Abstract

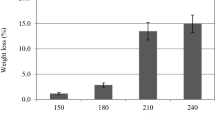

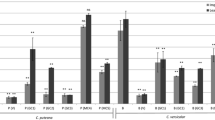

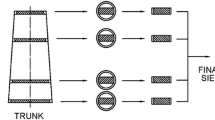

Wood bark is a source of extractives with potential for valorization based on their chemical functionalities. In this study, Acacia mangium bark was extracted with distilled water. Then bark extract solutions in distilled water at various concentrations (5%, 10%, 15%, and 20% w/w) were vacuum impregnated into rubberwood. The color of the impregnated rubberwood was observed. The retention of bark extract in rubberwood and weight percent gain (WPG) from it were calculated. The morphology, dimensional stability, resistance to fungal decay, and subterranean termite resistance were determined for impregnated rubberwood samples. It was found that a higher concentration of bark extract gave higher retention and WPG in vacuum-impregnated rubberwood. The color of impregnated wood got darker with the concentration of bark extract, from light brown to red brown and dark brown. The bark extract penetrated all the way to the center (in thickness direction) of the wood and remained in lumens of vessels, parenchyma, and ray cells. The bark extract can improve dimensional stability of rubberwood. Weight loss caused by the fungi Trametes versicolor and Gloeophyllum striatum decreased with retention of bark extract in the impregnated wood. The bark extract may be toxic to termites (Coptotermes gestroi) that consumed impregnated wood: termites died during the third and fourth weeks after they attacked wood impregnated with bark extract at 15% or 20% concentration.

Similar content being viewed by others

References

Hegde M, Palanisamy K, Yi JS (2013) Acacia mangium Willd.-a fast growing tree for tropical plantation. J For Sci 29:1–14. https://doi.org/10.7747/JFS.2013.29.1.1

Hoong YB, Paridah MT, Jalaluddin H, Chuah LA (2011) A new source of natural adhesive: Acacia mangium bark extracts co-polymerized with phenol-formaldehyde (PF) for bonding Mempisang (Annonaceae spp.). Int J Adhes Adhes 31:164–167. https://doi.org/10.1016/j.ijadhadh.2010.12.002

Jansone Z, Muizniece I, Blumberga D (2017) Analysis of wood bark use opportunities. Energy Procedia 128:268–274. https://doi.org/10.1016/j.egypro.2017.09.070

Hofmann T, Nebehaj E, Bányai ÉS, Albert L (2015) Antioxidant capacity and total phenol content of beech (Fagus sylvatica L.) bark extracts. Ind Crop Prod 77:375–381. https://doi.org/10.1016/j.indcrop.2015.09.008

Tung YT, Wu JH, Huang CY, Kuo YH, Chang ST (2009) Antioxidant activities and phytochemical characteristics of extracts from Acacia confusa bark. Bioresour Technol 100:509–514. https://doi.org/10.1016/j.biortech.2008.01.001

Miranda I, Lima L, Quiho T, Knapic S, Pereira H (2016) The bark of Ecalyptus sideroxylon as a source of phenolic extracts with anti-oxidant properties. Ind Crop Prod 82:81–87. https://doi.org/10.1016/j.indcrop.2015.12.003

Tascioglu C, Yalcin M, Sen S, Akcay C (2013) Antifungal properties of some plant extracts used as wood preservatives. Int Biodeterior Biodegradation 85:23–28. https://doi.org/10.1016/j.ibiod.2013.06.004

Ismayati M, Nakagawa IA, Ohi H, Tarmadi D (2014) In: Forschler BT (ed) Efficacy of tannin extracts isolated from acacia bark waste against the subterranean termite Coptotermes gestroi Wasmann. Proceedings of the 10th Pacific-Termite Research Group Conference, Kuala Lumpur, Malaysia

Nemli G, Kırcı H, Temiz A (2004) Influence of impregnating wood particles with mimosa bark extract on some properties of particleboard. Ind Crop Prod 20:339–344. https://doi.org/10.1016/j.indcrop.2003.11.006

Killmann W, Hong LT (2000) Rubberwood-the success of an agricultural by-product. Unasylva 51(201):66–72

