Abstract

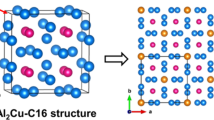

Advanced high-strength steels (AHSSs) have been applied to the automobile industry due to the advantages of low energy consumption and high safety. The non-reactive CaO–Al2O3-based mold fluxes with low/no SiO2 content have been proposed for developing the efficient casting technology of sustainable AHSSs, due to the occurrence of the reaction between AHSSs and conventional CaO–SiO2-based mold flux. Then, the effects of (CaO + BaO)/Al2O3 ratio on the melting, crystallization, and melt structure of a designed non-reactive CaO–Al2O3-10 wt% SiO2-based mold flux system have been studied. Results suggested that a higher (CaO + BaO)/Al2O3 ratio would lower the melting temperatures of the mold fluxes, and the slag system showed a good thermal stability during the melting process with the evaporation less than 5.10%. Besides, the crystallization behavior was promoted with the increase of (CaO + BaO)/Al2O3 ratio, which is associated with the reduction of the polymerization degree of the melt structure, because of the high polymerization degree of Q2(Si) structural units, and the symmetric and asymmetric [AlO4]5−-tetrahedral structures were destroyed by the released O2− ions. Thus, the migration resistance of ions and atom groups was reduced, and then the growth kinetics of LiAlO2 and Ca2SiO4 crystals were improved. When 7.42 wt% BaO was added to Sample D with (CaO + BaO)/Al2O3 ratio at 1.75, the crystallization was promoted with the decomposition of melt structure, and the Ba-bearing phase of Ba3Al2O6 crystal was precipitated to replace the main crystalline phase of LiAlO2 due to the tight junction of Ba2+ and [AlO4]5− for compensating the Al3+ charge.

Graphical Abstract

Similar content being viewed by others

References

Galán J, Samek L, Verleysen P, Verbeken K, Houbaert Y (2012) Advanced high strength steels for automotive industry. Rev Metal 48(2):118–131. https://doi.org/10.3989/revmetalm.1158

Grässel O, Krüger L, Frommeyer G, Meyer LW (2000) High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development-properties-application. Int J Plasticity 16(10–11):1391–1409. https://doi.org/10.1016/s0749-6419(00)00015-2

Kim MS, Lee SW, Cho JW, Park MS, Lee HG, Kang YB (2013) A reaction between high Mn-high al steel and CaO-SiO2-type molten mold flux: part I. Composition evolution in molten mold flux. Metall Mater Trans B 44:299–308. https://doi.org/10.1007/s11663-012-9770-z

Ji CX, Cui Y, Zeng Z, Tian ZH, Zhao CL, Zhu GS (2015) Continuous casting of high-Al steel in Shougang Jingtang steel works. J Iron Steel Res Int 22:53–56. https://doi.org/10.1016/S1006-706X(15)30138-2

Wang Q, Qiu ST, Zhao P (2012) Kinetic analysis of alumina change in mold slag for high aluminum steel during continuous casting. Metall Mater Trans B 43:424–430. https://doi.org/10.1007/s11663-011-9600-8

Zhang ZT, Wen GH, Tang P, Sridhar S (2008) The influence of Al2O3/SiO2 ratio on the viscosity of mold fluxes. ISIJ Int 48:739–746. https://doi.org/10.2355/isijinternational.48.739

He SP, Wang Q, Zeng JH, Zhang M, Xie B (2009) Properties control of mold fluxes for high aluminum steel. J Iron Steel Res 12:59–62

Omoto T, Ogata ST (2007) Development of ‘SIPS series’ mold powder for high Al electromagnetic steel. Shinagawa Technical Report 50:57–61

Yu X, Wen GH, Tang P, Ma FJ, Wang H (2011) Behavior of mold slag used for 20Mn23Al nonmagnetic steel during casting. J Iron Steel Res Int 18(1):20–25. https://doi.org/10.1016/S1006-706X(11)60005-8

Street S, James K, Minor N, Roelant A, Tremp J (2008) Production of high-aluminum steel slabs. Iron Steel Technol 5(7):38–49

Cho JW, Blazek K, Frazee M, Yin H, Park JH, Moon SW (2013) Assessment of CaO-Al2O3 based mold flux system for high aluminum trip casting. ISIJ Int 53(1):62–70. https://doi.org/10.2355/isijinternational.53.62

Blazek K, Yin H, Skoczylas G, McClymonds M, Frazee M (2011) Development and evaluation of lime alumina-based mold powders for casting high-aluminum TRIP steel grades. AIST Trans 8:232–240

Lu BX, Chen K, Wang WL, Jiang BB (2014) Effects of Li2O and Na2O on the crystallization behavior of lime-alumina-based mold flux for casting high-Al steels. Metall Mater Trans B 45(4):1496–1509. https://doi.org/10.1007/s11663-014-0063-6

