Abstract

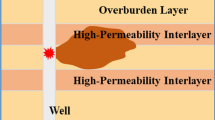

Shock wave pressure, high temperature flames, and toxic gases are among the factors that cause mine ventilation system failure following a gas explosion. Herein, we propose a Support Vector Regression (SVR)-based machine learning model to quickly determine the propagation of these disaster-causing hazards throughout the whole ventilation network. FLACS was used to simulate the explosions in a straight roadway with different spatial geometric parameters and gas explosion equivalents. Four SVR machine learning models were constructed by incorporating the roadway’s cross-sectional area, length of gas filling, gas concentration, and the distance between the observation point and the explosion source as inputs, while the shock wave pressure, flame temperature, time to the maximum temperature, and pressure served as outputs. The proposed model can quickly and accurately predict the propagation of disaster-causing hazards for a given explosion position and equivalent. As such, it plays a significant role in determining the ventilation system failure mode and aids decision makers and rescuers in developing a rescue and refuge plan.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the Corresponding author upon the reasonable request.

Code Availability

The code generated or used during the study is available from the corresponding author by request.

References

He, Z.; Wu, Q.; Wen, L.J.; Fu, G.: A process mining approach to improve emergency rescue processes of fatal gas explosion accidents in Chinese coal mines. Saf. Sci. 111, 154–166 (2019). https://doi.org/10.1016/j.ssci.2018.07.006

Azatyan, V.V.: Features of the physicochemical mechanisms and kinetic laws of combustion, explosion, and detonation of gases. Kinet. Catal. 61(3), 319–338 (2020). https://doi.org/10.1134/s0023158420030039

Xu, J.D.; Yang, G.Y.: Numerical simulation of the barricade encouraging effect in the process of gas explosion propagation. J. China Coal Soc. 29(1), 53–56 (2004)

He, X.Q.; Yang, Y.; Wang, E.Y.; Liu, Z.T.: Study on the influence of obstacles on the flame structure and flame propagation of gas explosion. J. China Coal Soc. 29(2), 186–189 (2004)

Jia, Z.W.; Liu, Y.W.; Jing, G.X.: Propagation characteristics of gas explosion shock wave under the condition of pipe turning. J. China Coal Soc. 36(1), 97–100 (2011)

Luo, Z.M.; Zhang, Q.; Wang, H.; Cheng, F.M.; Wang, T.; Deng, J.: Numerical simulation of gas explosion in confined space with FLACS. J. China Coal Soc. 38(8), 1381–1387 (2013)

Wang, Z.; Jiang, J.; Zheng, Y.: CFD simulation on gas explosion field in linked vessels. J. Ind. Eng. Chem. 58(4), 854–861 (2007)

Qi, Z.; Bin, Q.; Da-Chao, L.: Estimation of pressure distribution for shock wave through the bend of bend laneway. Saf. Sci. 48(10), 1263–1268 (2010). https://doi.org/10.1016/j.ssci.2010.04.003

Gieras, M.; Klemens, R.; Rarata, G.; Wolanski, P.: Determination of explosion parameters of methane-air mixtures in the chamber of 40 dm3 at normal and elevated temperature. J. Loss Prev. Process Ind. 19(2–3), 263–270 (2006). https://doi.org/10.1016/j.jlp.2005.05.004

Hisken, H.; Enstad, G.A.; Middha, P.; van Wingerden, K.: Investigation of concentration effects on the flame acceleration in vented channels. J. Loss Prev. Process Ind. 36, 449–461 (2015). https://doi.org/10.1016/j.jlp.2015.04.005

Lin, B.Q.; Zhou, S.N.; Zhang, R.G.: Influence of barriers on flame transmission and explosion wave in gas explosion. J. China Univ. Min. Technol. 28(2), 104–106 (1999)

Mittal, M.: Explosion pressure measurement of methane-air mixtures in different sizes of confinement. J. Loss Prev. Process Ind. 46, 200–208 (2017). https://doi.org/10.1016/j.jlp.2017.02.022

Salzano, E.; Cammarota, F.; Di Benedetto, A.; Di Sarli, V.: Explosion behavior of hydrogen-methane/air mixtures. J. Loss Prev. Process Ind. 25(3), 443–447 (2012). https://doi.org/10.1016/j.jlp.2011.11.010

Su, B.; Luo, Z.M.; Wang, T.; Liu, L.: Experimental and numerical evaluations on characteristics of vented methane explosion. J. Cent. South Univ. 27(8), 2382–2393 (2020). https://doi.org/10.1007/s11771-020-4456-1