Teoh YP, Don MM, Ujang S (2011) Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): a case study in Malaysia. J Wood Sci 57:255–266. https://doi.org/10.1007/s10086-011-1173-2

Deraman M, Zakaria S, Husin M, Aziz AA, Ramli R, Mokhtar A, Yusof MNM, Sahri MH (1999) X-ray diffraction studies on fiber of oil palm empty fruit bunch and rubberwood for medium-density fiberboard. J Mater Sci Lett 18:249–253. https://doi.org/10.1023/A:1006642114056

Severo ETD, Oliveira EFJ, Sansıgolo CA, Rocha CD, Calonego FW (2003) Properties of juvenile and mature woods of Hevea brasiliensis untapped and with tapping panels. Eur J Wood Wood Prod 71:815–818. https://doi.org/10.1007/s00107-013-0731-2

Kadir AA, Sudin R (1989) Carbohydrates in rubberwood (Hevea brasiliensis Muell.). Holzforschung 43:173–178. https://doi.org/10.1515/hfsg.1989.43.3.173

Simatupang MH, Schmitt U, Kasim A (1994) Wood extractives of rubberwood (Hevea brasiliensis) and their influences on the setting of the inorganic binder in gypsum-bonded particle boards. J Trop For Sci 6(3):269–285

Jayashree PKK, Nagaveni HC, Mahadevan KM (2011) Fungal resistance of rubber wood modified by fatty acid chlorides. Int Biodeterior Biodegradation 65:890–895. https://doi.org/10.1016/j.ibiod.2011.05.001

Pandey KK, Jayashree, Nagaveni HC (2009) Study of dimensional stability, decay resistance, and light stability of phenylisothiocyanate modified rubberwood. Bioresources 4(1):257–267. https://doi.org/10.15376/BIORES.4.1.257-267

Nair S, Pandey KK, Giridhar BN, Vijayalakshmi G (2017) Decay resistance of rubberwood (Hevea brasiliensis) impregnated with ZnO and CuO nanoparticles dispersed in propylene glycol. Int Biodeterior Biodegradation 122:100–106. https://doi.org/10.1016/j.ibiod.2017.05.008

Shukla SR, Zhang J, Kamdemc DP (2019) Pressure treatment of rubberwood (Heavea brasiliensis) with waterborne micronized copper azole: effects on retention, copper leaching, decay resistance and mechanical properties. Constr Build Mater 216:576–587. https://doi.org/10.1016/j.conbuildmat.2019.05.013

Owolabi IO, Songsamoe S, Khunjan K, Matan N (2021) Effect of tapioca starch coated-rubberwood box incorporated with essential oils on the postharvest ripening and quality control of mangosteen during transportation. Food Control 126:108007. https://doi.org/10.1016/j.foodcont.2021.108007

Na M, Ni M, Ketsa S (2012) Effect of heat curing on antifungal activities of anise oil and garlic oil against Aspergillus niger on rubberwood. Int Biodeterior Biodegradation 75:150–157. https://doi.org/10.1016/j.ibiod.2012.03.012

Bakar BFA, Hiziroglu S, Tahir PM (2013) Properties of some thermally modified wood species. Mater Des 43:348–355. https://doi.org/10.1016/j.matdes.2012.06.054

ASTM D1413-07e1 (2017) Standard test method for wood preservatives by laboratory soil-block cultures (withdrawn 2016). ASTM International, West Conshohocken, PA

Thybring EE (2013) The decay resistance of modified wood influenced by moisture exclusion and swelling reduction. Int Biodeterior Biodegradation 82:87–95. https://doi.org/10.1016/j.ibiod.2013.02.004

Dong Y, Yan Y, Wang K, Li J, Zhang S, Xia C, Shi SQ, Cai L (2016) Improvement of water resistance, dimensional stability, and mechanical properties of poplar wood by rosin impregnation. Eur J Wood Wood Prod 74:177–184. https://doi.org/10.1007/s00107-015-0998-6

ASTM D3345-17 (2017) Standard test method for laboratory evaluation of solid wood for resistance to termites. ASTM International, West Conshohocken, PA

