elastic stiffness tensor \({\mathbf{D}}^{e}\) can be expressed as:

where the elastic moduli in the normal and tangential directions can be, respectively, defined as:

where \(D_{n0}\) and \(D_{t0}\) are material constants, defining the elastic behaviour of the material, which can be determined by fitting the stress–displacement curve at the initial loading stage.

Moreover, \({\tilde{\mathbf{n}}}\) and \({\tilde{\mathbf{m}}}\) in Eq. (36) describe the plastic flow and loading directions of the interface, respectively. The plastic potential function for soil–structure interface can be provided by reformulating Eq. (13) in terms of the stresses, \(\tau\) and \(\sigma_{n}\), where \(\tilde{f} = \tau + t\tilde{\eta }_{c} \sigma_{n} {\text{ln}}\sigma_{n} - t\tilde{\eta }_{c} \sigma_{n} {\text{ln}}\sigma_{n0} = 0\). \(\tilde{\eta }_{c}\) is the stress ratio obtained at the ultimate state of the interface, where the ultimate state is similar to the critical state of soil; \(\sigma_{n0}\) is the intercept of \(\tilde{f}\) with the \(\sigma_{n} -\) axis. Due to the similar expressions of \(\tilde{f}\) and \(f\), \({\tilde{\mathbf{n}}}\) can be simply defined through the same algebraic operations shown in Eqs. (15)–(21). Therefore, analogous to Eq. (31), one has the following plastic flow direction for soil–structure interface:

where the stress ratio \(\tilde{\eta }\) within the interface is defined as \(\tilde{\eta } = \tau /\sigma_{n}\). In addition, cyclic experimental results [46, 48, 49] indicated that interface contraction took place, followed by dilation after each shear stress reversal, where the dilation rate was lower than the contraction rate, resulting in accumulated interface contraction [25, 26]. Therefore, to reasonably capture such dilatancy behaviour of the interface, the following modified expression for \(\alpha \) is suggested:

where \(\tilde{\Delta }\) and \(\chi\) are the material constants, defining the dependence of plastic flow direction of the interface on material state; \(\tilde{\Delta }\) can be determined from the phase transformation state of the interface at virgin loading, while \(\chi\) can be obtained by fitting the unloading stress–displacement curve of the interface during cyclic loading; \(W_{p}\) is the total plastic work at the last shear stress reversal; therefore, \(W_{p} = 0\) for virgin loading case. For cyclic loading case, \(W_{p}\) can be computed as:

where the superscript (p) indicates plastic displacement; \(\langle \rangle\) is the McCauley bracket. For soil–structure interface, the state parameter \(\Psi\) is defined as:

where \(\tilde{e}_{{\Gamma }}\) and \(\tilde{\lambda }\) are the material constants, describing the ultimate state line of the interface, which can be determined by fitting the ultimate state data points in the \(e - {\text{ln}}\sigma_{n}\) plane. This procedure is similar to the one used with soil; however, the void ratio (e) for the interface is defined as:

where \(e_{0}\) is the initial void ratio, prior to virgin shearing.

The plastic loading/unloading vector \({\tilde{\mathbf{m}}}\) can be defined by following Saberi et al. [24], such that:

where \(\tilde{\alpha }_{r}\) is the back stress ratio, defining the kinematic hardening (location) of the yielding surface (\(\mathop {\tilde{\alpha }_{r} }\limits^{.} = \mathop {\tilde{\eta }}\limits^{.}\)); \(\tilde{m} = 0.01\tilde{\eta }_{c}\) is the size of the yielding surface, defining the elastic region of the interface. During numerical implementation, the sign function (t) is determined by the following logic:

Finally, the plastic modulus \(K_{p}\) in Eq. (36) can be defined by measuring the distance between the current yielding surface and the bounding surface of the interface, such that:

where the peak stress ratio \(\tilde{\eta }_{p} =\) \(\tilde{\eta }_{c} {\text{exp}}\left( { - \tilde{k}\Psi } \right)\), in which \(\tilde{k}\) is a material constant, defining the dependence of peak state of interface on material state. \(\tilde{k}\) can be determined by fitting the peak stress ratio data points in the \(\tilde{\eta }_{p} - \Psi\) plane. \(K_{0}\) is a material constant, controlling the hardening behaviour of interface, which can be determined by fitting the tangential stress–displacement relation.

As the aim of this study is to develop a simple stress–dilatancy equation, details on how to identify model parameters will not be provided in a separate section, but instead described directly after each constitutive equation, as shown before. For more details on parameter identification, one can refer to Dafalias and Manzari [2] and Saberi et al. [24].

Rights and permissions

About this article

Cite this article

Sun, Y., Sumelka, W., Gao, Y. et al. Phenomenological fractional stress–dilatancy model for granular soil and soil-structure interface under monotonic and cyclic loads. Acta Geotech. 16, 3115–3132 (2021). https://doi.org/10.1007/s11440-021-01190-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01190-0