Qu, Z.M.; Zhou, X.Q.; Wang, H.Y.; Ma, H.L.: Attenuation law of pressure of gas explosion shock wave. J. China Coal Soc. 33(4), 410–414 (2008)

Zhou, X.Q.; Wu, B.; Xu, J.D.: Basic characteristics of gas explosion in coal mine. China Coal 28, 8–11 (2002)

Tauseef, S.M.; Rashtchian, D.; Abbasi, T.; Abbasi, S.A.: A method for simulation of vapour cloud explosions based on computational fluid dynamics (CFD). J. Loss Prev. Process Ind. 24(5), 638–647 (2011). https://doi.org/10.1016/j.jlp.2011.05.007

Pang, L.; Zhang, Q.; Wang, T.; Lin, D.C.; Cheng, L.: Influence of laneway support spacing on methane/air explosion shock wave. Saf. Sci. 50, 83–89 (2012). https://doi.org/10.1016/j.ssci.2011.07.005

Jiang, B.Y.; Lin, B.Q.; Shi, S.L.; Zhu, C.J.; Ning, J.: Numerical simulation on the influences of initial temperature and initial pressure on attenuation characteristics and safety distance of gas explosion. Combust. Sci. Technol. 184(2), 135–150 (2012). https://doi.org/10.1080/00102202.2011.622321

Ke, G.; Li, S.N.; Han, R.; Li, R.Z.; Liu, Z.M.; Qi, Z.P.; Liu, Z.Y.: Study on the propagation law of gas explosion in the space based on the goaf characteristic of coal mine. Saf. Sci. 127, 5 (2020). https://doi.org/10.1016/j.ssci.2020.104693

Li, L.L.; Wang, Y.: Mechanical characteristics of partially premixed methane/air explosion in a small closed tube based on simulation technology. Energy Sources Part A- Recovery Util. Environ. Eff. 42(10), 1255–1267 (2020). https://doi.org/10.1080/15567036.2019.1604850

Xie, B.J.; Du, Y.J.; Wang, L.: Experiment and numerical simulation of gas explosion flame propagation law in bifurcated pipeline. J. Chongqing Univ. 42(6), 69–77 (2019)

Zhu, Y.F.; Wang, D.M.; Shao, Z.L.; Zhu, X.L.; Xu, C.H.; Zhang, Y.T.: Investigation on the overpressure of methane-air mixture gas explosions in straight large-scale tunnels. Process Saf. Environ. Protect. 135, 101–112 (2020). https://doi.org/10.1016/j.psep.2019.12.022

Cui, G.; Yang, C.; Li, Z.L.; Zhou, Z.; Li, J.L.: Experimental study and theoretical calculation of flammability limits of methane/air mixture at elevated temperatures and pressures. J. Loss Prev. Process Ind. 41, 252–258 (2016). https://doi.org/10.1016/j.jlp.2016.02.016

Duan, X.W.; Wu, Y.L.; Jing, G.X.; Guo, S.S.; Shao, H.Y.: Study on the flame propagation law of gas and coal dust explosion in a semi-closed pipeline. J. Saf. Environ. 20(2), 524–529 (2020)

Li, P.; Liu, J.; Gao, K.: Experimental study on gas explosion temperature and pressure peak in pipeline. J. Saf. Environ. 15(2), 59–63 (2015)

Luo, Z.M.; Li, R.K.; Wang, T.; Cheng, F.M.; Liu, Y.; Yu, Z.J.; Fan, S.X.; Zhu, X.C.: Explosion pressure and flame characteristics of CO/CH4/air mixtures at elevated initial temperatures. Fuel (2020). https://doi.org/10.1016/j.fuel.2020.117377

Ma, Q.J.; Zhang, Q.; Li, D.; Chen, J.C.; Ren, S.Y.; Shen, S.L.: Effects of premixed methane concentration on distribution of flame region and hazard effects in a tube and a tunnel gas explosion. J. Loss Prev. Process Ind. 34, 30–38 (2015). https://doi.org/10.1016/j.jlp.2015.01.018

Wang, K.; Jiang, S.G.; Ma, X.P.; Wu, Z.Y.; Zhang, W.Q.; Shao, H.: Study of the destruction of ventilation systems in coal mines due to gas explosions. Powder Technol. 286, 401–411 (2015). https://doi.org/10.1016/j.powtec.2015.08.020

