Abstract

Engineered biocatalyst and its desired products using nanotechnology has intensified the research in food industries. Zinc oxide (ZnO) nanosheet is designed and prepared; the characterization studies include surface plasmon resonance peak (364 nm), X-ray diffraction pattern determined crystallite size (25 nm), and transmission electron microscopy confirms the porous surface nature. Atomic force microscopy showed substrate and enzyme adsorbed on ZnO nanosheets. The zeta potential of ZnO nanosheet (−41.9 mV) whereas α-amylase bound with ZnO nanosheets (−32.8 mV), and starch bound with ZnO nanosheets (−28.7 mV) was analyzed using dynamic light scattering. The circular dichroism spectra displayed α-helix in native amylase at optimum concentration 54.70% compared to the adsorbed α-amylase with ZnO nanosheet that showed 37%. Freundlich isotherm model revealed multilayer adsorption behavior of α-amylase onto porous ZnO nanosheet. Enzyme kinetics study presents alteration in Michaelis–Menten constant (Km) and maximum velocity (Vmax), the α-amylase bound with porous ZnO nanosheet showed a reduction in Km and Vmax. The substrate and enzyme adsorbed together on porous ZnO nanosheet exhibited increased Km (27.77 μM), whereas Vmax (2.85 μM) remains unchanged. Moreover, α-amylase once modified at optimum pH (5.8) and temperature (52 °C), produces less maltose than α-amylase adsorbed on ZnO nanosheet, which indicates higher maltose production. In this study, ZnO nanosheet enzyme catalytic system was created, wherein enzymatic reaction shifted to different pH and temperature other than optimum conditions. All these findings suggest that careful attention to the enzyme adsorption profiles can contribute to industrial applications.

Graphical abstract

Similar content being viewed by others

Introduction

Enzymes are macromolecules that act as specific bio-catalysts, accelerating or enabling chemical reactions by reducing activation energy [1, 2]. Enzymes in the industry have many potentials; new enzyme processing methods aim to reduce the associated costs, increase process efficiency, and stabilize the bio-catalytic function. Currently, nanotechnological approaches are used to overcome these problems. The nanoparticle’s high surface area makes the adsorption of enzymes effective, promoting protein catalytic activity [3]. Metal nano-enzyme (MN-Es) conjugate represents a specific class of bio-nano conjugates for numerous applications. They also have high catalytic specificity, prolonged reaction time, and the ability to recycle for further applications [4, 5]. Nanoparticle matrices provide reliable support, cellulose nanocrystal/gold nanoparticle composite as a matrix for enzyme immobilization [6], mesoporous silica nanoparticles for bio-adsorption [7], novel attractive enzyme immobilization matrix: calcium carbonate nanoparticles [8], graphene, zinc oxide (ZnO), and silver nanoparticles in a chitosan matrix [9], enzyme adsorption in colloidal solution [10]. Enzyme α-amylase has been utilized to improved stability on ZnO and iron nanoparticles; the adsorption of α-amylase used to enhance the resistance of biocatalysts to alter reaction conditions affecting the enzyme’s catalytic performance [11]. Enzyme undergoes structural alteration with adsorption on the metal nanoparticle, and improved methodologies are required to establish successful adsorption of enzymes on nanoparticles [12]. Significant challenges of many protocols previously described for enzyme adsorption on metal nano-surfaces are nonspecific as results loss of enzyme activity and even complete enzyme denaturation [13]. Adsorption positively affects the enzyme catalytic structure by stabilizing, high tolerance to pH, temperature, and other known physical parameters. Modifying the enzyme by metal carrier facilitates its separation from the reaction mixture after the process; the end products are not contaminated with enzymes. The enzyme deposited on the carrier also extends its catalytic activity and is reused in reactions [14]. The enzyme-substrate modification was previously studied for amylose-sucrose in-vitro digestion to control enzymatic reaction [15, 16]. Besides, nanostructure nature provides a mechanism for efficient recovery of the enzyme from reaction products, which is vital in various pharmaceutical industries where the final product’s enzyme contamination can cause detrimental side effects. Many enzymes currently used in biotechnology, including α-amylase, have been covalently adsorbed on ZnO nanoparticles [17, 18].

