Abstract

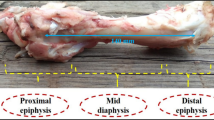

Overheating occurs during the bone drilling process using drill bits in orthopedic surgery. The temperatures frequently exceed 47 °C, usually accepted as critical value, since the bones and surrounding tissues burn and then cause the necrosis during the drilling process. To prevent this, orthopedic surgeons either spray coolants to the drilling zone or pause the drilling process until the bones and tissues cool down. Such heat damage in bones and soft tissues is undesirable event for surgeons. The bone chips, sometimes, are also complicating the bone fracture fixations. In this study, an investigation is described the effects of the processing parameters on bone chip formations, temperature levels and chip-vacuuming performances during drilling. The temperature levels are also measured using thermocouple devices. A bone chip collecting system is developed as a specific device to collect the chips or fragments using vacuuming technique. The collected bone chips are stored in a pot (reservoir) and delivered to a reparative site in case of necessary. Some design parameters for the developed vacuum system are identified considering the temperature rise during the drilling process. Analyzing the effects of these parameters on chip formation and developed vacuum system statistically and some results are presented. At the end of the study, the bone chip-vacuum device was developed and performed successfully to collect the whole fragments in the bone drilling experimental tests. The chip-collecting device was also useful to remove overheat from the drilling zone. The optimal level of the processing parameters was calculated as A1B3C1 for both vacuumed and non-vacuumed conditions. The fractured powder-type chips were formed as anticipated using the cortical structure of diaphyseal part of calf bone which is helpful for chip vacuuming device.

Similar content being viewed by others

References

Gok K, Buluc L, Muezzinoglu US, Kisioglu Y (2015) Development of a new driller system to prevent the osteonecrosis in orthopedic surgery applications. J Braz Soc Mech Sci Eng 37(2):549–558. https://doi.org/10.1007/s40430-014-0186-3

Hillery MT, Shuaib I (1999) Temperature effects in the drilling of human and bovine bone. J Mater Process Technol 92–93:302–308. https://doi.org/10.1016/S0924-0136(99)00155-7

Eriksson AR, Albrektsson T, Albrektsson B (1984) Heat caused by drilling cortical bone. Temperature measured in vivo in patients and animals. Acta Orthop Scand 55:629–631

Augustin G, Davila S, Mihoci K, Udiljak T, Vedrina D, Antabak A (2008) Thermal osteonecrosis and bone drilling parameters revisited. Arch Orthop Trauma Surg 128(1):71–77. https://doi.org/10.1007/s00402-007-0427-3

Sezek S, Aksakal B, Karaca F (2011) Ortopedik operasyonlardaki kemik delme işlemlerinde sıcaklık dağılım analizleri. In: 6th international advanced technologies symposium (IATS’11):276–281

Shakouri E, Haghighi Hassanalideh H, Gholampour S (2018) Experimental investigation of temperature rise in bone drilling with cooling: a comparison between modes of without cooling, internal gas cooling, and external liquid cooling. Proc Inst Mech Eng H 232(1):45–53

Sarparast M, Ghoreishi M, Jahangirpoor T, Tahmasbi V (2020) Experimental and finite element investigation of high-speed bone drilling: evaluation of force and temperature. J Braz Soc Mech Sci Eng 42(6):349. https://doi.org/10.1007/s40430-020-02436-w

Agarwal R, Jain V, Gupta V, Saxena S, Dwibedi V (2020) Effect of surface topography on pull-out strength of cortical screw after ultrasonic bone drilling: an in vitro study. J Braz Soc Mech Sci Eng 42(7):363. https://doi.org/10.1007/s40430-020-02449-5

Mercuri GM, Buss RA (2000) Bone harvesting collection and delivery system.

Enokida M, Kanaya H, Uehara K, Ueki M, Nagashima H (2019) An experimental comparative study of drilling efficiency and temperature elevation with unmodified and modified medical drills in pig tibia bone. Heliyon 5(8):e02189. https://doi.org/10.1016/j.heliyon.2019.e02189

Yang YX, Wang CY, Qin Z, Xu LL, Song YX, Chen HY (2010) Drilling force and temperature of bone by surgical drill. Adv Mater Res 126–128:779–784. https://doi.org/10.4028/www.scientific.net/AMR.126-128.779

Karaca F, Aksakal B (2013) Effects of various drilling parameters on bone during implantology: An in vitro experimental study. Acta Bioeng Biomech 15(4):25–32

Taguchi G, Elsayed EA, Hsiang TC (1989) Quality engineering in production systems. McGraw-Hill, New York

Montgomery DC (2000) Design and analysis of experiments. Wiley, New York

Gok K, Gok A, Kisioglu Y (2015) Optimization of processing parameters of a developed new driller system for orthopedic surgery applications using Taguchi method. Int J Adv Manuf Technol 76(5):1437–1448. https://doi.org/10.1007/s00170-014-6327-0

