Abstract

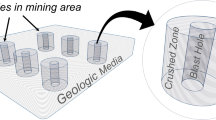

The dynamic mechanical properties of ore rock are important in blast designs and support designs for underground mines. However, few studies have focused on ore rock with varying grade, and the application of such studies to production in underground mines is rather limited. In this study, Split Hopkinson pressure bar (SHPB) tests were conducted on ore rock with varying grades. Images were recorded using high-speed cameras, and a digital image correlation method was used to reveal the process of compressive stress wave propagation and crack development during the tests. Experimental SHPB tests were also simulated using particle flow code, which reproduced the main dynamic characteristics of ore rock subjected to these tests. Blast simulation was induced by ball expansion, and a large-scale rock–backfill model was used to assess the effect of stress waves induced by blasting on backfills. Results revealed the relation between content of metallic minerals and the dynamic mechanical behavior of ore rock with varying grade. Response surface analysis for achieving a balance between safety and profit provided a basis for optimizing the burden between the bottom of blast holes and backfills in underground mines, especially for ore rock with varying grade.

Similar content being viewed by others

References

Bakhtavar E (2015) The practicable combination of open pit with underground mining methods—a decade’s experience. In: Proceedings of the 24th international mining congress and exhibition of Turkey (IMCET). Antalya, Turkey, pp 704–709

Bakhtavar E, Abdollahisharif J, Aminzadeh A (2017) A stochastic mathematical model for determination of transition time in the non-simultaneous case of surface and underground mining. J S Afr Inst Min Metall 117:1145–1153

Brady BH, Brown ET (2006) Rock mechanics: for underground mining 3rd. Springer, Berlin

Liu B, Gao YT, Jin AB, Elmo D (2020) Fracture characteristics of orebody rock with varied grade under dynamic Brazilian tests. Rock Mech Rock Eng 53:2381–2398

Bakhtavar E, Shirvand Y (2019) Designing a fuzzy cognitive map to evaluate drilling and blasting problems of the tunneling projects in Iran. Eng Comput 35:35–45

Zhang Z, Gao W, Li K, Li B (2020) Numerical simulation of rock mass blasting using particle flow code and particle expansion loading algorithm. Simul Model Pract Theory 104:102119

Hasanipanah M, Bakhshandeh Amnieh H (2020) Developing a new uncertain rule-based fuzzy approach for evaluating the blast-induced backbreak. Eng Comput. https://doi.org/10.1007/s00366-019-00919-6

Tedesco JW, Ross CA (1998) Strain-rate-dependent constitutive equations for concrete. J Press Vessel Technol Trans ASME 120:398–405

Zhao J, Zhou YX, Hefny AM et al (1999) Rock dynamics research related to cavern development for ammunition storage. Tunn Undergr Sp Technol 14:513–526

Demirdag S, Tufekci K, Kayacan R et al (2010) Dynamic mechanical behavior of some carbonate rocks. Int J Rock Mech Min Sci 47:307–312

Gao G, Huang S, Xia K, Li Z (2015) Application of digital image correlation (DIC) in dynamic notched semi-circular bend (NSCB) tests. Exp Mech 55:95–104

Xing HZ, Zhang QB, Ruan D et al (2018) Full-field measurement and fracture characterisations of rocks under dynamic loads using high-speed three-dimensional digital image correlation. Int J Impact Eng 113:61–72

Chen R, Dai F, Qin J, Lu F (2013) Flattened Brazilian disc method for determining the dynamic tensile stress–strain curve of low strength brittle solids. Exp Mech 53:1153–1159

Lu YB, Li QM, Ma GW (2010) Numerical investigation of the dynamic compressive strength of rocks based on split Hopkinson pressure bar tests. Int J Rock Mech Min Sci 47:829–838

Xu Y, Dai F, Xu NW, Zhao T (2016) Numerical investigation of dynamic rock fracture toughness determination using a semi-circular bend specimen in split Hopkinson pressure bar testing. Rock Mech Rock Eng 49:731–745

Gharehdash S, Shen L, Gan Y (2020) Numerical study on mechanical and hydraulic behaviour of blast-induced fractured rock. Eng Comput 36:915–929

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29:47–65

Potyondy D (2011) Parallel-bond refinements to match macroproperties of hard rock. In: Proceedings of the second international FLAC/DEM symposium. Melbourne: Minneapolis, Itasca, pp 459–465

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Zhang XP, Wong LNY (2012) Cracking processes in rock-like material containing a single flaw under uniaxial compression: a numerical study based on parallel bonded-particle model approach. Rock Mech Rock Eng 45:711–737

Yu TR, Counter DB (1983) Backfill practice and technology at Kidd creek mines. CIM Bull 76:56–65

Suazo G, Villavicencio G (2018) Numerical simulation of the blast response of cemented paste backfilled stopes. Comput Geotech 100:1–14

Emad MZ, Mitri H, Kelly C (2014) Effect of blast-induced vibrations on fill failure in vertical block mining with delayed backfill. Can Geotech J 51:975–983

Emad MZ, Mitri H, Kelly C (2018) Dynamic model validation using blast vibration monitoring in mine backfill. Int J Rock Mech Min Sci 107:48–54

Emad MZ, Mitri HS, Henning JG (2012) Effect of blast vibrations on the stability of cemented rockfill. Int J Min Reclam Environ 26:233–243

Wu S, Xu X (2016) A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech Rock Eng 49:1813–1830

Liu B, Gao YT, Jin AB, Wang X (2020) Dynamic characteristics of superfine tailings–blast furnace slag backfill featuring filling surface. Constr Build Mater 242:118173

Sun W, Wang H, Hou K (2018) Control of waste rock-tailings paste backfill for active mining subsidence areas. J Clean Prod 171:567–579

Bakhtavar E, Yousefi S (2019) Analysis of ground vibration risk on mine infrastructures: integrating fuzzy slack-based measure model and failure effects analysis. Int J Environ Sci Technol 16:6065–6076

Liu B, Gao YT, Jin AB, Wang X (2020) Influence of water loss on mechanical properties of superfine tailing–blast-furnace slag backfill. Constr Build Mater 246:118482

Rodriguez A, Laio A (2014) Clustering by fast search and find of density peaks. Science 344:1492–1496

Liu B, Zhou Y, Gao YT, Xu C (2020) Experimental and numerical study on crack development characteristics between two cavities in rock-like material under uniaxial compression. Theor Appl Fract Mec 109:102755

Ba D, Boyaci IH (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78:836–845

Yolmeh M, Jafari SM (2017) Applications of response surface methodology in the food industry processes. Food Bioprocess Technol 10:413–433

Danmaliki GI, Saleh TA, Shamsuddeen AA (2017) Response surface methodology optimization of adsorptive desulfurization on nickel/activated carbon. Chem Eng J 313:993–1003

Funding

This research was supported by National Natural Science Foundation of China (Grant 51674015) and China Scholarship Council (Grant 201806460044).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, B., Gao, YT. & Jin, AB. Dynamic mechanical properties of an ore rock with varying grade and engineering applications in mines. Engineering with Computers 38 (Suppl 3), 2433–2445 (2022). https://doi.org/10.1007/s00366-021-01394-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-021-01394-8