Abstract

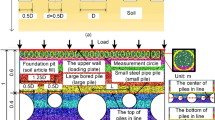

Large open-ended cylinder piles have been widely used for engineering foundation of port. The penetration process of the large-diameter steel cylinder exhibit complex behaviors, which is difficult to be measured by test and reproduced in numerical models. This study presents a friction analysis of large diameter steel penetration process by using the discrete element method (DEM), which can simulate large deformation and nonlinearity well. Centrifugal model and full-scale model were developed to analyze the sliding friction of the cylinder during installation and the contact force chain of soil particles. The validity of the DEM model was examined by comparing with theoretical values and published studies. Parametric studies were carried out to study the effects of contact parameters on side friction. Simulation results showed that, unlike pile penetration, there is no obvious soil-plug effect during the penetration process of large-diameter steel cylinder. Besides, the inside friction is smaller than the outside friction for large-diameter steel cylinder. What’s more, the computational cost of full-scale model based on the upscale theory was less than the centrifugal model. There is a close relationship between the side friction and micro contact parameters, which provides a reference for the follow-up study of cylinder or pile penetration using DEM.

Similar content being viewed by others

References

BBC News.: China opens longest sea-crossing bridge, 2018–10–23. Retrieved 2018–10–28

The Straits Times, Hermes, Smooth start for world's longest state of the art sea crossing, 2018–10–25. Retrieved 2018–10–28

Lehane, B.: Experimental investigations of pile behaviour using instrumented field piles. (1992)

Lehane, B., Jardine, R., Bond, A., Frank, R.: Mechanisms of Shaft Friction in Sand from Instrumented Pile Tests. J. Geotech. Eng. (1993). https://doi.org/10.1061/(ASCE)0733-9410(1993)119:1(19)

Chow, F., Jardine, R.J.: Investigations into the behaviour of displacement piles for offshore foundations. Ground Eng. 29, 24–25 (1996)

Gavin, K., O’Kelly, B.: Effect of Friction Fatigue on Pile Capacity in Dense Sand. J. Geotech. Geoenviron. Eng. (2007). https://doi.org/10.1061/(ASCE)1090-0241(2007)133:1(63)

Chan, S.T., Tham, L.G., Yang, J., Yu, F., Lee, P.K.K.: Behaviour of jacked and driven piles in sandy soil. Geotechnique 56, 245–259 (2006). https://doi.org/10.1680/geot.2006.56.4.245

Lehane, B., White, D.: Friction fatigue on displacement piles in sand. Geotechnique 54, 645–658 (2004). https://doi.org/10.1680/geot.2004.54.10.645

White, D., Bolton, M.: Displacement and strain paths during plane-strain model pile installation in sand. Geotechnique 54, 375–397 (2001). https://doi.org/10.1680/geot.54.6.375.45427

Leong, E., Houlsby, G., Randolph, M.: One-dimensional analysis of soil plugs in pipe piles. Géotechnique 41, 587–598 (1991). https://doi.org/10.1680/geot.1991.41.4.587

Paik, K., Salgado, R., Lee, J., Kim, B.: Behavior of Open and Closed-Ended Piles Driven Into Sands. J. Geotech. Geoenviron. Eng. (2003). https://doi.org/10.1061/(ASCE)1090-0241(2003)129:4(296)

Fattah, M., Al-Soudani, W.: Bearing capacity of open ended pipe piles with restricted soil plug. Ships Offshore Struct (2015). https://doi.org/10.1080/17445302.2015.1030247

Xing, H.-F., Zhao, H.-W., Ye, G.-B., Xu, C.: Effect of driving long pre-stressed high-strength concrete pipe piles in alluvium and its mechanical behavior. Bullet. Eng. Geol. Environ. 7, 1 (2012). https://doi.org/10.1007/s10064-012-0436-5

Kou, H.-L., Diao, W.-Z., Tao, L., Yang, D.-L.: Field performance of open-ended prestressed high-strength concrete pipe piles jacked into clay. Sensors 18, 4216 (2018). https://doi.org/10.3390/s18124216

Jardine, R., Lehane, B., Everton, S.: Friction Coefficients for Piles in Sands and Silts, vol. 28, pp. 661–677. Springer, Dordrecht (1993)

Lehane, B., White, D.: Lateral stress changes and shaft friction for model displacement piles in sand. Canad. Geotech. J. (2011). https://doi.org/10.1139/t05-023

