Abstract

Vinasse sugarcane is a valuable byproduct of the ethanol production process, presenting a perspective of volume increase with the development of second generation ethanol (2GE). However, this byproduct needs new methods of treatment and management for sustainability. Besides that, 2GE vinasse can be associated with some compounds (such as furan derivatives, phenolic compounds and organic acids), depending on the process used to solubilize hemicellulose, which could compromise vinasse destination or utilization. For this reason, detoxification methods of the hemicellulosic hydrolysates, from which vinasse is obtained in subsequent steps, are crucial. This study aimed to investigate whether the biological detoxification of vinasse from 2GE presents a difference concerning the microbial activity of biodegradation and toxicity when compared to vinasse without the detoxification process. Two vinasses (1, before; and 2, after detoxification) from fermented sugarcane bagasse (hemicellulose fraction) acid hydrolysate (supplemented with its molasses), under different concentrations: 2.5; 5 e 10% were evaluated. Their physicochemical characterization, biodegradation microbial activity (through Bartha and Pramer respirometric method, with total count of heterotrophic bacteria and fungi), and toxicity evaluation (through bioassays with Lactuca sativa at concentraction: 2.5; 5 e 10% and Daphnia similis to 1.5; 2.5; 3.5; 4.5; 5 and 10%) were performed. The results indicated high mineral and organic matter, which under a specific circumstance (2.5% of soil conditioning), enabled high efficiency in biodegradation (>80%). The bioassays with L. sativa signaled negative effect for radicular growth when the vinasses were applied at a concentration of 5 and 10% (sublethal effect and delayed root growth). Acute effects were observed in D. similis, with 50% of immobilization, at concentrations of 4.13% and 4.74% for vinasses 1 and 2, respectively. These results indicate that the biodegradation of vinasse from sugarcane bagasse acid hydrolysate occurs at relatively low levels (up to 5%) and suggests that higher concentrations (≥10%) may impair the growth of soil-associated microorganisms.

Similar content being viewed by others

Introduction

Vinasse sugarcane is a valuable byproduct from both processes of first generation ethanol (1GE) and second generation ethanol (2GE), which is in rising development. The 1GE process generates about 9 to 15 liters of vinasse per each liter of ethanol produced (España-Gamboa et al. 2011). The introduction of the 2G process would increase the volume of vinasse by almost 50% (Stambuk et al. 2008).

1GE vinasse contains a high concentration of organic matter (Parnaudeau et al. 2008). It is also a relevant source of nutrients, mainly nitrogen, phosphorus and potassium (Hoarau et al. 2018), favoring its use as fertilizer, animal ration and biogas production, among others (Baeyens et al. 2015). In Brazil, the most common application of vinasse (1GE) is in fertigation (Rodrigues Reis and Hu (2017)). Vinasse composition is variable and depends on the features of the material and the industrial process applied, among other aspects (Christofoletti et al. 2013; Hoarau et al. 2018). 2GE vinasse is a deficient source of nutrients (Moraes et al. 2015) and presents high organic matter content (Milanez et al. 2015), making its use in fertigation unfeasible. Furthermore, vinasse from sugarcane bagasse (hemicellulose) acid hydrolysate may be associated with some toxic compounds (such as furan derivatives, phenolic compounds, aliphatic and organic acids) (Candido et al. 2020), depending on the pretreatment process used to hydrolyse hemicellulose, which could compromise even more vinasse uses. Biological detoxification is an important technique that aims to reduce the presence of these compounds in the fermenting must (Silva-Fernandes et al. 2017; Vallejos et al. 2016; Candido et al. 2020); with this, the quality of vinasse obtained from the manufacture of ethanol or other value-added products can be favored.

Applying vinasse in fertigation systems is an excellent alternative for this byproduct (Coelho et al. 2018) because it can favor the improvement of microbial activity (Alves et al. 2019); on the other hand, its indiscriminate use is associated with various environmental impacts (Christofoletti et al. 2013). It might lead to soil salinization (Madejón et al. 2001; Parnaudeau et al. 2008), excess of potassium in groundwater (Silva et al. 2007), and leaching of metals and sulfates (Ribeiro et al. 2010). Furthermore, it might also cause gas emissions, such as nitrous oxide and methane (Moraes et al. 2017) and the compromise of microbial communities associated or not to the soil (España-Gamboa et al. 2011). Alternatives, as biodigestion for biogas (Moraes et al. 2015) and biomass production (Aparicio et al. 2017), have been receiving much attention and should be considered for more sustainable utilization.

It is essential to understand the physicochemical features, biodegradability, and toxicity of vinasse from acid hydrolysate hemicellulose, to propose management methods and a more appropriate destination. These kinds of data are scarce in the literature and can contribute to the establishment of norms and guidelines that justify its most adequate destination.

The diverse techniques applied in pre-treatment (Kumar and Sharma 2017; Melati et al. 2019), enzymatic hydrolysis, and fermentation of lignocellulosic material (cell recycle, different yeasts, control of chemical parameters) result in distinct vinasses. This diversity difficult the comparison among data in the scientific literature. Another essential point is the hydrolyzed supplementation, for example, with sugarcane molasses (Gutiérrez-Rivera et al. 2015; Candido et al. 2020), which have a direct implication in the variation of its composition.

