Abstract

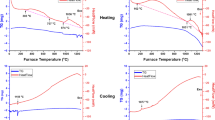

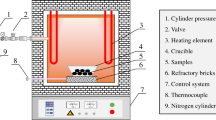

The technical viability of the marble waste as raw material in the iron ore pelletizing sector was investigated. The effects of binary basicity (0.15 to 0.45), fixed carbon (0.5 to 1.1 wt pct), and bentonite percentages (0.5 to 0.7 wt pct) on the pellet properties were also investigated. The physical properties of the pellets were determined for drop number, tumble strength, porosity, green pellet resistance, and fired pellet resistance. The reducibility test was determined by kinetic investigation under CO flow in the temperature range of 700 °C to 1100 °C applying the Forced Stepwise Isothermal Analysis method. The results demonstrated that the marble waste has potential to be used as raw material in the iron ore pelleting process. The maximum performance was obtained with a basicity of 0.45, fixed carbon of 0.5 wt pct, and bentonite content of 0.5 wt pct. This composition reached a mechanical strength of 284.38 kgf/pellet, drop number of 3.5 drops/pellet, tumble strength of 0.56 wt pct, and green pellet resistance of 1.53 kgf/pellet. The kinetic investigation reveals that the diffusion mechanism was the best-fitted mode that displayed an activation energy of 79.4 kJ/mol between 700 °C and 800 °C and 157.2 kJ/mol in the temperature range of 850 °C to 1050 °C.

Similar content being viewed by others

References

Abirochas, 2020. Balanço das Exportações e Importações Brasileiras de Rochas Ornamentais em 2019. https://abirochas.com.br/wp-content/uploads/2020/06/Informe-01_2020-Balan%C3%A7o-2019.pdf. Accessed 03 Aug 2020.

2.A.O. Mashaly, B.A. El-Kaliouby, B.N. Shalaby, A.M. El-Gohary and M.A. Rashwan: J. Cleaner Prod., 2016, vol. 112, pp. 731-41.

3.M.A. Silva, H.R. Paes Jr. and J.N.F. Holanda: J. Environ. Manage., 2011, vol. 92, pp. 936-40.

4.G. Tozsin, T. Oztas, A.I. Arol, E. Kalkan and O. Duyar: J. Cleaner Prod., 2014, vol. 81, pp. 146-49.

5.V. Nezerka, V. Hrbek, Z. Prosek, M. Somr, P. Tesarek and J. Fladr: J. Cleaner Prod., 2018, vol. 195, pp. 1081-90.

6.A. Khodabakhshian, M. Ghalehnovi, J. Brito and E.A. Shamsabadi: J. Cleaner Prod., 2018, vol. 170, pp. 42-60.

7.S. Yeşilaya, M. Çaki and H. Ergun: Ceram. Int., 2017, vol. 43, pp. 8912-21.

8.D.K. Ashish: J. Build. Eng., 2018, vol. 15, pp. 236-42.

ANM, 2020. Anuário Mineral Brasileiro: Principais Substâncias Metálicas (Brasília, 2020), http://www.anm.gov.br/dnpm/publicacoes/serie-estatisticas-e-economia-mineral/anuario-mineral/anuario-mineral-brasileiro/amb_2019_ano_base_2018. Accessed 9 Jul 2020.

10.S.K. Kawatra, and S.J. Ripke: Int. J. Miner. Process., 2002, vol. 65, pp. 141-49.

11.O. Sivrikaya and A.I. Arol: Int. J. Miner. Process., 2012, vol. 110-111, pp. 90-100.

12.K. Meyer: Pelletizing of iron ores, Springer, Berlin, 1980, pp. 138-39.

13.T. Umadevi, P. Kumar, N.F. Lobo, M. Prabhu, P.C. Mahapatra and M. Ranjan: ISIJ Int., 2011, vol. 51, pp. 14-20.

14.M. Iljana, A. Kemppainen, T. Paananen, O. Mattila, E. Pisilä, M. Kondrakov and T. Fabritius: Int. J. Miner. Process., 2015, vol. 141, pp. 34-43.

