Abstract

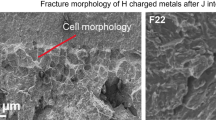

Silicon and molybdenum (SiMo) alloyed cast irons with spherical graphite are used for exhaust manifolds for service at high temperatures in air and combustion atmospheres containing water vapor. Analysis of degraded surfaces of in-service manifolds indicates existence of a combined oxidation and de-carburization (de-C) phenomena. Therefore, sequential high-temperature tests in air and combustion atmosphere with recording weight change together with carbon analysis at each time step were utilized to quantify the kinetics of both processes. The recorded weight change was related to weight gain due to oxidation and weight loss due to de-C. Carbon analysis was used to de-couple these two processes. SEM measured thicknesses of de-C layers were used to verify kinetics obtained from changes in carbon concentration during oxidation. It was shown that the oxidation and de-C kinetics have different sensitivities to testing temperature and the type of oxidizing atmospheres. At 700 °C and above, there are several significant mutual effects between scale formation and de-C processes which affect the kinetics of these processes and activation energy. The tested experimental methodology for decoupling these processes can be used for alloy optimization.

Similar content being viewed by others

References

S. Park et al., Development of a Heat Resistant Cast Iron Alloy for Engine Exhaust Manifolds, SAE Technical Paper Series, SAE International, Technical Paper 2005-01-1688 (2005).

F. Tholence, and M. Norell, High Temperature Corrosion of Cast Alloys in Exhaust Environments I-Ductile Cast Irons. Oxidation of Metals 69(1–2), 2007 (13–36).

M. Ibrahim, A. Nofal, and M. Mourad, Microstructure and Hot Oxidation Resistance of SiMo Ductile Cast Irons Containing Si-Mo-Al. Met. Mater. Trans. B 2, 2017 (1149–1157).

M. Brady, et al., Long-term oxidation of candidate cast iron and stainless steel exhaust system alloys from 650 to 800 °C in Air with Water Vapor. Oxidation of Metals 82(5–6), 2014 (359–381).

S. Lekakh, et al., Prevention of High-Temperature Surface Degradation in SiMo Cast Irons by Cr and Al Alloying. Met. Mater. Trans. B 51B, 2020 (2542–2554).

N. Scheidhauer, C. Dommaschk, and G. Wolf, Oxidation Resistant Cast Iron for High Temperature Application. Materials Science Forum 925, 2018 (393–399).

A. Ebel1et al., High-Temperature Oxidation of a High Silicon SiMo Spheroidal Cast Iron in Air with In Situ Change in H2O Content. Materials Science Forum 925, 2018 (353–360).

S. Xiang, B. Zhu, and S. Jonsson, High-Temperature Corrosion-Fatigue Behavior of Ductile Cast Irons for Exhaust Manifolds. Materials Science Forum 925, 2018 (369–376).

M. Ekström, P. Szakálos, and S. Jonsson, Influence of Cr and Ni on High-Temperature Corrosion Behavior of Ferritic Ductile Cast Iron in Air and Exhaust Gases. Oxidation of Metals 80, 2013 (455–466).

M. Ekström, Doctoral dissertation Oxidation and corrosion fatigue aspects of cast exhaust manifolds, (KTH Royal Institute of Technology, Stockholm, 2015).

J. Dossett, and G.E. Totten Steel Heat Treating Fundamentals and Processes, ASM, 2013 vol. 4A.

Y. Chen, X. Xu, and Y. Liu, Decarburization of 60Si2MnA in Atmospheres Containing Different Levels of Oxygen, Water Vapour and Carbon Dioxide at 700–1000 °C. Oxidation of Metals 93, 2020 (105–129).

Y. Chen, F. Zhang, and Y. Liu, Decarburization of 60Si2MnA in 20 Pct H2O–N2 at 700 °C to 900 °C. Met. Mater. Trans. A 51A, 2020 (1808–1821).

J.-O. Park, T. Van Long, and Y. Sasaki, Feasibility of Solid-state Steelmaking from Cast Iron. ISIJ international 52, 2012 (26–34).

S. Deng, and Y. Deng, Advanced Materials Research 1181–1185 (Trans Tech Publ, 2013).

E. Sharif-Sanavi and M. Mirjalili, A New Approach in Solid State Steelmaking from Thin Cast Iron Sheets through Decarburization in CaCO3 Pack, ISIJ International 58, 2018 (1791–1800).

W. Lee, et al., Solid state steelmaking by decarburisation of rapidly solidified high carbon iron sheet. Ironmaking & Steelmaking 39, 2012 (530–534).

Y. Yamaguchi, et al., Effect of graphite morphology on decarburized cast iron. International Journal of Cast Metals Research 16, 2003 (137–142).

S. Lekakh et al., Oxidation of Metals 94, 2020 (251–264).

R. Neu, and H. Sehitoglu, Thermomechanical fatigue, oxidation, and creep, Part 1. Metallurgical Trans. A 20A, 1989 (1755–1767).

S. Méndez et al., Effect of Silicon and Graphite Degeneration on High‑Temperature Oxidation of Ductile Cast Irons in Open Air. Oxid. Of Metals, Oxid. Met. 91, 2019 (225–242).

FactSage Thermochemical Software, www.factsage.com.

A. Kurbet, S. Dubey, A. Kumar, and S. Razdan, Design and Analysis of an Exhaust Manifold Subjected to Thermo-Mechanical Loading. International Engineering Research Journal (IERJ). Special Issue 2, 2015 (4494–4503).

A. Vasilyev and P. Golikov, Carbon diffusion coefficient in alloyed ferrite. Materials Physics and Mechanics 39, 2018 (111–119).

S. Valette, A. Denoirjean, D. Tétard, and P. Lefort, C40E steel oxidation under CO2: Kinetics and reactional mechanism. Journal of alloys and compounds 413, 2006 (222–231).

D. Porter, K. Easterling, Phase Transformations in Metals and Alloys, 2nd ed.; Chapman & Hall: London, UK, 1992; pp.74.

Acknowledgements

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Award No. DE-EE0008458. Experimental tests were supported by the Peaslee Steel Research Manufacturing Center at Missouri S&T.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lekakh, S.N., Bofah, A., Osei, R. et al. High Temperature Oxidation and Decarburization of SiMo Cast Iron in Air and Combustion Atmospheres. Oxid Met 95, 251–268 (2021). https://doi.org/10.1007/s11085-021-10022-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10022-1