Abstract

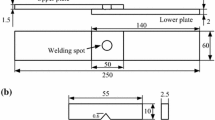

Refill friction stir spot welding (refill FSSW) is one of the most industrially promising friction stir spot welding variants. The absence of an exit hole improves the effectiveness of surface treatments and minimizes damage by fouling. Aerospace aluminium alloys AA2024-T3 and AA7075-T6 with a thickness of 2 mm were used in this investigation. A range of values for rotation speed and plunge depth were experimented to determine the most promising process parameter combination based on the cross-sectional analysis and lap shear strength. The effect of an interfacial sealant on the weld properties was determined for both alloys using the most promising process parameter combination. Fatigue life analysis and fractography using scanning electron microscopy were performed for specimens with and without sealant.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Mouritz AP (2012) Introduction to aerospace materials, 1st edn. Woodhead Publishing Limited, Cambridge, UK, pp 8–9

McCarthy CT, Irving MAMCIPE, Soutis C (2015) Polymer composites in the aerospace industry, 1st edn. Woodhead Publishing, Cambridge, UK, pp 295–334

Oliveira JP, Ponder K, Brizes E, Abke T, Edwards P, Ramirez AJ (2019) J Mater Process Tech 273:116192

Oliveira JP, Duarte JF, Inácio P, Schell N, Miranda RM, Santos TG (2017) Production of Al/NiTi composites by friction stir welding assisted by electrical current. Mater Design 113:311–318

Schilling C and dos Santos J, Gkss-Forschungszentrum Geesthacht GmbH, 2004. Method and device for joining at least two adjoining work pieces by friction welding. U.S. Patent 6,722,556

da Silva AAM, dos Santos JF, Rosendo TR, Ramos FD, Mazzaferro CCP, Tier MAD, Bergmann L, Mazzaferro JAE, Strohaecker TR (2007) SAE [Tech. Pap]

Amancio-Filho ST, Camillo AP, Bergmann L, Dos Santos JF, Kury SE, Machado NG (2011) Preliminary investigation of the microstructure and mechanical behaviour of 2024 Aluminium alloy friction spot welds. Mater Trans 52(5):985–991

Pieta G, dos Santos JF, Strohaecker TR, Clarke T (2014) Optimization of friction spot welding process parameters for AA2198-T8 sheets. Mater Manuf Process 29(8):934–940

Li Z, Ji S, Ma Y, Chai P, Yue Y, Gao S (2016) Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy. Int J Adv Manuf Tech 86(5–8):1925–1932

Yue Y, Shi Y, Ji S, Wang Y, Li Z (2017) J Mater Eng Perform 26(10), 5064–5071

de Castro CC, Plaine AH, de Alcântara NG, dos Santos JF (2018) Taguchi approach for the optimization of refill friction stir spot welding parameters for AA2198-T8 aluminum alloy. Int. J. Adv. Manuf. Tech. 99(5–8):1927–1936

Shen Z, Yang X, Zhang Z, Cui L, Li T (2013) Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des 44:476–486

Y. Zhao, H. Liu, , T. Yang, , Z. Lin, and Y. Hu: Study of temperature and material flow during friction spot welding of 7B04-T74 aluminum alloy Int J Adv Manuf Tech, 2016, vol. 83(9–12), 1467–1475

Kubit A, Trzepiecinski T, Faes K, Drabczyk M, Bochnowski W, Korzeniowski M (2019) Fatigue Fract Eng Mater Struct 42(6):1308–1321

Shen Z, Ding Y, Chen J, Fu L, Liu XC, Chen H, Guo W and P (2019) Sci Technol Weld Joining, 1–14

Boldsaikhan E, Fujimoto M, Kamimuki K, Okada H, Duncan B, Bui P, Yeshiambel M, Brown B, Handyside A (2016) SAE [Tech. Pap]

Schmal C, Meschut G, Nico BUHL (2019) Joining of high strength aluminum alloys by refill friction stir spot welding (III-1854-18). Weld World 63(2):541–550

