Abstract

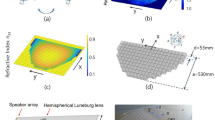

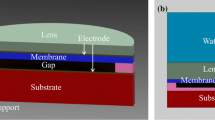

This study aims to investigate the frequency-dependent characteristics of the focal length of an acoustic lens made of a material with a frequency-dependent acoustic refractive index (ARI). For this purpose, an exchangeable plano-spherical convex subsonic index lens (PSCSIL) was fabricated using a polydimethylsiloxane (PDMS) material. The ARI of the lens material was evaluated via the tone-burst through-transmission method over the frequency range of 1–10 MHz. The frequency dependence of the focal length of the fabricated PSCSIL was evaluated through graphical analysis of the acoustic field scanned by a hydrophone as well as of that simulated using the finite element method. The measured ARI and focal length were observed to be dependent on frequency. The simulated and measured focal lengths of the PSCSIL exhibited a great discrepancy with their respective values predicted using the conventional focal length equation. This discrepancy was further studied using the ray-tracing method and is described in the discussion section. In conclusion, the spherical curvature of PSCSIL does not induce the convergence of rays to meet in a point. The ray tracing method does not take into account the phase complexity of the near-field region inside the lens. This causes the actual focal length to be shorter than the predicted one.

Similar content being viewed by others

References

D.L. Folds, Speed of sound and transmission loss in silicone rubbers at ultrasonic frequencies. J. Acoust. Soc. Am. (1974). https://doi.org/10.1121/1.1903422

H. Fujii et al., Acoustic properties of lens materials for ultrasonic probes. Jpn. J. Appl. Phys. (1995). https://doi.org/10.1143/JJAP.34.312

Y. Yamashita, Y. Hosono, K. Itsumi, Effects of metal particle dopant on acoustic attenuation properties of silicone rubber lens for medical echo array probe. Jpn. J. Appl. Phys. (2005). https://doi.org/10.1143/jjap.44.4558

Y. Yamashita, Y. Hosono, K. Itsumi, Effects of sub-100 nm platinum metal particle on the acoustic attenuation properties of silicone rubber lens for medical array probe. Jpn. J. Appl. Phys. (2006). https://doi.org/10.1143/JJAP.45.4684

Y. Yamashita, Y. Hosono, K. Itsumi, Effects of ceramic nanopowder dopants on acoustic attenuation properties of silicone rubber lens for medical echo probe. Jpn. J. Appl. Phys. (2007). https://doi.org/10.1143/JJAP.46.4784

Y. Yamashita et al., in the Proceedings of the 2008 IEEE Ultrason. Symp. (Beijing, November 2–5, 2008). https://doi.org/10.1109/ULTSYM.2008.0213

Y. Hosono, Y. Yamashita, K. Itsumi, in the Proceedings of the 2006 IEEE Ultrason. Symp. (Vancouver, October 3–6, 2006). https://doi.org/10.1109/ULTSYM.2006.204

Y. Hosono, K. Itsumi, Y. Yamashita, in the Proceedings of the 2007 IEEE Ultrason. Symp. (New York, October 28–31, 2007). https://doi.org/10.1109/ULTSYM.2007.481

K. Itsumi, Y. Hosono, N. Yamamoto, Y. Yamashita, Low acoustic attenuation silicone rubber lens for medical ultrasonic array probe. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. (2009). https://doi.org/10.1109/TUFFC.2009.1111

. Yamashita, Y. Hosono, K. Itsumi, in Piezoelectric Acoustic Material for Transducer Applications (Boston, 2008), Chap. 8, pp. 161–177. https://doi.org/10.1007/978-0-387-76540-2_8

K.S. Kim et al., Dependence of particle volume fraction on sound velocity and attenuation of EPDM composites. Ultrasonics (2007). https://doi.org/10.1016/j.ultras.2007.01.010

Y. C. Pu, Attenuation and velocity dispersion in rubbers and rubber/alumina composite materials, PhD. Thesis, Hankuk University of Foreign Studies, 2005

L. W. Schmerr Jr., S. Song, Ultrasonic Nondestructive Evaluation Systems: Models and Measurement (New York, 2007), Chap. 8, pp. 127–177

L. E. Kinsler, A. R. Frey, A. B. Coppens, J. V Sanders, Fundamentals of Acoustics (New York, 2000), Appendix A10, pp. 527. https://doi.org/10.1119/1.1969118

W. Marczak, Water as a standard in the measurements of speed of sound in liquids. J. Acoust. Soc. Am. (1997). https://doi.org/10.1121/1.420332