Studying vinasse biodegradability is fundamental to understand its behavior in soil. Bartha and Pramer respirometric method used in this study is recommended by international agencies to determine biodegradation residues in soils. The respirometric methods quantify carbon dioxide (CO2) from microbial metabolic activities of the organic residues degradation (Régo et al. 2014). This biological process’s efficiency signals the mineralization of pollutants (Almeida et al. 2013), providing subsidies for the implementation of bioremediation in degraded areas.

Besides that, toxicity bioindicators organisms (standard species) signal the toxic effects that might be caused by the introduction of different compounds (including vinasse) in the environment levels (producers and primary consumer) were used to assess vinasse’s toxicological potential. Toxicity tests with higher plants, such as L. sativa, are simple, rapid, trustworthy, and cost-effective (Lyu et al. 2018), being recommended by international organizations (ISO 1995, USEPA 1996, OECD 2003). The bioassay using lettuce seeds (L. sativa) is widely used in phytotoxicity assays (Lutterbeck et al. 2015) due to the possibility of evaluating parameters such as germination rate and root elongation. In turn, D. similis has great ecological importance due to its role in the food chain of aquatic systems (Almeida 2006), besides being a tropical species easily cultured in the laboratory with high sensitivity to contaminants (Buratini et al. 2004).

This study aimed to investigate whether the biological detoxification process of vinasse from the second generation ethanol production process (hemicellulose fraction with supplementation) shows a difference concerning the microbial activity of biodegradation (Bartha and Pramer 1965 respirometric method) and toxicity (bioassays with L. sativa and D. similis).

Materials and methods

Process for obtaining the acid hydrolysate from sugarcane bagasse

Sugarcane bagasse was pretreated with sulfuric acid solution 2.5% (m/v) at 1 atm for 1 h, obtaining a liquid fraction called acid hydrolysate. This fraction was rich in sugar monomers and intermediate compounds, such as 5-hydroxymethyl-furfural, furfural, acetic and formic acids. The liquid fraction was detoxified with Saccharomyces cerevisiae (4% m/v) active cells during 1 h resulting in a detoxified hydrolysate. The detoxified hydrolysate was enriched with industrial sugarcane molasses (47 g L−1 of total reducing sugars) (kindly supplied by production unit - Rio Pardo, Cerqueira César, Sao Paulo, Brazil) and subsequently fermented by the yeasts S. cerevisiae and Scheffersomyces stipitis. This part of the study was previously published by our research group (Candido et al. 2020).

Vinasse from hemicellulose hydrolysate

After fermentation of the hemicellulose hydrolysate, the must was centrifuged (2500 rpm for 25 min) to remove the yeasts. Then, it was distilled (Soxhlet: 78 °C for 15 min) to separate the residual ethanol. Two vinasses (vinasse 1 and 2) were obtained and evaluated. Vinasse 1 was obtained from the acid hydrolysate fermentation (non-detoxified) and vinasse 2 from the same process but of the detoxified acid hydrolysate. Both vinasses were submitted to analysis for physicochemical characterization, biodegradation assays and toxicity tests.

Vinasse physicochemical characterization

The physicochemical characterization of both vinasses (vinasse 1 from the acid hydrolysate fermentation without detoxification, and vinasse 2 after detoxification) was performed according to Standard Methods for Examination of Water and Wastewater (Apha 1998; APHA, 2012) and Association Official Analytical Chemist (AOAC 2005). For total organic carbon (TOC), the characterization was carried out according to Goldin (1987). The vinasses were diluted (10 and 90%) in ultrapure water (Milli-Q system – Millipore), various analyses were executed, and parameters measured. They include biochemical oxygen demand (BOD) (mg L−1), chemical oxygen demand (COD) (mg L−1), dissolved oxygen (mg L−1), conductivity (mS/cm2), nitrite (mg L−1), nitrate (mg L−1), total solids (g L−1), fixed solids (g L−1), volatile solids (g L−1), total organic carbon (TOC) (g L−1), Kjeldahl nitrogen (mg L−1), phosphate (mg L−1), potassium (mg L−1), and sulfate (mg L−1).

Biodegradation test

Biodegradation assay was performed according to the respirometric method of Bartha and Pramer (1965), modified by the Organization for Economic Cooperation and Development (OECD 2002) standard, which informs about the assessment of aerobic transformation of substances in the soil. São Paulo State University (Unesp), Rio Claro – Sao Paulo, Brazil (latitude: −22.39624915, longitude: −47.5431633 / climate: tropical altitude) provided the soil (sandy-clay) for the tests. The sampling was conducted following the technical standard L.6.245 of CETESB (1984). The soil used was characterized by Messetti et al. (2017) in our group’s previous study (Supplementary File, A). Field capacity was determined based on the maximum moisture that the soil could absorb (30.84%) and the moisture determined in the fresh soil (18.61%). With that, 2.98 g of water was added for every 100 g of soil, which corresponds to 70% of the field capacity. The soil moisture determination was carried out in an oven - 105 °C until constant weight.

