Abstract

This article is detected to the assessment of durable deformations of recycled mixtures made of foamed bitumen (MCAS) and emulsion (MCE). In the basic part of research and analyses, attention was focused on determining the scale of three-component composition modifying rheological phenomena of recycled mixtures and other selected features considering various methods of bituminous binder proportioning. Cement, hydrated lime, and dusts from cement dust extracting system were included in the composition hydraulic binder. In this paper, the effect of graining of recycled mixture was also taken into account. One of the main scientific aims of the paper was to evaluate the degree of changes in durable deformations described in the power model depending on proportions of elements making three-element hydraulic binder. In effect, it was pointed out that the influence of hydraulic binder differently affected the durable deformation of recycled mixture depending on ways of bitumen binder implementation. There-element binder exerted the highest influence on mechanical properties of mixtures with fine-grained mixtures made according to the MCAS technology. The presence of 4 groups of mixtures with different properties was demonstrated using the classification neuron net. Based on that information, a set of the most recommended solutions from the point of view of time deformation resistance, low sensitiveness to the load level at moderate stiffness was selected. The best representative among them was the arrangement with 20% of hydrated lime, less than 40% of CBPD dusts and 40 ÷ 60% of cement.

Similar content being viewed by others

1 Introduction

Recycled mixtures are universally applied materials for basic and auxiliary base courses both in reconstructions and new road structures [1]. They may be executed in the technologies of foamed bitumen as well as bitumen emulsions. The choice of binder influences their visco-elastic properties [2]. Also the application of adequately selected waste materials making the mix skeleton has a significant influence on durability of the designed recycled mixtures [3]. It should be remembered that application of waste or recycled materials qualifies that technology as a pro-ecological solution [4]. However, a very important role played by appropriate hydraulic binder should not be forgotten. Its presence is required on account of retaining an appropriate cohesion of recycled mixture [5] moving away the risk of exceeding critical state. According to the research of Ramanujam and others [6], application of hydraulic lime especially made of foamed bitumen allowed raising the durable deformation resistance in the early stage of technological use of a road section. In this case, the strong influence of a high content of CaO on well-distributed foamed bitumen binder would trigger off strong bitumen structuring as it takes place in mastic [7]. Moreover, the presence of hydraulic binder provides an additional improvement of bitumen binder dispersion, water resistance, and an additional increment of bitumen stiffness. However, the excess of hydraulic binder can lead to premature cracking induced thermally or through the shrinkage phenomenon [5, 8]. Many researchers have taken up the subject of hydraulic binder influence. Iwański et al. [9] in their project have applied an experimental plan enabling looking for complex relationships in three-element binder containing ashes and hydraulic lime. Finally, the researchers have demonstrated that the application of mixed binder caused an improvement of water resistance and frost resistance confirming its universal nature in creating mix structures. It should not be forgotten that the presence of each component in binder plays the role of a dispersion catalyst for foamed bitumen or a decomposition of bitumen emulsion causing a significant correctness of mechanical properties of recycled mixtures. The paper [8] discovers an advisable influence of foamed bitumen in the interaction with cement on fatigue resistance of recycled mixtures. Another work [10] proved that addition of rubber powder in MCE mixtures contributes to the reduction of their stiffness modules and indirect tensile strength.

The application of cement as a binder is the most frequent method of increasing the cohesion degree of recycled mixes. However, the lack of correctly executed process optimization of cement amount may lead to an excessive rigidifying of recycled mixtures and appearance of cracks [11]. Enriching the composition of hydraulic binder through introducing pulverized fly ashes may cause saving cement amounts simultaneously improving the tightness of recycled mix and its resistance to durable deformations [12]. On the other hand, the need to apply hydrated lime may be justified through conclusions contained in the paper [13] which confirms a favorable influence of hydrate lime on correction of shear strength of recycled mix without loss of its elasticity.

In spite of benefits of applying recycling technologies, there are still restrictions on their implementation and popularization. Therefore, it was one of the reasons for limiting its practicing in Poland for the traffic at intensity over ESAL100kN > 7.3 Mill. of axles. In the age of the need for recycling, the recycling technology can be an effective and economic solution.

In the present paper, the particular emphasis was placed on the analysis of creeping phenomenon in recycled mixtures from the angle of appropriately selected composition of hydraulic binder. Taking into account experiences of mentioned above selected authors of papers, it was decided to prepare three-element binder which had the task to limit excessive base-course stiffness, and simultaneously assure the high permanent deformation resistance. It was significant during technological works on newly executed sections. Moreover, the application of dusts from the cement de-dusting systems CPBD (cement by-pass dust) made the additional aspect taken into consideration. Their introduction was aimed at improving mechanical qualities of recycled mix and reducing amounts of cement by a material with reliable binding properties. In the works of Owsiak [14, 15], the possibility of significant implementation of CPBD was demonstrated. It was found that thanks to the content of a certain amount of CaO, this type of dust can be used to reduce a certain amount of cement, obtaining a significant increase in the tensile strength of the mortar made with the use thereof. However, to control swelling, the presence of hydrated lime was necessary. Taking into account hydrated lime was aimed at increasing elasticity which limits the possibility of occurrence of premature cracks in the base course because of its overloading, the favorable presence of hydrated lime, due to its rheological properties, in the binder can be explained by its high adhesion to asphalt binder described by numerous Lesuerur studies [16] and the existence of mechanisms at the asphalt-filler boundary presented in the works [7, 17, 18]. The complex classification assessment through the Kohonen’s network was carried out because of the lack of requirements. It allowed to choose the collection of the best solutions assuring behavior of high deformation resistance respecting required physical and mechanical parameters.

2 Materials and methods

2.1 Foamed bitumen and emulsion

2.1.1 Rheological bitumen properties

Actions aimed at the complex assessment and selection of bitumen subjected to the foaming process that would make good recycled mixtures were taken up in the early stage of research. By reason of that cause measurements of basic rheological properties of bitumen brought out from recycled asphalt paving mixtures coming from two sources with grading 0/10 and 0/31.5 were carried out. Moreover, Table 1 additionally presents two road bitumens with penetration 50/70 and 70/100 which were considered for making emulsion and performing bitumen foaming. The results in Table 1 are enriched with an average confidence range at the materiality level α = 0.05.

Results presented in Table 1 point out that bitumen from recycled asphalt paving mixtures has properties of hard bitumen, i.e., it has low penetration at temp. 25 °C, high softening temperature, high dynamic viscosity particularly at the temperature range from 60 °C to 90 °C, and very high breaking point. Bitumen from recycled asphalt paving mixtures 0/31.5 was disadvantageously marked by high-temperature susceptibility demonstrating definite viscosity changes with temperature rise. Also bitumen of recycled asphalt paving mixtures is characterized by a bit wider plasticity range (73 °C), while remaining bitumen has plasticity range at a lower nearer level (62–65 °C). Determining elastic recovery according to EN 13,398 [20] in case of bitumen from recycled asphalt paving mixtures was additionally carried out for checking possibilities of appearing modifications. Carrying out elastic recovery was possible only in case of bitumen from recycled asphalt paving mixtures 0/10, but the achieved result was at a very low level coming to 20%. It can reflect on properties of initial bitumen or possible minimal modification. At the general assessment, it should be taken into consideration that regained bitumen is subjected to technological ageing which causes lowering penetration, the rise of the softening point, and decisive growth of viscosity. In this case, the operational ageing resulting from the time of using road pavements from which recycled asphalt mixtures were acquired has an additional influence. Taking into account the influence of ageing, it can be found that research results of regained bitumen 0/10 show characteristics fulfilling requirements for typical bitumen of type 35/50, whereas differing from regained bitumen of recycled asphalt paving mixtures 0/31.5 toward road bitumen 20/30. It should be noted that results of road bitumen 50/70 and 70/100 concern bitumen in an original state not subjected to the ageing process. The important question in case of selection of road bitumen is its capability to increase workability of recycled mixture while mixing it with cold and rigid reclaimed asphalt. Moreover, preserving the tenacious nature of recycled mixture is another crucial issue. Observing results of measuring bitumen viscosity at 90 °C (the typical temperature during mixing with mineral mixture) and the softening point, both bitumens (50/70 and 70/100) had similar values suggesting possibility of receiving an approximate workability. The process of manufacturing foamed bitumen also entails some changes in the chemical composition. The result is the asphalt ageing. Effective mixing of foamed asphalt with recycled aggregate requires a careful recognition of the rheology of the asphalt from the point of view of the ageing effect during foaming and mixing. The combination of these effects significantly allowed for an optimal selection of foaming parameters. A more-detailed analysis of the simulation of this process was published in the paper [26].

