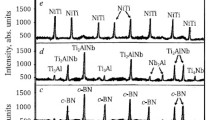

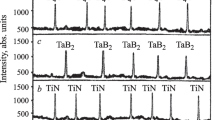

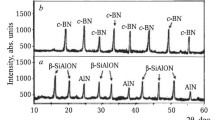

The effects of powder mixtures of W–Mo and Zr–Ti combined with sintered solid solution TiC–ZrC during spark plasma sintering of compositions at a pressing load of 60 MPa in the range 1200 – 1600°C on the phase composition, microstructure, grain sizes of crystalline phases, relative density, linear shrinkage, physical-mechanical properties, and linear correlation of elasticity modulus and fracture toughness of mullite–β-Si3N4–c-BN samples are shown in the present work. Synthesized powders of β-Si3N4 and c-BN are characterized by extensive crystallization of β-Si3N4 and c-BN. Solid solution TiC–ZrC sintered by a spark-plasma method at 1800°C shows roughly equal crystallization of (Zr,Ti)C and (Ti, Zr)C and a nonuniform and incompletely sintered crystalline microstructure. Samples with W–Mo and Zr–Ti mixtures sintered in the range 1200 – 1600°C show extensive mullitization; active crystallization of β-Si3N4, (Ti,Zr)C, solid solutions Mo, Wand W, Mo, and β-Zr,Ti; and lower crystallization of c-BN, (Zr,Ti)C, and β-Ti,Zr. The W–Mo mixture in the range 1400 – 1600°C favors the formation of a more uniformly and densely sintered microstructure of the ceramic phase; roughly round-shaped particles of solid solutions Mo, W and W, Mo in the metallic phase; more reinforced boundary areas of ceramic-metallic and metallic phases; and polydisperse grain compositions of crystalline phases. As a result, the composition with the W–Mo mixture sinters more uniformly and gradually in the range 1200 – 1600°C with the corresponding sample showing greater values of physical-mechanical properties, higher cracking resistance, and a greater linear correlation of the elasticity modulus and fracture toughness.

Similar content being viewed by others

References

M. Hotta and T. Goto, “Densification and microstructure of Al2O3–cBN composites prepared by spark-plasma sintering,” J. Ceram. Soc. Jpn., 116(6), 744 – 748 (2008).

D. Chakravarty and G. Sundararajan, “Microstructure, mechanical properties and machining performance of spark plasma sintered Al2O3–ZrO2–TiCN nanocomposites,” J. Eur. Ceram. Soc., 33(13/14), 2597 – 2607 (2013).

A. V. Hmelov, “Mullite–TiC–c-BN–c-ZrO2 materials produced by spark-plasma sintering and their properties,” Refract. Ind. Ceram., 60(1), 86 – 91 (2019); Nov. Ogneupory, No. 2, 23 – 29 (2019).

R. Vedant, “Development of ZrB2–B4C–Me ceramic-matrix composite for high temperature applications,” Thesis, Natl. Inst. Technol. Rourkela, 2014, pp. 1 – 61.

V. S. Balaji and S. Kumaran, “Densification and microstructural studies of titanium–boron carbide (B4C) power mixture during spark plasma sintering,” Powder Technol., 264(4), 536 – 540 (2014).

X. Ren, Z. Peng, Y. Peng, and C. Wang, “Spark plasma sintered WC–Ni carbides with various contents of ZrC nanopowder,” Key Eng. Mater., 591(3), 75 – 78 (2014).

P. Anupam M. Ragini, and K. Nagarajan, “Development of ZrB2–SiC–Ti by multi-stage spark plasma sintering at 1600°C,” J. Ceram. Soc. Jpn., 124(4), 393 – 402 (2016).

A. V. Hmelov, “Development of oxide-free oxide materials under spark-plasma sintering conditions of a mixture of oxide-free components and various metal powder additives,” Refract. Ind. Ceram., 61(1), 73 – 81 (2020); Nov. Ogneupory, No. 2, 18 – 24 (2020).

A. V. Hmelov, “Preparation of mullite–TiC–ZrC ceramic materials by a plasma-ARC method and their properties,” Refract. Ind. Ceram., 57(6), 645 – 650 (2017); Nov. Ogneupory, No. 12, 36 – 41 (2016).

A. V. Hmelov, “Strengthening oxide–oxide-free materials by incorporation of TiC–ZrC solid solutions into their structure during spark plasma sintering of initial powder mixtures under high compression load,” Refract. Ind. Ceram., 60(5), 486 – 494 (2020).

D.-L. Yung, S. Cygan, M. Antonov, and L. Jaworska, “Ultra high-pressure spark plasma sintered ZrC–Mo and ZrC–TiC composites,” Int. J. Refract. Met. Hard Mater., 61(2), 201 – 206 (2016).

B. Predel, Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys, Landolt–Bornstein, Group IV, Physical Chemistry, Springer, 1997, Vol. 5, pp. 1, 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 10, pp. 27 – 38, October, 2020.

Rights and permissions

About this article

Cite this article

Hmelov, A.V. Plasma-Spark Sintering of Oxide–Non-Oxide Components with the Addition of a TiC–ZrC Solid Solution and Various Metal Powder Mixtures. Refract Ind Ceram 61, 568–579 (2021). https://doi.org/10.1007/s11148-021-00522-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00522-7