Vesic, A.: A study of bearing capacity of deep foundations. Final Rep., Proj. No. B-189 (1967)

Terzaghi, K.: Theoretical Soil Mechanics. Wiley, Hoboken (1943)

Vesic, A.: Expansion of cavities in infinite soil mass. J. SM FE Div. 98, 265–290 (1972)

Collins, I.F., Pender, M.J., Yan, W.: Cavity expansion in sands under drained loading conditions. Int. J. Numer. Anal. Meth. Geomech. 16(1), 3–23 (1992). https://doi.org/10.1002/nag.1610160103

Carter, J., Randolph, M., Wroth, C.: Stress and pore pressure changes in clay during and after the expansion of a cylindrical cavity. Int. J. Numer. Anal. Meth. Geomech. 3, 305–322 (1979). https://doi.org/10.1002/nag.1610030402

Liu, J.W., Zhang, M.Y., Zhao, H.F., Wang, J.J.: Computational simulation of jacking force based on spherical cavity expansion theory and friction fatigue effect. Yantu Lixue/Rock Soil Mech. 30, 1181–1185 (2009)

Li, J., Li, L., Sun, D.A., Tang, J.H.: Theoretical study on sinking resistance of jacked piles in saturated soft clay. Yantu Gongcheng Xuebao/Chin. J. Geotech. Eng. 37, 1454–1461 (2015). https://doi.org/10.11779/CJGE201508014

Randolph, M., Carter, J., Wroth, C.: Driven piles in clay—the effects of installation and Subsequent consolidation. Geotechnique 29, 361–393 (1979). https://doi.org/10.1680/geot.1979.29.4.361

Gupta, R., Salgado, R., Mitchell, J., Jamiolkowski, M.: Calibration Chamber Size Effects on Penetration Resistance in Sand. J. Geotech. Geoenviron. Eng. (2001). https://doi.org/10.1061/(ASCE)1090-0241(2001)127:7(628)

Reul, O., Randolph, M.: Piled rafts in overconsolidated clay: Comparison of in situ measurements and numerical analyses. Geotechnique 53, 301–315 (2003). https://doi.org/10.1680/geot.53.3.301.37279

Basu, P., Loukidis, D., Prezzi, M., Salgado, R.: Analysis of shaft resistance of jacked piles in sands. Int. J. Numer. Anal. Meth. Geomech. 35(15), 1605–1635 (2011). https://doi.org/10.1002/nag.968

Ting, J., Corkum, B., Kauffman, C., Greco, C.: Discrete numerical model for soil mechanics. Wiley, New York (2016)

Cundall, P.A., Strack, O.: A discrete numerical mode for granular assemblies. Geotechnique 29, 47–65 (1979). https://doi.org/10.1680/geot.1979.29.1.47

Huang, A.-B., Ma, M.: Analytical study of cone penetration tests in granular material. Can. Geotech. J. 31, 91–103 (2011). https://doi.org/10.1139/t94-010

Jiang, M., Dai, Y., Cui, L., Shen, Z., Wang, X.: Investigating mechanism of inclined CPT in granular ground using DEM. Granular Matter (2014). https://doi.org/10.1007/s10035-014-0508-2

Ciantia, M., Arroyo, M., Butlanska, J., Gens, A.: DEM modelling of cone penetration tests in a double-porosity crushable granular material. Comput. Geotech. 73, 109–127 (2016). https://doi.org/10.1016/j.compgeo.2015.12.001

Esposito, R., Velloso, R., Vargas, E., Jr., Danziger, B.: Multi-scale sensitivity analysis of pile installation using DEM. Comput. Particle Mech. 5(1), 12 (2017). https://doi.org/10.1007/s40571-017-0175-2

Duan, N., Cheng, H., Liu, J.: DEM analysis of pile installation effect: comparing a bored and a driven pile. Granular Matter (2018). https://doi.org/10.1007/s10035-018-0805-2

Li, L., Wu, W., El Naggar, M.H., Mei, G., Liang, R.: DEM analysis of the sand plug behavior during the installation process of open-ended pile. Comput. Geotech. 109, 23–33 (2019). https://doi.org/10.1016/j.compgeo.2019.01.014

Wang, J., Zhao, B.: Discrete-continuum analysis of monotonic pile penetration in crushable sands. Geotech. J. Canad. (2014). https://doi.org/10.1139/cgj-2013-0263