In connection with that additional advanced rheological research were carried out aimed at evaluation of changing rate of bitumen susceptibility in time. It was crucial from the influence viewpoint of a given bitumen on the compaction process of recycled mixture.

The 2S2P1D model and the application of the principle of superposition applied for the complex comparison therein were used for creating the model of master curve [21, 22]. The proposed model for assessing the rheological nature of the base and extracted asphalt, marked as 2S2P1D, is a generalization of the Huet–Sayegh model. It originates from a group of mechanical models and allows to describe the state of stress and deformation of the material in the range of linear visco-elasticity (LVE). This model was developed by Olard and Di Benedetto [29]. The stress amplitude level applied to the specimen had to be lower than the stress limit value of the linear visco-elastic range (LVE). Therefore, the test should be performed for very small deformations. On the basis of the preliminary tests, a shear stress limit of the LVE range of 30 Pa was established. A Rheotest 4.1 rheometer with an 8 mm-diameter parallel plate system was used for the test. The limit value of the LVE range corresponded to a reduction of G* by 5% [30]. Dynamic tests were carried out in a rotational viscometer type Rheotest 3.1 with an oscillating mode. It is represented in Fig. 1.

The 2S2P1D model contains two spring elements: G∞ (an equivalent of static modulus with an endless loading time), Go (moment modulus with the loading time tending to zero), two parabolic dumpers h and k, and a linear dumper β (taking into account viscosity of zero shear ηo), t—loading time, and h—exponent changing from 0 to 1 (h = 0 meaning elastic behavior, h = 1 meaning viscous behavior). After transformation of the 2S2P1D model, the function describing changes in the complex shear modulus G* in time has the following form (1):

where:

\({\text{G}}^{*} \left( \omega \right)\)—the complex shear modulus in frequency domain, k and h—exponents 0 < k < h < 1 h changing from 0 to 1 (h = 0—elastic behavior, h = 1—viscous behavior), α, \({ }\beta\)—constants, and\({\uptau }\)—characteristic time.

The superposition principle TTSP was taken into account through the characteristic time formula (2):

where:

T—research temperature, \({\uptau }_{{\text{o}}}\)—initial characteristic time, and A0, A1—model parameters.

The estimation of model parameters required the application of nonlinear method of minimizing the objective function at fixed preliminary values. To do it, the complex macroscript in the MathCad program was made. Two quality measurements, i.e., the determination index R2 and relative mean-squared error (RMSE) [22], were used for assessment of matching the model for experimental data. Results of identified parameters of the 2S2P1D model can be seen in Table 2, while the graphic interpretation of the visco-elastic nature of bitumen can be showed in Fig. 2.

Attention should be drawn to bitumen 70/100 which was characterized by the higher value of parameter h than bitumen 50/70 suggesting its decisive viscous characteristics. Moreover, the low value of parameter δ in bitumen 70/100 indicates its low stiffening level. The low value of parameter k and β correlating with low value of viscosity at zero shearing (ηo) proved that bitumen 70/100 will be deformed quickly, which significantly facilitates the mixing process and compacting recycled mix in comparison with bitumen 50/70.

Finally, bitumen 70/100 was chosen and applied for the foaming process. It was justified with the results of rheological measurements showing high susceptibility of bitumen to loading time and temperature. Selection of the present bitumen was also driven by the necessity of increasing its workability due to the occurrence of hard bitumen contained in reclaimed asphalt. Bitumen 70/100 also allowed for the fulfillment of the initial assumption of limiting stiffness of recycled mix located in the base-course layer and higher resistance to low temperatures designated on the grounds of measurements BBR (Table 2).

2.1.2 Properties of foaming bitumen

The usefulness assessment for foaming accepted road bitumen 70/100 was carried out according to the methodology applied by the authors of paper [6, 23]. The optimal water content indispensable for receiving bitumen foam was determined acc. to requirements [24]. The result of assessment is shown in Fig. 3.

Foaming binder was carried out at a temperature of 160˚C, water pressure of 6.0 kPa, and air pressure of 5.5 kPa. These foaming parameters also took into account the effect of ageing during the foaming process. As a result of using the model, the increase in bitumen rigidity 70/100 after ageing (IS) did not exceed the value of IS = 1.05 [26] while maintaining high compliance. The optimal foamed water content equal to 2.5% toward the mass of bitumen binders was determined using results of papers [25, 26]. Foamed bitumen with optimal values of the maximal expansion Emax = 14.0 and half life time = 10.0 s was directly introduced during mixing of recycled mix.

2.1.3 Properties of asphalt emulsion

The assessment of asphalt emulsion C60B10ZM/R was carried out in accordance with requirements of the national annex to harmonized standard EN 13,808 [27]. The results are presented in Table 3.

It should be added that asphalt emulsion was also made of bitumen 70/100 aiming at the comparison of results of recycled mixes by applying foamed bitumen. That treatment allowed to set off the influence of bitumen scattering process (foaming or emulsification) on properties of recycled mixes.

2.2 Three-component binder

Proportions of components in the present experiment were named based on the plan of mix with limits (simplex-centroid plan). The basic plan of mix was modified in such a way that the amount of each component was in a range from 20 to 80% [28, 29]. Due to the fact that the binder components had a similar volumetric density, it was decided that their proportions would be determined by weight (w/w). The plan of experiment included making 7 different compositions of universal binder including their randomization. The binder compositions were presented in Table 4.

Additional information on a subject of the influence of three-component binder on properties of standard grouts and their chemical composition can be found in the paper [9, 30].

2.3 The mineral composition design of a deep cold recycling mixture

Application of materials coming from the existing system of construction layers is necessary according to recommendations [24, 31] for composing recycled mixes in the cold state. In this connection, the mineral skeleton of recycled mixture will contain reclaimed asphalt (RAP) 0/31.5 mm originated as a result of milling of existing layers of mineral–bitumen mixtures and natural aggregate with continuous grading 0/31.5 mm coming from existing base course. The content of bitumen in reclaimed asphalt (RAP) was 5.1%. The project of laboratory reception of recycled mixture in the cold state was worked out acc. to guidelines for MCE and MCAS mixes [24, 31]. Fulfilling the grading criteria both for recycled mixture with foamed asphalt (MCAS) and asphalt emulsion (MCE) was aimed at designing laboratory composition of mixture recycled in the cold state. The received course of grading curve is presented in Fig. 4.

The upshot was that two grading curves were designed. The first one was of the fine-grained nature (D), while the second one was coarse-graded (G). This action was aimed at taking into account the characteristic effect of grading recycled mixture. Both curves were applied for making recycled mixtures considering two different recycling technologies, i.e., MCE and MCAS.Taking into account the applied plan of the binder mixture in Table 4 and the granulation (Fig. 4), the following system of determining samples (cases) is adopted. The acronym of the case consisted of the part identifying the type of mixture, the type of granulation and the type of binder mixture. The MCAS_G designation denoted a coarse-grained mixture of MCAS (a recycled mixture with foamed asphalt), while MCAS_D with fine grades, respectively. Prefix MCE denotes the application of emulsion in the recycled mix. The type of binder combination is given below. For example, MCAS_G_6_C denoted the case of a coarse-grained mix recycled with foamed asphalt in which a binder with a composition corresponding to case 6C (hydrated lime 40%, cement 40%, and CBPD 20%) was used. In addition, the analysis included a case where cement was used as a reference mix. Therefore, the samples were labeled MCAS_G_CEM.

2.4 Cyclic compression test

Testing creeping (CCT) of recycled cement–bitumen mixtures with foamed bitumen (MCAS) and mineral–cement mixtures with asphalt emulsion (MCE) was carried out in accordance with resolutions of the standard EN 12,697–25 Method B [32]. The test was carried out on the basis of 4 samples for each composition of recycled mixtures. This research method defines the resistance of a cylindrical probe of asphalt mixture to permanent deformation caused by repeatable loading. The probes were prepared in the laboratory fulfilling the assumption on a minimal relationship H (height) / D (diameter). The accepted proportions of H/D amounted to 1.8. The scheme of test in the UTM apparatus is presented in Fig. 5.

