Abstract

Purpose

The main goal of this work is to evaluate the environmental impact of a 63-m blade for wind generators. The embodied energy and the carbon footprint are used as supporting tools for material selection in the initial project stages.

Methods

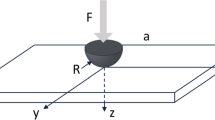

Real industrial data regarding the most used materials for wind turbine blade construction are used. Two eco-parameters, embodied energy and carbon footprint, were calculated from each selected material together with values of manufacture, transport, use, and final disposal. The blades must be built to have a mechanical strength high enough to withstand vibrations caused by manufacturing flaws, turbulence, or irregular loading. In this sense, Young’s modulus, yield strength, and density were compared to the environmental footprint data to support the final material choice. This evaluation process of the possible materials to be used in the blade manufacture was carried out in the initial stages of the project.

Results

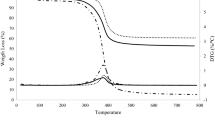

Composite materials such as glass fiber-reinforced polymer (GFRP) and carbon fiber-reinforced polymer (CFRP), bonded together with an adhesive material, are used to build modern wind turbine blades. Those composites comprise a considerable number of different materials that can be mixed to reach adequate performance. Comparisons were made with 46 pre-selected materials, considering the mechanical behavior and environmental impacts. The final selected materials have better properties than the reference material. Finally, two materials with the desired mechanical properties and with a potential lower negative environmental impact than the reference material were selected.

Conclusions

Replacing the reference resin—epoxy/E-glass fiber—with the epoxy resin with the lowest environmental impact—epoxy/S-glass fiber—will reduce the total value of the environmental load to 102 GJ of energy and 3.4 t of CO2. As important as the material selection in the early stages of product development is the end of life (EoL) choice. In this case, the glass fiber has an EoL potential of 370 GJ of energy and 460 t of CO2 in the remanufacturing option, against zero for the landfill. This work shows that carefully selected raw materials and EoL alternatives for WTB can significantly reduce the environmental impact of this component.

Similar content being viewed by others

References

Ashby MF (2009) Materials and the Environment: Eco-informed Material Choice. Butterworth-Heinemann, Burlington

Beauson J, Lilholt H, Brondsted P (2014) Recycling solid residues recovered from glass fibre-reinforced composites – a review applied to wind turbine blade materials. J Reinf Plast Comp 33:1542–1556

Bonou A, Laurent A, Olsen SI (2016) Life cycle assessment of onshore and offshore wind energy – from theory to application. Appl Energy 180:327–337. https://doi.org/10.1016/j.apenergy.2016.07.058

Chang B, Starcher K (2019) Evaluation of wind and solar energy investments in Texas. Renew Energy 132:1348–1359

Cousins DS, Suzukia Y, Murray RE, Samaniuk JR, Stebner AP (2018) Recycling glass fiber thermoplastic composites from wind turbine blades. J Clean Prod 209:1252–1263

Davidsson S, Höök M, Wall G (2012) A review of life cycle assessments on wind energy systems. Int J Life Cycle Ass 17:729–742

Garrett P, Rønde K (2013) Life cycle assessment of wind power: comprehensive results from a state-of-the-art approach. Int J Life Cycle Ass 18:37–48

Guangxing Wu, Zhang C, Cai C, Yang Ke, Shi K (2020) Uncertainty prediction on the angle of attack of wind turbine blades based on the field measurements. Energ 200:117515–117526

Jensen JP, Skelton K (2018) Wind turbine blade recycling: experiences, challenges and possibilities in a circular economy. Renew Sust Energy Rev 97:165–176

Kerstin B (2013) Oebels, Sergio Pacca, Life cycle assessment of an onshore wind farm located at the northeastern coast of Brazil. Renew Energy 53:60–70

Liu Pu, Meng F, Barlow CY (2019) Wind turbine blade end-of-life options: an eco-audit comparison. J Clean Prod 212:1268–1281

Martínez E, Sanz F, Pellegrini S, Jiménez E, Blanco J (2009) Life-cycle assessment of a 2-MW rated power wind turbine: CML method. Int J Life Cycle Ass 14:52–63

Ming-Sung Wu, Bo Cheng Jin, Xin Li & Steven Nutt (2019) A recyclable epoxy for composite wind turbine blades. Adv Manuf Polym Compos Sci 5(3):114–127

Morini AA, Ribeiro MJ (2019) Dachamir Hotza, Early-stage materials selection based on embodied energy and carbon footprint. Mater Design 178:107861–107874

Nicoletti R, Liebich R (2018) Analysis of long wind turbine blades with shape memory alloy wires in super-elastic phase. J Intel Mat Syst Str 29:3108–3123

Robynne E. Murray, Jason Roadman, Ryan Beach (2019) Fusion joining of thermoplastic composite wind turbine blades: Lap-shear bond characterization. Renew Energy 501–512

Tazi N, Kim J, Bouzidi Y, Chatelet E, Liu G (2019) Waste and material flow analysis in the end-of-life wind energy system. Resour Conserv Recycl 145:199–207

The Granta Selector Eco Audit Tool (2020) Granta Design Ltd

Ying Du, Zhou S, Jing X, Peng Y, Hongkun Wu, Kwok N (2020) Damage detection techniques for wind turbine blades: a review. Mech Syst Signal Pr 141:106445–106467

Zhao Q, Yuan Y, Sun W, Fan X, Fan P, Ma Z (2020) Reliability analysis of wind turbine blades based on non-Gaussian wind load impact competition failure model. Measurement 164:107950–107964

Zhu J, Zhou Z, Cai X (2020) Multi-objective aerodynamic and structural integrated optimization design of wind turbines at the system level through a coupled bladetower model. Renew Energy 150:523–537

Acknowledgements

The authors acknowledge the support of the National Council for Scientific and Technological Development (CNPq, Brazil) and the Coordination for the Improvement of Higher Education Personnel (CAPES, Brazil) as well as of the Foundation for Science and Technology (FCT, Portugal). Particularly, the authors are grateful to CAPES-PrInt, project number 88881.310728/2018-01.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Matthias Finkbeiner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morini, A.A., Ribeiro, M.J. & Hotza, D. Carbon footprint and embodied energy of a wind turbine blade—a case study. Int J Life Cycle Assess 26, 1177–1187 (2021). https://doi.org/10.1007/s11367-021-01907-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-021-01907-z