Biodegradation assays with vinasses 1 and 2, and the control (only soil) were conducted in Bartha and Pramer system. In each of its bottle cup (250 mL), 50 g of conditioned soil was placed with the vinasses 1 and 2 in concentrations of 2.5; 5; e 10% (Table 1). Then, the cups were incubated at 30 ± 2 °C. The analyses were all performed in triplicate.

Biodegradation was monitored using the Bartha and Pramer test system (1965). Microbial activity was quantified by altering the conductivity of potassium hydroxide (KOH) that reacts with carbonic gas (CO2) and produce the salt potassium carbonate (K2CO3). The gas was originated from the consumption of organic matter by the microorganisms in the soil. This reaction occurs as follows: 2 KOH + 1 CO2 → 1 K2CO3 + 1 H2O as supported by Bartha and Pramer (1965).

The conductivity was monitored for 52 days. A new KOH solution 0.2 mol L−1 was added in a specific compartment of the respirometric system, after each conductivity measure.

To quantify the biodegraded carbon, it was considered that approximately 50% of the CO2 stays retained in the soil (OECD, 2010). Thus, the quantity of biodegraded carbon was calculated according to Equation 1, and the biodegradation efficiency according to Equation 2.

Biodegraded carbon

Biodegradation efficiency

Microorganisms in the soil before and after biodegradation

Around 10 g of soil was suspended and homogenized in 90 mL of saline solution 0.85% (30 min, 120 rpm). Then, it was diluted in decimal series and plated in selective media: Plate Count Agar (PCA) for bacteria total counting with the addition of 5 ppm of cycloheximide (35 °C and 48 h of incubation) and Sabouraud for fungi counting, with the inclusion of 5 ppm of chloramphenicol (28 °C and 120 h of incubation). Microbial quantification was performed by manual enumerating in a counter (Phoenix-Luferco CP 608) of colony-forming unity per g of soil (CFU g−1).

Phytotoxicity test

Vinasses 1 and 2 phytotoxicity was evaluated using Lactuca sativa (Asteralis, Asteraceae) according to the guideline OPPTS 850.4200 - Seed Germination/Root Elongation Toxicity Test (EPA 1996). L. sativa seeds (butterhead lettuce, Isla Pak, lot: 118031-003, 98% of germination and 100% of purity) were used. The bioassay was performed in Petri dishes and filter paper was used as a substrate for twenty seeds that were exposed to 4 mL of vinasses at concentrations of 2.5; 5 and 10% (v/v), diluted in ultrapure water. The samples were incubated under biological oxygen demand chamber (BOD) (20 ± 2 °C), in a 12 h: 12 h light-dark cycle, during 120 h. The seeds were evaluated regarding their germination percentage (%), the root length (mm) and the phytotoxicity rate (%), which was calculated according to equation 3. Germination percentage (%) was determined by dividing the total germinated seeds by all the distributed seeds and multiplying by 100. Two reference control were used, distilled water (negative control) and zinc sulfate 0.05 mol L−1 (positive control).

Where: NC is the negative control.

Toxicity test

Vinasses 1 and 2 toxicity was evaluated using Daphnia similis (Cladocera, Daphnidae) according to the Brazilian Technical Standards Association procedure (NBR 12713/2016).

The vinasses were diluted in natural spring water and tested in the concentrations 1.5; 2.5; 3.5; 4.5; 5 and 10%. Ten neonates of D. similis (6 to 24 h of age) were added into 10 mL of sample and incubated at 22 °C, with a 12 h: 12 h light-dark cycle in BOD. The negative control was natural spring water. After 24 h and 48 h of exposure, the immobilized organisms were quantified.

Preliminary tests to determine the range of concentration of vinasse was carried out.

The maximum toxicity observed for vinasse 1 at a 10% concentration was 64 and 100% immobilization for 24 and 48 h of exposure, respectively. The vinasse submitted to the detoxification process (vinasse 2) was less toxic (14%) for D. similis (48 h).

The biotic factors: life stage (6 to 24 h age) and nutritional condition, and abiotic (conductivity, dissolved oxygen, pH, and temperature) were monitored according to Zagatto and Bertoletti (2008). The abiotic factors were verified at the beginning and the end of the test (Supplementary File, B).

Statistical analysis

The data were submitted to a variance analysis/one-way ANOVA, followed by Dunnett’s post-hoc for multiple comparisons (biodegradation and phytotoxicity test) and t test Student (physicochemical characterization). The Shapiro Wilk and Levene’s tests were used in preliminary tests. The EC50 (effective concentration that immobilizes 50 % of the test-organisms) for the toxicity tests with D. similis was estimated by Trimmed Spearman-Karber method (Hamilton et al. 1977). The statistical differences were considered significant for p < 0.05.

Results

Physicochemical characterization of the vinasse bagasse sugarcane

The samples showed a little variation for the DBO (<1.2%) and DQO (<6.0%) analysis (Table 2). The detoxification process did not significantly interfere (P > 0.05) in the results (vinasses 1 and 2) of the other parameters, with less than 4% of difference. There was no difference between the physicochemical parameters of vinasse 1 and 2, with the exception of nitrate, which presented a higher value in non-detoxified vinasse (12%). The lack of data available in the literature for hemicellulose acid hydrolysate makes it challenging to compare the values obtained.