ZnO nanoparticles have advantages over other nanometal oxides, such as biocompatibility, high surface area, non-toxicity, chemical stability, and low cost [19]. Food and Drug Administration approves ZnO as a food additive. Incorporating antimicrobial nanomaterials like nano ZnO in packaging and food contact materials was observed, designed not to be released so that packaging itself acts as an antimicrobial agent [20]. These features advocate nano ZnO as biomimetic support to adsorb and modify the protein and enzyme [21]. The effect of ZnO morphology was reported in horseradish peroxidase enzyme adsorbed on modified ZnO nanoparticles [22]. The establishment of bonds between the enzyme and the carrier molecule is resulting in hydrogen, hydrophobic, electrostatic, ionic, and van der Waals forces [23].

The thermal plasma method is one of the exciting and alternative approaches to developing pure metal nanosheets. ZnO nanosheets possess unique surface properties. Hence, their interaction with biological species is expected to be different [24].

α-amylase plays an essential role in carbohydrate metabolism in various lifeforms such as microorganisms, plants, and animals [25,26,27]. Amylases are hydrolase enzymes, which hydrolyze starch to reduce sugars [28, 29]. Amylase plays a vital contribution ranging from food, fermentation, paper industries, and medical fields [30, 31]. This study presents a better understanding of enzyme-substrate adsorption interface on porous ZnO nanosheet, and its structure-function kinetics are determined to enhance catalytic functions.

Material and Methods

Chemicals

Zinc acetate, α-amylase (enzyme), sodium hydroxide (NaOH), sodium potassium tartrate, 3, 5-dinitrosalicylic acid, dibasic and monobasic, starch soluble (potato), and maltose purchased from S D Fine-Chem Limited Mumbai, India.

Synthesis of ZnO Nanosheets Using Thermal Plasma Method

A thermal plasma reactor is used to prepare ZnO nanosheets. The zinc metal powder was subjected to the water-cooled graphite anode; ZnO material is made by applying the pressure of 100 kg/cm2. The direct current thermal plasma was operated at 6 kW to obtain a 5–6 cm plasma plume in length and about 1 cm in diameter. Argon, a gas flow rate of 5 l per minute (LPM), was used to flow through the plasma torch; oxygen is pass through the plasma reactor’s side ports with a flow rate of 20 LPM. Water flow rates [cathode (LPM): 8; substrate] (LPM): 6; Gas flow rates (Plasmon Forming gas (Nitrogen) (LPM):5. The plasma plume generated between anode and cathode was enclosed in a double-walled water-cooled chamber with a diameter of 450 mm. Initially, the plasma chamber was evacuated to the bare pressure: 500 k pascal (Pa) and then filled with oxygen through the plasma reactor. The plasma plume impinged onto metallic zinc precursor results in evaporation of zinc species, and its interaction with oxygen species present at the periphery of the plasma plume results in the formation of the ZnO phase. As a result, steep in temperature gradient inside the plasma plume and outside the plasma plume, the ZnO phase so formed gets stabilized. In the powder form, ZnO gets deposited onto the water-cooled chamber’s inner wall, collected for further characterization [32, 33]. Transmission electron microscopy images (TEM) and Selected Area Electron Diffraction (SAED) patterns were analyzed using a TECNAI G2–20 electron microscope. The X-ray diffraction (XRD) pattern was recorded using BRUKER AXS D8 ADVANCE X-ray diffractometer with Cu Kα (1.5402 ̊A) incident radiation. The width of the highest intensity diffraction line observed in the X-ray diffraction pattern of the ZnO nanosheet was used to determine crystallite size using the Scherrer formula, as shown in (Eq. 1).

Where¸ λ is the wavelength of the source, i.e., X-rays, θ the Bragg angle and β the full width of the characteristic diffraction line at half of the maximum intensity.

Standardization of Enzyme Activity

The stock solution of α-amylase 10 mg/mL and 2% starch (soluble) solution prepared in phosphate buffer. DNSA (dinitrosalicylic acid) 2.5 g added in 2 M NaOH (50 mL) and sodium-potassium tartrate 75 g dissolved in 125 mL Milli-Q water. Working concentration of α-amylase (enzyme:1 mg/mL) prepared in phosphate buffer. The α-amylase activity was measured at different pH (5.4 to 6.4), temperature (42 °C to 60 °C), and time (10 to 70 min). Release maltose in the reaction mixture was calibrated using a standard maltose calibration curve at 540 nm, DNS used as the reducing agent [34]. The optimum concentration of α-amylase and starch with various sets of the experiment performed to follow Michaelis-Menten Curve.

