Abstract

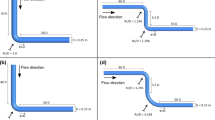

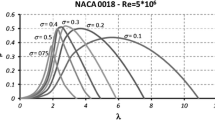

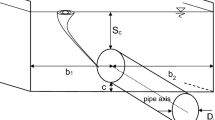

Effects of vaneless region length on the performance of a centrifugal compressor with vaned diffuser are studied in this paper. The vaneless region is defined as the space between the impeller outlet and the vaned diffuser inlet. In this work, the studied ratio between the diffuser inlet and impeller outlet is from 1.06 to 1.20. The simulation results show that the variation in the vaneless region has a great impact on the performance of the compressor stage. It is found that the proper extension of vaneless region improves the performance of compressor stage by significantly reducing the separation near shroud and uniformly disturbing flow velocity at impeller outlet and diffuser inlet. Sufficient extension of the vaneless region is necessary to produce beneficial effects, while the excessive extension will instead deteriorate the compressor performance. The mechanism of performance improvement is that reasonable vaneless space length is able to constrain the flow separation and to make the flow more uniform in the diffuser.

Similar content being viewed by others

Abbreviations

- Q :

-

Volume flow (m3/s)

- B :

-

Vane diffuser height (m)

- R :

-

Radius (m)

- P :

-

Static pressure (Pa)

- P T :

-

Total pressure (Pa)

- G :

-

Mass flow rate (kg/s)

- V :

-

Number of stator vanes

- Z :

-

Number of impeller blades

- N :

-

Rotational speed (r/min)

- LE:

-

Leading edge of blade

- TE:

-

Trailing edge of blade

- SS:

-

Suction side of blade surface

- PS:

-

Pressure side of blade surface

- U :

-

Impeller blade speed

- T :

-

Temperature (K)

- η :

-

Compressor stage efficiency

- \(\pi_{{\text{t}}}\) :

-

Total pressure ratio

- κ :

-

Adiabatic exponent

- ρ :

-

Density (kg/m3)

- φ :

-

Flow coefficient

- α :

-

Flow angle (degree)

- 1:

-

Impeller inlet

- 2:

-

Impeller outlet

- 3:

-

Diffuser inlet

- 4:

-

Diffuser outlet

- 5:

-

Return channel inlet

- 6:

-

Return channel outlet

References

Cumpsty NA (2004) Compressor aerodynamics. Krieger, Malabar

Dou H-S (1989) A method of predicting the energy losses in vaneless diffusers of centrifugal compressors. In: ASME conference on gas turbine and aeroengine congress and exposition, Toronto, Canada, 4–8 June, ASME 89-GT-158. ASME, New York, pp 1–6

Dou H-S (1990) On the problems for the design for radial vaneless diffuser with convergent wall. In: Chen N (ed) Proceedings of the first international symposium on experimental and computational aerothermodynamics, Beijing, China, 8–12 July, pp 595–601

Dou H-S (1991) Investigation of the prediction of losses in radial vaneless diffusers. In: ASME conference on gas turbine and aeroengine congress and exposition, Orlando, FL, US, 3–6 June, ASME 91-GT-323. ASME, New York, pp 1–12

Dou H-S (1994) The stability regimes of radial vaneless diffuser. J Eng Thermophys 2:166–169 (in Chinese)

Dou H-S, Mizuki S (1998) Analysis of the flow in vaneless diffusers with large width-to-radius ratios. ASME J Turbomach 120(1):193–201

Du Y, Dou H-S, Lu F (2020) Counter-propagating rotating stall of vaned diffuser in a centrifugal compressor near design condition. ASME J Turbomach 142(11):111007

Xi G, Wang SJ, Yuan MJ, Li DJ (1992) Experimental research for the discharge flow of centrifugal compressor impeller and the flow field in the vaneless diffusers. J Eng Therm 2:156–160 (in Chinsse)

Ubaldi M, Zunino P, Ghiglione A (1998) Detailed flow measurements within the impeller and the vaneless diffuser of a centrifugal turbomachine. Exp Therm Fluid Sci 17(1–2):147–155

Turunen ST, Reunanen A, Larjola J (2006) Computational and experimental study of pinch on the performance of a vaneless diffuser in a centrifugal compressor. J Therm Sci 3:306–313

Ahti JV, Pekka R, Teemu TS, Aki G (2013) Experimental study of centrifugal compressor vaneless diffuser width. J Mech Sci Tech 4:1011–1020

Koth H, Oeder K (1981) A study on centrifugal impeller and vaned diffuser flow. J Eng Gas Turb Power 1981:688–697

Agrawal N, Agrawal K, Mhaske S (1990) Experimental investigation of rotor–stator interaction in a centrifugal pump with several vaned diffusers. ASME J Turbomach 1:1–6

Shum YKP, Tan CS, Cumpsty NA (2009) Impeller–diffuser interaction in a centrifugal compressor. ASME J Turbomach 4:777–786

Engeda A (2001) The unsteady performance of a centrifugal compressor with different diffusers. Proc IMechE Part A J Power Energy 5:585–599

Reddy TCS, Murty GR, Prasad M (2014) Effect of diffuser vane shape on the performance of a centrifugal compressor stage. J Therm Sci 2:127–132

Fujisawa N, Hara S, Ohta Y (2016) Unsteady behavior of leading-edge vortex and diffuser stall in a centrifugal compressor with vaned diffuser. J Therm Sci 25(1):13–21

Fujisawa N, Ema D, Ohta Y (2017) Unsteady behavior of diffuser stall in a centrifugal compressor with vaned diffuser. In: Proceedings of the ASME turbo expo: turbine technical conference and exposition, 2017, Charlotte, NC, USA, June 26–30, vol 2D

Taher H, Mohamed A, Mohamed SG, Ibrahim S, Osama B (2015) Numerical investigation of rotating stall in centrifugal compressor with vaned and vaneless diffuser. J Therm Sci 4:323–333

Tang H, Du JY, Chu LZ, Zhao XL, Xu JZ (2006) Influence of the vaneless diffuser shape on centrifugal compressor performance. J Eng Therm 6:959–961

Simpson AT, Spence SWT, Watterson JK (2013) Numerical and experimental study of the performance effects of varying vaneless space and vane solidity in radial turbine stators. ASME J Turbomach 3:420–431

Justen F, Ziegler KU, Gallus HE (1999) Experimental investigation of unsteady flow phenomena in a centrifugal compressor vaned diffuser of variable geometry. ASME J Turbomach 121(4):763–771

Shum YKP, Tan CS, Cumpsty NA (2000) Impeller–diffuser interaction in a centrifugal compressor. ASME J Turbomach 122(4):777–786

Zemp A, Abhari RS (2013) Vaned diffuser induced impeller blade vibrations in a high-speed centrifugal compressor. ASME J Turbomach 135(2):021015

Tabatabaian M (2015) CFD module-turbulent flow modeling. Mercury Learning and Information, Dulles

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51579224).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: André Cavalieri.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Xu, W., Yang, S. et al. Effects of vaneless region length on the performance of centrifugal compressor with vaned diffuser. J Braz. Soc. Mech. Sci. Eng. 43, 227 (2021). https://doi.org/10.1007/s40430-021-02952-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02952-3