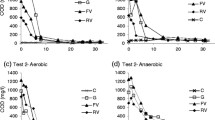

CO2 accumulation in biodegradation

Profiles curve of CO2 production over time for different concentrations of both vinasses, non-detoxified (vinasse 1) and detoxified (vinasse 2), are presented in Fig. 1. CO2 accumulation increased gradually, and its variation was proportional to the amount of carbon initially conditioned in the soil by vinasse addition (10 > 5 > 2.5%). In the detoxified vinasse (vinasse 2), the accumulated CO2 values from the third day of incubation were significantly higher in the treatments with 5 and 10% vinasse in relation to non-detoxified vinasse (vinasse 1). This result indicates that under these conditions, detoxified vinasse favors biodegradation. In the control system, which contained only soil (without previous enrichment with vinasse), CO2 production was 77% lower on average compared to treatments with 2.5% of vinasse 1 and 2. In this concentration, CO2 production, despite being similar, differed significantly (P < 0.05) in vinasse 2 over the 52 days.

Quantity of CO2 (µmol) released in the respirometric system of Bartha and Pramer (1965) during biodegradation evaluation for two vinasses from 2GE before (vinasse 1) and after detoxification (vinasse 2), added in the soil in concentrations of 2.5, 5 and 10% during 52 days at 28 °C. The symbols represented the mean and the vertical lines the standard deviation (n = 3)

Efficiency of biodegradation

The highest efficiency occurred in the soil with 2.5 % of vinasse, with mean biodegradation of 84 % for vinasse 2 (after 52 days of incubation), 2 % higher than vinasse 1 (non-detoxified). Despite low, this value was considered significantly different (P > 0.001). In the other treatments (5 and 10%), the detoxified vinasse also showed a higher efficiency (45 and 61%, respectively) in relation to vinasse 1.

Both vinasses 1 and 2 at the level of 2.5% in the soil had an efficiency of almost 80% (after 52 days). This result suggests that biodegradation was not complete in this period. Consequently, the double and quadrupole (5 and 10%, respectively) of this concentration presented lower degradation efficiency.

Near the 25th day of biodegradation (Fig. 2), approximately half (51 %) of both vinasses at a concentration of 2.5 % had been degraded. While in the 5 % treatment, the efficiency for vinasse 1 was 45%, and for vinasse 2 was 57%, after 52 days of incubation. For the double concentration (10%), vinasse 1 and vinasse 2 were degraded by 28% and 68%, respectively (52 days).

Microorganisms

After 24 h (bacteria, Fig. 3a) and 120 h (fungi, Fig. 3b) of incubation, microorganisms were counted. The presence of vinasses under all concentrations conditioned in soil potentiated the growth of bacteria and fungi compared to the soil without the addition of vinasses (control).

Total bacteria quantification (A) and fungi quantification (B) (CFU g−1) in the soil before and after biodegradation of control (only soil), and two vinasses from 2GE, non-detoxified (vinasse 1) and detoxified (vinasse 2), at concentrations of 2.5, 5 and 10% during 52 days at 28 °C, in Bartha and Pramer respirometric system. The symbols represented the mean and the vertical lines the standard deviation (n = 3)

Bacteria quantification showed that the detoxified vinasse presented a better bacterial growth rate in all concentrations tested (Fig. 3a). The most representative difference (23%, P > 0.000003) was observed in the vinasse at the level of 5%. Considering the total bacteria count per gram of soil (4.9 × 104 CFU.g−1 / 52 days), the quantification for the 2.5% sample was more representative, with a 7.6% variation among the vinasses (P > 0.003). With a concentration of 10 %, the difference observed was 5.7% (P > 0.024). Thus, the total of bacteria was significantly higher in soil with detoxified vinasse (P values).

The detoxified vinasse favored the growth of fungi colonies (Fig. 3b). Vinasse 2 facilitated fungi growth at the concentration of 2.5% (22% of difference, P > 0.0001) and 5.0% (40% of difference, P > 0.002), presenting the highest stimulus (64%) at the level of 10%.

Bioassays with Lactuca sativa

Data obtained for germination (%), root growth (mm), and phytotoxicity rate (%) for the assays with L. sativa are presented in Table 3. Both vinasse at 2.5% showed no difference in germination and root growth when compared to the negative control. On the other hand, at 5 and 10%, there was a sublethal effect with delayed root growth (mean: 74 and 95%). The vinasse 1 (non-detoxified) was more toxic in both concentrations: 6.3% (P: 0.04275) and 2.7% (P: 0.01139), respectively.

Bioassays with Daphnia similis

Based on the statistical results of the toxicity tests with D. similis after 48 h of exposure, vinasse 1 and 2 presented a CE50 of 4.13% (3,83–4,46) and 4.74%, respectively, with a significant difference (P: 0.034).