Preparation of Enzyme and Substrate with Porous ZnO Nanosheets

2 mM ZnO nanosheets prepared in Milli-Q water with ultrasonication method. Starch solution 5.33 mg/mL was optimized. Starch and α-amylase 1 mg/mL were incubated with porous ZnO nanosheet at 52 °C in a mixing water bath.

UV-Visible Measurement

The UV-Visible spectra of α-amylase on ZnO nanosheet were recorded in the wavelength range between 200 nm to 800 nm using a nanophotometer (Implen) Germany. The solutions for the measurements were prepared in Milli-Q water.

Synchronous Fluorescence Spectra Measurement

The initial excitation wavelength was set at 250 nm in fluorescence synchronous scan and scanned up to 500 nm. The (Δλ) was kept at 15 nm (tyrosine) and 60 nm (tryptophan) for measurement. One cm path length rectangular mirror quartz cuvette was used. The excitation-emission slit was set to 5.0 nm and photomultiplier tube voltage at 450 V for measurements.

Circular Dichroism (CD) Spectroscopy Study

CD analysis was performed on a Jasco J-815-1505 spectrometer. The spectra were recorded over the wavelength range 200–260 nm in a 1 mm cell at the bandwidth of 5 nm with a 10 nm/min scan rate was adjusted. The sample concentration 0.2 mg/mL at 20 °C, and the sample volume required for analysis was 0.4 mL.

Dynamic Light Scattering Study

The instrument comprises a laser light as the source, sample cell, and detector placed at a fixed angle, a photomultiplier amplifying the signal for measurement. Analyses were performed using (Malvern ZS 90 Nano series, Germany). Before a zeta sizer cell was placed into the sample holder, its outer surface area was wiped gently with a sheet of soft lens cleaning tissue. Corresponding quartz cells were filled with 1 mL of the reaction (sample) solution. The cells were placed inside the round-bottom tube. At least three successive measurements were performed per sample after 2 min waiting time to allow solutions to be at rest. In DLS, like in other spectroscopic methods, great emphasis was placed on measurement cell cleanliness. The quartz cells were cleaned immediately after use to remove the sample from optical surfaces with deionized water.

Atomic Force Microscopy Analysis

An optical deflection detection system (Bruker Dimension Edge Nanoscope 8), micro-fabricated silicon nitride cantilever with a spring constant (0.1 to 0.5 N/m), used for measurement and analysis. The concentration of α-amylase (4 mg/mL) and starch (10 mg/mL) dissolved in phosphate buffer for sample preparation.

Adsorption Isotherm Study of α-Amylase Bound on Porous ZnO Nanosheet

The various concentrations of α-amylase (0.2 to 1.2 mg/mL) with a fixed amount of porous ZnO nanosheets (2 mM) were used for analysis. The porous dimensions present on the plane nanosheet were adsorbed by α-amylase. Adsorption mixture of α-amylase-ZnO nanosheets kept for 30 min, the presence of unbound α-amylase was determined using standard enzyme fluorescence calibration plot, i.e., area under the curve. The adsorbed amount at equilibrium qe (mg/mg) calculated using the following (Eq. 2).

Where C0 and Ce (mg/L), the amounts of α-amylase at initial and equilibrium concentration, and W is the amount of ZnO nanosheets. The Freundlich isotherm model could best evaluate α-amylase multilayer adsorption on the porous-ZnO nanosheets, calculated by the Freundlich adsorption (Eq. 3).

The Ce is the presence of free α-amylase in solution (mg/L) qe is the amount of α-amylase (mg) adsorbed per millimolar of ZnO nanosheets at equilibrium concentration (mg/L). The Kf and n are parameters that depend on the adsorbate and adsorbent. To obtain the Freundlich equation’s linear form by taking logarithms on both sides (eq. 2). The α-amylase-ZnO nanosheet adsorption parameters were fitted to both Freundlich and Langmuir models to optimize isothermal adsorption (Eq. 4).

