Abstract

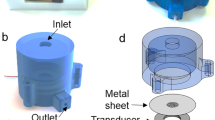

Sealing is one of the inevitable process in microfluidic chip fabrication to form complex networks for the biosensing applications. Currently, only a few materials can be used in microfluidic biosensor due to the lack of reliable bonding technique for most materials. To solve the problem of versatility for chip sealing, a novel adhesive bonding method as simple as “tear off–paste on” is developed. PDMS is mixed with a small amount of polyethylenimine solution to prepare a sticky thin layer, which works like a tape to paste on different materials. Various substrates including glass, plastic, metal and ceramics are used for preparation of microfluidic chips with good bonding strength. This method is appealing for its compatibility to traditional replication method using PDMS and SU8 channel mold while the small surface structures of channel walls can be retained. This method is reliable and versatile for microfluidic biosensor sealing, especially for those with biological sensitive recognition elements on the surfaces since neither aggressive chemicals, high temperature nor high-energy plasma is used. The applicability of the developed method is demonstrated to fabricate a novel long-term cell culture 3D microfluidic chip which keeps bacteria viable for more than 7 days.

Similar content being viewed by others

References

Carroll S, Crain MM, Naber JF, Keynton RS, Walsh KM, Baldwin RP (2008) Room temperature UV adhesive bonding of CE devices. Lab Chip 8:1564–1569

Cira NJ, Ho JY, Dueck ME, Weibel DB (2012) A self-loading microfluidic device for determining the minimum inhibitory concentration of antibiotics. Lab Chip 12:1052–1059

Dang F, Shinohara S, Tabata O, Yamaoka Y, Kurokawa M, Shinohara Y, Ishikawa M, Baba Y (2005) Replica multichannel polymer chips with a network of sacrificial channels sealed by adhesive printing method. Lab Chip 5:472–478

Deng L, Wang YZ, Shang L, Wen D, Wang F, Dong SJ (2008) A sensitive NADH and glucose biosensor tuned by visible light based on thionine bridged carbon nanotubes and gold nanoparticles multilayer. Biosens Bioelectron 24:951–957

Di Lorenzoab F, Seiffert S (2015) Nanostructural heterogeneity in polymer networks and gels. Polym Chem 6:5515–5528

Dou M, Macias N, Shen F, Bard JD, Dominguez DC, Li X (2019) Rapid and accurate diagnosis of the respiratory disease pertussis on a point-of-care biochip. EClinMed 8:72–77

Eddings MA, Johnson MA, Gale BK (2008) Determining the optimal PDMS-PDMS bonding technique for microfluidic devices. J Micromech Microeng 18:1171–1185

Fan Y, Li H, Yi Y, Foulds IG (2013) PMMA to polystyrene bonding for polymer based microfluidic systems. Microsyst Technol 20:59–64

Flachsbart BR, Wong K, Iannacone JM, Abante EN, Vlach RL, Rauchfuss PA, Bohn PW, Sweedler JV, Shannon MA (2006) Design and fabrication of a multilayered polymer microfluidic chip with nanofluidic interconnects via adhesive contact printing. Lab Chip 6:667–674

Gong X, Yi X, Xiao K, Li S, Kodzius R, Qin J, Wen W (2010) Wax-bonding 3D microfluidic chips. Lab Chip 10:2622–2627

Hunter AC (2006) Molecular hurdles in polyfectin design and mechanistic background to polycation induced cytotoxicity. Adv Drug Deliv Rev 58:1523–1531

Jena RK, Yue CY, Lam YC (2011) Micro fabrication of cyclic olefin copolymer (COC) based microfluidic devices. Microsyst Technol 18:159–166

Jeong SH, Zhang S, Hjort K, Hilborn JN, Wu ZG (2016) Stretchable electronic devices: PDMS-based elastomer tuned soft, stretchable, and sticky for epidermal electronics. Adv Mater 28:5765–5765

Kersey L, Ebacher V, Bazargan V, Wang R, Stoeber B (2009) The effect of adhesion promoter on the adhesion of PDMS to different substrate materials. Lab Chip 9:1002–1004

Kimura H, Yamamoto T, Sakai H, Sakai Y, Fujii T (2008) An integrated microfluidic system for long-term perfusion culture and on-line monitoring of intestinal tissue models. Lab Chip 8:741–746

Krenkova J, Foret F (2004) Immobilized microfluidic enzymatic reactors. Electrophoresis 25:3550–3563

Li SB, Gong XQ, Mc Nally CS, Zeng ML, Gaule T (2016) Rapid preparation of highly reliable PDMS double emulsion microfluidic devices. RSC Adv 6:25927–25933

Lu CM, Lee LJ, Juang YJ (2010) Packaging of microfluidic chips via interstitial bonding technique. Electrophoresis 29:1407–1414

Luka G, Ahmadi A, Najjaran H, Alocilja E, DeRosa M, Wolthers K, Malki A, Aziz H, Althani A, Hoorfar M (2015) Microfluidics integrated biosensors: a leading technology towards lab-on-a-chip and sensing applications. Sensors 15:30011–30031