Physicochemical characterization was performed at the beginning (t0) and the end (t48) of the assays (Supplementary File, B), showing little variation (P > 0.05) when the vinasses samples were compared in the different periods.

Discussion

Based on the statistical analysis of the vinasses physicochemical data (Table 2), the detoxification process did not significantly differentiate the parameters evaluated (P > 0.05), except for the nitrate present in greater quantity in vinasse 1. According to Candido et al. (2020), the detoxification performed with S. cerevisiae living cells enables the absorption/metabolization of furan derivatives (48%) and organic acids (12%) present in the sugarcane bagasse acid hydrolysate. With vinasses physicochemical characterization (Table 2), it is possible to verify that the quantity of organic material is higher compared to 1GE vinasse (Mariano et al. 2009; Coelho et al. 2018). These data are in agreement with those obtained by Gruposo Silveira et al. (2012), showing that 2GE (traditional vinasses – glucose fermentation) vinasse composition presents a considerable quantity of organic material, similar to the results found in this study (Table 2). In contrast, sulfate and potassium concentration was significantly higher in the present study. These results are probably due to supplementation with sugarcane molasses (rich in minerals) from the hydrolyzed must (sugarcane bagasse (hemicellulose) acid hydrolysate) before fermentation.

There is a wide variety of processes that can be used in the pretreatment of lignocellulosic materials (Kumar and Sharma 2017; Melati et al. 2019). Supplementation with hydrolyzed is another fundamental point in the process, which can directly imply the differentiation of vinasse composition. Sulfate presence in molasses is due to the use of sulfuric acid for bacterial control in alcoholic fermentation. Minerals such as potassium, phosphorus, and magnesium are introduced during sugar processing. This process is performed in stages, as well as the clarification with magnesium, carbonation with calcium, and phosphating with phosphoric acid (Moraes et al. 2015). These minerals justify one of the main applications of vinasse, the fertigation. Knowing vinasse composition is fundamental to defining better strategies for its destination, mitigating environmental impacts, and enhancing the sugar and alcohol production results. Physicochemical analysis of non-detoxified and detoxified vinasses (Table 2) shows a suitable medium for agriculture because of their nutrient content (nitrogen, phosphorous, and potassium). On the other hand, there are problems associated with environmental impacts caused by the excessive introduction of these compounds, as with 1GE vinasse. Therefore, other forms of allocation should be evaluated (Moraes et al. 2015).

A biodegradation study is essential to evaluate vinasse application in soil. CO2 accumulation in biodegradation of both vinasses (Fig. 1) showed to be directly proportional to the vinasses concentration. However, the analysis of biodegradation efficiency indicates that the vinasses at the level of 2.5% present better biodegradability, reaching 82% after 52 days of evaluation (Table 3). The data also show that detoxification improved biodegradation efficiency in detoxified vinasse at concentrations of 2.5 and 5% compared with non-detoxified vinasse. Despite being a bench test, these data are essential to establish dosage control for the use of vinasse in some cultures, as with 1GE vinasse. In Brazil, its use is widespread in the cultivation of sugarcane. On the other hand, data obtained in the laboratory may differ from those obtained in natural systems. Also, certain environmental conditions can decrease or enhance the action of a compound on a given organism. Therefore, it is recommended that further studies should be implemented to better understand the action of vinasse in environmental compartments.

In a biodegradation study, Ribeiro et al. (2017) verified that the anaerobic biodegradation (Upflow Anaerobic Sludge Blanket, UASB, reactor) of the liquid fraction, obtained from the sugarcane bagasse by hydrothermal pretreatment, reaches high degradation rates, such as the 86% of COD remotion. Furthermore, this type of pretreatment is associated with the low formation of toxic compounds, like furfural and 5-hydroxymethyl-furfural, which may be one of the reasons for the high efficiency in biodegradation. Another study using a respirometric test to check the biodegradation of 1GE vinasse shows an average efficiency of 90% in 50 days of testing (Almeida et al. 2013).

The presence of metals, organic acids, and compounds such as furan derivatives may be among the leading causes of inefficiency in the biodegradation of crude or high-content vinasses (Wilkie et al. 2000). These features are accentuated in 2GE vinasse (hemicellulose), explaining the decrease in biodegradation efficiency in non-detoxified vinasse at concentrations 5 and 10% (Fig. 2). The physicochemical characterization of these compounds (present in the acid hydrolysate) was previously published in a study by our group (Candido et al. 2020). The presence of these compounds remains stable or little changed in the vinasse obtained from the fermentation process.

In general, the vinasses in soil potentiated the growth of bacteria and fungi, especially the detoxified vinasse (evidenced by CO2 production). However, biodegradation efficiency is calculated based on the initial and final quantity of carbon released from the soil. Thus, the addition of 10% vinasse to the soil considerably increased the CO2 production, but the amount of remaining carbon was higher, affecting biodegradation’s efficiency.