The Langmuir isothermal model equation is shown (Eq. 5).

Where Ce is the amount of free concentration of α-amylase (mg/L), qe is the mass of α-amylase adsorbed on porous ZnO sheets, qmax is the maximum adsorption amount of α-amylase bound to porous ZnO nanosheets to form a monolayer, and Ka is the adsorption constant (L/mg), shows α-amylase binding affinity onto porous ZnO nanosheets. Eq. 6 shows that Ka and qm is the intercepts and slope of the linear plots of \( \frac{C_e}{q_e} \) versus Ce

Results and Discussion

Characterization of ZnO Metal Nanosheet

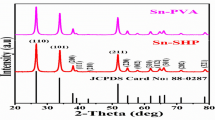

The surface plasmon resonance of the ZnO nanosheet was observed at 364 nm (Fig. 1a). Figure 1b shows that the XRD pattern has the crystallite size (25 nm), which was determined using the Scherrer formula (Eq. 1). Comparison of experimentally recorded data with the JCPDS File no. (79–0205) reveals that ZnO possesses a hexagonal crystal structure with a diffraction line corresponding to (101) as displayed in Fig. 1b. The powder morphology and crystalline structure were analyzed with High-Resolution Transmission Electron Microscope (HR-TEM) model Tecnai G2, F30, 200 kV confirms ZnO nanosheets with the porous surface (pore ~1.5 nm to 2 nm) presented in Fig. 1c and d. The high-resolution transmission electron microscopy image (Fig. 1d) indicates that the building particles have a lattice spacing of 0.25 nm, corresponding to the wurtzite ZnO lattice plane.

Adsorption Isotherm Study of α-Amylase Bound on Porous (ZnO) Nanosheet

The log qe and log Ce plot allow the adsorption coefficient Kf and the exponent 1/n. Kf shows the capacity of adhesion of the adsorbate, and 1/n represents the adsorption intensity onto the adsorbent surface. Figure 2a shows a 1/n value of 0.94 that indicates porous ZnO nanosheets have favorable adsorption isotherm for α-amylase. The Freundlich isotherm model and Langmuir, which can apply to multilayer adsorption behavior, presumes that the behavior adsorbent is heterogeneous. Their energies distribute exponentially over a short growth of the period. Our results fitted effectively to the Freundlich model that showed the multilayer adsorption behavior of α-amylase onto porous ZnO nanosheets (Fig. 2a). Langmuir adsorption isotherm presumes that adsorption is limited to monolayer; only a single layer of adsorbate molecule occupies a site on the adsorbent, no further adsorption can take place in that site (Fig. 2b). A smaller value of Ka denotes that lower adsorption energy. The low R2 value shows that the Langmuir model does not fit the monolayer adsorption behavior of α-amylase on porous ZnO nanosheets, which agreed with our previous Bovine Serum Albumin (BSA) adsorption report on the surface of silver nanoparticles [35].

Surface Analysis of Adsorbed Starch and α-Amylase on Porous ZnO Nanosheet Using Atomic Force Microscopy

Atomic Force Microscopy (AFM) measures surface topography at a sub-nanometre resolution; recently, some sugars and proteins have been structurally characterized by AFM [36, 37]. AFM imaging in the air has elucidated the difference in network structure between ZnO nanosheet and starch. Figure 3a displays only the ZnO nanosheet, and Fig. 3b showed the hydrophobic nature of starch adsorbs on porous nanosheets. The molecular starch structure seems to be more hydrophobic with homogeneity in vertical height, as shown in Fig. 3b. Adsorbed α-amylase and starch on the surface of ZnO nanostructure reported earlier [17]. Besides, AFM’s structure reflects nanosheet’s behavior, and enzyme-bound with a nanosheet shows mechanical properties. ZnO nanosheet thickness is approximately 10–12 nm, roughness (Ra) 18.47 nm, and height 17.7 μm [38]. After adsorption of starch on porous ZnO nanosheet, the starch structure was affected for an enzymatic reaction. The aggregation of α-amylase adsorbed on ZnO nanosheet was examined by atomic force microscopy at the single-molecule level (Fig. 3c). The enzymatic activity (kinetics) was checked by UV spectroscopy. It has been confirmed that an increased aggregation of enzymes is adsorbed on the ZnO nanosheet. As a result, α-amylase activity was varied in the reaction solution. Thus, the enzyme alters its secondary structure, and maybe the substrate is not accessible to the α-amylase active site. Hence, the decreasing enzyme activity.