Test parameters were accepted based on the standard EN 13,108–20 table D.2 [33] which unambiguously imposed conditions of the test:

-

Condition temperature—15 °C,

-

Test temperature—40 °C,

-

Side constrainment (σc)—50 kPa,

-

Axis stress (σA(t) = σv(t) + σc)—200 kPa,

-

Load frequency—3 Hz,

-

Wave shape—haversine.

Analyzing the layout of typical road structures placed in the Polish Catalogue [34, 35], the adoption of the present input values was also dictated by the fact that the established stress state was in conformity with the stress state appearing in base-course layers on the basis of EN 13,108–20 [33].

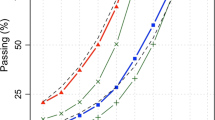

2.5 Wheel tracking test: large device

The wheel tracking test for resistance to permanent deformations in a large apparatus (WTT) is the practice applied for assessment of such deformations of mineral–asphalt mixtures including mixtures for base courses. That method relies on subjecting the compacted samples of mineral–asphalt mixture to many passes of a standard pneumatic solid tire wheel in specified conditions of temperature, pressure and number of passes down the probe. The test result makes proportional rut depth P expressed in percentage of a function of a number of loading cycles with the use of two samples for each composition of the recycled mix. There were the following test conditions according to the standard EN 12,697–22 [36]:

-

Length of a wheel pass 410 mm ± 5 mm,

-

Frequency of a wheel movement: 1 Hz ± 0.1 Hz,

-

Pressure in a tire 6.0 ± 0.1 bar,

-

Traffic loading 5,000 ± 50 N,

-

Test temperature + 60 ± 0.2 °C,

-

Loading cycle number 30,000.

2.6 Void content

The void content Vm [37] makes the content of air pores in a probe of mineral mixture with foamed bitumen expressed as percentage of complete probe volume acc. to the formula (3):

where: ρm—density of a mineral mixture MCAS/MCE [Mg/m3] and ρbssd—volume density of a mineral mixture MCAS/MCE [Mg/m3]. The test was carried out on the basis of 4 samples for each composition of the recycled mix.

2.7 Indirect tensile test

Testing indirect tensile strength ITSDRY [38] of mixture was carried out on Marshall’s probes of diameter 101.6 ± 0.3 mm and height 62.5 ± 2.5 mm, cured 28 days at relative humidity from 40% up to 70%. The test was performed at a temperature of + 25 °C. Performing tests consist in placing samples between two plates and compressing them with a constant deformation speed of 50 ± 2 mm/min. The test was carried out on the basis of 4 samples for each composition of the recycled mix. Indirect tensile strength ITS is calculated acc. to the formula (4):

where:

P—maximal force destructing probe [N]; h—probe height [mm], and D—probe diameter [mm].

2.8 Dynamic modulus

Testing dynamic modulus |E*| was carried out through the DTC-CY method on cylindrical probes aiming at an assessment of rheological properties of MCE mixes with different binders. The test was executed according to EN 1297-26D [39] and depended on a cycle axial loading cylindrical probe. The force, displacement, angle of phase shoving, and cycle number were registered during testing. Finally, the dynamic modulus |E*| was calculated on the basis of 4 samples for each composition of the recycled mix. The following conditions were accepted at testing dynamic modulus:

-

Temperature: − 10, 5, 13, 25, 40 °C,

-

Frequency: 0.1, 0.3, 1, 3.5, 10, 20 Hz,

-

Controlled deformation 25με,

-

Shape of load wave—sinusoidal.

2.9 Creep power law

There is a principle adopted in the literature that the scope of linear visco-elasticity (the Boltzman’s superposition principle) for mineral–bitumen mixes as well as for recycled mixes is obligatory for deformations in a probe below 100 micro-displacements [40, 41]. However, mineral–bitumen mixtures show nonlinear behavior in relation σ → ε already at a very low level of deformation [7, 42]. A material can be regarded as linear visco-elastic one when the compliance depending on time J(t) (creeping test) does not rely on the stress level. In the reverse case, the Boltzman’s superposition principle is not obligatory and the material behaves like a non-linear visco-elastic one. At that time, significant irreversible deformations occur in the material and the level of dissipated energy is significant. The most frequently applied in the literature approach to the description of non-linear behavior is the models of non-linear visco-elasticity based on integral passages such as Leaderman, Schapery, or Findley models [43, 44]. However, these models, in spite of satisfactory implementation FEM, contain many parameters. The power model is a certain compromise, especially convenient for describing creeping phenomenon [44,45,46,47]. The time-hardening power model in an implementation form in the ABAQUS program is a special case of the Findley’s model [48] (5): the Findley’s model for a single burden of proof has the form [43, 49] (5):

where:

\(h_{o} \left( \sigma \right), h_{1} \left( \sigma \right)\)—coefficients depending on the stress level, \(J_{o}\)—instantaneous compliance (1/\(E_{o}\)), \(\Delta J\left( t \right)\)—compliances depending on time, and \(\sigma\)—equivalent axial stress.

Based on an assumption that the behavior of material depends on an open form of stress and its variability will be low during the process of creeping, the power model with time-hardening will be the most suitable solution. Simplifying that problem, the differential form of time-hardening power model expressing the growth rate of deformation in fact characterizing the term \(h_{1} \left( \sigma \right) \cdot \Delta J\left( t \right)\) of Eq. (5) can be expressed as (6):

where:

A, n, m—parameters of the power model (A > 0, n > 0, − 1 < m ≤ 0).

Integrating the Eq. (6), we receive the term of Eq. (5) depending on time in a form (7):

Taking into account the fact of occurring in the power model parts of deformation independent of time and taking \(h_{o} \left( \sigma \right) = 1\) [50], the term \(h_{o} \left( \sigma \right) \cdot J_{o} \cdot \sigma\) of Eq. (5) can be expressed as \(\frac{\sigma }{{E_{o} }}\). Pertinently, the equivalent axial deformation in the creep effect can be pointed out from the formula (8):

where: Eo—instantaneous elastic modulus at t → 0.

Finally, the formula (8) was compacted with the record implemented in the ABAQUS program on the basis of Findley’s model. In connection with that, the identification of the power model with time-hardening should be carried out to enable the prediction of deformations obtained in the creep process. Certainly, the above model has not taken into account the temperature effect. The implementation of temperature influence on deformations caused by creeping is not difficult. It needs taking into account additional part in the formula (8) resulting from the Arrhenius’s formula [51, 52].

2.10 Kohonen’s classification network

The network proposed by Kohonen has a very simple structure. Two layers of neurons: input layer and output layer make its composition. The connections occurring in the network are of “each with each” nature. The Kohonen’s network is characterized by the one-way flow of information: from the input layer to the output layer. Teaching in the Kohonen’s network is performed “without a teacher”. The base of teaching makes the teaching collection which every element is a vector of the number of elements corresponding with the number of neurons in the input layer of the network. The distance between input data and weights of the following neurons of output layer is calculated after presentation of a teaching master. The specific quality of the Kohonen’s network is carrying out the modification process of neuron weights not only for the winning neuron but also for all neurons within the limits of winner [53]. The weight vector of winning neuron ww is calculated through the formula (9):

The distance d is most often expressed through the Euclidean’s formula or scalar product. Both the winning neuron and its proximity are subjects of adaptation acc. to the dependency (10):

where: k is a subsequent step of adaptation, \({\text{G}}_{{\text{i}}} \left( {{\text{i}},{\text{x}}_{{\text{k}}} } \right)\) is a proximity function, and \({\upeta }_{{\text{i}}}\) is a teaching constant.

The parameter \(\eta_{i}\) is a teaching stage decreasing under interaction. Commonly, there is a real need to normalize input data in case of the low number of input vectors. A significant number of individual studies are essential for the construction of the Kohonen maps. In the work, the minimum number of samples of MCE and MCAS mixtures was determined by the provisions of the above-mentioned European standards. The Kohonen network diagram—SOM (self-organizing map) and the number of sample replications are shown in Fig. 6.

Having completed teaching weights imitate the distribution of input data of the vector x. Consequently, the teaching process leads to making the topographical map. It has the possibility of imitating dependencies between objects on similar objects corresponding with the same space (neuron) or areas situated close to each other. The objects significantly differing from each other cause activating neurons located in the areas distant from each other. It should be noted that SOM networks are constantly an astounding algorithm. In spite of an easy implementation and practical results, its reasonable properties still remain without a general proof in spite of contribution of many scientists [54].