Jiang BB, Wang WL, Sohn I, Wei J, Zhou LJ, Lu BX (2014) A kinetic study of the effect of ZrO2 and CaO/Al2O3 ratios on the crystallization behavior of a CaO-Al2O3-based slag system. Metall Mater Trans B 45(3):1057–1067. https://doi.org/10.1007/s11663-014-0026-y

Lu BX, Wang WL (2015) Effects of fluorine and BaO on the crystallization behavior of lime–alumina-based mold flux for casting high-Al steels. Metall Mater Trans B 46(2):852–862. https://doi.org/10.1007/s11663-014-0285-7

Yan W, Chen WQ, Yang YD, Lippold C, Mclean A (2015) Effect of slag compositions and additive on heat transfer and crystallization of mold fluxes for high-Al non-magnetic steel. ISIJ Int 55(5):1000–1009. https://doi.org/10.2355/isijinternational.55.1000

Gao JX, Wen GH, Huang T, Bai BW, Tang P, Liu Q (2016) Effect of Al speciation on the structure of high-Al steels mold fluxes containing fluoride. J Am Ceram Soc 99(12):3941–3947. https://doi.org/10.1111/jace.14444

Zhang L, Wang WL, Shao HQ (2019) Review of non-reactive CaO-Al2O3-based mold fluxes for casting high-aluminum steel. J Iron Steel Res Int 26:336–344. https://doi.org/10.1007/s42243-018-00226-2

Zhou LJ, Li H, Wang WL, Xiao D, Zhang L, Yu J (2018) Effect of Li2O on the behavior of melting, crystallization, and structure for CaO-Al2O3-based mold fluxes. Metall Mater Trans B 49(5):2232–2240. https://doi.org/10.1007/s11663-018-1327-3

Xiao D, Wang WL, Lu BX (2015) Effects of B2O3 and BaO on the crystallization behavior of CaO-Al2O3-based mold flux for casting high-Al steels. Metall Mater Trans B 46(2):873–881. https://doi.org/10.1007/s11663-014-0286-6

Gao EZ, Wang WL, Zhang L (2017) Effect of alkaline earth metal oxides on the viscosity and structure of the CaO-Al2O3 based mold flux for casting high-Al steels. J of Non-Cryst Solids 473:79–86. https://doi.org/10.1016/j.jnoncrysol.2017.07.029

Zhao H, Wang WL, Zhou LJ, Lu BX, Kang YB (2014) Effects of MnO on crystallization, melting, and heat transfer of CaO-Al2O3-based mold flux used for high Al-TRIP steel casting. Metall Mater Trans B 45(4):1510–1519. https://doi.org/10.1007/s11663-014-0043-x

Wu T, Wang Q, He SP, Xu JF, Long X, Lu YJ (2012) Study on properties of alumina-based mould fluxes for high-Al steel slab casting. Steel Res Int 83(12):1194–1202. https://doi.org/10.1002/srin.201200092

Qi J, Liu C, Jiang M (2017) Properties investigation of CaO-Al2O3-SiO2-Li2O-B2O3-Ce2O3 mould flux with different w(CaO)/w(Al2O3) for heat-resistant steel continuous casting. Can Metall Quart 56(2):212–220. https://doi.org/10.1080/00084433.2017.1309165

Fu XJ, Wen GH, Tang P, Liu Q, Zhou ZY (2014) Effects of CaO/Al2O3 ratio on crystallisation behaviour of CaO-Al2O3 based mould fluxes for high aluminium TRIP steel. Ironmak Steelmak 41(5):342–349. https://doi.org/10.1179/1743281213Y.0000000156

Shao HQ, Gao EZ, Wang WL, Zhang L (2019) Effect of fluorine and CaO/Al2O3 mass ratio on the viscosity and structure of CaO-Al2O3-based mold fluxes. J Am Ceram Soc 102(8):4440–4449. https://doi.org/10.1111/jace.16322

Wang WL, Gao EZ, Zhou LJ, Zhang L, Li H (2019) Effect of Al2O3/SiO2 and CaO/Al2O3 ratios on wettability and structure of CaO-SiO2-Al2O3-based mold flux system. J Iron Steel Res Int 26(4):355–364. https://doi.org/10.1007/s42243-018-0207-z

Zhang L, Wang WL, Xie SL, Zhang KX, Sohn I (2017) Effect of basicity and B2O3 on the viscosity and structure of fluorine-free mold flux. J Non-Cryst Solids 460:113–118. https://doi.org/10.1016/j.jnoncrysol.2017.01.031

Zhang L, Wang WL, Sohn I (2019) Crystallization behavior and structure analysis for molten CaO-SiO2-B2O3 based fluorine-free mold fluxes. J Non-Cryst Solids 511:41–49. https://doi.org/10.1016/j.jnoncrysol.2019.01.035

Li JL, Kong BW, Galdino B, Xu JF, Chou KC, Liu QC, Shu QF (2017) Investigation on properties of fluorine-free mold fluxes based on CaO-Al2O3-B2O3 system. Steel Res Int 88(9):1600485. https://doi.org/10.1002/srin.201600485