Dynamic Light Scattering Analysis of Adsorbed α-Amylase and Starch on ZnO Nanosheet

Dynamic light scattering is a technique widely used for particle size, size distribution studies, and zeta potential measurement [39]. The ZnO nanosheet’s intense light scattering property quickly measures the size, conductivity, and bandgap energy, as displayed in (Table 1). The zeta potential increases from −41.9 to −28.7 mV, confirming that enzyme and starch stabilize electrostatic interaction bound with ZnO nanosheet. The conductivity between the ZnO nanosheet, enzyme, and starch decrease from 0.07 to 0.035mS/cm. ZnO nanosheet has bandgap energy 3.85 eV after adsorption of ZnO nanosheet with an enzyme (4.37 eV) and starch (4.19 eV) bandgap energy increased, suggesting destabilization of α-amylase secondary structure [40,41,42,43].

Enzyme Activity

Kinetics of enzymes is a practical approach to investigate the catalytic power of the enzyme. The catalytic power of enzymes arises from bringing substrate together in a favorable condition to promote the enzyme-substrate complex formation. At the enzyme’s constant concentration, the reaction rate increases with substrate until the maximum velocity is reached. The kinetic parameters, like the Michaelis–Menten constant (Km) and the maximum rate (Vmax), K-cat, provides the catalytic features of the enzyme [44]. The maximum activity of (enzyme) α-amylase (0.33 μg/mL) with (substrate) starch (5.33 μM) at optimum experimental conditions pH (5.8), temperature (52 °C), and incubation time (60 min) as shown in Fig. 4. The Km of α-amylase obtains 26.31 μM, which measures the substrate concentration required for significant catalysis, and the Vmax of α-amylase is 2.85 μM, i.e., the maximum velocity of the enzyme-substrate reaction.

α-Amylase Activities Adsorbed on Porous ZnO Nanosheets

Generally, the Km is inversely proportional to affinities, and adsorb α-amylase on ZnO nanosheet exhibits higher Km and lower Vmax than free enzymes indicating a decreased activity [45]. Inactivation of enzymes and their subunits partial dissociation due to non-covalent interaction and the active site’s steric hindrance. This structural change in enzyme with ZnO adsorption or diffusional limitation of the substrate resulted in its decreased affinity to its substrate. It is reflected in Km’s increased value and decreased Vmax value compared to free enzyme [46]. The change in the adsorbing enzyme’s affinity on the ZnO porous nanosheet is shown in schematics (Fig. 5), as this might happen due to inappropriate orientation and weak interaction caused by physical adsorption. It indicates that the reaction rate of α-amylase alters when different molecules cover the surface area for a substrate. Guzik et al. [47] reported Km as 6.22 mM for free α-amylase and 4.77 mM on modified magnetite nanoparticles. As a result, of α-amylase molecule might expand over the particle surface with better orientation leading to higher affinity towards the substrate [47]. To understand the enzymatic reaction’s catalytic efficiency, Homaei et al. [48] reported Km and Vmax of the α-amylase adsorb by various chemical agents. When α-amylase adsorb on gold nanorods, the free and adsorb enzyme Km was 6.4 μM and 5.9 μM respectively [48]. In the present study, free enzyme Km showed 26.31 μM whereas calculated Vmax 2.85 μM. The various activity assays performed to control the reaction indicate that there was a change in affinity. The values of modified α-amylase Km (12.82 μM), Vmax (1.17 μM), and Kcat (3.54 × 106 μM) significantly decreased as depicted in (Table 1). To investigate further, when the substrate adsorbs on ZnO nanosheets, the values of Km (22.72 μM), Vmax (1.81 μM), Kcat (5.48 × 106 μM) were less than control and more with porous ZnO nanosheets. Most of the enzyme does not saturate with the substrate under the physiological condition, the ratio of (S)/Km is typically falling between 0.01and 1.0 when (S) < < Km. S/Km values for the free enzyme (1.77 μM), α-amylase-modified (3.64 μM), starch-modified (2.05 μM), α-amylase and starch-modified together (1.68 μM) confirm that enzyme does not saturate at physiological conditions shown in Table 2 [49]. The enzyme reaction rate is much lower than Kcat because most active sites are unoccupied [49]. The Kcat of free α-amylase was (8.63 × 106 μM). The α-amylase was modified with a ZnO nanosheet. For Km analysis, the slope (14.27 μM) and standard error (3.60), whereas for Vmax analysis, slope (1.22 μM) and standard error (0.35) are calculated (Fig. 6a and b) with different pH conditions (Table 2). Temperature plays a vital role in enzyme kinetics, and modified α-amylase alters its activity at various temperatures. The Km varies in the range of (83.33 μM to 20 μM), and Vmax differs (2.22 μM to 1.05 μM) as shown in Table 2. When the enzyme adsorbs on ZnO nanosheets, the saturation of substrate is higher than control. These results state that the enzyme’s structure inactivation due to its subunits partial dissociation results from non-covalent interaction between enzyme and the support or due to steric hindrance at the active site [50].