Gabr S, Nikles S, Wenzing EMP, Woelkart KA, Hathout RM, Ahmady SE, Motaal AA, Singab A, Bauer R (2018) Characterization and optimization of phenolics extracts from Acacia species in relevance to their anti-inflammatory activity. Biochem Syst Ecol 78:21–30. https://doi.org/10.1016/j.bse.2018.03.001

Yamamoto I, Casida JE (1999) Nicotinoid insecticides and the nicotinic acetylcholine receptor. Springer, Tokyo, New York

Li W, Kubo I (2004) QSAR and kinetics of the inhibition of benzaldehyde derivatives against Sarcophaga neobellaria phenoloxidase. Bioorg Med Chem 12:701–713. https://doi.org/10.1016/j.bmc.2003.11.014

Tondi G, Thevenon MF, Mies B, Standfest G, Petutschnigg A, Wieland S (2003) Impregnation of Scots pine and beech with tannin solution: effect of viscosity and wood anatomy in wood infiltration. Wood Sci Technol 47:615–626. https://doi.org/10.1007/s00226-012-0524-5

Chupin L, Motillon C, Bouhtoury FCE, Pizzi A, Charrier B (2013) Characterization of maritime (Pinus pinaster) bark tannins extracted under different conditions by spectroscopic methods, FTIR and HPLC. Ind Crop Prod 49:897–903. https://doi.org/10.1016/j.indcrop.2013.06.045

Soto R, Freer J, Baeza J (2005) Evidence of chemical reactions between di- and poly-glycidyl ether resins and tannins isolated from Pinus radiata D. Don bark. Bioresour Technol 96(1):95–101. https://doi.org/10.1016/j.biortech.2003.05.006

Can A, Huseyin S, Baki H (2018) Fungal inhibition and chemical characterization of wood treated with novel polystyrene-soybean oil copolymer containing silver nanoparticles. Int Biodeterior Biodegradation 133:210–215. https://doi.org/10.1016/j.ibiod.2018.06.022

Gabrielli CP, Frederick AK (2010) Phenol–formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci Technol 44:95–104. https://doi.org/10.1007/s00226-009-0253-6

Chen H, Miao X, Feng Z, Pu J (2014) In situ polymerization of phenolic methylolurea in cell wall and induction of pulse-pressure impregnation on green wood. Ind Eng Chem 53:9721–9727. https://doi.org/10.1021/ie5006349

Eaton RA, Hale MD (1993) Wood: decay, pests, and protection. Chapman and Hall, London

Carll CG, Highley TL (1999) Decay of wood and wood-based products above ground in buildings. J Test Eval 27(2):150–158. https://doi.org/10.1520/JTE12045J

Rosdiana NA, Dumarcay A, Gerardin C, Chapuis H, Medina FJS, Sari RK, Syafii W, Gelhaye E, Raharivelomanana P, Mohammed R, Gerardin P (2017) Characterization of bark extractives of different industrial Indonesian wood species for potential valorization. Ind Crop Prod 108:121–127. https://doi.org/10.1016/j.indcrop.2017.06.034

Adedeji GA, Olukayode YO, Taiwo OE (2017) Quantifications of phytochemicals and biocide actions of Lawsonia inermis linn. extracts against wood termites and fungi. Int Biodeterior Biodegradation 116:155–162. https://doi.org/10.1016/j.ibiod.2016.10.026

Tascioglu C, Yalcin M, Troya TD, Sivrikaya H (2012) Termiticidal properties of some wood and bark extracts used as wood preservatives. Bioresources 7(3):2960–2969. https://doi.org/10.15376/biores.7.3.2960-2969

Acknowledgements

The authors would like to thank Assoc. Prof. Dr. Seppo Karrila for the helpful comments and linguistic assistance.

Funding

This research was supported by the Office of the Higher Education Commission and the Thailand Research Fund. This work was supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yingprasert, W., Cherdchim, B. & Peaklin, S. Effects of Acacia mangium bark extracts on dimensional stability, termite resistance, and fungal decay resistance of rubberwood. Biomass Conv. Bioref. 13, 7623–7632 (2023). https://doi.org/10.1007/s13399-021-01484-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01484-z