Abstract

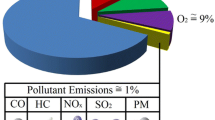

The process used by engine manufacturers for the development of a new engine includes the planning and conceptual design phases, followed by the detailed design phase, in which the design target specifications are met. In the conceptual design phase, a rough specification of the target engine is presented to facilitate a detailed design and the additional cost of modification is reduced exponentially. In the conceptual design phase, however, not only is there no real engine. but there are also no 1D and 3D models present, so it is impossible to test and simulate them. Therefore, at this stage, a model that can predict emission and performance only according to the specifications and operating conditions of the engine would be very useful. Previous studies developed an EGR prediction model that can be used in the 0-D NOx prediction using a deep learning method. In this study, a NOx prediction model with high accuracy using only the operating conditions as input variables, without ECU data, was developed using deep neural networks. The developed model has high accuracy with an R-square of 0.988. The feature of this model is that all the input parameters for the deep neural network come from the operating conditions of the engine. Therefore, this model can be used in the early stages of the development of new engines when testing and simulation cannot be performed because they do not exist. The designer can set the range of the operating conditions such that they do not exceed the NOx limits at the specific operating point (specific rpm and BMEP). This variable operating design methodology is expected to be useful in the development of new engines for automobile manufacturers with various engine data.

Similar content being viewed by others

Abbreviations

- ANN :

-

Artificial neural networks

- BMEP :

-

Brake mean effective pressure

- DNN :

-

Deep neural networks

- ECU :

-

Engine control unit

- EGR :

-

Exhaust gas recirculation

- ELU :

-

Exponential linear unit

- NOx :

-

Nitrogen oxides

- PM :

-

Particulate matters

- RELU :

-

Rectified linear unit

- (R)MSE :

-

(Root) mean squared error

References

EPA (Environmental Protection Agency), Nitrogen Oxides, Why and How They are Controlled, Technical Bulletin, EPA 456/F-99-006R (2012).

D. G. Ullman, The Mechanical Design Process, New York, McGraw-Hill, 2 (1992).

F. Rosenblatt, The perceptron: a probabilistic model for information storage and organization in the brain, Psychological Review, 65(6) (1956) 386–408.

M. Minsky and S. Papert, Perceptrons: An Introduction to Computational Geometry (Expanded Edition), Editorial the MIT Pres. Libro publicado, 28 (1987).

J. L. McClelland, D. E. Rumelhart and PDP Research Group, Parallel Distributed Processing, Cambridge, MA: MIT press, 2 (1987).

M. Ayeb, D. Lichtenthäler, T. Winsel and H. J. Theuerkauf, SI engine modeling using neural networks, SAE Technical Paper, 980790 (1998).

G. Najafi, B. Ghobadian, T. Tavakoli, D. R. Buttsworth, T. F. Yusaf and M. Faizollahnejad, Performance and exhaust emissions of a gasoline engine with ethanol blended gasoline fuels using artificial neural network, Applied Energy, 86(5) (2009) 630–639.

R. K. Mehra, H. Duan, S. Luo, A. Rao and F. Ma, Experimental and artificial neural network (ANN) study of hydrogen enriched compressed natural gas (HCNG) engine under various ignition timings and excess air ratios, Applied Energy, 228 (2018) 736–754.

S. H. Shin, S. Y. Lee, M. J. Kim, J. H. Park and K. D. Min, Performance and emission prediction of gasoline engine using deep neural networks, Korean Society of Automotive Engineering Autumn Conference (2018).

J. H. Park, S. W. Cho, C. H. Song, S. Y. Lee, M. J. Kim and K. D. Min, Development of a knock onset determination model in SI engine by deep learning, Korean Society of Automotive Engineering Autumn Conference (2018).

S. Cho, J. Park, C. Song, S. Oh, S. Lee, M. Kim and K. Min, Prediction modeling and analysis of knocking combustion using an improved 0D RGF model and supervised deep learning, Energies, 12(5) (2019) 844.

S. Lee, Y. Lee, Y. Lee, M. Kim, S. Shin, J. Park and K. Min, EGR prediction of diesel engines in steady-state conditions using deep learning method, Int. J. of Automotive Tech., 21(3) (2020) 571–578.

Keras Documents, https://keras.io.

P. Kingma and J. Ba, Adam: a method for stochastic optimization, arXiv preprint arXiv: 1412.6980 (2014).

V. Nair and G. Hinton, Rectified linear units improve restricted Boltzmann machines, International Conference on Machine Learning (2010).

D. A. Clevert and T. Unterthiner, Fast and accurate deep network learning by exponential linear units (ELUs), arXiv:1511.07289 (2015).

N. Srivastava, G. Hinton, A. Krizhevsky, I. Sutskever and R. Salakhutdinov, Dropout: a simple way to prevent neural networks from overfitting, The Journal of Machine Learning Research (2014) 1929–1958.

S. Ioffe and C. Szegedy, Batch normalization: accelerating deep network training by reducing internal covariate shift, arXiv:1502.03167 [cs.LG] (2015).

A. Krogh and J. A. Hertz, A simple weight decay can improve generalizaztion, NIPS’91: Proceedings of the 4th International Conference on Neural Information Processing Systems (1991) 950–957.

F. Chollet, Deep Learning mit Python unt Keras: Das Praxis-Handbuch vom Entwicker der Keras-Bibliothek, MITP-Verlags GmbH & Co. KG. (2018).

W. Park, J. Lee, K. Min, J. Yu, S. Park and S. Cho, Prediction of real-time NO based on the incylinder pressure in diesel engines, Proc. Combustion Institute, 34(2) (2013) 3075–3082.

Acknowledgments

This research was supported by the Hyundai Motor Group and the SNU IAMD for Kyoungdoug Min, and also financially supported by Hansung University for Sangyul Lee.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Yong Tae Kang

Sangyul Lee obtained his B.S. (2006), M.S. (2008) and Ph.D. (2013) in Mechanical Engineering from Seoul National University, respectively. Presently he is an Assistant Professor in Division of Mechanical and Electronic Engineering at Hansung University, Seoul, S. Korea.

Kyoungdoug Min received his B.S. and M.S. degrees from the Department of Mechanical Engineering at Seoul National University in 1986 and 1988, respectively. He obtained his Ph.D. degree from M.I.T in 1994. He is now a Professor in the School of Mechanical and Aerospace Engineering at Seoul National University.

Rights and permissions

About this article

Cite this article

Lee, S., Lee, Y., Lee, Y. et al. Proposal of a methodology for designing engine operating variables using predicted NOx emissions based on deep neural networks. J Mech Sci Technol 35, 1747–1756 (2021). https://doi.org/10.1007/s12206-021-0337-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-0337-2