Production of Maltose with an Enzyme (α-Amylase) and Substrate (Starch) Modified with ZnO Porous Nanosheet

Enzymes catalyze reactions in different states as individual molecules in solution, in aggregates with other entities, and as attached to surfaces. The enzyme (α-amylase) and substrate (starch) independently adsorb with porous ZnO nanosheet for 60 min. After adsorption, α-amylase activity was monitored with varying temperature and pH using a standard maltose calibration curve. Observed percent production of maltose was varied with temperature [51, 52]. The optimum temperature and pH (Fig. 7a and b) for the best enzyme activity were studied carefully; maltose production decreased with adsorbed enzyme and substrate with ZnO nanosheet. α-amylase and starch adsorbed together on ZnO nanosheet and used to study maltose production (Fig. 7a) at the optimum temperature (52 °C) and pH (5.8). The reaction results showed that the enzyme (α-amylase) and substrate (starch) adsorbed with ZnO nanosheet depict starch conversion into maltose in a higher amount. Adsorb enzyme and substrate at different pH used for further analysis (Fig. 7b). Enzyme reaction showed less maltose production with the substrate (starch) adsorbing ZnO nanosheet. In both experimental reactions with varying temperature and pH, adsorb enzyme, and substrate, it was seen that enzyme reaction (i.e., optimum condition) shifted to another temperature (50 °C, 60 °C, 65 °C) and pH (5.4, 5.6, 6.0, 6.2, and 6.4). Enzyme and starch structural alterations are possible with the porous ZnO nanosheet. Thus, maximum activity with varying pH and temperature was observed [18].

Conformational Study of α-Amylase Bound with ZnO Nanosheet

Ultraviolet-visible spectrometry confirms that α-amylase showed two peaks in the UV regions (Fig. 8a). One at 280 nm, which arises due to π-π transition of aromatic amino acid residues, and the other at 210 nm, which is contributed by the π-π transition of the peptide carbonyl bond. The surface plasmon resonance peak of α-amylase found at 208 nm [53], the peak observed at 211 nm showed a slight increase in intensity and a blueshift in α-amylase-ZnO nanosheet bound complex. Surface plasmon resonance peaks are sensitive to changes in the local environment, hypsochromic shift, and increased intensity of the adsorbing enzyme (α-amylase) was observed. In CD spectra (Fig. 8b), two negative bands at 208 and 222 nm were observed, which confirmed the alteration in the secondary structure of α-amylase. The adsorb α-amylase on porous ZnO nanosheet caused a significant decrease in both negative band’s intensity, while the peak position shape remains the same. The α-helix percentage in native α-amylase at optimum concentration was calculated to be 54.70%, while (α-amylase-ZnO nanosheet complex) was found to be 37.00%, which means a decrease in helical content of α-amylase while adsorbing. We have monitored the synchronous fluorescence spectrum in the microenvironments of tryptophan (Fig. 8c) and tyrosine (Fig. 8d) residues in the enzyme (α-amylase). Adsorbs α-amylase with porous ZnO nanosheets decrease fluorescence emission intensity, and a significant blue shift was observed with tryptophan residue. The binding of α-amylase to ZnO nanosheets has caused the tryptophan residues to expose to a more hydrophobic environment. Simultaneously, tyrosine amino acid does not affect the fluorescence wavelength shift during adsorption (Fig. 8d), possibly because of buried tyrosine in α-amylase. We can infer that porous ZnO nanosheets surface chemistry could play an essential role in altering enzyme activity.