Ma K, Rivera J, Hirasaki GJ, Biswal SL (2011) Wettability control and patterning of PDMS using UV-ozone and water immersion. J Colloid Interface Sci 363:371–378

Ma WR, Liu LL, Xu Y, Wang L, Li SB (2020) A highly efficient preconcentration route for rapid and sensitive detection of endotoxin based on an electrochemical biosensor. Analyst 145:4204–4211

Nayak NC, Yue CY, Lam YC, Tan YL (2010) Thermal bonding of PMMA: effect of polymer molecular weight. Microsyst Technol 16:487–491

Pan YJ, Yang RJ (2006) A glass microfluidic chip adhesive bonding method at room temperature. J Micromech Microeng 16:2666–2666

Patko D, Martonfalvi Z, Kovacs B, Vonderviszt F, Kellermayer M, Horvath R (2014) Microfluidic channels laser-cut in thin double-sided tapes: Cost-effective biocompatible fluidics in minutes from design to final integration with optical biochips. Sens Actuators B 196:352–356

Peterson SL, Mcdonald A, Gourley PL, Sasaki DY (2005) Poly(dimethylsiloxane) thin films as biocompatible coatings for microfluidic devices: cell culture and flow studies with glial cells. J Biomed Mater Res Part A 72a:10–18

Pijanowska DG, Remiszewska E, Lysko JM, Jazwinski J, Torbicz W (2003) Immobilisation of bioreceptors for microreactors. Sens Actuators B 91:152–157

Riegger L, Strohmeier O, Faltin B, Zengerle R, Koltay P (2010) Adhesive bonding of microfluidic chips: influence of process parameters. J Micromech Microeng 20:87003–87007

Sanjay ST, Li MH, Zhou W, Li XC, Li XJ (2020) A reusable PMMA/paper hybrid plug-and-play microfluidic device for an ultrasensitive immunoassay with a wide dynamic range. Microsyst Nanoeng 6:1044–1053

Shamsi MH, Chen S (2017) Biosensors-on-chip: a topical review. J Micromech Microeng 27:083001–083017

Suzuki Y, Yamada M, Seki M (2010) Sol–gel based fabrication of hybrid microfluidic devices composed of PDMS and thermoplastic substrates. Sens Actuators B 148:323–329

Thompson CS, Abate AR (2013) Adhesive-based bonding technique for PDMS microfluidic devices. Lab Chip 13:632–635

Trantidou T, Elani Y, Parsons E, Ces O (2017) Hydrophilic surface modification of PDMS for droplet microfluidics using a simple, quick, and robust method via PVA deposition. Microsyst Nanoeng 3:16091–16100

Umbrecht F, Müller D, Gattiker F, Boutry CM, Neuenschwander J, Sennhauser U, Hierold C (2009) Solvent assisted bonding of polymethylmethacrylate: characterization using the response surface methodology. Sens Actuators A 156:121–128

Wang W, Yang C, Li CM (2009) On-demand microfluidic droplet trapping and fusion for on-chip static droplet assays. Lab Chip 9:1504–1506

Wang LJ, Chang YC, Sun RR, Li L (2017) A multichannel smartphone optical biosensor for high-throughput point-of-care diagnostics. Biosens Bioelectron 87:686–692

Xu YC, Vaidya B, Patel AB, Ford SM, Mccarley RL, Soper SA (2003) Solid-phase reversible immobilization in microfluidic chips for the purification of dye-labeled DNA sequencing fragments. Anal Chem 75:2975–2984

Ye Z, Wang K, Lou M, Jia X, Ye G (2020) Consecutive synthesis of gold nanobipyramids with controllable morphologies using a microfluidic platform. Microfluid Nanofluid 24:38–46

Zhang H, Xue L, Huang FC, Wang SY, Wang L, Liu N, Lin JH (2019) A capillary biosensor for rapid detection of Salmonella using Fe-nanocluster amplification and smart phone imaging. Biosens Bioelectron 127:142–149

Acknowledgements

This research was funded by the Fundamental Research Funds for the Central Universities, grant number 2020CDJYGGD004, 2020CDJGFGDZD016, 2020CDJXZ001, the National Natural Science Foundation of China, grant number 61904021, 61971074, Key project of science and technology research program of Chongqing Education Commission of China, grant number KJZD-K201900103, the Pioneer Natural Science Foundation of Chongqing, grant number cstc2019jcyj-xfkxX0003 and National Key Research and Development Program of China, grant number 2019YFC0214400. We thank Mr. Hong He from College of Physics, Chongqing University for the help in calculation of bonding strength using COMSOL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, P., Lv, Z., Sun, B. et al. A universal bonding method for preparation of microfluidic biosensor. Microfluid Nanofluid 25, 43 (2021). https://doi.org/10.1007/s10404-021-02445-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-021-02445-8