Vinasses 1 and 2 toxicity was analyzed using a terrestrial (L. sativa) and an aquatic (D. similis) test-organisms. After 120 h of exposing L. sativa to concentrations of ≥5% of vinasse, their root growth suffered considerable impairments (>70%). One of the reasons for lower root growth (L. sativa) under higher vinasse concentrations (5 and 10%) is the liquid fraction’s quality from acid hydrolysates from which the vinasse was obtained. The compounds associated with the acid hydrolysate were previously determined before and after the biological detoxification process that proved to be efficient in removing these compounds (Candido et al. 2020). It is likely that the removal of part of the compounds present in the acid hydrolysate allowed lower phytotoxicity values when comparing vinasse 1 and 2 in the concentration at 5 and 10% (Tab 3).

In levels above 14% (preliminary tests - data not shown), vinasse 1 and 2 have a lethal effect in L. sativa, with irreversibility in germination. The delay in root growth (< 5 mm) indicates a sublethal response since some concentrations are not sufficient to inhibit germination (Sobrero and Ronco 2004). Tests with L. sativa play an essential role in the evaluation of 2GE vinasse in the environment, which could also impair similar vegetation.

In toxicity tests with D. similis, the EC50 values for the non-detoxified vinasse (4.1%) show that the vinasse from 2GE (from sugarcane hemicellulose acid hydrolysate), under the conditions tested, was less toxic than the 1GE vinasse (EC50: 2.2%) obtained by Ferreira et al. (2011). Another study was reported by Velásquez-Riaño et al. (2019), who investigated the effects against D. magna of vinasse 1GE; in this study, the authors found EC50 (48 h) at a concentration of 4.7%. The findings showed that these vinasses (levels: 2.2–4.7%) could affect primary consumers present in natural aquatic systems.

In bioassays, the control of abiotic factors (conductivity, dissolved oxygen, pH, and temperature) is essential, as they can compromise the results obtained. The abiotic parameters quantified during the bioassay had little oscillation between the beginning and the end of the tests (P > 0.05). These results did not reflect changes in the monitored physicochemical parameters. The toxicity answer is also not due to their variations but to the effect of vinasse on them.

The authors suggest that further studies should be performed to verify the possibility of impacts on environmental compartments, mainly on the soil. We recommend implementing full-scale studies. Due to the complexity of extrapolating data obtained in the laboratory, it is necessary to consider interferences that can be fundamental to potentiate or minimize the toxicity of vinasse in the environment. Although the assay’s results indicate the application of this byproduct in the lettuce (up to 2.5%), its application in the soil depends on further studies.

Conclusion

Investigation of two vinasses (1, before; and 2, after detoxification) from fermented sugarcane bagasse (hemicellulose fraction) acid hydrolysate show gains in biodegradation, by the Bartha and Pramer system, of detoxified vinasse related to the non-detoxified (2%), with COD removal higher than 80% at a concentration up to 2.5% (52 days of evaluation). In this same concentration, the phytotoxicity test suggest that detoxified and non-detoxified vinasses can be applied without prejudice to the development of L. sativa, on the other hand concentrations of 5 and 10% showed sublethal effect with delayed root growth. For aquatic environments, bioassays with D. similis showed that sublethal doses occur at relatively low levels (4.5%), signaling the importance of reducing vinasse concentration when its application has the possibility of surface runoff to water bodies. The trials also show that the physicochemical composition of 2GE vinasse is strictly dependent on the biomass origin and the additives used in its production process.

Data availability

Data available on request from the authors.

References

Almeida LM de (2006) Crustacea. In: Ribeiro-Costa CR, Rocha RM (Coords). Invertebrados: Manual de Aulas Práticas. Ribeirão Preto: Editora Holos, 2. ed. p. 144.e145

Almeida NC, Tomasella RC, Govone S, Kinjo S, Angelis DF (2013) Study of stillage biodegradation by respirometry in sandy and clay soils. Afr J Agric 8:35

Alves PRL, Estrada-Bonilla GA, Bini D, Cardoso EJBN (2019) Changes in the microbial metabolism of agricultural tropical soils amended with sugarcane vinasses. Sugar Tech 21(2):364–369

AOAC - Association Official Analytical Chemist (2005) Official Methods of Analysis, 18th edn. AOAC International, Gaitherburg, MD

Aparicio JD, Benimeli CS, Almeida, Polti MA, Colin VL (2017) Integral use of sugarcane vinasse for biomass production of actinobacteria: potential application in soil remediation. Chemosphere 181:478–484

APHA Standard methods for the examination of water and wastewater (1998) American Public Health Association/American Water Works Association / Water Environment Federation, 20. ed. Washington, DC, USA

APHA Standard methods for the examination of water and wastewater (2012) American Public Health Association/American Water Works Association / Water Environment Federation, 22. ed. Washington, DC, USA

Baeyens J, Kang Q, Appels L, Dewil R, Yongqin LV, Tan T (2015) Challenges and opportunities in improving the production of bio-ethanol. Prog Energ Combust 47:60–88

Bartha R, Pramer D (1965) Features of flask and method for measuring the persistence and biological effects of pesticides in soil. Soil Sci 100(1):68–70

Buratini SV, Bertoletti E, Zagatto PA (2004) Evaluation of Daphnia similis as a test species in ecotoxicological assays. Bull Environ Contam Toxicol 73:878–882