Conclusion

In this study, α-amylase was successfully adsorbed on the surface of the porous ZnO nanosheet. The process equilibrium and kinetic parameters showed that the chemical character of the enzyme adsorption indicates chemisorption. The enzyme adsorbed on the ZnO nanosheet exhibited low Km and Vmax values than the free α-amylase, which indicated a higher affinity towards the substrate. DLS represented structural alteration in α-amylase and electrostatic interactions between enzyme and substrate. This work reveals the possibility of designing a modified catalytic system for maximum end-product formation in reaction with altered optimum conditions. The results make promises in developing the designed catalyst and can be used to prove the impact of modified enzyme and substrate concentration-dependent effect on the reaction mechanism. The work’s novelty resides in the production of maltose with enzyme-modified, substrate modified, and enzyme-substrate modified together on ZnO nanosheets, which may be used in industrial applications.

References

Jajpura, L., 2018. Enzyme: A bio catalyst for cleaning up textile and apparel sector. In Detox Fashion (pp. 95-137). Springer, Singapore

P.D. Tomke, V.K. Rathod, Enzyme as biocatalyst for synthesis of octyl ethanoate using acoustic cavitation: Optimization and kinetic study. Biocatalysis and Agricultural Biotechnology 7, 145–153 (2016)

H. Vaghari, H. Jafarizadeh-Malmiri, M. Mohammadlou, A. Berenjian, N. Anarjan, N. Jafari, S. Nasiri, Application of magnetic nanoparticles in smart enzyme immobilization. Biotechnol. Lett. 38(2), 223–233 (2016)

P.E. Swanson, Dehalogenases applied to industrial-scale biocatalysis. Curr. Opin. Biotechnol. 10(4), 365–369 (1999)

M. Alcalde, M. Ferrer, F.J. Plou, A. Ballesteros, Environmental biocatalysis: From remediation with enzymes to novel green processes. Trends Biotechnol. 24(6), 281–287 (2006)

K.A. Mahmoud, K.B. Male, S. Hrapovic, J.H. Luong, Cellulose nanocrystal/gold nanoparticle composite as a matrix for enzyme immobilization. ACS Appl. Mater. Interfaces 1(7), 1383–1386 (2009)

A. Popat, S.B. Hartono, F. Stahr, J. Liu, S.Z. Qiao, G.Q.M. Lu, Mesoporous silica nanoparticles for bioadsorption, enzyme immobilisation, and delivery carriers. Nanoscale 3(7), 2801–2818 (2011)

D. Shan, M. Zhu, H. Xue, S. Cosnier, Development of amperometric biosensor for glucose based on a novel attractive enzyme immobilization matrix: Calcium carbonate nanoparticles. Biosens. Bioelectron. 22(8), 1612–1617 (2007)

Z. Li, L. Sheng, A. Meng, C. Xie, K. Zhao, A glassy carbon electrode modified with a composite consisting of reduced graphene oxide, zinc oxide and silver nanoparticles in a chitosan matrix for studying the direct electron transfer of glucose oxidase and for enzymatic sensing of glucose. Microchim. Acta 183(5), 1625–1632 (2016)

S. Datta, L.R. Christena, Y.R.S. Rajaram, Enzyme immobilization: An overview on techniques and support materials. 3. Biotech 3(1), 1–9 (2013)

Długosz, O., Matysik, J., Matyjasik, W. and Banach, M., 2020. Catalytic and antimicrobial properties of α-amylase immobilised on the surface of metal oxide nanoparticles. J. Clust. Sci., pp.1-14

G.A. Petkova, К. Záruba, P. Žvátora, V. Král, Gold and silver nanoparticles for biomolecule immobilization and enzymatic catalysis. Nanoscale Res. Lett. 7(1), 287 (2012)