A. Kubit, , D. Wydrzynski, and T. Trzepiecinski: Refill friction stir spot welding of 7075-T6 aluminium alloy single-lap joints with polymer sealant interlayer Compos Struct, 2018, vol. 201, 389–397

Boldsaikhan E, Fukada S, Fujimoto M, Kamimuki K, Okada H (2019) Refill friction stir spot welding of surface-treated aerospace aluminum alloys with faying-surface sealant. J Manuf Process 42:113–120

Rosendo T, Tier M, Mazzaferro J, Mazzaferro C, Strohaecker TR, Dos Santos JF (2015) Fatigue Fract. Eng Mater Struct 38(12):1443–1455

Li G, Zhou L, Luo L, Wu X, Guo N (2019) Microstructural evolution and mechanical properties of refill friction stir spot welded alclad 2A12-T4 aluminum alloy. J Mater Res Technol 8(5):4115–4129

Amancio-Filho ST, Bueno C, Dos Santos JF, Huber N, Hage E Jr (2011) Mat Sci Eng A-Struct 528(10–11):3841–3848

Suhuddin U, Gera D, Alcantara N, dos Santos JF (2019) In Y. Hovanski, R. Mishra, Y. Sato, P. Upadhyay, D. Yan (eds): Friction Stir Welding and Processing X, (pp. 245–253)

de Castro CC, Plaine AH, Dias GP, de Alcântara NG, dos Santos JF (2018) Investigation of geometrical features on mechanical properties of AA2198 refill friction stir spot welds. J Manuf Process 36:330–339

Zhao Y, Wang C, Li J, Tan J, Dong C (2018) Local melting mechanism and its effects on mechanical properties of friction spot welded joint for Al-Zn-mg-cu alloy. J Mater Sci Technol 34(1):185–191

Ji S, Wang Y, Li Z, Yue Y, Chai P (2017) Effect of tool geometry on material flow behavior of refill friction stir spot welding. Trans Indian Inst Metals 70(6):1417–1430

Kwee I, De Waele W, Faes K (2019) Weldability of high-strength aluminium alloy EN AW-7475-T761 sheets for aerospace applications, using refill friction stir spot welding. Weld. World 63(4):1001–1011

Santana LM, Suhuddin UFH, Ölscher MH, Strohaecker TR, dos Santos JF (2017) Process optimization and microstructure analysis in refill friction stir spot welding of 3-mm-thick Al-mg-Si aluminum alloy. Int J Adv Manuf Tech 92(9–12):4213–4220

Kubit A, Kluz R, Trzepieciński T, Wydrzyński D, Bochnowski W (2018) Analysis of the mechanical properties and of micrographs of refill friction stir spot welded 7075-T6 aluminium sheets. Arch Civ Mech Eng 18(1):235–244

Lage SBM, Campanelli LC, de Bribean Guerra AP, Shen J, dos Santos JF, da Silva PSCP and Bolfarini C (2018) Int J Adv Manuf Tech, 1–10

Effertz PS, Infante V, Quintino L, Suhuddin U, Hanke S, Dos Santos JF (2016) Int J Fatigue 87:381–390

Funding

This work was co-funded by the Industrial Members of TWI as part of the Core Research Programme and Coventry University via a PhD programme. The work was enabled through, and undertaken at, the National Structural Integrity Research Centre (NSIRC), a postgraduate engineering facility for industry-led research into structural integrity established and managed by TWI through a network of both national and international Universities.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis was performed by Pedro de Sousa Santos. The first draft of the manuscript was written by Pedro de Sousa Santos and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

•The effect of the main process parameters on weld static strength of single-spot AA2024-T3 and AA7075-T6 was determined.

•The lap shear strength of the parameter window explored exceeded the requirements of the spot welding standard AWS D17.2/D17.2M:2013.

•The impact of using an interfacial sealant on joint properties like the static and fatigue strength as well as microstructure characteristics of refill FSSW was assessed.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

de Sousa Santos, P., McAndrew, A.R., Gandra, J. et al. Refill friction stir spot welding of aerospace alloys in the presence of interfacial sealant. Weld World 65, 1451–1471 (2021). https://doi.org/10.1007/s40194-021-01113-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01113-3