3 Test results

3.1 Dynamic modulus and phase angle

The dynamic modulus |E*| and corresponding value of phase shift δ were described to reflect visco-elastic characteristics of recycled mixes. This test was important in terms of assessing the material reply within the scope of small deformations (a linear visco-elasticity region). Results of medium values characterizing spread of data below 5% are presented in Fig. 7. They reflect rheological effects of recycled mixes at a testing temperature of 40 °C and frequency 3 Hz.

Results of the dynamic modulus in circumstances described above were not directly introduced to the power model which needs application of values of dynamic modulus aiming at infinity, which is presented in further part of this paper. However, the given value of dynamic modulus (Fig. 7a) is proportional to results of dynamic modulus in other conditions, while it allows to describe deformability of recycled mix in conditions stipulated in EN 13,108–20 [33]. It should be noted that the highest changeability (width of a rectangular object) was observed in a recycled mix of MCAS type. It confirms the strong influence of composition of hydraulic binder on changeability of the feature |E*|. In case of MCE, mix changeability |E*| was decidedly lower and all cases were contained below the median of mixes MCE_D and MCE_G. Moreover, results |E*| obtained within the collection of results ascribed to the MCE technology were comparable on a similar level and to a low degree depending on binder type. The value of dynamic modulus was almost five times lower as |E*| commonly received in recycled MCAS mixes. The similar relation, inversely proportional, was registered for distributing the mark δ (Fig. 7b). Analyzing results of the angle of phase displacement in MCAS recycled mixes, one should notice that it was almost two times lower than in MCE mixes. Pertinently, MCE mixes were showing decidedly more viscous nature due to the high share of viscous part E'' in dynamic modulus. Thereby the level of dissipated energy will be decidedly higher than in recycled mixes MCAS, which will probably occur as the higher accumulation of permanent deformations caused by long-lasting loading.

3.2 Calibration of power model parameters using CCT data

A lot of information about originating permanent displacements in recycled mixture with three-element binder was collected based on the series of tests carried out using cylindrical probes. The calibration process of the power model was executed based on at least two replications of probes of recycled mixtures acc. to the paper [32]. The power model implemented in the Abaqus program is basically dedicated to tests in which loading is apposed in a monotonic way. Defining very little step of integration time in numerical analyses is required, because there is a high risk of getting the lack of convergence in succeeding steps of integrating. The calibration process was performed based on the results of irreversible deformations containing a series of cycles: loading 0.33 s and unloading 0.33 s [55, 56]. The summary persistence time of testing was ca. 6700 s (10,000 cycles). In the calibration process, the value of instantaneous resilient modulus Eo was adopted for the short loading time (10 Hz) at test temperature of -10 °C in other words representing a part of compliance independent of time acc. to works [44, 57].

The test was carried out for two loading cases. The first one consisted in putting axial loading to a cylinder probe with a value of σ1 = σequiv = 100 kPa at a lack of side constrainment, while the second one subsisted in putting to the probe axial loading σ1 = 200 kPa and a side loading σ1 = σ3 = 50 kPa (σequiv = 150 kPa). Such a stress level results from the fact that there are no stresses in recycled layers of base course equal to the contact pressure of a car tire figuring out 700 kPa. Moreover, adopting a wide range of stress values could cause serious errors of adapting the power model to experimental data [43, 57]. The estimation of the power model was executed for deformation rates at time dε/dt in which the value of modulus Eo did not appear. The selected results of changes of deformation rate for cases MCAS_D_5C and MCAS_D_7C can be viewed in Fig. 8a and c.

Attention should paid to a very good adjustment of results of deformation rate of the power model (\(\dot{\varepsilon })\) represented by the formula (6) to results of experiment within the given stress range. Making next moves, using the formula (6), the simulation of deformation change in loading time was carried out (Fig. 8b and Fig. 8d). In case of results presented in Fig. 8d for the case MCAS_D_7C, the adjustment was also on a high level. However, in case of binder MCAS_D_5C in spite of a good adjustment of results of deformation increase at time (\(\dot{\varepsilon })\) with a relative root master square error equal to 4.4%, adjusting the deformation curve in time was different (Fig. 8b). That fact was caused by the constant value Eo which was not optimized during estimation but adopted directly from testing. It did not change the fact that the value \(\dot{\varepsilon }\) was almost identical for probes 1 and 2 in a given case.

The calibration of parameters for the power model and fixing their stability was accomplished using a series of solvers following each other, applying algorithms Nelder–Mead simplex, Levenberg–Marquardt, and Quasi-Newton implemented in a form of procedure of the program MathCad [58]. Results of identification parameters of the power model in a form of arithmetic averages with results of relative adjustment errors are put together in Table 5.

For the complex assessment of identification results, the power model parameters included in Table 5 are presented in a form of changeability diagrams (Fig. 9) with information on a subject of value of the whole collectivity with additional assembling, taking into consideration the kind of production technology of recycled mix.

The reason why the median was used for assessment of an average of a given sample was the fact that results not in all cases were subjected to the normal distribution. In case of the parameter A (Fig. 9a) which was directly connected with an immediate deformation, its value inversely correlated with the value of immediate modulus Eo amounting to 1.48e−5 (the sample median). For comparing, the value of parameter A of mineral–bitumen mixtures obtained at comparable temperature of measurement defined by Huang [59] was on average 0.86e−5, while in the paper [60], that value was in the range from 0.47e−5 to 1.03e−5 for stresses from the scope 100 ÷ 800 kPa. The decidedly lowest values compared with results of other authors were received for recycled mixtures made in the MCAS technology. In case of MCE mixes, their average value was placed below the median of the whole set suggesting the occurrence of a large deformation in a short loading time.

In case of the parameter n (Fig. 9c) reflecting the influence of stress level on the creep speed of recycled mixture, the lowest value received mixtures made in MCAS technology. Median values of MCAS mixtures both fine-grained as well as coarse-grained ones contained below the median of the whole set [median (n) = 0.92]. Regardless of the type of technology, the highest susceptibility to stress level received recycled mixtures with binder 2 V containing hydrated lime CaOH2 > 60%. That conclusion confirmed observations of other authors showing the advantageous influence of this component on tracking recycled mixtures [13]. Recycled mixtures MCE and MCAS with dominating large amounts of cement > 60% but also recycled mixes with leading components UCPP > 40%, i.e., cement > 40% or binders 5C and 1 V collected the lowest value of parameter n. The present outcome may be the effect of the high stiffness introduced by cement resulting in the high probability of formatting reflected cracks in the base course [11].

The value of parameter m (Fig. 9b) reflecting the deformation speed of recycled mixture in time turned out to be the lowest in case of MCAS mixtures, especially with those of coarse-graded nature. The best solution was binder with a high content of CaOH2 > 40% and the component UCPP > 40% or the variant 4C. That conclusion again confirmed the thesis that the presence of hydrated lime makes forms of bitumen parcels causing the formation of mastics with increased stiffness [61]. The intensity of this phenomenon was the higher as the better bitumen scatter (foamed bitumen). In case of the parameter m, the high amount of that component UCPP (1 V) consequently caused the increase in deformation rate. Solutions 5C and 6C with low deformation rates and placed decidedly below the result median of mixtures MCE and MCAS were beneficial explanations. To sum up, on deformation rate, the mineral skeleton and the presence of mixed binder, in which high amounts of the component UCPP > 60% (for the case 1 V) should be avoided, had the highest influence on deformation speed.

In case of prompt resilient modulus Eo, the highest values received mixtures containing high amounts of cement (3 V) or the component UCPP (1 V). That observation was confirmed in the paper [62]. Received results correlated inversely proportionally with results of parameter A. It should be noted that the same trend was obtained for the dynamic modulus |E*| in similar conditions to the test CCT (40 °C, 3 Hz) used in classification through the Kohonen’s network. The highest results of modulus Eo received recycled mixtures made in the MCAS technology. However, it should be emphasized that the effect of excessive stiffness is not a desired feature of recycled base courses because of a high susceptibility to cracking and fast exhausting bearing capacity of the road pavement structure.

Comparing results of recycled mixes made in different technologies, it should be stated that recycled MCAS mixtures will mark out by the low deformation in the initial period of exploitation (the low parameter A) and the low increase in permanent deformation in the further time of exploitation (the low parameter m). However, some MCAS mixtures (e.g., variants 5C and 6C) will be more susceptible to changes of stress level. From the viewpoint of influence of an innovative hydraulic binder on power model parameters, it imposed the higher impact on recycled mixtures in MCE rather than MCAS technology. However, in case of the parameter n in MCAS mixtures, binder played the biggest role in distributing changeability of that parameter.

