Abstract

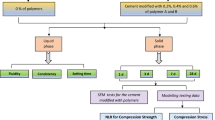

In this study, the cement-based parameters affecting CEMI portland cements-polycarboxylate ether-based high-range water-reducing (HRWR) admixtures compatibility were investigated. For this purpose, eight CEMI cements and three commercial HRWR admixtures were used. The rheological properties of 112 paste mixtures with different admixture dosages and water/cement (W/C) ratios were determined in accordance with Herschel–Bulkley model. Then after, using the experimental data, proper models were established to predict the dynamic yield stress and final viscosity of the pastes. In addition to cement characteristics (such as fineness, compound composition and equivalent alkali content), water-reducing admixture content and its solid material content as well as water/cement ratio of the pastes were considered as input data. Multivariate adaptive regression splines (MARS) and multiple additive regression trees (MART) methods were used in the models. Besides, artificial neural network (ANN) and conventional regression analysis (CRA) including linear, power, and exponential functions were applied to determine the accuracy of the heuristic regression methods. Three statistical indices, root-mean-square error, mean absolute error, and Nash–Sutcliffe, were used to evaluate the performance of the models. Modeling findings indicated that the model with the lowest error for both of the rheological variables in the testing set is the MART, followed by ANN, MARS, and CRA-Exponential methods. The most effective cement characteristics causing incompatibility, hence detraction of paste rheological properties, in decreasing order, were determined as cement fineness, C3S, C3A and equivalent alkali contents. C4AF and C2S contents of the cement were found to have less effect on the cement–admixture incompatibility. It will be possible to determine the rheological properties of mixtures containing different cements without conducting an experimental study by using the model based on MART method.

Similar content being viewed by others

References

Tagnit-Hamou A, Aïtcin PC (1993) Cement and superplasticizer compatibility. World Cem 38–42

Schatzmann M, Fischer P, Bezzola GR (2003) Rheological behavior of fine and large particle suspensions. J Hydraul Eng 129:796–803. https://doi.org/10.1061/(ASCE)0733-9429(2003)129:10(796)

Schatzmann M, Bezzola GR, Fischer P, et al (2004) The ball measuring system-a new rheometric tool to determine the flow curve of large particle material. In: Swiss Group of Rheology Annual Meeting. Lausanne/Switzerland

Koehler E, Fowler D (2004) Development of a Portable rheometer for fresh Portland cement concrete. Int Cent Aggregates Res 321

Özen S, Altun MG, Mardani-Aghabaglou A (2020) Effect of the polycarboxylate based water reducing admixture structure on self-compacting concrete properties: main chain length. Constr Build Mater 255:119360. https://doi.org/10.1016/j.conbuildmat.2020.119360

Altun MG, Özen S, Mardani-Aghabaglou A (2020) Effect of side chain length change of polycarboxylate-ether based high range water reducing admixture on properties of self-compacting concrete. Constr Build Mater 246:118427. https://doi.org/10.1016/j.conbuildmat.2020.118427

Hanehara S, Yamada K (1999) Interaction between cement and chemical admixture from the point of cement hydration, absorption behaviour of admixture, and paste rheology. Cem Concr Res 29:1159–1165. https://doi.org/10.1016/S0008-8846(99)00004-6

Dodson VH, Hayden TD (1989) Another look at the Portland cement/chemical admixture incompatibility problem. Cem Concr Aggregates 11:52–56

Bonen D, Sarkar SL (1995) The superplasticizer adsorption capacity of cement pastes, pore solution composition, and parameters affecting flow loss. Cem Concr Res 25:1423–1434. https://doi.org/10.1016/0008-8846(95)00137-2

Jiang S, Kim BG, Aïtcin PC (1999) Importance of adequate soluble alkali content to ensure cement/superplasticizer compatibility. Cem Concr Res 29:71–78. https://doi.org/10.1016/S0008-8846(98)00179-3

Erdogdu S (2000) Compatibility of superplasticizers with cements different in composition. Cem Concr Res 30:767–773. https://doi.org/10.1016/S0008-8846(00)00229-5