C.H. Borgert, L. Rosso Neto, F.E. Santos, F.F. Grillo, J.R. Oliveira and E. Junca: Proc. of 6º Simpósio Brasileiro de Aglomeração de Minérios, Associação Brasileira de Metalurgia, Materiais e Mineração, 2018, pp. 1-8.

ISO: ISO 3271:2015 - Determination of the tumble and abrasion indices (2015), https://www.iso.org/standard/62135.html. Accessed 10 Feb 2020.

17.P.L. Husum and O.T. Sorensen: Thermochim. Acta, 1987, vol. 114, pp. 131-8.

18.F. Chen, O.T. Sorensen, G. Meng and D. Peng: J. Therm. Anal., 1998, vol. 53, pp. 397-410.

19.L.A.P. Maqueda, A. Ortega and J.M. Criado: Thermochim. Acta, 1996, vol. 277, pp. 165-73.

20.P. Prusti, K. Barik, N. Dash, S.K. Biswal and B.C. Meikap: Powder Technol., 2020, vol. 379, pp. 154-64.

21.A.Z.M. Abouzeid, I.M. Kotb and A.A. Negm: Powder Technol., 1985, vol. 42, pp. 225-30.

22.S.N. Sahu, P.K. Baskey, S.D. Barma, S. Sahoo, B.C. Meikap and S.K. Biswal: Powder Technol., 2020, vol. 374, pp. 190-200.

T.Q.G. Vigneron, C.M.F. Vieira, G.C.G. Delaqua, F. V. Júnior and A. C. Neto: J. Mater. Res. Technol., 2019, vol. 8, pp. 5707-15.

24.Y. Ma and X. Du: Mater. Res., 2019, vol. 22, pp. 1-8.

25.M.M. Machado, L.E. Lagoeiro, L.M. Graça and C.J. Silva: Miner. Process. Extr. Metall. Rev., 2016, vol. 37, pp. 295-304.

26.T. Wiltowski, K. Piotrowski, H. Lorethova, L. Stonawski, K. Mondal and S.B. Lalvani: Chem. Eng. Process., 2005, vol. 44, pp. 775-83.

27.E. Junca, J.R. Oliveira, T.A.G. Restivo, D.C.R. Espinosa and J.A.S. Tenório: J. Therm. Anal. Calorim., 2016, vol. 123, pp. 631-41.

28.V.P. Ponomar, O.B. Brik, Y.I. Cherevko and V.V. Ovsienko: Chem. Eng. Res. Des., 2019, vol. 148, pp. 393-402.

29.K. He, Z. Zheng, Z. Chen, H. Chen and W. Hao: Int. J. Hydrogen Energy, 2020, https://doi.org/10.1016/j.ijhydene.2020.10.263.

30.R.J. Fruehan, Y. Li, L. Brabie and E.J. Kim: Scand. J. Metall., 2005, vol. 34, pp. 205-12.

31.Z. Wei, J. Zhang, B. Qin, Y. Dong, Y. Lu, Y. Li, W. Hao and Y. Zhang: Powder Technol., 2018, vol. 332, pp. 18-26.

32.D. Yu, M. Zhu, T.A. Utigard and M. Barati: Themochim. Acta, 2014, vol. 575, pp. 1–11.

33.E. Junca, F.F. Grillo, T.A.G. Restivo, J.R. Oliveira, D.C.R. Espinosa and J.A.S. Tenório: J. Therm. Anal. Calorim., 2017, vol. 129, pp. 1215-23.

34.A. Pineau, N. Kanari, I. Gaballah: Thermochim. Acta, 2007, vol. 456, pp. 75-88.

Y. Man and J.-X. Feng: Powder Technol., 2016, vol. 301, pp. 1213-17.

Acknowledgments

This work was supported by the Universidade do Extremo Sul Catarinense - UNESC, Conselho Nacional de Desenvolvimento Científico e Tecnológico - CNPq, and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - CAPES, Brazil.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 10 August 2020; accepted 17 February 2021.

Rights and permissions

About this article

Cite this article

Santos, F.E., Borgert, C.H., Neto, L.R. et al. Physical Characterization and Kinetic Analysis of the Iron Ore Pellets Produced with Marble Waste. Metall Mater Trans B 52, 1664–1680 (2021). https://doi.org/10.1007/s11663-021-02131-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02131-8