Candido JP, Claro EMT, de Paula CBC, Shimizu FL, Leite DANO, Brienzo M, Angelis DF (2020) Detoxification of sugarcane bagasse hydrolysate with different adsorbents to improve the fermentative process. World J Microb Biot 36:43

CETESB. Environmental Sanitation and Technology Company (1984) Soil-collection and sample preparation procedures. São Paulo: Technical Standard L6. 245

Christofoletti CA, Pedro-Escher J, Correia JE, Marinho JFU, Fontanetti CS (2013) Sugar cane vinasse: environmental implications of its use. Waste Manag 33:2752–2761

Coelho MPM, Correia JE, Vasquesa LI, Marcato ACC, Guedes TA, Sotob MA, Bassob JB, Kiang C, Fontanetti CS (2018) Toxicity evaluation of leached of sugarcane vinasse: histopathology and immunostaining of cellular stress protein. Ecotox Environ Safe 165:367–375

de Almeida, LM, Crustacea (2006) Invertebrados: Manual de Aulas Práticas, 2nd edn. In: Ribeiro-Costa, C.R.; Rocha, R.M. (Coords). Ribeirão Preto: Editora Holos, p. 144e–145

EPA / U.S. Environmental Protection Agency (1996) Ecological Effects Test Guidelines OPPTS850.4200 Seed Germination/Root Elongation Toxicity Test. 712c, 96–154

España-Gamboa E, Mijangos-Cortes J, Barahona-Perez L, Dominguez- Maldonado J, Hernández-Zarate G, Alzate-Gaviria L (2011) Vinasses: characterization and treatments. Waste Manage Res 29:1235–1250

Ferreira LFR, Aguiar MM, Messias TG, Pompeu GB, Lopez AMG, Silva DP, Monteiro RT (2011) Evaluation of sugar-cane vinasse treated with Pleurotus sajor-caju utilizing aquatic organisms as toxicological indicators. Ecotox Environ Safe 74(1):132–137

Goldin A (1987) Reassessing the use of loss-on-ignition for estimating organic matter content in noncalcareous soils. Commun Soil Sci Plant Anal 18:1111–1116

Gruposo Silveira, CJ, Melo Santa Anna, LM, Machado de Castro, A, Nogueira Moyses, D, Da Conceição Gomes, A, Martins Bandeira, LF, Cammarota, MC, De Carvalho Alves, L, Camporese Sérvulo, EF (2012) Method for producing energy-rich gases from lignocellulosic material streams. Patent Process: WO 2012/003556 Al

Gutiérrez-Rivera B, Ortiz-Muniz B, Gómez-Rodríguez J, Cárdenas-Cagal A, González JMD, Aguilar-Uscanga MG (2015) Bioethanol production from hydrolyzed sugarcane bagasse supplemented with molasses “B” in a mixed yeast culture. Renew Energ 74:399–405

Hamilton MA, Russo RC, Thurfton RB (1977) Trimmed Spearman-Karber method for estimating median lethal concentration in toxicity bioassays. Environ Sci Technol 11:714–719

Hoarau J, Caro Y, Grondin I, Petit T (2018) Sugarcane vinasse processing: toward a status shift from waste to valuable resource a review J Water Process Eng 24:11–25

ISO 11269-2, (1995) Soil quality-determination of the effects of pollutants on soil flora. Part 2: effects of chemicals on the emergence of higher plants. International Organization for Standardization, Genève, Switzerland

Kumar, AK, Sharma, S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess. 4 (7)

Lutterbeck CA, kern DI, Machado EL, Kummerer K (2015) Evaluation of the toxic effects of four anti-cancer drugs in plant bioassays and its potency for screening in the context of waste water reuse for irrigation. Chemosphere 35:403–410

Lyu J, Park J, Pandey KL, Choi S, Lee H, De Saeger J, Depuydt S, Han T (2018) Testing the toxicity of metals, phenol, effluents, and receiving waters by root elongation in Lactuca sativa L. Ecotoxicol Environ Saf 149:225–232

Madejón E, López R, Murillo JM, Cabrera F (2001) Agricultural use of three (sugar- beet) vinasse composts: effect on crop sand chemical properties of a Cambisol soil in the Guadalquivir river valley (SW Spain). Agric Ecosyst Environ 84:55–65

Mariano AP, Crivelaro SHR, Angelis DF, Bonotto DM (2009) The use of vinasse as an amendment to ex-situ bioremediation of soil and ground-water contaminated with diesel oil. Braz Arch Biol Technol 52:1043–1055

Melati RB, Shimizu FL, Oliveira G, Pagnocca FC, Souza W, Sant’Anna C, Brienzo M (2019) Key factors affecting the recalcitrance and conversion process of biomass. BioEnergy Res 12:1–20

Messetti MA, da Silva JA, Santos MG, Govone JS, Angelis DF (2017) Biodegradation and toxicity of waste from anaerobic fermentation of stillage. Afr J Biotechnol 16(37):1863–1870