Bedard C, Mailvaganam NP (2005) The use of chemical admixtures in concrete. Part II: Admixture-admixture compatibility and practical problems. J Perform Constr Facil 19:263–266. https://doi.org/10.1061/(ASCE)0887-3828(2005)19:4(263)

Ramachandran VS (1995) Concrete admixtures handbook. Noyes Publications, New Jersey

Ramachandran VS (2002) Concrete admixtures handbook. Standard Publishers, New Delhi

Uchikawa H, Hanehara S, Shirasaka T, Sawaki D (1992) Effect of admixture of hydration of cement, adsorptive behaviour of admixture and fluidity and setting of fresh cement paste. Cem Concr Res 22:1115–1129

Yousuf M, Mollah A, Palta P et al (1995) Chemical and physical effects of sodium lignosulfonate superplasticizer on the hydration of portland cement and solidification/stabilization consequences. Cem Concr Res. https://doi.org/10.1016/0008-8846(95)00055-H

Rixom R, Mailvaganam N (1999) Chemical admixtures for concrete. E&FN Spon, London

Flatt RJ, Houst YF (2001) A simplified view on chemical effects perturbing the action of superplasticizers. Cem Concr Res 31:1169–1176. https://doi.org/10.1016/S0008-8846(01)00534-8

Griesser A (2002) Cement-superplasticizer ınteractions at ambient temperatures; rheology, phase composition, pore water and heat of hydration of cementitious systems. Swiss Federal Institute of Technology

Mardani-Aghabaglou A, Tuyan M, Yilmaz G et al (2013) Effect of different types of superplasticizer on fresh, rheological and strength properties of self-consolidating concrete. Constr Build Mater 47:1020–1025. https://doi.org/10.1016/j.conbuildmat.2013.05.105

Aïtcin PC (2004) High performance concrete. E&FN SPON, New York

Prince W, Edwards-Lajnef M, Aïtcin PC (2002) Interaction between ettringite and a polynaphthalene sulfonate superplasticizer in a cementitious paste. Cem Concr Res 32:79–85. https://doi.org/10.1016/S0008-8846(01)00632-9

Vernet C, Noworyta G (1992) Reactivity test for fine silicas and pozzolonic mineral additives. In: Proceedings of the 9th ınternational congress on the chemistry of cement Vol. III. New Delhi, pp 79–85

Burgos-Montes O, Palacios M, Rivilla P, Puertas F (2012) Compatibility between superplasticizer admixtures and cements with mineral additions. Constr Build Mater 31:300–309. https://doi.org/10.1016/j.conbuildmat.2011.12.092

Gołaszewski J (2012) Influence of cement properties on new generation superplasticizers performance. Constr Build Mater 35:586–596. https://doi.org/10.1016/j.conbuildmat.2012.04.070

He T, Shi C, Li G, Song X (2012) Effects of superplasticizers on the carbonation resistance of C 3S and C 3A hydration products. Constr Build Mater 36:954–959. https://doi.org/10.1016/j.conbuildmat.2012.06.071

Sonebi M, Lachemi M, Hossain KMA (2013) Optimisation of rheological parameters and mechanical properties of superplasticised cement grouts containing metakaolin and viscosity modifying admixture. Constr Build Mater 38:126–138. https://doi.org/10.1016/j.conbuildmat.2012.07.102

Ouyang X, Jiang X, Qiu X et al (2009) Effect of molecular weight of sulfanilic acid-phenol-formaldehyde condensate on the properties of cementitious system. Cem Concr Res 39:283–288. https://doi.org/10.1016/j.cemconres.2009.01.002

Alonso MM, Palacios M, Puertas F (2013) Compatibility between polycarboxylate-based admixtures and blended-cement pastes. Cem Concr Compos 35:151–162. https://doi.org/10.1016/j.cemconcomp.2012.08.020

Özcan F, Atiş CD, Karahan O et al (2009) Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Adv Eng Softw 40:856–863. https://doi.org/10.1016/j.advengsoft.2009.01.005

Saridemir M, Topçu IB, Özcan F, Severcan MH (2009) Prediction of long-term effects of GGBFS on compressive strength of concrete by artificial neural networks and fuzzy logic. Constr Build Mater 23:1279–1286. https://doi.org/10.1016/j.conbuildmat.2008.07.021

