Abstract

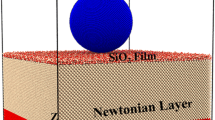

Long-lasting constant loading commonly exists in silicon-based microelectronic contact, as well as the chemical mechanical polishing area. In this work, the stress relaxation analysis of single crystal silicon coated with an amorphous SiO\(_{2}\) film is performed by varying the maximum indentation depth using molecular dynamics simulation. It is found that during holding, the applied indentation force declines sharply at the beginning and then steadily towards the end of the holding period. The stress relaxation amount of bilayer composites increases as the maximum indentation depth increases. It is also found that the deformation features of SiO\(_{2}\) film and silicon substrate during holding are inherited from the loading process. The SiO\(_{2}\) film during holding is further densified when the maximum indentation depth is equal to or less than a certain value (5.5 nm for the 0.8-nm film). The amount of generated phases and phase distributions of silicon substrate during holding are affected by the plastic deformation of silicon during loading.

Similar content being viewed by others

References

Bhushan B. Nanotribology and nanomechanics of MEMS/NEMS and BioMEMS/BioNEMS materials and devices. Microelectron Eng. 2007;84:387–412.

Priolo F, Gregorkiewicz T, Galli M, Krauss TF. Silicon nanostructures for photonics and photovoltaics. Nat Nanotechnol. 2014;9:19–32.

Kim SH, Asay DB, Dugger MT. Nanotribology and MEMS. Nano Today. 2007;2:22–9.

Kasai T, Bhushan B. Physics and tribology of chemical mechanical planarization. J Phys Condens Matter. 2008;20:1–13.

Xu J, Luo JB, Wang LL, Lu XC. The crystallographic change in sub-surface layer of the silicon single crystal polished by chemical mechanical polishing. Tribol Int. 2007;40:285–9.

Estragnat E, Tang G, Liang H, Jahanmir S, Pei P, Martin JM. Experimental investigation on mechanisms of silicon chemical mechanical polishing. J Electron Mater. 2004;33:334–9.

Lim MS, van der Heide PAW, Perry SS, Galloway HC, Koeck DC. Microscopic investigations of chemo-mechanical polishing of tungsten. Thin Solid Films. 2004;457:346–53.

Fu W-E, Chen C-CA, Lin Y-D, Chang Y-Q, Huang Y-H. Passivation layer effect on surface integrity induced by Cu-CMP. Thin Solid Films. 2011;519:4874–9.

Cao ZQ, Zhang X. Density change and viscous flow during structural relaxation of plasma-enhanced chemical-vapor-deposited silicon oxide films. J Appl Phys. 2004;96:4273–80.

Chudoba T, Richter F. Investigation of creep behaviour under load during indentation experiments and its influence on hardness and modulus results. Surf Coat Technol. 2001;148:191–8.

Wang C, Cao QP, Wang XD, Zhang DX, Qu SX, Jiang JZ. Time-dependent shear transformation zone in thin film metallic glasses revealed by nanoindentation creep. J Alloy Compd. 2017;696:239–45.

Li H, Ngan AHW. Size effects of nanoindentation creep. J Mater Res. 2011;19:513–22.

Spaepen F. Homogeneous flow of metallic glasses: a free volume perspective. Scripta Mater. 2006;54:363–7.

Spaepen F. Microscopic mechanism for steady-state inhomogeneous flow in metallic glasses. Acta Metall. 1977;25:407–15.

Argon AS. Plastic-deformation in metallic glasses. Acta Metall. 1979;27:47–58.

Schuh CA, Lund AC. Atomistic basis for the plastic yield criterion of metallic glass. Nat Mater. 2003;2:449–52.

Wang F, Li JM, Huang P, Wang WL, Lu TJ, Xu KW. Nanoscale creep deformation in Zr-based metallic glass. Intermetallics. 2013;38:156–60.

Yoo B-G, Kim K-S, Oh J-H, Ramamurty U, Jang J-I. Room temperature creep in amorphous alloys: influence of initial strain and free volume. Scripta Mater. 2010;63:1205–8.

Yavari AR, Le Moulec A, Inoue A, Nishiyama N, Lupu N, Matsubara E, Botta WJ, Vaughan G, Di Michiel M, Kvick A. Excess free volume in metallic glasses measured by X-ray diffraction. Acta Mater. 2005;53:1611–9.

Wright WJ, Hufnagel TC, Nix WD. Free volume coalescence and void formation in shear bands in metallic glass. J Appl Phys. 2003;93:1432–7.

Bhowmick R, Raghavan R, Chattopadhyay K, Ramamurty U. Plastic flow softening in a bulk metallic glass. Acta Mater. 2006;54:4221–8.

Cao ZQ, Zhang X. Nanoindentation creep of plasma-enhanced chemical vapor deposited silicon oxide thin films. Scripta Mater. 2007;56:249–52.

Taylor TA, Barrett CR. Creep and recovery of silicon single-crystals. Mater Sci Eng. 1972;10:93.

Shikimaka O, Prisacaru A, Bruk L, Usatyi Y, Burlacu A. Influence of loading holding time under quasistatic indentation on electrical properties and phase transformations of silicon. Surf Eng Appl Electrochem. 2012;48:444–9.