Li Z, You XC, Li M, Wang Q, He SP, Wang QQ (2019) Effect of substituting CaO with BaO and CaO/Al2O3 ratio on the viscosity of CaO-BaO-Al2O3-CaF2-Li2O mold flux system. Metals 9(2):142. https://doi.org/10.3390/met9020142

Jung SS, Sohn I (2014) Crystallization control for remediation of an FetO-rich CaO-SiO2-Al2O3-MgO EAF waste slag. Environ Sci Technol 48(3):1886–1892. https://doi.org/10.1021/es404277w

Supaphol P, Dangseeyun N, Srimoaon P, Nithitanakul M (2003) Nonisothermal melt-crystallization kinetics for three linear aromatic polyesters. Thermochim Acta 406(1–2):207–220. https://doi.org/10.1016/S0040-6031(03)00258-2

Haratian S, Haddad-Sabzevar M (2015) Thermal stability and non-isothermal crystallization kinetics of Ti41.5Cu42.5Ni7.5Zr2.5Hf5Si1 bulk metallic glass. J Non-Cryst Solids 429:164–170. https://doi.org/10.1016/j.jnoncrysol.2015.09.009

Wang ZJ, Sun YQ, Sridrar S, Zhang M, Zhang ZT (2017) Investigation on viscosity and nonisothermal crystallization behavior of P-bearing steelmaking slags with varying TiO2 content. Metall Mater Trans B 48(1):527–537. https://doi.org/10.1007/s11663-016-0825-4

Park JH, Min DJ, Song HS (2002) FT-IR spectroscopic study on structure of CaO-SiO2 and CaO-SiO2-CaF2 slags. ISIJ Int 42(4):344–351. https://doi.org/10.2355/isijinternational.42.344

Matson DW, Sharma SK, Philpotts JA (1983) The structure of high-silica alkali-silicate glasses. A Raman spectroscopic investigation. J Non-Cryst Solids 58(2–3):323–352. https://doi.org/10.1016/0022-3093(83)90032-7

Mysen BO, Virgo D, Scarfe CM (1980) Relations between the anionic structure and viscosity of silicate melts: a Raman spectroscopic study. Am Mineral 65(7–8):690–710

Mysen BO (1998) Phosphorus solubility mechanisms in haplogranitic aluminosilicate glass and melt: effect of temperature and aluminum content. Contrib Mineral Petr 133(1–2):38–50. https://doi.org/10.1007/s004100050435

Kim GH, Sohn I (2012) Effect of Al2O3 on the viscosity and structure of calcium silicate-based melts containing Na2O and CaF2. J Non-Cryst Solids 358(12–13):1530–1537. https://doi.org/10.1016/j.jnoncrysol.2012.04.009

McMillan P (1984) Structural studies of silicate glasses and melts-applications and limitations of Raman spectroscopy. Am Mineral 69(7–8):622–644

Kim GH, Sohn I (2012) Influence of Li2O on the viscous behavior of CaO-Al2O3-12mass%Na2O-12mass%CaF2 based slags. ISIJ Int 52(1):68–73. https://doi.org/10.2355/isijinternational.52.68

Park JH, Kim H, Min DJ (2008) Novel approach to link between viscosity and structure of silicate melts via Darken’s excess stability function: focus on the amphoteric behavior of alumina. Metall Mater Trans B 39(1):150–153. https://doi.org/10.1007/s11663-007-9122-6

Jung EJ, Min DJ (2012) Effect of Al2O3 and MgO on interfacial tension between calcium silicate-based melts and a solid steel substrate. Steel Res Int 83(7):705–711. https://doi.org/10.1002/srin.201200023

Beall DM, Beall GH (2003) Lithium aluminosilicate ceramic. United States Patent No. 6566290, 2003-03-20

Shabanova GN, Bykanov SN (2002) The system BaO-Al2O3-Fe2O3. Refract Ind Ceram 43(7–8):247–250. https://doi.org/10.1023/A:1021067331621

Wang WL, Yan X, Zhou LJ, Xie SL, Huang DY (2016) Influences of basicity and Li2O on the properties of fluorine-free mold flux for the casting of medium carbon steels. Metall Mater Trans B 47(2):963–973. https://doi.org/10.1007/s11663-016-0597-x

Acknowledgements

The financial support from the National Science Foundation of China (U1760202), Guangxi Scientific technology project (AD 18281073), and Hunan Scientific Technology projects (2018RS3022, 2018WK2051) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Sharif Jahanshahi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, L., Zhai, B., Wang, W. et al. Effects of (CaO + BaO)/Al2O3 Ratio on the Melting, Crystallization, and Melt Structure of CaO–Al2O3-10 wt% SiO2-Based Mold Fluxes for Advanced High-Strength Steels. J. Sustain. Metall. 7, 559–568 (2021). https://doi.org/10.1007/s40831-021-00358-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00358-y