Zhang J, Ma G, Huang Y et al (2019) Modelling uniaxial compressive strength of lightweight self-compacting concrete using random forest regression. Constr Build Mater 210:713–719. https://doi.org/10.1016/j.conbuildmat.2019.03.189

Amlashi AT, Abdollahi SM, Goodarzi S, Ghanizadeh AR (2019) Soft computing based formulations for slump, compressive strength, and elastic modulus of bentonite plastic concrete. J Clean Prod 230:1197–1216. https://doi.org/10.1016/j.jclepro.2019.05.168

Asteris PG, Mokos VG (2020) Concrete compressive strength using artificial neural networks. Neural Comput Appl 32:11807–11826. https://doi.org/10.1007/s00521-019-04663-2

Saha P, Debnath P, Thomas P (2020) Prediction of fresh and hardened properties of self-compacting concrete using support vector regression approach. Neural Comput Appl 32:7995–8010. https://doi.org/10.1007/s00521-019-04267-w

Selvaraj S, Sivaraman S (2019) Prediction model for optimized self-compacting concrete with fly ash using response surface method based on fuzzy classification. Neural Comput Appl 31:1365–1373. https://doi.org/10.1007/s00521-018-3575-1

Ashrafian A, Shokri F, Taheri Amiri MJ et al (2020) Compressive strength of foamed cellular lightweight concrete simulation: new development of hybrid artificial intelligence model. Constr Build Mater 230:117048. https://doi.org/10.1016/j.conbuildmat.2019.117048

Chou JS, Chiu CK, Farfoura M, Al-Taharwa I (2011) Optimizing the prediction accuracy of concrete compressive strength based on a comparison of data-mining techniques. J Comput Civ Eng 25:242–253

Yuan Z, Wang LN, Ji X (2014) Prediction of concrete compressive strength: Research on hybrid models genetic based algorithms and ANFIS. Adv Eng Softw 67:156–163. https://doi.org/10.1016/j.advengsoft.2013.09.004

Dutta S, Ramachandra Murthy A, Kim D, Samui P (2017) Prediction of compressive strength of self-compacting concrete using intelligent computational modeling. Comput Mater Contin 53:167–185

Eskandari-Naddaf H, Kazemi R (2017) ANN prediction of cement mortar compressive strength, influence of cement strength class. Constr Build Mater 138:1–11. https://doi.org/10.1016/j.conbuildmat.2017.01.132

Yaseen ZM, Deo RC, Hilal A et al (2018) Predicting compressive strength of lightweight foamed concrete using extreme learning machine model. Adv Eng Softw 115:112–125. https://doi.org/10.1016/j.advengsoft.2017.09.004

Al-Shamiri AK, Kim JH, Yuan TF, Yoon YS (2019) Modeling the compressive strength of high-strength concrete: an extreme learning approach. Constr Build Mater 208:204–219. https://doi.org/10.1016/j.conbuildmat.2019.02.165

Ghanizadeh AR, Abbaslou H, Amlashi AT, Alidoust P (2019) Modeling of bentonite/sepiolite plastic concrete compressive strength using artificial neural network and support vector machine. Front Struct Civ Eng 13:215–239. https://doi.org/10.1007/s11709-018-0489-z

Nguyen T, Kashani A, Ngo T, Bordas S (2019) Deep neural network with high-order neuron for the prediction of foamed concrete strength. Comput Civ Infrastruct Eng 34:316–332. https://doi.org/10.1111/mice.12422

Hoang ND, Tran XL, Nguyen H (2020) Predicting ultimate bond strength of corroded reinforcement and surrounding concrete using a metaheuristic optimized least squares support vector regression model. Neural Comput Appl 32:7289–7309. https://doi.org/10.1007/s00521-019-04258-x

Xu J, Zhao X, Yu Y et al (2019) Parametric sensitivity analysis and modelling of mechanical properties of normal- and high-strength recycled aggregate concrete using grey theory, multiple nonlinear regression and artificial neural networks. Constr Build Mater 211:479–491. https://doi.org/10.1016/j.conbuildmat.2019.03.234