Lobo-Guerrero, S., Vallejo, L.: Influence of pile shape and pile interaction on the crushable behavior of granular materials around driven piles: DEM analyses. Granular Matter 9, 241–250 (2007). https://doi.org/10.1007/s10035-007-0037-3

Butlanska, J., Arroyo, M., Gens, A., O’Sullivan, C.: Multi-scale analysis of cone penetration test (CPT) in a virtual calibration chamber. Can. Geotech. J. 51(1), 51–66 (2014). https://doi.org/10.1139/cgj-2012-0476

Zhang, Z., Wang, Y.-H.: Three-dimensional DEM simulations of monotonic jacking in sand. Granular Matter 17, 359–376 (2015). https://doi.org/10.1007/s10035-015-0562-4

Wang, Z., Jacobs, F., Ziegler, M.: Visualization of load transfer behaviour between geogrid and sand using PFC2D. Geotext. Geomembr. 42, 83–90 (2014). https://doi.org/10.1016/j.geotexmem.2014.01.001

Itasca Consulting Group, Inc. (2014a). PFC (particle flow code in 2 and 3 dimensions), version 5.0 [User’s manual]. Minneapolis, MN: ICG

Konrad, J.M., Leroueil, S.: An efficient technique to generate homogeneous specimens for DEM studies. Comput. Geotech. 30, 579–597 (2003). https://doi.org/10.1016/S0266-352X(03)00064-8

Yu, F., Yang, J.: Improved evaluation of interface friction on steel pipe pile in sand. J. Perform. Construct. Facilities 26, 170–179 (2012). https://doi.org/10.1061/(ASCE)CF.1943-5509.0000256

Budhu, M.: Soil Mechanics and Foundations. Firewall Media, New Delhi (2011)

Jardine, R.: ICP design methods for driven piles in sands and clays. Thomas Telford, London (2020)

Zhao, Z., Zhou, M., Hu, Y., Hossain, M.: Behavior of Soil Heave Inside of Stiffened Caissons Installing in Clay. Canad. Geotech. J. 1, 1 (2017). https://doi.org/10.1139/cgj-2016-0667

Liu, J., Duan, N., Cui, L., Zhu, N.: DEM investigation of installation responses of jacked open-ended piles. Acta Geotech. (2019). https://doi.org/10.1007/s11440-019-00817-7

Zhao, C., Hobbs, B., Ord, A., Peng, S., Liu, L.: An upscale theory of particle simulation for two-dimensional quasi-static problems. Int. J. Numer. Meth. Eng. 72, 397–421 (2007). https://doi.org/10.1002/nme.2018

Potyondy, D., Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41, 1329–1364 (2004). https://doi.org/10.1016/j.ijrmms.2004.09.011

Ding, X., Zhang, L., Zhu, H., Zhang, Q.: Effect of model scale and particle size distribution on PFC3D simulation results. Rock Mech. Rock Eng. 47(6), 2139–2156 (2014). https://doi.org/10.1007/s00603-013-0533-1

Itasca (2004) PFC3D (particle flow code in 3 dimensions) manual. Version 4.0 edn. ICG, Minneapolis, Minnesota

ISRM: Suggested methods for determining the uniaxial compressive strength and deformability of rock materials, ISRM Commission on Standardization of Laboratory and Field Tests. Int. J. Rock Mech. Min. Sci. 16, 135–140 (1979)

Zhang, X.-P., Wong, L.: Loading rate effects on cracking behavior of flaw-contained specimens under uniaxial compression. Int. J. Fract. 180(1), 93–110 (2013)

Wang, F.Z., Zhu, H.: Shear band formation in ideal dense sand in direct shear test by discrete element analysis. Yantu Lixue/Rock Soil Mech. 31, 253–298 (2010)

Acknowledgements

This study was supported by National Natural Science Foundation of China (Grant No. 41702295, 51708041), Natural Science Foundation of Shaanxi Province, China (Grant No. 2018JQ5001), and the Fundamental Research Funds for the Central Universities (Grant No. 310821161002, 2017MS096).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, X., Shi, Y., Chen, R. et al. Friction anlysis of large diameter steel cylinder penetration process using 3D-DEM. Granular Matter 23, 24 (2021). https://doi.org/10.1007/s10035-021-01086-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01086-6