Abstract

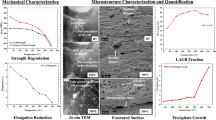

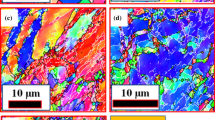

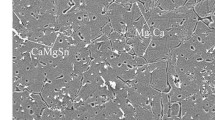

Structural material AA-7075-T6, an aluminium-based alloy, was subjected to thermal exposure for 60 min in the temperature range 100–300 °C with an interval of 20 °C. Harris analysis of the XRD patterns of specimens showed that the un-exposed AA-7075-T6 material was texture free, but upon thermal exposure, it developed texture. The crystallite size and lattice strain of the specimens were evaluated by Williamson-Hall analysis of the XRD patterns. Thermal exposure in the temperature range 100‒200 °C had no noticeable effect on the surface hardness. However, it decreased rapidly with the increase in temperature from 200 to 300 °C. This behaviour was accounted for in terms of dislocation glide by Orowan mechanism in an atmosphere of semi-coherent ή precipitates (MgZn2) in the main matrix. Breakdown of Hall–Petch relation established that crystallite boundaries do not make any significant contribution to the surface hardness, but the resistance to glide dislocations is offered by the semi-coherent ή precipitates (MgZn2) present in the matrix.

Similar content being viewed by others

References

G. Peng, K. Chen, S. Chen, H. Fang, Mater. Sci. Eng., A 528, 4014 (2011)

Ł Kaczmarek, M. Stegliński, J. SawickI, J. Świniarski, D. Batory, K. Kyzioł, Ł Kołodziejczyk, W. Szymański, P. Zawadzki, D. Kottfer, Arch. Metall. Mater. 58, 535 (2013)

K. Shen, J.-L. Chen, Z.-M. Yin, Trans. Nonferrous Met. Soc. China 19, 1405 (2009)

G. Sha, A. Cerezo, Acta Mater. 52, 4503 (2004)

J.D. Robson, O. Engler, C. Sigli, A. Deschamps, W.J. Poole, Metall. and Mater. Trans. A. 15A, 4377 (2020)

J. Gjønnes, C.J. Simensen, Acta Metall. 18, 881 (1970)

J. C. Benedyk, International Temper Designation Systems for Wrought Aluminum Alloys: part II – thermally treated (T temper) aluminum alloys, Light Metal Age, (August 2010) 16 – 22

K.-M. Wang, Light Alloy Fabrication Technology 12, 30 (1990)

F. Habiby, A. Ul Haq, F. H. Hashmi and A. Q. Khan, Metallurgical Transactions A, 18A, 350 (1987)

Y. Fan, X. Tang, S. Wang, B. Chen, Metals and Materials International (published online 25 September 2020) https://doi.org/10.1007/s12540-020-00875-7

B.D. Cullity, Elements of X-Ray Difraction (AddisonWesley Publishing Company Inc, Massachusetts, 1956), pp. 272–274

M. Z. Butt, D. Ali, M. Aftab, F. Bashir, M. S. Pervaiz, M. U. Tanveer, M. W. Khaliq, Metals and Materials International, (Published online: 04 September 2020) https://doi.org/10.1007/s12540-020-00861-z

M.Z. Butt, Ammal Javed, M. Waqas Khaliq, Dilawar Ali and Farooq Bashir, International Journal of Advanced Manufacturing Technology 90, 1857 (2017)

E.O. Hall, Proceedings of the Physical Society. Section B 64, 747 (1951)

N.J. Petch, J. Iron Steel Inst. 174, 25 (1953)

C.S. Pande, K.P. Cooper, Prog. Mater Sci. 54, 689 (2009)

M.Z. Butt, A. Mannan Majeed, M. Waqas Khaliq, and Dilawar Ali, Journal of Alloys and Compounds 695, 3069 (2017)

M.Z. Butt, M.S. Khilji, J. Alloy. Compd. 479, 252 (2009)

M.W. Khaliq, M.Z. Butt, and Murtaza Saleem. Mater. Res. Express 4, 076513 (2017)

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, E. Ma, Acta Mater. 55, 4041 (2007)

R.A. Masumura, P.M. Hazzledine, C.S. Pande, Acta Mater. 46, 4527 (1998)

J.D. Makinson, J.S. Lee, S.H. Magner, R.J. De Angelis, W.N. Weins, A.S. Hieronymus, Adv. X-Ray Anal. 42, 407 (2000)

G.B. Harris, Philos. Mag. 424, 113 (1952)

M.Z. Butt, Farooq Bashir, and Shamaila Arooj. Appl. Surf. Sci. 259, 740 (2012)

Y. Zhong, D. Ping, X. Song, F. Yin, J. Alloy. Compd. 476, 113 (2009)

T. Ungar, Scripta Mater. 51, 777 (2004)

T. Ungár, J. Mater. Sci. 42, 1584 (2006)

G.K. Williamson, W.H. Hall, Acta Metall. 1, 22 (1953)

R. E. Smallman, Modern Physical Metallurgy, 3rd Edition, Great Britain: Butterworths, p.421 (1970)

B. Cao, S.P. Joshi, K.T. Ramesh, Scripta Mater. 60, 619 (2009)

M. Rafique, M Z Butt and Sajjad Ahmad. Materials Research. Express 4, 096507 (2017)

M. R. Khan, M. Phil. Thesis, Effect of different temperature treatments on the structural and mechanical properties of aluminium 7075 alloy, Allama Iqbal Open University, Islamabad, (2015)

E. Cadırlı, H. Tecer, M. Şahin, E. Yılmaz, T. Kırındı, M. Gündüz, J. Alloys and Compounds 632, 229 (2015)

E. Acer, E. Çadırlı, H. Erol, T. Kırındı, M. Gündüz, Mat. Sci. Eng. A 662, 144 (2016)

E. Çadırlı, E. Nergiz, H. Kaya, U. Büyük, M. Şahin, M. Gündüz, Int. J. Cast Met. Res. 33, 11 (2020)

Acknowledgements

The authors are grateful to Engr. Muhammad Irfan, Head PITMAEM, PCSIR Laboratories Complex, Lahore, for providing the elemental composition of the AA-7075-T6 material used in this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Butt, M.Z., Khan, M.R., Ullah, S. et al. Effect of Thermal Exposure on the Crystallographic Features and Surface Hardness of AA-7075-T6 Material. Braz J Phys 51, 566–575 (2021). https://doi.org/10.1007/s13538-021-00895-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13538-021-00895-7