Milanez AY, Nyko D, Valente MS, Sousa LC, Bonomi AMFLJ, Jesus CDF, Watanabe MDB, Chagas MF, Rezende MCAF, Cavalett O, Junqueira TL, Gouvêia VLR (2015) De promessa a realidade: como o etanol celulósico pode revolucionar a indústria da cana-de-açúcar: uma avaliação do potencial competitivo e sugestões de política pública. BNDES Setorial, Rio de Janeiro 41:237–294

Moraes BS, Petersen SO, Zaia TM, Sommer SG, Triolo JM (2017) Reduction in greenhouse gas emissions from vinasse through anaerobic digestion. Appl Energy 189:21–30

Moraes BS, Zaia TM, Bonomi A (2015) Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: challenges and perspectives. Renew Sust Energ Rev 44:888–903

OECD - Organization for Economic Cooperation and Development. Guideline 307., 2002. Guideline for the Testing of Chemicals. Aerobic and Anaerobic Transformation in Soil. OECD

OECD - Organization for Economic Cooperation and Development. Guideline 208., 2003. Terrestrial Plant Test: 208; Seedling Emergence and Seedling Growth Test. OECD

OECD - Organization for Economic Cooperation and Development. Guideline 317., 2010. Guideline for the Testing of Chemicals. Bioaccumulation in Terrestrial Oligochaetes. OECD

Parnaudeau V, Condom N, Oliver R, Cazevieille P, Recous S (2008) Vinasse organic matter quality and mineralization potential, as in fluenced by raw material, fermentation and concentration processes. Bioresour Technol 99:1553–1562

Ribeiro BT, Lima JMD, Guilherme LRG, Julião LGF (2010) Lead sorption and leaching from an Inceptisol sample amended with sugarcane vinasse. Sci Agric 67:441–447

Ribeiro FR, Passos F, Gurgel LVA, Baêta BEL, Aquino SF (2017) Anaerobic digestion of hemicellulose hydrolysate produced after hydrothermal pretreatment of sugarcane bagasse in UASB reactor. Sci Total Environ 584-585:1108–1113

Rodrigues Reis CE, Hu B (2017) Vinasse from sugarcane ethanol production: better treatment or better utilization?. Front Energy Res 5:2017

Régo APJ, Reganhan-Coneglian CM, Montagnolli RN, Bidoia ED (2014) CO2 production of soil microbiota in the presence of Ametryne and Biofertilizer Water Air Soil Pollut 225:2222

Silva MAS, Griebeler NP, Borges LC (2007) Uso de vinhaça e impactos nas propriedades do solo e lençol freático. Rev Bras Eng Agríc v.11:108–114

Silva-Fernandes T, Santos JC, Hasmann F, Rodrigues RCLB, Izario Filho HJ, Felipe MGA (2017) Biodegradable alternative for removing toxic compounds from sugarcane bagasse hemicellulosic hydrolysates for valorization in biorefineries. Biores Technol 243:384–392

Sobrero MC, Ronco A (2004) Ensayo de toxicidad aguda con semillas de lechuga (Lactuca sativa L.). In: G Castillo (ed.) Ensayos toxicológicos y métodos de evaluación de calidad de aguas. Estandarización, intercalibración, resultados y aplicaciones. Canadá: IDRC/IMTA. p. 490, 71–79

Stambuk BU, Eleutherio ECA, Florez-Pardo LM, Souto-Maior AM, Bom EPS (2008) Brazilian Potencial for biomass ethanol: challenge of using hexose and pentose co-fermentation yeast strains. J Sci Ind Res 67:918–926

Vallejos ME, Chade M, Mereles EB, Bengoechea DI, Brizuela JG, Felissia FE, Area MC (2016) Strategies of detoxification and fermentation for biotechnological production of xylitol from sugarcane bagasse. Ind Crop Prod 91:161–169

Velásquez-Riaño M, Meneses-Sánchez JS, Carvajal Arias CE (2019) Evaluation of acute toxicity of vinasse by means of Daphnia magna and Aliivibrio fischeri: a comparative study Interdiscip. Toxicol 12(3):143–148

Wilkie AC, Riedesel KJ, Owens JM (2000) Stillage characterization and anaerobic treatment of ethanolstillage from conventional and cellulosic feedstocks. Biomass Bioenerg 19:63–102

Zagatto PA, Bertoletti E (2008) Ecotoxicologia Aquática – Princípios e Aplicações. 2° Ed. São Carlos, SP. RiMA, 486 p

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. The authros are thankfull to the São Paulo Research Foundation (FAPESP, grant 2017/22401-8).

Author information

Authors and Affiliations

Contributions

DFA, DNOL and MB contributed to the study conception and design. JPC and ECA performed the study, analyzed the data and drafted the paper. DFA, DNOL and MB contributed to and approved the final paper. All authors commented on previous versions of the paper. All authors read and approved the final paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Animal research

All applicable international, national, and/or institutional guidelines for the care and use of animals were followed.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Candido, J.P., Almeida, É.C., de Oliveira Leite, D.N. et al. Vinasse from sugarcane bagasse (hemicellulose) acid hydrolysate and molasses supplemented: biodegradability and toxicity. Ecotoxicology 30, 818–827 (2021). https://doi.org/10.1007/s10646-021-02401-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10646-021-02401-w