Zipf, R.K.; Gamezo, V.N.; Sapko, M.J.; Marchewka, W.P.; Mohamed, K.M.; Oran, E.S.; Kessler, D.A.; Weiss, E.S.; Addis, J.D.; Karnack, F.A.; Sellers, D.D.: Methane-air detonation experiments at NIOSH Lake Lynn laboratory. J. Loss Prev. Process Ind. 26(2), 295–301 (2013). https://doi.org/10.1016/j.jlp.2011.05.003

Zhang, L.L.; Yang, Q.Y.; Shi, B.M.; Niu, Y.H.; Zhong, Z.: Influences of a pipeline’s bending angle on the propagation law of coal dust explosion induced by gas explosion. Combust. Sci. Technol. (2019). https://doi.org/10.1080/00102202.2019.1673381

He, Y.; Zhu, C.; He, Z.; Gu, C.; Cui, J.: Big data oriented root cause identification approach based on axiomatic domain mapping and weighted association rule mining for product infant failure. Comput. Ind. Eng. (2017). https://doi.org/10.1016/j.cie.2017.05.012

Duan, P.; He, Z.; He, Y.; Liu, F.; Zhang, A.; Zhou, D.: Root cause analysis approach based on reverse cascading decomposition in QFD and fuzzy weight ARM for quality accidents. Comput. Ind. Eng. (2020). https://doi.org/10.1016/j.cie.2020.106643

Prayogo, D.; Cheng, M.Y.; Wu, Y.W.; Tran, D.H.: Combining machine learning models via adaptive ensemble weighting for prediction of shear capacity of reinforced-concrete deep beams. Eng. Comput. 36(3), 1135–1153 (2020). https://doi.org/10.1007/s00366-019-00753-w

Cortes, C.; Vapnik, V.: Support-vector networks. Mach. Learn. 20(3), 273–297 (1995). https://doi.org/10.1007/bf00994018

Valente, J.M.; Maldonado, S.: SVR-FFS: a novel forward feature selection approach for high-frequency time series forecasting using support vector regression. Expert Syst. Appl. 160, 13 (2020). https://doi.org/10.1016/j.eswa.2020.113729

Sun, Z.M.; Li, D.: Coal mine gas safety evaluation based on adaptive weighted least squares support vector machine and improved Dempster-Shafer evidence theory. Discret. Dyn. Nat. Soc. (2020). https://doi.org/10.1155/2020/8782450

Deng, J.; Lei, C.K.; Xiao, Y.; Cao, K.; Ma, L.; Wang, W.F.; Bin, L.W.: Determination and prediction on “three zones” of coal spontaneous combustion in a gob of fully mechanized caving face. Fuel 211, 458–470 (2018). https://doi.org/10.1016/j.fuel.2017.09.027

Yu, J.Y.; Hou, B.X.; Lelyakin, A.; Xu, Z.J.; Jordan, T.: Gas detonation cell width prediction model based on support vector regression. Nucl. Eng. Technol. 49(7), 1423–1430 (2017). https://doi.org/10.1016/j.net.2017.06.014

Wang, Z.F.; Wang, S.T.; Kong, D.M.; Liu, S.Y.: Methane detection based on improved chicken algorithm optimization support vector machine. Appl. Sci.-Basel (2019). https://doi.org/10.3390/app9091761

Li, D.; Peng, S.P.; Du, W.F.; Guo, Y.L.: New method for predicting coal seam gas content. Energy Sources Part A-Recovery Util. Environ. Eff. 41(10), 1272–1284 (2019). https://doi.org/10.1080/15567036.2018.1545003

Zheng, L.G., Yu, M.G., Yu, S.J., Jia, H.L., Pan, R.K.: comparative study of nonlinear approaches for predicting explosion limits of multi-component gas mixture. In: International Symposium on Safety Science and Technology, 7, 1096-1101 (2008)

Xue, Y., Zhang, T.T.: The disaster risk assessment of coal mine gas explosion based on the model of SVM classification - regression. In: 6th Annual Meeting of Risk-Analysis-Council-of-China-Association-for-Disaster-Prevention. 102, 322–327 (2014)

Acknowledgements

The National Key Research and Development Program of China (No. 2017YFC0804401). The Natural Science Foundation of China (No. 51574142 and No.51774169).

Funding

This paper is financially supported by the National Key Research and Development Program of China (No. 2017YFC0804401) and the Natural Science Foundation of China (No. 51574142 and No.51774169).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by LL, JL, QZ, and MQ. The first draft of the manuscript was written by LL, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, L., Liu, J., Zhou, Q. et al. An SVR-based Machine Learning Model Depicting the Propagation of Gas Explosion Disaster Hazards. Arab J Sci Eng 46, 10205–10216 (2021). https://doi.org/10.1007/s13369-021-05616-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05616-5