Abstract

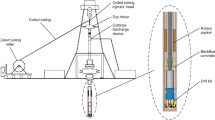

Badger exploration is a novel drilling technology that removes the need for a fixed rig and can achieve drilling without drill strings and drilling fluid. To achieve bit cooling during badger drilling, this paper proposes a self-cooling bit that can achieve self-cooling based on transpiration cooling technology. The self-cooling bit is characterized by the coolant chambers, capillary tubes and transpiration holes, the coolant can be pumped to flow through capillary tubes and transpiration holes to absorb the cutting heat and reduce the temperature of the cutters during drilling. The transpiration cooling model of the self-cooling bit cutter is developed theoretically, liquid metal is chosen as the coolant, and numerical simulations are conducted to investigate the cooling process of the cutter. Finally, a simplified self-cooling bit is built and tested in a rock breaking experiment, and the experimental results show that the temperature of the self-cooling bit cutter can be reduced significantly and maintained at a low value during the rock-breaking process, verifying the feasibility of the self-cooling bit. Analysis of the experimental results obtained with different parameters shows that the radial transpiration holes, the small size transpiration holes and the high flow rate of coolant are conducive to cutter cooling and promote the full and rapid absorption of the cutting heat by the coolant. The above work is helpful for the improvement and application of badger exploration technology.

Similar content being viewed by others

References

Cao, T.; Yu, K.; Chen, X.; Gao, D.; Zhu, H.; Luo, Y.: Numerical and experimental investigation on the feasibility of horizontal drilling with a new type of jet mill bit. J. Energy Res. Technol. 141(9), 093101 (2019)

Chen, P.; Meng, M.; Miska, S.; Yu, M.; Ozbayoglu, E.; Takach, N.: Study on integrated effect of PDC double cutters. J. Pet. Sci. Eng. 178, 1128–1142 (2019)

Chen, P.; Meng, M.; Ren, R.; Miska, S.; Yu, M.; Ozbayoglu, E.; Takach, N.: Modeling of PDC single cutter–Poroelastic effects in rock cutting process. J. Petrol. Sci. Eng. 183, 106389 (2019)

Chen, X.; Gao, D.; Guo, B.: A method for optimizing jet-mill-bit hydraulics in horizontal drilling. SPE J. 21(02), 416–422 (2016)

He, Y.; Cheng, S.; Sun, Z.; Chai, Z.; Rui, Z.: Improving oil recovery through fracture injection and production of multiple fractured horizontal wells. J. Energy Resour. Technol. 142(5), 053002 (2020)

Wang, Z.; Bai, Y.; Zhang, H.; Liu, Y.: Investigation on gelation nucleation kinetics of waxy crude oil emulsions by their thermal behavior. J. Petrol. Sci. Eng. 181, 106230 (2019)

Oyedere, M.; Gray, K.: New approach to stiff-string torque and drag modeling for well planning. J. Energy Resour. Technol. 142(10), 103004 (2020)

Seyedmohammadi, J.: The effects of drilling fluids and environment protection from pollutants using some models. Model. Earth Syst. Environ. 3(1), 23 (2017)

Siddique, S.; Kwoffie, L.; Addae-Afoakwa, K.; Yates, K.; Njuguna, J.: Oil based drilling fluid waste: an overview on environmentally persistent pollutants, IOP Conference Series: Materials Science and Engineering, p. 012008 (2017)

Zhong, H.; Li, Y.; Zhang, W.; Li, D.: Study on microscopic flow mechanism of polymer flooding. Arab. J. Geosci. 12(2), 56 (2019)

Al-Hameedi, A.T.T.; Alkinani, H.H.; Alkhamis, M.M.; Dunn-Norman, S.: Utilizing food waste product (date tree seeds) to enhance the filtration characteristics in water-based drilling fluid system: a comparative study. J. Energy Resour. Technol. 142(12), 123201 (2020)

Krishna, S.; Ridha, S.; Vasant, P.; Ilyas, S.U.; Ofei, T.N.: Simplified predictive model for downhole pressure surges during tripping operations using power law drilling fluids. J. Energy Resour. Technol. 142(12), 123001 (2020)

Stokka, S.; Cayeux, E.; Gardner, D.; Kragset, S.; Lohne, H. P.; Randeberg, E.; Skadsem, H. J.; Aas, B.; Kyllingstad, H.; Larsen, T.: Long Reach Well Concept, IADC/SPE Drilling Conference and Exhibition, Society of Petroleum Engineers (2016)

Jacobs, T.: Breaking from the Norm to Reach Marginal Offshore Fields. J. Petrol. Technol. 68(07), 27–33 (2016)

Nesse, A.; Wetteland, O.; Kvingedal, B.: Planar High Voltage Transformer Device. U.S. Patent Application No. 11/570,070 (2007)

Stokka, S.: Drilling device. U.S. Patent No. 7,093,673 (2006)

Fallet, T.: System for communicating over a power cable. U.S. Patent No. 8,842,744 (2014)

Glass, D.E.; Dilley, A.D.; Kelly, H.N.: Numerical analysis of convection/transpiration cooling. J. Spacecraft Rockets 38(1), 15–20 (2001)

Huang, G.; Zhu, Y.; Liao, Z.; Xu, R.; Jiang, P.-X.: Biomimetic self-pumping transpiration cooling for additive manufactured porous module with tree-like micro-channel. Int. J. Heat Mass Transf. 131, 403–410 (2019)

Le Brocq, P.; Launder, B.; Priddin, C.: Experiments on transpiration cooling: first paper: discrete hole injection as a means of transpiration cooling; an experimental study. Proc. Instit. Mech. Eng. 187(1), 149–157 (1973)