Comparing parameter results of the power model with results of papers [45, 46, 59, 60], it is found that recycled MCE mixtures and particularly MCAS in relation to mineral–bitumen mixtures are technologies in which deformations caused by creeping develop slower and are distinguishable by a lower compliance to the level of applied stress. Recycled mixtures containing a significant amount of hydrated lime (2 V, 5C, and 6C) in the binder composition were highly sensitive to the increase in deformation in relation to the change in stress. However, the presence of hydrated lime significantly decreased the rate of deformation in time resulting from the structuring of asphalt mastic (mixture of hydrated lime, filler, and foamed asphalt). At a comparable level of parameter A, the deformation process in recycled mixture proceeds fast in several seconds of loading. Then, the increase in deformation aims fast to zero due to lower values of parameter m and n. The presence of mixed binder in the composition of recycled mixtures was a dominating factor which veritably influenced changeability of those parameters. A numerical simulation was carried out to receive complex information about interaction of particular parameters of the power model caused by different combinations of the component of hydraulic binder.

3.3 Numerical prediction of rutting on the basis of CCT

The finite-element method is a very good tool for solving complicated problems of mechanics. In a research work, two-dimensional model (2D) was used for the simulation of durable deformation of recycled mix. Taking into account experience of authors of papers [55, 60], they pointed out acceptable precise results coming from the 2d analysis comparing to the 3D model. The numerical simulation of increasing irreversible deformation was qualified based on parameters of the power model estimated from results of a CCT test carried out earlier (Table 5). The basic aim of the numerical analysis was to describe the behavior of recycled mixtures through the prism of qualifying their maximal deformation in a complex stress state in conditions similar to the WTT tracking test. Dimensions of the numerical model were in accordance with probe dimensions required for WTT tests acc. to the standard EN 12,697–22 [36]. Considering the loading symmetry, the half of transverse section of a probe measured 500 × 180 × 100 mm. Consequently, the transverse section of the probe measured 90 × 100 mm (width × height). The width of tire contact with probe surface was 40 mm. The probe loading was 600 kPa in accordance with loading of the wheel of device WWT [63]. In consonance with that, the conversion of the total loading time coming from cyclic testing into monotonic testing needed reading total deformation after time calculated multiplying 30,000 cycles (acc. to WWT) by the sum of a single loading equal to 0.126 s and the time of increasing load calculated with reference to the paper [64].

The possibility of vertical shoving was prepared exclusively for the probe symmetry edge and its side edge. Elements of CPS8R (8-node bi-quadratic plane stress quadrilateral) were applied in the analysis. The dimension of single net element applied in the model was 2 × 2 mm. The static scheme of numerical model is presented in Fig. 10a when results of selected numerical model for the selected case MCAS_5C_D are displayed in Fig. 10b.

An arrangement of 48 mixes including their replication in a form of diagram numerical analysis would be noneffective. That is why, the deformation values of medium results obtained according to the WTT test (PRD) and numerical simulation (PRDnum), assigned to each mixture, were presented in the form of spread diagram with information about average values in Fig. 11.

When analyzing test results presented in Fig. 11, it should be noted that displacement received by numerical simulation (red color) was characterized by higher changeability (higher range of data set) than in case of results obtained through WTT (Large Device). It should be remembered that numerical simulation was carried out based on displacement test results at a temperature of 40 °C but not as the test WWT at 60 °C. In connection with that, the constant logical difference of results (PRD vs. PRDnum) results from the different stiffness of mixtures. The Wald–Wolfowitz’s test was carried out to prove diversification. It was dedicated to tests in which compatibility of test result distribution with the normal circulation was not confirmed. Test results are presented in Table 6.

Taking into account the significance level 0.05, it can be confidently stated that there is a significant difference between medians of both methods confirming earlier assumptions. Moreover, the equivalent of the ANOVA test was performed for collections with a normal distribution in a form of the Kruskal–Wallis’s test separately for results coming from the PRD experience and the PRDnum numerical simulation. Observing results in Fig. 11 definitely the greatest influence on changeability of PRD and PRDnum features was exerted by the binder type, especially in MCE mixes (red color marked). It should be noticed that in fine-grained MCE and MCAS mixtures, the median difference between PRD and PRDnum results was low. In case of the MCE-D mixture, the numerical simulation results were on average higher than those coming from the experiment designated at a temperature of 60 °C. However, the additionally performed Kruskal–Wallis’s test being an equivalent of the parametric analysis of variance confirmed statistically essential influence of mix type on changeability of PRD and PRDnum qualities at the confidence level α = 0.05. Test results are presented in Table 7.

Knowing that there is a significant diversification (Table 7) between PRD and PRDnum characteristics and taking into account an additional factor: the type of recycled mixture and the proper test of repeated (two-sided) comparisons were carried out. Finally, it was discovered that the most differentiated pairs of recycled mixes in respect of the PRD feature are: MCE_G-MCAS_G, MCE_D-MCAS_G, and MCE_D-MCAS_D. On the other hand, in case of the PRDnum parameter, only one extremely substantial mixture MCE_D-MCAS_G was received. The present results confirm the influence of the effect of type of the recycled mixture on changeability of results calculated through experimental or numerical methods. Additionally, it has a significant meaning from the point of view of correlations and possibility of anticipation of PRD values which can be obtained through the WTT test based on PRDnum results issued from the CCT test.

3.4 Correlation between rut depths from WTT and CCT

Test results contained in the NCHRP 465 report [65] point out the weak correlation of results of deformations of bituminous mixtures received directly from the CCT method and tracking test at a temperature of 100°F (37.87 °C). Nonetheless, correlations between tracking test carried out in a large device (Wheel Tracking Test—Large Device) and results of simulated deformation received based on notations of deformation results through the CCT test. The information from the previous paragraph relates to mixes having influence on changeability of result of PRD rut depth simulated based on CCT and WTT test results. Therefore, that fact should be taken into account in the statistical conclusion. To make the correct analysis of correlations, you should be sure that collections of amount data have the normal distribution. Doubts occurring in the previous paragraph needed verification through Shapiro–Wilk’s test. In case of a data collection coming from an experiment of PRD results, the condition of a normal distribution of data collection was not satisfied. Pertinently, a transformation of the present results was required. To this end, the Box–Cox’s functional transformation stabilizing variance [66] was employed. In accordance with the foregoing, it was determined that logarithmic transformation [log(PRD)] of results allowed for receiving a new collection of transformed data, which is the most compatible with the model of normal distribution. Correlation connections between log(PRD) and PRDnum with a division into types of recycled mixtures.

In case of application of the classic linear regression, the correlation coefficient would suggest weak but significant capacity for explaining changeability of collections at a level of 23%. Taking observations of results in the Fig. 12, it should be stated that the level of determination coefficients separately defined for each recycled mixture was relatively low and its significant difference from zero can be confirmed only for coarse-graded mixtures MCAS_G and MCE_G. On the other hand, it was revealed in the previous paragraph that the consequence effect of the mixture representing also the mode of engineering has an influence on result distribution of the rut depth. The covariance algorithm [28] was used for further analysis, which was motivated by occurring the covariance variable. The type of mixture "TYPE" was regarded as a companion variable. In case of adopting covariance analysis, it was possible to isolate the changeability part which concerns only the mixture type and therefore allowing description of the pure relation log (PRD) vs. PRDnum. Finally, having conducted covariance analysis, the regressive model had the following form (Table 8).

Results presented in Table 8 make a model of parallels consisting of four linear regressions selected in dependence on mixture type. In case of the MCAS_D mixture regarded in analysis as a reference one, the TYPE parameter amounted to 0. It should be noted that only the free word turned out to be statistically inessential. It suggested that the log (PRD) vs. PRDnum relation should start from the beginning of coordinate system. Meanwhile, the other parameters turned out to be statistically significant while observing the level of parameter β, the influence force proved to be unquestionably the highest one. Nevertheless, it should be stressed that using co-variance analysis caused the two-fold rise in forecasting performance of the log (PRD) term up to 56% (Table 8), while the correlation coefficient rose up to r = 0.75 suggesting a strong positive correlation between log(PRD) and PRDnum.