Gholampour A, Mansouri I, Kisi O, Ozbakkaloglu T (2020) Evaluation of mechanical properties of concretes containing coarse recycled concrete aggregates using multivariate adaptive regression splines (MARS), M5 model tree (M5Tree), and least squares support vector regression (LSSVR) models. Neural Comput Appl 32:295–308. https://doi.org/10.1007/s00521-018-3630-y

Cheng MY, Cao MT (2016) Estimating strength of rubberized concrete using evolutionary multivariate adaptive regression splines. J Civ Eng Manag 22:711–720. https://doi.org/10.3846/13923730.2014.897989

Karthiyaini S, Senthamaraikannan K, Priyadarshini J et al (2019) Prediction of mechanical strength of fiber admixed concrete using multiple regression analysis and artificial neural network. Adv Mater Sci Eng. https://doi.org/10.1155/2019/4654070

Ashrafian A, Taheri Amiri MJ, Rezaie-Balf M et al (2018) Prediction of compressive strength and ultrasonic pulse velocity of fiber reinforced concrete incorporating nano silica using heuristic regression methods. Constr Build Mater 190:479–494. https://doi.org/10.1016/j.conbuildmat.2018.09.047

Kaveh A, Bakhshpoori T, Hamze-Ziabari SM (2018) M5’ and mars based prediction models for properties of selfcompacting concrete containing fly ash. Period Polytech Civ Eng 62:281–294. https://doi.org/10.3311/PPci.10799

Rezaie M, Sadighi N (2017) Prediction of slump and density of lightweight concretes using ANFIS and linear regression. Int J Civ Eng Technol 8:1635–1648

Yu Y, Zhang C, Gu X, Cui Y (2019) Expansion prediction of alkali aggregate reactivity-affected concrete structures using a hybrid soft computing method. Neural Comput Appl 31:8641–8660. https://doi.org/10.1007/s00521-018-3679-7

Sezer A, Sezer Gİ, Mardani-Aghabaglou A, Altun S (2020) Prediction of mechanical and penetrability properties of cement-stabilized clay exposed to sulfate attack by use of soft computing methods. Neural Comput Appl. https://doi.org/10.1007/s00521-020-04972-x

Sadowski Ł, Nikoo M, Shariq M et al (2019) The nature-ınspired metaheuristic method for predicting the creep strain of green concrete containing ground granulated blast furnace slag. Mater (Basel). https://doi.org/10.3390/ma12020293

Shahriar A, Nehdi ML (2013) Modelling rheological properties of oil well cement slurries using multiple regression analysis and artificial neural networks. J Mater Civ Eng 3:26–37

Friedman JH (1991) Multivariate adaptive regression splines (with Discussion). Ann Stat 19:1–141. https://doi.org/10.1214/aos/1176347969

Zhang W, Goh ATC (2016) Multivariate adaptive regression splines and neural network models for prediction of pile drivability. Geosci Front. https://doi.org/10.1016/j.gsf.2014.10.003

Tiryaki S, Tan H, Bardak S et al (2019) Performance evaluation of multiple adaptive regression splines, teaching–learning based optimization and conventional regression techniques in predicting mechanical properties of impregnated wood. Eur J Wood Wood Prod 77:645–659. https://doi.org/10.1007/s00107-019-01416-9

Friedman JH, Meulman JJ (2003) Multiple additive regression trees with application in epidemiology. Stat Med 22:1365–1381. https://doi.org/10.1002/sim.1501

Fu J-C, Huang H-Y, Jang J-H, Huang P-H (2019) River stage forecasting using multiple additive regression trees. Water Resour Manag 33:4491–4507. https://doi.org/10.1007/s11269-019-02357-x

Felekoğlu B (2014) Rheological behaviour of self-compacting micro-concrete. Sadhana Acad Proc Eng Sci 39:1471–1495. https://doi.org/10.1007/s12046-014-0281-2

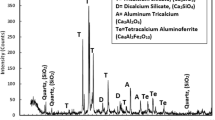

Mardani-Aghabaglou A, Boyaci OC, Hosseinnezhad H et al (2016) Effect of gypsum type on properties of cementitious materials containing high range water reducing admixture. Cem Concr Compos 68:15–26. https://doi.org/10.1016/j.cemconcomp.2016.02.007

