Abstract

One of the main goals of polymer science has been to relate the process variable to their vital macroscopic properties in order to obtain tailor-made products. In particular, this goal is significant when we have to use a catalyst that has a unique and unknown behavior with its own complex kinetics such as a Ziegler–Natta catalyst for polypropylene production. Today, computer simulation with acceptable accuracy has come to the aid of polymer science. The final product properties are highly dependent on the crucial factors comprising the average molecular weight, its dispersity, and bulk density of a polymer, and these factors also depend on process variables with the complexity of a kinetic reaction. A mathematical model can be a worthy replacement to the conventional manner, experiment by trial and error, for designing a favorite product. In this study, a mathematical model is proposed to fulfill this aim. By the model with its offered algorithm, kinetic constants can be easily adjusted with fairly good prediction of the desired product. The modeling approach is a polymer moment balance technique (population balance) in a slurry semibatch reactor and coded in MATLAB/SIMULINK software. The model has been validated via experimental data from a laboratory scale reactor with an acceptable margin of error.

Similar content being viewed by others

REFERENCES

Ceresana, Market study: Polypropylene (4th ed.). https://www.ceresana.com/en/market-studies/plastics/polypropylene. Accessed July 20, 2018.

Varshouee, G.H., Heydarinasab, A., Shaheen, U., Aborehab, M.A.S., Vaziri, A., El Ouadi, Y., Roozbahani, B., Bouyanzer, A., Hammouti, B., and Hadda, T.B., Hydrogen effect modeling on Ziegler-Natta catalyst and final product properties in propylene polymerization, Bull. Chem. Soc. Ethiop., 2018, vol. 32, no. 2, pp. 371–386.

Ali, M.A., Betlem, B., Roffel, B., and Weickert, G., Hydrogen response in liquid propylene polymerization: Towards a generalized model, AIChE J., 2006, vol. 52, no. 5, pp. 1866–1876 . https://doi.org/10.1002/aic.10783

Pater, J.T., Weickert, G., and van Swaaij, W.P., Polymerization of liquid propylene with a 4th generation Ziegler–Natta catalyst—Influence of temperature, hydrogen and monomer concentration and prepolymerization method on polymerization kinetics, Chem. Eng. Sci., 2002, vol. 57, no. 16, pp. 3461–3477.

Shimizu, F., Pater, J., van Swaaij, W.P., and Weickert, G., Kinetic study of a highly active MgCl2-supported Ziegler–Natta catalyst in liquid pool propylene polymerization. II. The influence of alkyl aluminum and alkoxysilane on catalyst activation and deactivation, J. Appl. Polym. Sci., 2002, vol. 83, no. 12, pp. 2669–2679.

Reginato, A.S., Zacca, J.J., and Secchi, A.R., Modeling and simulation of propylene polymerization in nonideal loop reactors, AIChE J., 2003, vol. 49, no. 10, pp. 2642–2654.

Luo, Z.H., Zheng, Y., Cao, Z.K., and Wen, S.H., Mathematical modeling of the molecular weight distribution of polypropylene produced in a loop reactor, Polym. Eng. Sci., 2007, vol. 47, no. 10, pp. 1643–1649.

Chatzidoukas, C., Perkins, J.D., Pistikopoulos, E.N., and Kiparissides, C., Optimal grade transition and selection of closed-loop controllers in a gas-phase olefin polymerization fluidized bed reactor, Chem. Eng. Sci., 2003, vol. 58, no. 16, pp. 3643–3658.

Samson, J.J.C., Bosman, P.J., Weickert, G., and Westerterp, K.R., Liquid-phase polymerization of propylene with a highly active Ziegler–Natta catalyst: Influence of hydrogen, cocatalyst, and electron donor on the reaction kinetics, J. Polym. Sci., Part A: Polym. Chem., 1999, vol. 37, no. 2, pp. 219–232.

Yang, X.F., Zheng, T., Che, L.M., and Luo, Z. H., A dynamically distributed reactor model for identifying the flow fields in industrial loop propylene polymerization reactors, J. Appl. Polym. Sci., 2013, vol. 128, no. 6, pp. 4302–4313.

Zhu, Y.P., Luo, Z.H., and Xiao, J., Multi-scale product property model of polypropylene produced in a FBR: From chemical process engineering to product engineering, Comput. Chem. Eng., 2014, vol. 71, pp. 39–51.

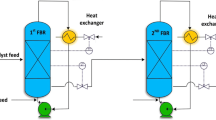

Kim, S.H., Baek, S.W., Lee, J.C., Lee, W.J., Hong, S.U., and Oh, M., Dynamic simulation of liquid polymerization reactors in Sheripol process for polypropylene, J. Ind. Eng. Chem. (Amsterdam, Neth.), 2016, vol. 33, pp. 298–306.

LeGrand, D.G. and Gaines, G.L., Jr., The molecular weight dependence of polymer surface tension, J. Colloid Interface Sci., 1969, vol. 31, no. 2, pp. 162–167.

Poser, C.I. and Sanchez, I.C., Surface tension theory of pure liquids and polymer melts, J. Colloid Interface Sci., 1979, vol. 69, no. 3, pp. 539–548.

McAuley, K.B. and MacGregor, J.F., On-line inference of polymer properties in an industrial polyethylene reactor, AIChE J., 1991, vol. 37, no. 6, pp. 825–835.

Wang, Y., Seki, H., Ohyama, S., Ogawa, M., and Ohshima, M., Optimal grade transition control for polymerization reactors, Comput. Chem. Eng., 2000, vol. 24, nos. 2–7, pp. 1555–1561.

Costa, G.M.N., Kislansky, S., Oliveira, L.C., Pessoa, F.L.P., Vieira de Melo, S.A.B., and Embiruçu, M., Modeling of solid–liquid equilibria for polyethylene and polypropylene solutions with equations of state, J. App. Polym. Sci., 2011, vol. 121, no. 3, pp. 1832–1849.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varshouee, G.H., Heydarinasab, A., Vaziri, A. et al. Predicting Molecular Weight Distribution, Melt Flow Index, and Bulk Density in a Polypropylene Reactor via a Validated Mathematical Model. Theor Found Chem Eng 55, 153–166 (2021). https://doi.org/10.1134/S0040579521010152

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579521010152