Abstract

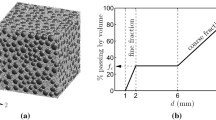

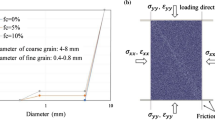

The effect of the intermediate principal stress (b quantifies its relative magnitude) on macroscale and microscale shear responses of binary granular mixtures with different fines contents (FCs) was investigated using the discrete element method. Mixtures were made up of coarse particles with real gravel shapes and fine particles with sphere shapes. True triaxial compression tests were conducted on their dense specimens. The shapes of coarse particles play an important role in the peak and critical friction angles and the peak dilatancy angles of binary granular mixtures. For mixtures with different FCs and an identical b, there is a linear relationship between the peak friction angle (or peak dilatancy angle) and the change in the void ratio. An acceptable equation was proposed to predict the peak dilatancy angle of a mixture. When b = 0.2 and 0.4, the coaxiality of strain increments and stresses is affected by the FC. A previous study classified mixtures as “underfilled”, “interactive-underfilled”, “interactive-overfilled” and “overfilled” based on the percentage contributions of coarse–coarse, coarse–fine and fine–fine contacts to the shear strength. This study shows that the b value has little effect on the classification of mixtures at the peak and critical states. Furthermore, it was observed that there is a linear relationship between the relative peak dilatancy angle and the difference between the partial coordination numbers based on the “subsphere–subsphere” approach at the peak and critical states.

Similar content being viewed by others

References

Kumruzzaman, M., Yin, J.-H.: Influences of principal stress direction and intermediate principal stress on the stress–strain–strength behaviour of completely decomposed granite. Can. Geotech. J. 47(2), 164–179 (2010)

Kumruzzaman, M., Yin, J.H.: Influence of the intermediate principal stress on the stress–strain–strength behaviour of a completely decomposed granite soil. Geotechnique 62(3), 275–280 (2012)

Xiao, Y., Liu, H., Chen, Y., Chu, J.: Influence of intermediate principal stress on the strength and dilatancy behavior of rockfill material. J. Geotech. Geoenviron. Eng. 140(11), 04014064 (2014)

Kandasami, R.K., Murthy, T.G.: Experimental studies on the influence of intermediate principal stress and inclination on the mechanical behaviour of angular sands. Granul. Matter 17(2), 217–230 (2015)

Xiao, Y., Sun, Y., Liu, H., Yin, F.: Critical state behaviors of a coarse granular soil under generalized stress conditions. Granul. Matter 18(2), 17 (2016)

Kandasami, R.K., Murthy, T.G.: Manifestation of particle morphology on the mechanical behaviour of granular ensembles. Granul. Matter 19(2), 21 (2017)

Qu, T., Feng, Y.T., Wang, Y., Wang, M.: Discrete element modelling of flexible membrane boundaries for triaxial tests. Comput. Geotech. 115, 103154 (2019)

Barnett, N., Rahman, M.M., Karim, M.R., Nguyen, H.B.K.: Evaluating the particle rolling effect on the characteristic features of granular material under the critical state soil mechanics framework. Granul. Matter 22(4) (2020)

Ng, T.-T., Ge, L.: Packing void ratios of very dense ternary mixtures of similar ellipsoids. Granul. Matter 22(2) (2020)

Ng, T.T.: Shear strength of assemblies of ellipsoidal particles. Geotechnique 54(10), 659–669 (2004)

Barreto, D., O’Sullivan, C.: The influence of inter-particle friction and the intermediate stress ratio on soil response under generalised stress conditions. Granul. Matter 14(4), 505–521 (2012)

Sazzad, M.M., Suzuki, K., Modaressi-Farahmand-Razavi, A.: Macro-micro responses of granular materials under different b values using DEM. Int. J. Geomech. 12(3), 220–228 (2012)

O’Sullivan, C., Wadee, M.A., Hanley, K.J., Barreto, D.: Use of DEM and elastic stability analysis to explain the influence of the intermediate principal stress on shear strength. Geotechnique 63(15), 1298–1309 (2013)

Sazzad, M.M., Suzuki, K.: Density dependent macro-micro behavior of granular materials in general triaxial loading for varying intermediate principal stress using DEM. Granul. Matter 15(5), 583–593 (2013)

Huang, X., Hanley, K.J., O’Sullivan, C., Kwok, C.Y., Wadee, M.A.: DEM analysis of the influence of the intermediate stress ratio on the critical-state behaviour of granular materials. Granul. Matter 16(5), 641–655 (2014)

Li, B., Zhang, F., Gutierrez, M.: A numerical examination of the hollow cylindrical torsional shear test using DEM. Acta Geotech. 10(4), 449–467 (2014)

Li, B., Chen, L., Gutierrez, M.: Influence of the intermediate principal stress and principal stress direction on the mechanical behavior of cohesionless soils using the discrete element method. Comput. Geotech. 86, 52–66 (2017)

