Abstract

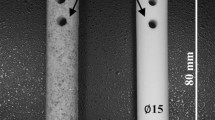

Desulfurization phenomenon of Ni-base superalloy using a solid CaO was identified by adjusting the temperature of melt. Ni-base superalloy and NiS powder were heated together at 1400 °C, 1500 °C, and 1600 °C. Dense and porous CaO rods were inserted into the melts individually. After the rods were pulled out, CaO, CaS, and calcium aluminates were detected on the rods by X-ray diffraction analysis. Electron probe microanalysis showed that only Ca, O, Al, and S distributed at the melt/CaO interfaces. At 1500 °C and 1600 °C, Al and S were also detected at particle boundaries in the rods. S contents in the alloys decreased as the desulfurization time passed and the temperature was raised. There was no prominent correlation between the rod porosity and the S contents. The desulfurization reaction was suggested to be that CaO, Al, and S react to generate CaS and calcium aluminates. When the temperature is high enough, the calcium aluminates form a solid–liquid coexisting state. Effective diffusion coefficient, which shows the S diffusivity in the generated layer at the melt/CaO interface, depends on the temperature and can be expressed by the Arrhenius equation. It has been supposed that the desulfurization reaction mainly occurs on CaO, and a macroscale surface area controls the desulfurization rate.

Similar content being viewed by others

Abbreviations

- [Pct Al]:

-

Content of Al in the melt (pct)

- [Pct S]:

-

Content of S in the melt (pct)

- a i :

-

Activity of each material

- A :

-

Area of the melt/CaO interface (m2)

- CS,0 :

-

Initial S content in the melt (ppm)

- C S,t :

-

S content in the melt at time t (ppm)

- C S, fin :

-

Final S content in the melt (ppm)

- D :

-

Effective diffusion coefficient (m2/s)

- \( e_{i}^{j} \) :

-

Interaction parameter of each material

- f Al :

-

Activity coefficient of Al in the melt

- \( \Delta G_{i}^{0} \) :

-

Gibbs free energy of each chemical reaction (J/mol)

- i, j :

-

Material

- K :

-

Equilibrium constant of each chemical reaction

- M i :

-

Molar mass of each material (g/mol)

- R:

-

The gas constant: 8.31 (J/(mol K))

- t :

-

Desulfurization time (= holding time of the CaO rod in the melt) (s)

- T :

-

Absolute temperature of the melt during the experiment (K)

- \( W_{\text{Ni}} \) :

-

Weight of the melt (g)

- \( \rho_{i} \) :

-

Density of each material (g/m3)

References

H. Harada, T. Tetsui, Y. Gu, J. Fujioka, K. Kawagishi, and K. Matsumoto: Journal of the Gas Turbine Society of Japan, 2013, vol. 41, pp.85–92.

T. Matsui: Journal of the Gas Turbine Society of Japan, 2011, vol. 39, pp. 261–266.

P. Caron: Superalloys. TMS, Champion, PA, 2000, pp. 737–746.

K. Kawagishi, A. Yeh, T. Yokokawa, T. Kobayashi, Y. Koizumi, and H. Harada: Superalloys. TMS, Seven Springs, 2012, pp. 189–195.

V. V. S. Prasad, A. S. Rao, U. Prakash, V. R. Rao, P. K. Rao, and K. M. Gupt: ISIJ Int., 1996, vol. 36, pp. 1459-1464.

S. K. Mamo, M. Elie, M. G. Baron, A. M. Simons, and J. Gonzalez-Rodriguez: Sep. Purif. Technol., 2019, vol. 212, pp. 150-160.

S. Utada, Y. Joh, M. Osawa, T. Yokokawa, T. Kobayashi, K. Kawagishi, S. Suzuki, and H. Harada: Superalloys.. TMS, Champion, PA, 2016, pp. 591–599.

