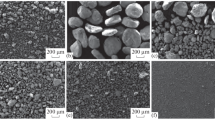

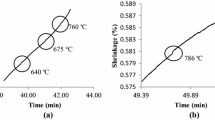

Investigations of the process of liquid-phase sintering of powder compositions of the Cu–Al system were carried out. As a result, the dependence of their final porosity indicators on the corresponding initial factors, comprising sintering temperatures and the number of constituent components, was revealed. Based on the obtained experimental data, the dependences of the microstructure of Cu–Al system compositions having a 25% aluminum content on sintering temperature and aluminum concentration are presented. In the course of the research, the dependence of the aluminum solid phase distribution in the Cu–Al system on the sintering temperature was studied at various concentrations. Experimental data on determining the porosity of the Cu–Al system compacts, the amount of the solid phase component in the liquid, as well as the amount of aluminum in the solid phase after sintering, depending on its initial concentration, are presented. The sintering of Cu–Al system compacts is shown to proceed with the participation of the liquid phase. In this case, changes in the dimensions of the sintered briquettes, on which the stability of the resulting powder blanks depends, turns out to be important. The technique and results of dilatometric studies of changes in compact dimensions depending on the sintering temperature and the initial porosity of the workpieces are presented. Additionally, the dependence of the relative change in the sample length and the medium temperature on the aluminum composition concentration was investigated.

Similar content being viewed by others

References

S. M. Gorbatyuk, A. N. Pashkov, A. Yu. Zarapin, and A. D. Bardovskii, “Development of technology for the production of metalmatrix composite materials based on aluminum by hot pressing,” Metallurg, No. 12, 54–58 (2018).

E. A. Chernyshov, E. A. Romanov, and E. A. Romanova, “Obtaining a highly reinforced dispersion-hardened composite material based on aluminum by the method of internal oxidation,” Metallurg, No. 8, 70–81 (2018).

A. T. Mamedov, Structural and Anti-Friction Powder Materials [in Russian], Elm, Baku (2006).

G. Petzow and W. A. Kaysser, “Influence of sintering and thermomechanical treatment on microstructure and properties of W–Ni–Fe alloys,” in: G.S. Upadhyaya (editor), Sintered Metal-Ceramic Composites, Elsevier Science Publ., Amsterdam (1984).

K. V. Savitskii, et al., “Influence of dispersion of aluminum powder on sintering of Cu-Al alloy in the presence of a liquid phase,” Poroshkovaya Metallurgiya, No. 11, 20–25 (1985).

K. V. Savitskii, et al., “Investigation of the mechanism of sintering of metal-ceramic alloys of copper and aluminum in the presence of a liquid phase,” Poroshkovaya Metallurgiy, No. 1, 5–11 (1986).

F. F. Nia and S. L. Davies, “Production of Al-Cu-Si alloys by PM methods,” Powder Metallurgy, 25, No. 4. 209–215 (1982).

J. Puckert, W.A. Kaysser, and G. Petzow, Int. J. Powder Metal, and Powder Techn., 20, 301 (1984).

W. Kehl and H. F. Fischmeister, “Observation on dimensional changes during sintering of Al-Cu compacts,” Sintering Theory and Practice. Material Science Monograph, 14, 269–274 (1981).

G. Bocrstigel, Erscheinungsbild und Ursachen von Volumenanderungen beim Sintern von Preblingen aus Eisen-Kupfer und Eisen-Kupfer-Graphit-Pulvermischungen-Stahl und Eisen, 79, 1187–1201 (2009).

A. P. Savitskii, “Features of the sintering process of binary systems,” Poroshkovaya Metallurgiya, No. 7-8, 62–69 (2000).

A. P. Savitskii, E. S. Kim, and L. S. Martsunova, “Shrinkage of briquettes during liquid-phase sintering,” Poroshkovaya Metallurgiya, No. 9/10, 9–13 (2000).

A. P. Savitskii and N. N. Burtsev, “Growth of briquettes during liquid-phase sintering,” Poroshkovaya Metallurgiya, No. 11/12, 31–38 (2009).

M. Khansen and K. Anderko, Structures of Double Alloy [In Russian], Vol. 1, Metallurgizdat, Moscow (1962).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 12, pp. 65–70, December, 2020.

Rights and permissions

About this article

Cite this article

Yagubov, E.K. Features of Structural Formation in a Cu–Al Powder System. Metallurgist 64, 1307–1314 (2021). https://doi.org/10.1007/s11015-021-01120-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01120-1