In connection with that, despite high data entanglement, it was possible to prognosticate log (PRD) results through numerical simulation obtained based on fast measuring with the CCT method. The measurement of creeping cylinder probes carried out at a temperature of 40 °C and stress lower than the one applied at the WWT method causes that the proposed model did not explain remaining 44% (1-R2) changeability of collection. Nevertheless, the efficiency of received regression met with approval.

3.5 Indirect tensile strength and void content

Testing tensile strength on indirect tension (ITS) and content of air voids (Vm) was aimed at the utilization of additional variables in the classification of recycled mixtures which have a direct influence on values of durable deformations [63] (Fig. 13). Furthermore, the present variables were added to the instruction for designing recycled mixture MCE [34].

When analyzing results presented in Fig. 13a, it should be noted that the median values representing results ascribed to recycled mixtures made in the MCAS technology were higher than median results of recycled mixtures made in the MCE technology. Moreover, the interaction effect of the binder turned out to be higher for recycled mixtures MCAS. Pertinently, the cohesion of MCAS mixtures would have decidedly higher influence on the level of plasticity borderline state.

With regard to the Vm value in Fig. 13b, the structural nature of mineral skeleton definitely was significant. In mixtures with coarse-graded skeletons (G), the level of free space was higher than in fine-graded structure (D). The superior role of skeleton type caused that binder played a lower role in shaping result changeability. However, recycled MCAS mixtures received on an average lower level of free space than MCE. Results placed in Table 5 were used to describe the connection level of qualities Vm and ITSDRY with mechanical properties and parameters of the creep phenomenon. The correlation connections of analyzed attributes are presented in Table 9.

The present co-relative connections are of rough nature. However, they deliver a lot of important information. Coherence expressed through the ITSDRY feature correlated most strongly with the dynamic modulus, angle of phase shift, and results of tracking by the WWT method; just because that the DTC-CY test was conducted without side constrainment results and reasonably high coherence correlation with the dynamic modulus. Moreover, the cohesion of recycled mixtures inversely co-related with a parameter responsible for immediate non-reversible deformations expressed by a parameter A. The higher coherence caused more advantageous effect of deformation reduction, which could appear in an initial period of exploitation of pavement structure. The connection between deformation rate in time m and ITSDRY was another essential relation. Also in this case, high coherence has a beneficial effect on reducing the deformation level cumulated in the perspective of a long loading time. In case of the Vm feature, its strongest relation was recorded before mechanical properties but also the PRD rut depth. The correlation level was decidedly low (R2 < 0,5) but still essential.

3.6 Kohonen’s classification of mixture rutting resistance

Already mentioned, Kohonen’s network (SOM—Self Organizing Maps) is a type of network for scholars without a teacher. According to that, input data but not model answers are presented in an ordered form. Neurons are arranged spaciously against each other. In the present tests, they were implemented in a form of two-dimensional network. The dimensionality of input data did not have to be equal to the dimensionality Kohonen’s network. The value of input signals being an expecting reaction of nodes was not fully recognized. Due to the difficult formal description of phenomenon occurring in self-organizing networks, its activity was presented in a practical form of result. That is why, the stress was put on the presentation of experiment results in the present article. Before executing the basic analysis, the input data were normalized (min–max) receiving coded features within a scope < 0,1 > . The sub-ensemble of the learning part SOM made 70% of the whole collectivity. And the number of the test and validation part of the model was randomly selected 15% of the whole collectivity.

Basically, there are no recommendations for the number of approaching pile ups. That stage of statistical concluding remained in the management of researchers. Fixing the topology of two aspects was taken into account. The first one relied on minimisation of too high level of the standard generalization (the case of too low size of concentrations). Whereas the second one was aimed at the elimination of too much expanded topology making pattern interpretation difficult and useless. That is why before starting the base analysis, the comparison of data collection |E*|@(− 10 deg.C; 10 Hz), |E*|@(40 deg.C, 3 Hz), δ@(40 deg.C;3 Hz), A, n, m, log(PRD), and ITSDRY with their reference values representing mixtures in which 100% cement was used as binder was carried out. It was aimed at the identification whether the application of hydraulic binder, and at what degree, veritably influenced physical and mechanical properties of recycled mixtures and the confirmation of desirability of using SOM classification. Table 10 presents the comparison test with reference values of a t student.

Results in Table 10 suggest that the more fine-graded nature of recycled mixture, the more significant influence of hydraulic binder (more qualities really different from the reference value), which was confirmed at the assessment stage of power model parameters. The present observation was probably connected with a higher content of dusty-silty parts with larger specific surface stronger reacting with three-component hydraulic binder. Another important effect was the higher susceptibility to stress changes (parameter n) in fine-graded mixtures than in coarse-graded ones. The interaction effect of a high internal friction angle dominated over the cohesion level introduced by the composition of hydraulic binder which exerted a stronger influence on Eo, ITSDRY mechanical qualities and the parameter m, which can be ascribed to the modification of cohesion of recycled mixture through binder.

Therefore, there were real circumstances to look for certain standards in recycled mixtures from the point of view of resistance to durable deformation rheological effects. Before a fundamental analysis was made, the k-means algorithm, which grouped the collectivity on the basis of the largest inter-group and the smallest intra-group variation, was also considered. Its results were nearing the division received through SOM with dimensions 1 × 3 (rows × columns). Nevertheless, the effect of competition between neurons arranged in series led to too high generalization giving low differentiation of means in a given group against the mean of the whole sample. The best division was received using two-dimensional net with a size of 2 × 2. As a result of application interaction algorithms SOM for each neuron characterizing a certain pattern, cases of recycled mixtures were assigned. The lack of empty neurons decided about the quality of net. The amount distribution of numbers of mixtures qualified for a certain group (neuron) is presented in Fig. 14.

Consequently, four significantly differing groups of mixtures were fixed. They had characteristics similar to each other, but simultaneously maximally differed from each other and were maximally differentiated toward remaining groups. Each of four neurons representing a certain model (profile) in the general collectivity had some characteristic qualities. The so-called importance index [67] was used for assessment of significance of every quality in profiling collections, taking advantage of some analogies from techniques of making decision trees. The higher value ascribed to a given feature, the higher its influence on the division of neurons. Results of the analysis carried out are presented in Fig. 14.

It should be noted that PRD and m indicators had the highest influence on the profile effect (Fig. 15). Determinedly, those two parameters connected with the creep test both with an experimental meaning and model one decided on the division of changeability of ensemble into strictly defined groups. Moreover, the second group deciding on profiling made physical–mechanical factors such as Vm, ITSDRY, E(40 deg.C, 3 Hz), δ(40 deg.C, 3 Hz), and the coefficient A. The value of coefficient n had the lowest significance in division. That fact was probably the result of relatively low compliance of recycled mixtures on the stress level caused by the presence of hydraulic binder. The diagram of normalized mean values assigned to each neuron was a convenient form of presenting traced out patterns in a given collection (Fig. 16).

The formation of open mean values with 95% confidence range presented in Table 11 was the supplement of analysis.

It is worth mentioning that the received division of profiles was characterized by the high diversification of means assigned to each neuron (Table 11). In a decisive majority of cases, that difference make at least half of confidence range. Another significant observation was the fact the confidence division inside each group was at a similarly low level. It increases the usefulness of profiling received. The interpretation of its results is given below:

3.6.1 Group 1 (neuron 1)

Recycled mixtures characterized by a high differentiation ITSDRY close to the critical value of 350 kPa (the normalized value amounted to 9,6%). That result suggested the high probability of losing fastness to water potentially caused by the contamination effect in mineral mixture. The low coherence was followed by the lower value of dynamic modulus denoted at a temperature of 40 °C as well as the modulus Eo. It also resulted in a higher susceptibility to load time and higher value of cumulated deformation PRDnum. Almost all recycled mixtures made in the MCE technology were found in that group, but none of mixtures made in MCAS was qualified to that profile.

3.6.2 Group 2 (neuron 2)

Only cases of recycled mixtures made in MCAS technology are included in that standard. That group is characterized with the highest values of dynamic modulus regardless of temperature and measurement. Recycled mixtures classified to that group are also distinguished by a lower sensibility to loading time expressed with the parameter m. Moreover, they received the highest value of ITSDRY and the lowest content of air voids Vm. However, in spite of beneficial physical and mechanical qualities, the present mixtures characterized with the highest susceptibility to applied stress and among all mixtures decidedly elastic–brittle nature expressed in a low value of parameter δ. The Group 2 makes a contrast to recycled mixtures qualified to the Group 1.