H. Harada, K. Kawagishi, T. Kobayashi, T. Yokokawa, M. Osawa, M. Yuyama, S. Suzuki, Y. Joh, S. Utada, US Patent, patent number 10689741 (2020.06.23).

J. X. Dong, X. S. Xie, and R. G. Thompson: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2135–2144.

Y. Joh, S. Utada, M. Osawa, T. Kobayashi, T. Yokokawa, K. Kawagishi, S. Suzuki, and H. Harada: Mater.Trans., 2016, vol. 57, pp. 1305–08.

S. Utada, Y. Joh, M. Osawa, T. Yokokawa, T. Sugiyama, T. Kobayashi, K. Kawagishi, S. Suzuki, and H. Harada: Metall. Mater. Trans. A, 2018, vol. 49, pp. 4029-4041.

H. J. Grabke, D. Wiemer, and H.Viefhaus: Appl. Surf. Sci., 1991, vol. 47, pp. 243–250.

M. A. Smith, W. E. Frazier, and B. A. Pregger: Mater. Sci. Eng. A, 1995, vol. A203, pp. 388-398.

C. Sarioglu, C. Stinner, J. R. Blachere, N. Birks, F. S. Pettit, G. H. Meier, and J. L. Smialek: Superalloys. TMS, Seven Springs, Champion, PA, 1996, pp. 71-81.

Y. Joh, T. Kobayashi, T. Yokokawa, K. Kawagishi, M. Osawa, S. Suzuki, and H. Harada: 10th Liège Conf.: Materials for Advanced Power Engineering, 2014, pp. 538–44.

D. W. Yun, S. M. Seo, H.W. Jeong, and Y. S. Yoo: Corros. Sci., vol. 90, 2015, pp. 392–401.

T. Sugiyama, S. Utada, T. Yokokawa, M. Osawa, K. Kawagishi, S. Suzuki, and H. Harada: Metall. Mater. Trans. A, 2019, vol. 50, pp. 3903-3911.

T. Yokokawa, H. Harada, K. Kawagishi, M. Osawa, Y. Takata, M. Yuyama, T. Kobayashi, T. Sugiyama, and S. Suzuki: Superalloys 2020, TMS, Seven Springs, Champion, PA, Accepted for publication.

V. V. Sidorov and P. G. Min: Russ. Metall., 2014, vol. 2014, pp. 982–986.

J. Niu, K. Yang, T. Jin, X. Sun, H. Guan, and Z. Hu: J. Mater. Sci. Technol., 2003, vol. 19, pp. 69-72.

Y. Kishimoto, S. Utada, T. Iguchi, Y. Mori, M. Osawa, T. Yokokawa, T. Kobayashi, K. Kawagishi, S. Suzuki, and H. Harada: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 293-305.

Y. Kishimoto, T. Iguchi, T. Kono, T. Yokokawa, M. Osawa, K. Kawagishi, S. Suzuki, and H. Harada: Proceedings of Joint EPRI-123HiMAT International Conference on Advances in High-Temperature Materials, 2019, pp. 426–32.

A. K. Chatterjee and G. I. Zhmoidin: J. Mater. Sci., 1972, vol. 7, pp. 93-97.

K. Kawagishi, T. Yokokawa, T. Kobayashi, Y. Koizumi, M. Sakamoto, M. Yuyama, H. Harada, I. Okada, M. Taneike, and H. Oguma: Superalloys. TMS, Champion, PA, 2016, pp. 115-122.

K. Kawagishi, H. Harada, T. Yokokawa, Y. Koizumi, T. Kobayashi, M. Sakamoto, M. Yuyama, M. Taneike, I. Okada, S. Shimohata, H. Oguma, R. Okimoto, K. Tsukagoshi, Y. Uemura, J. Masada, and S. Torii: Patent WO2014024734A1, 2013, WPIO/PCT.