Zhou, W., Liu, J., Ma, G., Chang, X.: Three-dimensional DEM investigation of critical state and dilatancy behaviors of granular materials. Acta Geotech. 12(3), 527–540 (2017)

Vallejo, L.E., Mawby, R.: Porosity influence on the shear strength of granular material-clay mixtures. Eng. Geol. 58(2), 125–136 (2000)

Vallejo, L.E.: Interpretation of the limits in shear strength in binary granular mixtures. Can. Geotech. J. 38(5), 1097–1104 (2001)

Gong, J., Nie, Z., Zhu, Y., Liang, Z., Wang, X.: Exploring the effects of particle shape and content of fines on the shear behavior of sand-fines mixtures via the DEM. Comput. Geotech. 106, 161–176 (2019)

Ng, T.T., Zhou, W., Chang, X.L.: Effect of particle shape and fine content on the behavior of binary mixture. J. Eng. Mech. 143(1), 9 (2016)

Gong, J., Liu, J.: Mechanical transitional behavior of binary mixtures via DEM: Effect of differences in contact-type friction coefficients. Comput. Geotech. 85, 1–14 (2017)

Gong, J., Liu, J., Cui, L.: Shear behaviors of granular mixtures of gravel-shaped coarse and spherical fine particles investigated via discrete element method. Powder Technol. 353, 178–194 (2019)

Xiao, Y., Long, L., Evans, T.M., Zhou, H., Liu, H., Stuedlein, A.W.: Effect of particle shape on stress-dilatancy responses of medium-dense sands. J. Geotech. Geoenviron. Eng. 145(2), 04018105 (2019)

Xiao, Y., Stuedlein, A.W., Ran, J., Evans, T.M., Cheng, L., Liu, H., van Paassen, L.A., Chu, J.: Effect of particle shape on strength and stiffness of biocemented glass beads. J. Geotech. Geoenviron. Eng. 145(11), 06019016 (2019)

Lopez, R.D., Silfwerbrand, J., Jelagin, D., Birgisson, B.: Force transmission and soil fabric of binary granular mixtures. Geotechnique 66(7), 578–583 (2016)

ICOLD: Bulletin 164: Internal Erosion of Dams, Dikes, and their Foundations. Paris, France, (2013)

Itasca: User's Manual for PFC3D version PFC5.0. Itasca Consulting Group Inc., Minneapolis (2014)

Taghavi, R.: Automatic clump generation based on mid-surface. In: Proceedings of the Continuum and Distinct Element Numerical Modeling In Geomechanics (2011)

Salgado, R., Bandini, P., Karim, A.: Shear strength and stiffness of silty sand. J. Geotech. Geoenviron. Eng. 126(5), 451–462 (2000)

Lee, J., Salgado, R., Carraro, J.A.H.: Stiffness degradation and shear strength of silty sands. Can. Geotech. J. 41(5), 831–843 (2004)

Carraro, J.A.H., Prezzi, M., Salgado, R.: Shear strength and stiffness of sands containing plastic or nonplastic fines. J. Geotech. Geoenviron. Eng. 135(9), 1167–1178 (2009)

Lopez, R.D., Ekblad, J., Silfwerbrand, J.: Resilient properties of binary granular mixtures: A numerical investigation. Comput. Geotech. 76, 222–233 (2016)

Lade, P.V., Liggio, C.D., Yamamuro, J.A.: Effect of nonplastic fines on minimum and maximum void ratios of sand. Geotech. Test. J. 21(4), 336–347 (1998)

Shire, T., O’Sullivan, C., Hanley, K.J.: The influence of fines content and size-ratio on the micro-scale properties of dense bimodal materials. Granul. Matter 18(3), 52 (2016)

Horn, H.M., Deere, D.U.: Frictional characteristics of minerals. Geotechnique 12(4), 319–335 (1962)

Rowe, P.W.: Stress-dilatancy relation for static equilibrium of an assembly of particles in contact. In: Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences (1962)

Senetakis, K., Coop, M.R., Todisco, M.C.: The inter-particle coefficient of friction at the contacts of Leighton Buzzard sand quartz minerals. Soils Found. 53(5), 746–755 (2013)

Senetakis, K., Coop, M.R., Todisco, M.C.: Tangential load–deflection behaviour at the contacts of soil particles. Geotech. Lett. 3(2), 59–66 (2013)

Guo, N., Zhao, J.: The signature of shear-induced anisotropy in granular media. Comput. Geotech. 47, 1–15 (2013)

Guo, N., Zhao, J.: Local fluctuations and spatial correlations in granular flows under constant-volume quasistatic shear. Phys. Rev. E 89(4), 042208 (2014)