3.6.3 Group 3 (neuron 3)

That profile represents recycled mixtures with a high stiffness of values comparable with results received for mixtures in Group 2. The basic difference relating to Group 2 was in the decidedly higher value of displacement of phase angle δ suggesting the higher participation of viscous part of the dynamic modulus. Furthermore, recycled mixtures qualified to group 2 had low speed of deformation increment in time m and a low susceptibility to the level of adopted stress n, comparable with results of group 2. It should be added that in that group, there were solutions having an ultra-ordinary value of Vm, ordinary value of PRD, and high value of ITSDRY on a level of 530 kPa. That group represented recycled mixtures with mixed binder with the composition containing CEM60%/CPBD20%/HL20% with a fine-grained skeleton (D) regardless of the technological type. Moreover, there were also solutions with an application of MCAS technology at the content of CBPD not exceeding 40% when the dust content CBPD not exceeding 40%, the cement content was limited to 40% with the content of HL remaining on the same level 20% (case 4C). The decisive majority of mixes qualified to that profile were distinguished with fine-grained grading.

3.6.4 Group 4 (neuron 4)

In that group, results of only one recycled mixture made in the MCE technology with a coarse-graded skeleton with a 100% content of cement can be found. Observing its results, one gets the impression that its parameters are very similar to the profile of Group 3 with the difference that an immediate and durable deformation defined with parameter A was on a significantly higher level. With some generalization, Group 4 is a remarkable case of standard of the Group 3. Assigning all recycled mixtures to a given profile group was the completion of the above analysis.

In the first place, results presented in Table 12 indicate basic division on account of the type of technology, in other words MCE and MCAS. It was an interesting observation that the part of MCAS recycled mixtures (Group 2) was compiled with cases where cement (100%) was applied as a reference binder. It should be pointed out that solutions belonging to the groups 3 and 4 created the most desirable pattern. These were the cases of recycled mixtures which did not have extreme solutions. Their profile indicated high stiffness and low accumulation speed of permanent deformation in time (parameter m), and what is the most important, the lowest susceptibility to the level of compressive stress (parameter n). Furthermore, the present mixtures were characterized by the average cohesion (ITSDRY > 350 kPa) and above average low values of the PRD and PRDnum index. The data analysis of recycled mixture through the Kohonen’s network revealed that results in Groups 3 and 4 differed from representatives of the Group 2 in the lower value of the phase shift, which fulfilled the requirement of cutting down excessive stiffness caused by effects of low temperatures. Additionally taking into account the fact that binder compositions introduced to MCE and MCAS mixtures remaining in the Group 3 and 4 reached the above average level of the PRD and PRDnum parameter, causing that they can be treated as the most profitable ones from the point of view of resistance to fixed deformation of recycled mixtures. Concurrent conclusions were formulated in the course of multi-criteria optimization [72] on the basis of the cases of composition of recycled mixtures contained in. Taking into account other variables dependent on the measurements of resistance to permanent deformations, it was found that the most advantageous areas of the composition of the innovative binder were common with the cases of group 3 and group 4 mixtures.

An important aspect of the analysis carried out was that having at the disposal other results, they can be replicated and assigned to one of the profiles. In this case, results should be normalized (min–max) using data from Table 11, and then, differences between own and mean results should be defined. The variant in which the value of the difference sum will be the lowest one should be regarded as the most adequate profile for a given collection of results.

4 Conclusions

The following conclusions were formulated based on research carried out and the analysis of recycled mixtures made in two technologies connected with dosing bitumen and using three-component binder:

-

Test results confirmed the advantageous influence of hydrated lime and CBPD dusts on the improvement of resistance to durable deformations of recycled mixtures especially those made in the MCAS technology. Moreover, it was observed that a large amount of hydrated lime caused an increase in the rate of sample deformation with a simulated change in stress,

-

Application of 100% Portland cement as binder in the composition of MCE/MCAS mixture does not guarantee obtaining high resistance to durable deformations in recycled mixture,

-

It was stated on the basis of many analyses that the application of three-component binder caused significant changes of physical and mechanical properties in recycled mixtures. The influence of composition of three-element binder on reducing the deformation speed was more significant in fine-graded mixture due to the higher interaction of hydraulic binder with silt-powder particles,

-

Recycled MCAS mixtures were distinguishable by the lower level of deformations accumulated in time than MCE mixtures. Therefore, the results of durable PRD deformation in MCAS mixtures were on an average lower than in MCE mixtures,

-

The covariance analysis showed that there is a possibility of predicting PRD qualities through CCT test results using numerical PRDnum simulation,

-

The Kohonen’s network exerted a significant influence on the present division of standards with the highest domination of the following features: PRD, m, ITS, ITSR, E, δ, and A. Finally, four groups of standards were established. The first one was connected with mixtures susceptible to the contamination effect. Recycled MCE mixtures were decidedly included in that group. The cases of mixtures dominated by the MCAS technology with a high stiffness and cohesion. The group 3 and 4 was defined by solutions with the best utility values for road purposes. These mixtures fulfilled the requirement of a limited compliance, maintaining appropriate levels of other physical and mechanical features,

-

Based on the classification analysis, the application of hydraulic binder containing cement within the scope from 40% up to 60%, hydrated lime 20%, and CBPD dusts within the scope from 20% up to 40% turned out to be the most advantageous.

References

C. Leek, G. Jameson, Austroads, Review of foamed bitumen stabilisation mix design methods, Austroads, Sydney, NSW, 2011. https://www.onlinepublications.austroads.com.au/items/AP-T178-11 (accessed July 20, 2018).

Chomicz-Kowalska A, Maciejewski K. Performance and visco-elastic assessment of high-recycle rate cold foamed bitumen mixtures produced with different penetration binders for rehabilitation of deteriorated pavements. J Clean Prod. 2020;258:120517. https://doi.org/10.1016/j.jclepro.2020.120517.

Mazurek G, Iwański M. Multidimensional analysis of the effects of waste materials on physical and mechanical properties of recycled mixtures with foamed bitumen. Appl Sci. 2018;8:282. https://doi.org/10.3390/app8020282.

Jamshidi A, White G. Evaluation of performance and challenges of use of waste materials in pavement construction: a critical review. Appl Sci. 2019;10:226. https://doi.org/10.3390/app10010226.

Gonzalez Andres A. An experimental study of the deformational and performance characteristics of foamed bitumen stabilised pavements, University of Canterbury. Civil and Natural Resources Engineering.2009. http://hdl.handle.net/10092/3285. Accessed 23 Mar 2020.

Ramanujam JM, Jones JD. Characterization of foamed-bitumen stabilisation. Int J Pavement Eng. 2007;8:111–22. https://doi.org/10.1080/10298430601149676.

Mazurek G, Pszczoła M, Szydłowski C. Non-linear mastic characteristics based on the modified mscr (multiple stress creep recovery) test. Structure and Environment. 2019;11:23–34. https://doi.org/10.30540/sae-2019-002.

Wirtgen Group. Cold recycling technology, pierwsze. Windhagen: Wirtgen GmbH; 2012.

Iwański M, Buczyński P, Mazurek G. Optimization of the road binder used in the base layer in the road construction. Constr Build Mater. 2016;125:1044–54. https://doi.org/10.1016/j.conbuildmat.2016.08.112.

Kukiełka J, Bańkowski W. The experimental study of mineral-cement-emulsion mixtures with rubber powder addition. Constr Build Mater. 2019;226:759–66. https://doi.org/10.1016/j.conbuildmat.2019.07.276.

Xiao F, Yao S, Wang J, Li X, Amirkhanian S. A literature review on cold recycling technology of asphalt pavement. Constr Build Mater. 2018;180:579–604. https://doi.org/10.1016/j.conbuildmat.2018.06.006.

Wen H, Tharaniyil MP, Ramme B. Investigation of performance of asphalt pavement with fly-ash stabilized cold in-place recycled base course. Transport Res Rec J Transport Res Board. 1819;2003:27–31. https://doi.org/10.3141/1819b-04.

Betti G, Cocurullo A, Marradi A, Tebaldi G, Airey G, Jenkins K. Effect of lime on short-term bearing capacity of bitumen emulsion recycled mixtures. Asphalt Pavements CRC Press. 2014. https://doi.org/10.1201/b17219-128.