T. Iida: Journal of the Japan Welding Society, 1993, vol. 62, pp. 590-594.

T. Tanaka, Y. Ogiso, M. Ueda, and J. Lee: ISIJ Int., 2010, vol. 50, pp. 1071-1077.

I. Barin: Thermochemical Data of Pure Substances, 3rd ed., VCH Verlagsgesellschaft mbH, Weinheim and VCH Publishers, Inc., New York, NY, 1995.

G. K. Sigworth, J. F. Elliott, G. Vaughn, and G. H. Geiger: Can. Metall. Q., 1977, vol. 16, pp.104-110.

W. V. Venal and G. H. Geiger: Metall. Trans., 1973, vol. 4, pp. 2567-2573.

S. W. Cho and H. Suito: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 249-256.

R. H. Rein and J. Chipman: Trans. Metall. Soc. AIME, 1965, vol. 233, pp. 415-425.

K. Saito and Y. Kawai: J.Japan Inst.Met.Mater., 1953, vol. 17, pp. 434-438.

E. S. Vorontsov and O. A. Esin: Izv. Akad. Nauk. SSSR Otd. Tekh. Nauk., 1958, pp. 152–55.

Acknowledgments

This research was financially supported by Japan Science and Technology (JST), under the Advanced Low Carbon Technology Research and Development Program (ALCA) project “Development of Direct and Complete Recycling Method for Superalloy Turbine Aerofoils (Grant No. JPMJAL1302)”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 13, 2020, accepted February 5, 2021.

Appendix

Appendix

Derivation of Thermodynamic Equilibrium Calculation

Thermodynamics equilibrium in Figure 13 is explained as follows. Gibbs free energies at 1873 K (1600 °C) are calculated by references.[28,29,30]

Therefore, the Gibbs free energy of the desulfurization reaction at 1873 K is

The Equilibrium constant K1 is

K1 is written as

Therefore, logarithm of Al activity: \( { \log }(a_{\text{S}} ) \) is

Using the value of \( a_{\text{CaO}} \) = 0.99, \( a_{{{\text{Al}}_{2} {\text{O}}_{3} }} \) = 0.0095,[31] and assuming that \( a_{\text{CaS}} \) = 1, Eq. [A-14] is written as

The Gibbs free energy of following reaction at 1873 K is[32]

The following desulfurization reaction at 1873 K can be also calculated as

The equilibrium constant K2 is

Therefore, \( { \log }(a_{\text{S}} ) \) is

The values are \( a_{\text{CaO}} \) = 1 and \( a_{{{\text{Al}}_{2} {\text{O}}_{3} }} \) = 0.06,[32] therefore \( a_{{3{\text{CaO}} \cdot {\text{Al}}_{2} {\text{O}}_{3} }} \) = 0.06 calculated by Eqs. [A-16] and [A-17]. The value of \( a_{{3{\text{CaO}} \cdot {\text{Al}}_{2} {\text{O}}_{3} }} \) is assumed as 0.01 and 0.1 in this calculation. Assuming that \( a_{\text{CaS}} \) = 1, Eq. [A-21] is

Derivation of log(a Al) and log(a S)

Logarithm of Al activity: aAl can be written by activity coefficient: fAl, and content of Al in the melt: [Al pct].

In this paper, only Al and S in molten Ni are considered to derive aAl. log(aAl) is written by interaction parameters:\( e_{i}^{j} \) as

Similar to log(aAl), log(aS) is written as

log(aAl) and log(aS) are calculated by these values: \( e_{\text{Al}}^{\text{Al}} \) = 0.08,[29] \( e_{\text{S}}^{\text{Al}} \) = 0.133,[30] \( e_{\text{S}}^{\text{S}} \) = − 0.035,[31] and

Rights and permissions

About this article

Cite this article

Kishimoto, Y., Kono, T., Horie, T. et al. Temperature Dependence of CaO Desulfurization Mechanism in Molten Ni-Base Superalloy. Metall Mater Trans B 52, 1450–1462 (2021). https://doi.org/10.1007/s11663-021-02112-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02112-x