I.Y. Kuo, B. Hete, K.K. Shung, A novel method for the measurement of acoustic speed. J. Acoust. Soc. Am. (1990). https://doi.org/10.1121/1.400242

P. He, Measurement of acoustic dispersion using both transmitted and reflected pulses. J. Acoust. Soc. Am. (2000). https://doi.org/10.1121/1.428263

H. Wang, T. Ritter, W. Cao, K.K. Shung, High frequency properties of passive materials for ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. (2001). https://doi.org/10.1109/58.895911

W. Sachse, Y.H. Pao, On the determination of phase and group velocities of dispersive waves in solids. J. Appl. Phys. 49, 4320–4327 (1978). https://doi.org/10.1063/1.325484

S. Selladurai, A.K. Thittai, Towards quantitative quasi-static ultrasound elastography using a reference layer for liver imaging application: a preliminary assessment. Ultrasonics 93, 7–17 (2019). https://doi.org/10.1016/j.ultras.2018.10.007

Shin-Etsu Chemical Co. Ltd., Liquid silicone rubber for mold making (2020). https://doi.org/10.3139/9783446433458.011

IEC62127–2, Ultrasonics-Hydrophones-Part 2:Calibration for ultrasonic fields up to 40 MHz, International Electrotechnical Commision, Geneva (2014)

T. L. Szabo, Diagnostic Ultrasound Imaging Inside Out (Newburyport, Massachusetts, 2004), Chap. 6, pp. 137–169

H. Krautkramer, J. Krautkramer, Ultrasound Testing of Materials (Cologne, 1983), Chap. 4, pp. 62–89

Y.T. Kim et al., Evaluation of tissue mimicking quality of tofu for biomedical ultrasound. Ultrasound Med. Biol. (2009). https://doi.org/10.1016/j.ultrasmedbio.2008.09.005

Acknowledgements

We acknowledge the financial support of the Korea Research Institute of Standards and Science (KRISS) under the project “Development Convergence Measurement Technology for Precision Public Health (KRISS-1801183).”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Measurement of acoustic properties of pure rubbers

Appendix A: Measurement of acoustic properties of pure rubbers

A preliminary study of ten pure rubber sample materials was conducted using the aforementioned method at 1 MHz frequency. The pure rubber samples were classified into urethane rubbers and polydimethylsiloxane (PDMS), as tabulated in Table 1.

The sample IDs of urethane rubbers, CF30, VF30, VF40, and VF60 represent Clearflex30, Vytaflex30, Vytaflex40, and Vytaflex60 (Smooth-On. Inc.), respectively. The alphabets “K” and “S” appearing in the sample IDs of PDMS rubbers represent the elastomer type, while “C1,” “C2,” and “C3” represent the curing agent type. “K” and “S” were taken to be KE1606 (Shin-Etsu Chemical Co., Ltd.) and Sylgard 184A (Dow Chemical Korea Ltd.), respectively. “C1,” “C2,” and “C3” were taken to be Sylgard 184B (Dow Chemical Korea Ltd.), CAT-RG (Shin-Etsu Chemical Co., Ltd.) and CAT-1600 (Shin-Etsu Chemical Co., Ltd.), respectively. This enabled the fabricated PDMS rubber samples to be interpreted as cross-combinations of two elastomers and three curing agents. All the test samples were prepared based on the manufacturer recommended ratio of 1:1 and 10:1 for urethane rubbers and PDMS, respectively.

This preliminary study aimed to investigate acoustic properties, including the longitudinal phase velocity (\(\upsilon \)p), ARI (n), characteristic acoustic impedance (Z), acoustic bulk modulus (β), and acoustic attenuation coefficient (α), as recorded in Table 1.

As is evident from Table 1, all urethane samples exhibited greater ARI compared to PDMS samples. The greatest and lowest ARI values (1.0308 and 0.6897, respectively) were exhibited by CF30 and KC3. As a result, PDMS samples exhibited a high capability to deflect the sound waves at the material-water boundary and induce convergence of waves at the focal point. Afterwards, the attenuation coefficient was observed to vary with respect to the samples. The lowest attenuation coefficient of 1.120 dB cm−1 was observed in the case of VF30. However, KC3 exhibited the lowest attenuation coefficient (1.690 dB cm−1) in the PDMS series. Consequently, KC3 was selected as the acoustic lens material in the present work.

Rights and permissions

About this article

Cite this article

Yusof, N.M., Kim, WG., Baik, K. et al. Frequency-dependent focal length of a plano-spherical convex subsonic index lens. J. Korean Phys. Soc. 78, 784–795 (2021). https://doi.org/10.1007/s40042-021-00132-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-021-00132-z