Shikimaka O, Prisacaru A, Burlacu A. Effect of long-term holding under contact loading on the specific features of phase changes in silicon. Mater Sci. 2015;51:405–11.

Gerbig YB, Michaels CA, Cook RF. In situ observations of Berkovich indentation induced phase transitions in crystalline silicon films. Scripta Mater. 2016;120:19–22.

Chen J, Shi J, Zhang M, Peng W, Fang L, Sun K, Han J. Effect of indentation speed on deformation behaviors of surface modified silicon: a molecular dynamics study. Comput Mater Sci. 2018;155:1–10.

Chen J, Fang L, Sun K, Han J. Creep behaviors of surface-modified silicon: a molecular dynamics study. Comput Mater Sci. 2020;176.

Chen J, Shi J, Chen Z, Zhang M, Peng W, Fang L, Sun K, Han J. Mechanical properties and deformation behaviors of surface-modified silicon: a molecular dynamics study. J Mater Sci. 2019;54:3096–110.

Chen J, Shi J, Wang Y, Sun J, Han J, Sun K, Fang L. Nanoindentation and deformation behaviors of silicon covered with amorphous SiO2: a molecular dynamic study. RSC Adv. 2018;8:12597–607.

Chen J, Shi JQ, Chen Z, Zhang M, Peng WX, Fang L, Sun K, Han J. Mechanical properties and deformation behaviors of surface-modified silicon: a molecular dynamics study. J Mater Sci. 2019;54:3096–110.

Wu M, Liang YF, Jiang JZ, Tse JS. Structure and properties of dense silica glass. Sci Rep. 2012;2:398–404.

Cao Z, Zhang X. Nanoindentation stress-strain curves of plasma-enhanced chemical vapor deposited silicon oxide thin films. Thin Solid Films. 2008;516:1941–51.

Zarudi I, Zhang LC. Structure changes in mono-crystalline silicon subjected to indentation—experimental findings. Tribol Int. 1999;32:701–12.

Goel S, Kovalchenko A, Stukowski A, Cross G. Influence of microstructure on the cutting behaviour of silicon. Acta Mater. 2016;105:464–78.

Goel S, Faisal NH, Luo X, Yan J, Agrawal A. Nanoindentation of polysilicon and single crystal silicon: molecular dynamics simulation and experimental validation. J Phys D Appl Phys. 2014;47:275304.

Sun J, Li C, Jing H, Ma A, Fang L. Nanoindentation induced deformation and pop-in events in a silicon crystal: molecular dynamics simulation and experiment. Sci Rep. 2017;7:10282.

Sun J, Ma A, Jiang J, Han J, Han Y. Orientation-dependent mechanical behavior and phase transformation of mono-crystalline silicon. J Appl Phys. 2016;119:095904.

Sun J, Fang L, Han J, Han Y, Chen H, Sun K. Phase transformations of mono-crystal silicon induced by two-body and three-body abrasion in nanoscale. Comput Mater Sci. 2014;82:140–50.

Gerbig YB, Michaels CA, Forster AM, Cook RF. In situ observation of the indentation-induced phase transformation of silicon thin films. Phys Rev B. 2012;85:104102.

Gerbig YB, Michaels CA, Forster AM, Hettenhouser JW, Byrd WE, Morris DJ, Cook RF. Indentation device for in situ Raman spectroscopic and optical studies. Rev Sci Instrum. 2012;83:125106.

Chowdhury SC, Haque BZ, Gillespie JW Jr. Molecular dynamics simulations of the structure and mechanical properties of silica glass using ReaxFF. J Mater Sci. 2016;51:10139–59.

Munetoh S, Motooka T, Moriguchi K, Shintani A. Interatomic potential for Si-O systems using Tersoff parameterization. Comput Mater Sci. 2007;39:334–9.

Zhao S, Xue J. Modification of graphene supported on SiO\(_{\rm 2}\) substrate with swift heavy ions from atomistic simulation point. Carbon. 2015;93:169–79.

Wang J, Rajendran AM, Dongare AM. Atomic scale modeling of shock response of fused silica and alpha-quartz. J Mater Sci. 2015;50:8128–41.

Shi J, Chen J, Wei X, Fang L, Sun K, Sun J, Han J. Influence of normal load on the three-body abrasion behaviour of monocrystalline silicon with ellipsoidal particle. RSC Adv. 2017;7:30929–40.

Plimpton S. Fast parallel algorithms for short-range molecular-dynamics. J Comput Phys. 1995;117:1–19.

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mater Sci Eng. 2010;18:015012.

Acknowledgements

The authors thank Zhi Chen for his help in radial distribution function. This study was supported by the National Natural Science Foundation of China (Grant Numbers 51375364, 51475359, and 51505479) and Natural Science Foundation of Jiangsu Province of China (BK20150184).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Fang, L., Zhang, M. et al. Stress Relaxation Behaviors of Monocrystalline Silicon Coated with Amorphous SiO\(_{2}\) Film: A Molecular Dynamics Study. Acta Mech. Solida Sin. 34, 506–515 (2021). https://doi.org/10.1007/s10338-021-00231-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-021-00231-1