Singh, K.: Three dimensional Couette flow with transpiration cooling. Zeitschrift für angewandte Mathematik und Physik ZAMP 50(4), 661–668 (1999)

Cao, T.; Yu, K.; Li, W.; Chen, X.; Zhu, H.: Theoretical and experimental studies of internal cuttings removal bit. J. Energy Res. Technol. 143(4), 043002 (2020)

Wang, J.; Lu, S.; Wang, Y.; Li, C.; Wang, K.: Effect analysis on thermal behavior enhancement of lithium–ion battery pack with different cooling structures. J. Energy Storage 32, 101800 (2020)

Song, Y.; Li, C.; Yu, H.; Tang, Y.; Xia, Z.: Optimization of the phase-change wallboard test method: experimental and numerical investigation. J. Storage 30, 101559 (2020)

van Foreest, A.; Sippel, M.; Gülhan, A.; Esser, B.; Ambrosius, B.; Sudmeijer, K.: Transpiration cooling using liquid water. J. Thermophys. Heat Transfer 23(4), 693–702 (2009)

Bonetto, F.; Lebowitz, J.L.; Rey-Bellet, L.: Fourier's law: a challenge to theorists. In: Fokas, A., et al. (eds.) Mathematical Physics 2000, pp. 128–150. Imperial College Press, London (2000)

Dubi, Y.; Di Ventra, M.: Fourier’s law: insight from a simple derivation. Phys. Rev. E 79(4), 042101 (2009)

He, F.; Wang, J.; Xu, L.; Wang, X.: Modeling and simulation of transpiration cooling with phase change. Appl. Therm. Eng. 58(1–2), 173–180 (2013)

Bruch, J.C., Jr.; Zyvoloski, G.: Transient two-dimensional heat conduction problems solved by the finite element method. Int. J. Numer. Meth. Eng. 8(3), 481–494 (1974)

Curry, D.M.: An analysis of a charring ablation thermal protection system. NASA TN D-3150 (1965)

Yan-Hou, X.; Xue-Shi, Y.: Control of transpiration cooling system and its characteristics. Appl. Math. Mech. 14(11), 1047–1056 (1993)

Yang, X.; Zhang, J.; Qin, S.; Ning, H.: Mathematical modeling of heat transfer process in a variable domain. Russ. Aeronaut. (Iz VUZ) 50(2), 164–171 (2007)

Baliga, B.; Patankar, S.: A control volume finite-element method for two-dimensional fluid flow and heat transfer. Numer. Heat Transf. 6(3), 245–261 (1983)

Lienhard, I.; John, H.: A heat transfer textbook. Phlogiston Press, Cambridge (2005)

Jarny, Y.: Determination of heat sources and heat transfer coefficient for two-dimensional heat flow–numerical and experimental study. Int. J. Heat Mass Transf. 44(7), 1309–1322 (2001)

Prakash, V.; Appl, F.: Temperature distribution in synthetic diamond cutters during orthogonal rock cutting. SPE Drill. Eng. 4(02), 137–143 (1989)

Chui, E.; Raithby, G.: Computation of radiant heat transfer on a nonorthogonal mesh using the finite-volume method. Numerical Heat Transfer 23(3), 269–288 (1993)

Nedin, R.; Nesterov, S.; Vatulyan, A.: Identification of thermal conductivity coefficient and volumetric heat capacity of functionally graded materials. Int. J. Heat Mass Transf. 102, 213–218 (2016)

Yang, X.-H.; Tan, S.-C.; Liu, J.: Thermal management of Li-ion battery with liquid metal. Energy Convers. Manag. 117, 577–585 (2016)

Ma, K.; Liu, J.: Liquid metal cooling in thermal management of computer chips. Front. Energy Power Eng. Chin. 1(4), 384–402 (2007)

Wang, Q.; Yu, Y.; Liu, J.: Preparations, characteristics and applications of the functional liquid metal materials. Adv. Eng. Mater. 20(5), 1700781 (2018)

Guo, R.; Sun, X.; Yao, S.; Duan, M.; Wang, H.; Liu, J.; Deng, Z.: Semi-Liquid-Metal-(Ni-EGaIn)-Based Ultraconformable Electronic Tattoo. Adv. Mater. Technol. 4(8), 1900183 (2019)

Deng, Y.; Liu, J.: Design of practical liquid metal cooling device for heat dissipation of high performance CPUs. J. Electron. Packag. 132(3), 031009 (2010)

Li, P.; Liu, J.: Self-driven electronic cooling based on thermosyphon effect of room temperature liquid metal. J. Electron. Packag. 133(4), 041009 (2011)

Mayle, R.E.; Camarata, F.J.: Multihole cooling film effectiveness and heat transfer. J. Heat Transf. 97(4), 534–538 (1975)

Gritsch, M.; Colban, W.; Schär, H.; Döbbeling, K.: Effect of hole geometry on the thermal performance of fan-shaped film cooling holes. J. Turbomach. 127(4), 718–725 (2005)

Bazdidi-Tehrani, F.; Andrews, G.: Full-coverage discrete hole film cooling: investigation of the effect of variable density ratio. J. Eng. Gas Turbines Power. 116(3), 587–596 (1994)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant numbers: 51804322; 51821092; 51434009; 51774301), China Scholarship Council (201906440047), National Key Research and Development Project (Grant numbers: 2016YFC0303303; 2017ZX05009-003) and other projects (Grant numbers: 2462017YJRC050).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cao, T., Yu, K., Din, K. et al. A Self-cooling Bit with Transpiration Cooling Structures. Arab J Sci Eng 47, 11007–11019 (2022). https://doi.org/10.1007/s13369-021-05542-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05542-6