Abstract

The deformation of supply drives due to inertia of the moving parts of machine tools is considered. High-speed machining in systems with traditional serial kinematic structure is found to be of limited use for parts with complex geometry. Parallel kinematics offers an alternative.

Similar content being viewed by others

REFERENCES

Schulz, H., High-speed machining, in Manufacturing Technologies for Machines of the Future, New York: Springer-Verlag, 2003, pp. 197–214.

Gutyrya, S.S. and Yaglinskii, V.P., Parallel structure mechanisms in modern machine engineering manufacture, Tekhnol. Kompl. (Ukr.), 2010, no. 2, pp. 25–35.

Pandilov, Z. and Dukovski, V., Parallel kinematics machine tools: overview from history to the future, Ann. Fac. Eng. Hunedoara, 2012, vol 10, pp. 111–124.

Serebritskii, P.P., High-speed mechanical treatment, Obrab. Mater. Rezaniem, 2007, no. 4 (40), pp. 6–15.

Vittington, K. and Vlasov, V., High-speed mechanical treatment, SAPR Graf., 2003, no. 11, pp. 7–12.

Olenin, L.D. and Ochkin, D.I., Specific high-speed milling, Izv. Mosk. Gos. Tekh. Univ., MAMI, 2014, vol. 2, no. 3 (21), pp. 25–31.

Akmaev, O.K., Enikeev, B.A., and Yusupov, A.F., RF Patent 2542878, Byull. Izobret., 2015, no. 6.

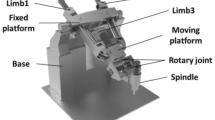

Akmaev, O.K., Enikeev, B.A., and Nigmatullin, A.I., A machine tool with parallel two-level kinematics, Russ. Eng. Res., 2016, vol. 36, no. 2, pp. 129–133.

Kudoyarov, R.G. and Basharov, R.S., Rigidity of a multi-purpose 500V/5 machine, in Sovremennye tendentsii v tekhnologiyakh metalloobrabotki i konstruktsiyakh metalloobrabatyvayushchikh mahsin i komplektuyushchikh izdelii (Modern Metalworking Technologies and Designs of Metalworking Machines and Components), Ufa: Ufimsk. Gos. Aviats. Tekh. Univ., 2011, pp. 234–240.

Enikeev, B.A., Akmaev, O.K., and Kudoyarov, R.G., Experimental stiffness analyses of a 3-DOF parallel kinematics machine-tool, Proc. Int. Russian Automation Conf. (RusAutoCon), Sochi, 2018, pp. 1–4.

Precision ball screws DIN standard compliant ball screw: catalogue. https://tech.thk.com/upload/catalog_claim/pdf/335-2E.pdf. Accessed July 28, 2020.

https://medias.schaeffler.com/medias/ru!hp.ec.br.pr/ ZKLN..-2Z*ZKLN4075-2Z. Accessed July 28, 2020.

Funding

Financial support was provided by the Russian Ministry of Science and Higher Education (project 0838-2020-0006), for the development of new design principles permitting the construction of world-beating electromechanical energy converters—characterized by high efficiency and minimal density—from new high-efficiency materials.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Enikeev, B.A., Akmaev, O.K. & Kudoyarov, R.G. More Accurate Machining by Means of Parallel Kinematics. Russ. Engin. Res. 41, 266–268 (2021). https://doi.org/10.3103/S1068798X21030047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21030047