Gu, X.Q., Huang, M.S., Qian, J.G.: DEM investigation on the evolution of microstructure in granular soils under shearing. Granul. Matter 16(1), 91–106 (2014)

Coetzee, C.J.: Calibration of the discrete element method and the effect of particle shape. Powder Technol. 297, 50–70 (2016)

Goldenberg, C., Goldhirsch, I.: Friction enhances elasticity in granular solids. Nature 435(7039), 188–191 (2005)

Jiang, M., Shen, Z., Wang, J.: A novel three-dimensional contact model for granulates incorporating rolling and twisting resistances. Comput. Geotech. 65, 147–163 (2015)

da Cruz, F., Emam, S., Prochnow, M., Roux, J.N., Chevoir, F.: Rheophysics of dense granular materials: Discrete simulation of plane shear flows. Phys. Rev. E 72(2), 021309 (2005)

Perez, J.C.L., Kwok, C.Y., O’Sullivan, C., Huang, X., Hanley, K.J.: Assessing the quasi-static conditions for shearing in granular media within the critical state soil mechanics framework. Soils Found. 56(1), 152–159 (2016)

Christoffersen, J., Mehrabadi, M.M., Nemat-Nasser, S.: A micromechanical description of granular material behavior. J. Appl. Mech. 48(2), 339–344 (1981)

Schanz, T., Vermeer, P.A.: Angles of friction and dilatancy of sand. Geotechnique 46(1), 145–151 (1996)

Nie, Z., Fang, C., Gong, J., Liang, Z.: DEM study on the effect of roundness on the shear behaviour of granular materials. Comput. Geotech. 121, 103457 (2020)

Jamiolkowski, M., Kongsukprasert, L., Lo Presti, D.: Characterization of gravelly geomaterials. In: Proceedings of the Fifth International Geotechnical Conference, Bangkok, Thailand (2004)

Zhao, J., Guo, N.: Unique critical state characteristics in granular media considering fabric anisotropy. Geotechnique 63(8), 695–704 (2013)

Zhou, W., Wu, W., Ma, G., Ng, T.-T., Chang, X.: Undrained behavior of binary granular mixtures with different fines contents. Powder Technol. 340, 139–153 (2018)

Radjai, F., Wolf, D.E., Jean, M., Moreau, J.J.: Bimodal character of stress transmission in granular packings. Phys. Rev. Lett. 80(1), 61–64 (1998)

Minh, N.H., Cheng, Y.P.: A DEM investigation of the effect of particle-size distribution on one-dimensional compression. Geotechnique 63(1), 44–53 (2013)

Markauskas, D., Kacianauskas, R., Dziugys, A., Navakas, R.: Investigation of adequacy of multi-sphere approximation of elliptical particles for DEM simulations. Granul. Matter 12(1), 107–123 (2010)

Azema, E., Radjai, F., Saint-Cyr, B., Delenne, J.Y., Sornay, P.: Rheology of three-dimensional packings of aggregates: Microstructure and effects of nonconvexity. Phys. Rev. E 87(5), 052205 (2013)

Nie, Z., Zhu, Y., Wang, X., Gong, J.: Investigating the effects of Fourier-based particle shape on the shear behaviors of rockfill material via DEM. Granul. Matter 21(2), 22 (2019)

Oda, M.: Fabric tensor for discontinuous geological materials. Soils Found. 22(4), 96–108 (1982)

Satake, M.: Fabric tensor in granular materials. In: Proceedings of the IUTAM Symposium on Deformation and Failure of Granular Materials, Delft (1982)

Ouadfel, H., Rothenburg, L.: ‘Stress–force–fabric’ relationship for assemblies of ellipsoids. Mech. Mater. 33, 201–221 (2001)

Kanatani, K.I.: Distribution of directional data and fabric tensors. Int. J. Eng. Sci. 22(2), 149–164 (1984)

Foroutan, T., Mirghasemi, A.A.: CFD-DEM model to assess stress-induced anisotropy in undrained granular material. Comput. Geotech. 119, 103318 (2020)

Acknowledgments

The authors are grateful for the financial support given by these projects, including the Fundamental Research Funds for the Central Universities of Central South University (No. 2018zzts195) and the National Natural Science Foundation of China (No. 51809292). The authors thank Prof. Nie (Zhihong Nie) for his help in the initial stage of the paper.

Author information

Authors and Affiliations

Contributions

Xiaoping Cao: conceptualization, investigation, validation, visualization, data curation. Yangui Zhu: formal analysis, writing-original draft, writing- reviewing and editing, funding acquisition, supervision, project administration. Jian Gong: methodology, software, funding acquisition, resources.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, X., Zhu, Y. & Gong, J. Effect of the intermediate principal stress on the mechanical responses of binary granular mixtures with different fines contents. Granular Matter 23, 37 (2021). https://doi.org/10.1007/s10035-021-01110-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01110-9