Mardani-Aghabaglou A, Felekoğlu B, Ramyar K (2017) Effect of cement C3A content on properties of cementitious systems containing high-range water-reducing admixture. J Mater Civ Eng 29:1–12. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001925

Mardani-Aghabaglou A, Son AE, Felekoglu B, Ramyar K (2017) Effect of cement fineness on properties of cementitious materials containing high range water reducing admixture. J Green Build 12:142–167. https://doi.org/10.3992/1552-6100.12.1.142

Bayram A, Uzlu E, Kankal M, Dede T (2015) Modeling stream dissolved oxygen concentration using teaching–learning based optimization algorithm. Environ Earth Sci 73:6565–6576. https://doi.org/10.1007/s12665-014-3876-3

Kankal M, Yüksek Ö (2014) Artificial neural network for estimation of harbor oscillation in a cargo harbor basin. Neural Comput Appl. https://doi.org/10.1007/s00521-013-1451-6

Bayram A, Kankal M (2015) Artificial neural network modeling of dissolved oxygen concentration in a Turkish watershed. Polish J Environ Stud 24:1507–1515

Nacar S, Hınıs MA, Kankal M (2018) Forecasting daily streamflow discharges using various neural network models and training algorithms. KSCE J Civ Eng. https://doi.org/10.1007/s12205-017-1933-7

Uzlu E, Akpinar A, Özturk HT et al (2014) Estimates of hydroelectric generation using neural networks with the artificial bee colony algorithm for Turkey. Energy. https://doi.org/10.1016/j.energy.2014.03.059

Suman S (2015) Prediction of pile capacity parameters using functional networks and multivariate adaptive regression splines. National Institute of Technology

Samui P (2013) Multivariate adaptive regression spline (MARS) for prediction of elastic modulus of jointed rock mass. Geotech Geol Eng 31:249–253. https://doi.org/10.1007/s10706-012-9584-4

Khuntia S, Mujtaba H, Patra C et al (2015) Prediction of compaction parameters of coarse grained soil using multivariate adaptive regression splines (MARS). Int J Geotech Eng 9:79–88. https://doi.org/10.1179/1939787914Y.0000000061

Dey P, Das AK (2016) Application of multivariate adaptive regression spline-assisted objective function on optimization of heat transfer rate around a cylinder. Nucl Eng Technol 48:1315–1320. https://doi.org/10.1016/J.NET.2016.06.011

Friedman JH (2001) Estimation of daily streamflow using multivariate adaptive regression splines. Ann Stat 29:1189–1232

Chen L, Peng S, Yang B (2015) Predicting alien herb invasion with machine learning models: biogeographical and life-history traits both matter. Biol Invasions 17:2187–2198. https://doi.org/10.1007/s10530-015-0870-y

Li B, Goel PK (2007) Additive regression trees and smoothing splines—predictive modeling and interpretation in data mining

Moriasi DN, Arnold JG, Van Liew MW et al (2007) Model evaluation guidelines for systematic quantification of accuracy in watershed simulations. Trans ASABE 50:885–900. https://doi.org/10.13031/2013.23153

Nacar S, Kankal M, Hınıs MA (2018) Estimation of daily streamflow using multivariate adaptive regression splines (MARS): a case study of Haldizen Stream. Gümüşhane Univ J Sci Technol Inst 8:38–47. https://doi.org/10.17714/gumusfenbil.311188

Acknowledgement

The authors would like to express sincere thanks to Oyak, BatiÇim, Çimentaş, Akçansa, and Nuh cement plants as well as Draco, BASF, and Inka admixture companies for providing the cements and admixtures used in this study. The first author would also acknowledge the financial support provided by Turkish Cement Manufacturers Association during his PhD study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None of the authors has any conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mardani-Aghabaglou, A., Kankal, M., Nacar, S. et al. Assessment of cement characteristics affecting rheological properties of cement pastes. Neural Comput & Applic 33, 12805–12826 (2021). https://doi.org/10.1007/s00521-021-05925-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-021-05925-8