EN 1426, Bitumen and bituminous binders- determination of needle penetration. Brussels; 2015.

EN 1427, Bitumen and bituminous binders- determination of the softening point: ring and Ball method. Brussels; 2015.

EN 12593, Bitumen and bituminous binders- determination of the Fraass breaking point. Brussels. 2015.

EN 14771, Bitumen and bituminous binders- determination of the flexural creep stiffness: bending beam rheometer (BBR), Brussels; 2012.

EN 14023, Bitumen and bituminous binders. Specification framework for polymer modified bitumens. Brussels; 2010.

ASTM D4402, Standard Test method for viscosity determination of asphalt at elevated temperatures using a rotational viscometer. West Conshohocken; 2020.

EN 13398, Bitumen and bituminous binders. Determination of the elastic recovery of modified bitumen. Brussels. 2017.

Mazurek G, Iwański M. Applying of 2S2P1D model for assessing visco-elastic properties of bituminous binder extracted from SMA mixture with hydrated lime addition. Cement Wapno Beton. 2018;23:124.

N.I. Yusoff, Modelling the linear visco-elastic rheological properties of bituminous binders, University of Nottingham, 2012. http://eprints.nottingham.ac.uk/12582/1/Nur_Izzi_Md._Yusoff.pdf. Accessed 23 Mar 2020.

Iwański M, Chomicz-Kowalska A, Maciejewski K. Application of synthetic wax for improvement of foamed bitumen parameters. Constr Build Mater. 2015;83:62–9. https://doi.org/10.1016/j.conbuildmat.2015.02.060.

Wirtgen Group. Podręcznik recyklingu na zimno, drugie. Windhagen: Wirtgen GmbH; 2006.

Technical Guideline TG2. Bitumen stabilised materials. A guideline for the design and construction of bitumen emulsion and foamed bitumen stabilised materials, 2nd ed., Pretoria, South Africa; 2009.

Iwański M, Mazurek G, Buczyński P. Bitumen foaming optimisation process on the basis of rheological properties. Materials. 2018;11:1854. https://doi.org/10.3390/ma11101854.

EN 13808, Bitumen and bituminous binders: framework for specifying cationic bituminous emulsions. Brussels; 2013.

Montgomery DC. Design and analysis of experiments. 8th ed. Hoboken, NJ: John Wiley and Sons Inc; 2013.

Ž.R. Lazić (2004). Design of experiments in chemical engineering: a practical guide, Wiley-VCH, Weinheim [Germany].

Czapik P, Zapała-Sławeta J, Owsiak Z, Stępień P. Hydration of cement by-pass dust. Constr Build Mater. 2020;231:117139. https://doi.org/10.1016/j.conbuildmat.2019.117139.

Judycki J, Jaskuła P, Pszczoła M, Alenowicz J, Dołżycki B, Jaczewski M, Ryś D, Stienss M, Katalog Typowych Konstrukcji Nawierzchni Podatnych i Półsztywnych (Catalogue of typical flexible and semi-rigid pavements) (in polish). GDDKiA. Warsaw; (2014).

EN 12697-25, (2016). Bituminous mixtures: test methods: part 25: cyclic compression test. Brussels; 2016.

EN 13108-1, Bituminous mixtures: material specifications: part 20: type testing. Brussels; 2016.

Dołżycki B. Polish experience with cold in-place recycling. IOP Conf Ser Mater Sci Eng. 2017;236:012089. https://doi.org/10.1088/1757-899X/236/1/012089.

Judycki J, Jaskuła P, Pszczoła M, Ryś D, Jaczewski M, Alenowicz J, Dołżycki B, Stienss M. New polish catalogue of typical flexible and semi-rigid pavements. MATEC Web Conf. 2017;122:04002. https://doi.org/10.1051/matecconf/201712204002.

EN 12697-22, Bituminous mixtures - Test methods - Part 22: Wheel tracking. Brussels; 2005.

EN 12697-8, Bituminous mixtures. Test methods. Determination of void characteristics of bituminous specimens. Brussels; 2018.

EN 12697-23, Bituminous mixtures. Test methods. Determination of the indirect tensile strength of bituminous specimens. Brussels; 2017.

12697-26 D, Bituminous mixtures: test methods: part 26: Stiffness. Brussels; 2016.

Airey GD, Rahimzadeh B, Collop AC. Linear rheological behavior of bituminous paving materials. J Mater Civ Eng. 2004;16:212–20. https://doi.org/10.1061/(ASCE)0899-1561(2004)16:3(212).

Kim YR, editor. Modeling of asphalt concrete, ASCE Press; McGraw-Hill, Reston. New York: VA; 2009.

Woldekidan MF. Response modelling of bitumen. Bituminous Mastic and Mortar: Technische Universiteit Delft; 2011.

Brinson HF, Brinson LC. Polymer engineering science and visco-elasticity: an introduction. New York: Springer; 2008.

Gao D, Wang P, Li M, Luo W. Modelling of nonlinear visco-elastic creep behaviour of hot-mix asphalt. Constr Build Mater. 2015;95:329–36. https://doi.org/10.1016/j.conbuildmat.2015.07.112.

Leonardi G. Finite element analysis for airfield asphalt pavements rutting prediction. Bull Polish Acad Sci Tech Sci. 2015;63:397–403. https://doi.org/10.1515/bpasts-2015-0045.

W. Huang, X. Zhang, H. Rong, B. Chen (2015) finite-element method for predicting rutting depth of steel deck asphalt pavement based on accelerated pavement test, in: proceedings of the 3rd international conference on mechanical engineering and intelligent systems (ICMEIS 2015), Atlantis Press, Yinchuan, China https://doi.org/10.2991/icmeis-15.2015.177.

S.P.C. Marques, G.J. Creus (2012) Computational visco-elasticity, Springer, Heidelberg ; New York.

Kraus H. Creep analysis. New York: Wiley; 1980.

Findley WN, Lai JS, Onaran K. Creep and relaxation of nonlinear visco-elastic materials: with an introduction to linear visco-elasticity. New York: Dover; 1989.

Manda K, Wallace RJ, Xie S, Levrero-Florencio F, Pankaj P. Nonlinear visco-elastic characterization of bovine trabecular bone. Biomech Model Mechanobiol. 2017;16:173–89. https://doi.org/10.1007/s10237-016-0809-y.

Pszczola M, Jaczewski M, Szydlowski C. Assessment of thermal stresses in asphalt mixtures at low temperatures using the tensile creep test and the bending beam creep test. Appl Sci. 2019;9:846. https://doi.org/10.3390/app9050846.

Bonaquist RF. Refining the simple performance tester for use in routine practice. Washington, D.C.: Transportation Research Board; 2008.

T. Kohonen, T.S. Huang, M.R. Schroeder, Self-Organizing Maps., Springer Berlin / Heidelberg, Berlin, Heidelberg, 2012. https://public.ebookcentral.proquest.com/choice/publicfullrecord.aspx?p=5577667 (accessed May 14, 2020).

Cottrell M, Fort JC, Pagès G. Theoretical aspects of the SOM algorithm. Neurocomputing. 1998;21:119–38. https://doi.org/10.1016/S0925-2312(98)00034-4.

Arabani M, Jamshidi R, Sadeghnejad M. Using of 2D finite-element modeling to predict the glasphalt mixture rutting behavior. Constr Build Mater. 2014;68:183–91. https://doi.org/10.1016/j.conbuildmat.2014.06.057.

Wesołowski M, Blacha K, Pietruszewski P, Iwanowski P. Analysis of the actual contact surface of selected aircraft tires with the airport pavement as a function of pressure and vertical load. Coatings. 2020;10:591. https://doi.org/10.3390/coatings10060591.

Saboo N, Kumar P. A study on creep and recovery behavior of asphalt binders. Constr Build Mater. 2015;96:632–40. https://doi.org/10.1016/j.conbuildmat.2015.08.078.

H. Benker, Practical Use of Mathcad®: Solving Mathematical Problems with a Computer Algebra System, Springer London : Imprint : Springer, London, 1999. http://dx.doi.org/https://doi.org/10.1007/978-1-4471-0539-8 (accessed June 18, 2018).

Huang H, Analysis of accelerated pavement tests and finite element modeling of rutting phenomenon, Purdue University, 1995. https://docs.lib.purdue.edu/dissertations/AAI9601511/. Accessed 23 Mar 2020.