Gok K, Gok A, Kisioglu Y Computer Aided Finite Element Simulation of the Developed Driller System for bone Drilling Process in Orthopedic Surgery. J Adv Manuf Syst 0 (ja):null. https://doi.org/10.1142/s0219686719500318

Gok A, Gologlu C, Demirci HI (2013) Cutting parameter and tool path style effects on cutting force and tool deflection in machining of convex and concave inclined surfaces. Int J Adv Manuf Technol 69(5):1063–1078. https://doi.org/10.1007/s00170-013-5075-x

Lee J, Ozdoganlar OB, Rabin Y (2012) An experimental investigation on thermal exposure during bone drilling. Med Eng Phys 34(10):1510–1520

Sezek S, Aksakal B, Karaca F (2012) Influence of drill parameters on bone temperature and necrosis: a FEM modelling and in vitro experiments. Comput Mater Sci 60:13–18. https://doi.org/10.1016/j.commatsci.2012.03.012

Basiaga M, Paszenda Z, Szewczenko J, Kaczmarek M (2011) Numerical and experimental analyses of drills used in osteosynthesis. Acta Bioeng Biomech Wroclaw Univ Technol 13(4):29–36

Abouzgia MB, James DF (1995) Measurements of shaft speed while drilling through bone. J Oral Maxillofac Surg 53(11):1308–1315. https://doi.org/10.1016/0278-2391(95)90590-1

Toews AR, Bailey JV, Townsend HGG, Barber SM (1999) Effect of feed rate and drill speed on temperatures in equine cortical bone. Am J Vet Res 60:942–944

Matthews LS, Green CA, Goldstein SA, AA M (1984) The thermal effects of skeletal fixation-pin insertion in bone. J Bone Joint Surg 66(7):1077–1083

Augustin G, Davila S, Udiljak T, Vedrina D, Bagatin D (2009) Determination of spatial distribution of increase in bone temperature during drilling by infrared thermography: preliminary report. Arch Orthop Trauma Surg 129(5):703–709. https://doi.org/10.1007/s00402-008-0630-x

Mellinger JC, Ozdoganlar OB, Devor RE, Kapoor SG (2002) Modeling chip-evacuation forces and prediction of chip-clogging in drilling. J Manuf Sci Eng 124(3):605–614

Costich ER, Youngblood PJ, Walden JM (1964) A study of the effects of high-speed rotary instruments on bone repair in dogs. Oral Surg Oral Med Oral Pathol 17:563–571

Natali C, Ingle P, Dowell J (1996) Orthopaedic bone drills—can they be improved? temperature changes near the drilling face. J Bone Joint Surg British 78-B(3):357–362

Ohashi H, Therin M, Meunier A, Christel P (1994) The effect of drilling parameters on bone. J Mater Sci Mater Med 5(4):237–241. https://doi.org/10.1007/bf00121095

Nam O, Yu W, Choi MY, Kyung HM (2006) Monitoring of bone temperature during osseous preparation for orthodontic micro-screw implants: effect of motor speed and pressure. Key Eng Mater 321–323:1044–1047

Sharawy M, Misch CE, Weller N, Tehemar S (2002) Heat generation during implant drilling: the significance of motor speed. J Oral Maxillofac Surg Off J Am Assoc Oral Maxillofac Surg 60(10):1160–1169

Stabler GV (1951) The fundamental geometry of cutting tools. Proce Inst Mech Eng 165:14–26

Shamoto E, Altintas Y (1999) Prediction of shear angle in oblique cutting with maximum shear stress and minimum energy principles. J Manuf Sci Eng 121(3):399–407. https://doi.org/10.1115/1.2832695

Cordioli G, Majzoub Z (1997) Heat generation during implant site preparation: an in vitro study. Int J Oral Maxillofac Implants 12(2):186–193

Tehemar SH (1999) Factors affecting heat generation during implant site preparation: a review of biologic observations and future considerations. Int J Oral Maxillofac Implants 14(1):127–136

Kalidindi V (2004) Optimization of drill design and coolant systems during dental implant surgery. Master Thesis, University of Kentucky,

Liao Z, Axinte DA (2016) On monitoring chip formation, penetration depth and cutting malfunctions in bone micro-drilling via acoustic emission. J Mater Process Technol 229:82–93. https://doi.org/10.1016/j.jmatprotec.2015.09.016

Alam K, Mitrofanov AV, Silberschmidt VV (2011) Experimental investigations of forces and torque in conventional and ultrasonically-assisted drilling of cortical bone. Med Eng Phys 33(2):234–239. https://doi.org/10.1016/j.medengphy.2010.10.003

Acknowledgments

This project was granted by the Scientific and Technological Research Council of Turkey (TUBITAK) under the project number of 117M958. The authors would like to thank TUBITAK for valuable support and their understanding during the study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Adriano Fagali de Souza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gok, K., Erdem, M., Kisioglu, Y. et al. Development of bone chip-vacuum system in orthopedic drilling process. J Braz. Soc. Mech. Sci. Eng. 43, 224 (2021). https://doi.org/10.1007/s40430-021-02959-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02959-w