S.R. Saptarshi, A. Duschl, A.L. Lopata, Interaction of nanoparticles with proteins: Relation to bio-reactivity of the nanoparticle. Journal of nanobiotechnology 11(1), 26 (2013)

N. Aissaoui, L. Bergaoui, S. Boujday, J.F. Lambert, C. Méthivier, J. Landoulsi, Enzyme immobilization on silane-modified surface through short linkers: Fate of interfacial phases and impact on catalytic activity. Langmuir 30(14), 4066–4077 (2014)

Wang, R., Zhang, H., Chen, Z. and Zhong, Q., 2020. Structural basis for the low digestibility of starches recrystallized from side chains of amylopectin modified by amylosucrase to different chain lengths. Carbohydr. Polym., p.116352

H. Zhang, R. Wang, Z. Chen, Q. Zhong, Enzymatically modified starch with low digestibility produced from amylopectin by sequential amylosucrase and pullulanase treatments. Food Hydrocoll. 95, 195–202 (2019)

N. Antony, S. Balachandran, P.V. Mohanan, Immobilization of diastase α-amylase on nano zinc oxide. Food Chem. 211, 624–630 (2016)

S.A. Ansari, Q. Husain, Potential applications of enzymes immobilized on/in nano materials: A review. Biotechnol. Adv. 30(3), 512–523 (2012)

R. Yakimova, L. Selegård, V. Khranovskyy, R. Pearce, A. Lloyd Spetz, K. Uvdal, ZnO materials and surface tailoring for biosensing. Frontiers in bioscience (Elite edition) 4(1), 254–278 (2012)

S.M. Alfadul, A.A. Elneshwy, Use of nanotechnology in food processing, packaging and safety–review. Afr. J. Food Agric. Nutr. Dev. 10(6) (2010)

D.K. Kamaldeep, K.K. Dubey, Optimization of zinc oxide nanoparticles synthesis to fabricate glucose oxidase sensor. Adv. Appl. Sci. Res. 3(5), 3081–3088 (2012)

Y. Zhang, H. Wu, X. Huang, J. Zhang, S. Guo, Effect of substrate (ZnO) morphology on enzyme immobilization and its catalytic activity. Nanoscale Res. Lett. 6(1), 1–7 (2011)

Ahmad, R. and Sardar, M., 2015. Enzyme immobilization: An overview on nanoparticles as immobilization matrix Biochemistry and Analytical Biochemistry, 4(2), p.1

B.S. Khade, V.L. Mathe, P.M. Dongre, α-Amylase binding to thermal plasma synthesized zinc oxide nanosheets: A fluorescence study. J. Lumin. 187, 449–456 (2017)

R. Gupta, P. Gigras, H. Mohapatra, V.K. Goswami, B. Chauhan, Microbial α-amylases: A biotechnological perspective. Process Biochem. 38(11), 1599–1616 (2003)

A. El-Fallal, M.A. Dobara, A. El-Sayed, N. Omar, Starch and microbial α-amylases: From concepts to biotechnological applications. Carbohydrates–Comprehensive Studies on Glycobiology and Glycotechnology, 459–488 (2012)

Q. Zhang, Y. Han, H. Xiao, Microbial α-amylase: A biomolecular overview. Process Biochem. 53, 88–101 (2017)

A. Sundarram, T.P.K. Murthy, α-Amylase production and applications: A review. J. Appl. Environ. Microbiol. 2(4), 166–175 (2014)

M.J. Van der Maarel, B. Van der Veen, J.C. Uitdehaag, H. Leemhuis, L. Dijkhuizen, Properties and applications of starch-converting enzymes of the α-amylase family. J. Biotechnol. 94(2), 137–155 (2002)

N. Gurung, S. Ray, S. Bose, V. Rai, A broader view: Microbial enzymes and their relevance in industries, medicine, and beyond. Biomed. Res. Int. (2013)

Benjamin, S., Smitha, R.B., Jisha, V.N., Pradeep, S., Sajith, S., Sreedevi, S., Priji, P., Unni, K.N. and Josh, M.S., 2013. A Monograph on Amylases from Bacillus Spp.

V.L. Mathe, V. Varma, S. Raut, A.K. Nandi, A. Pant, H. Prasanth, R.K. Pandey, S.V. Bhoraskar, A.K. Das, Enhanced active aluminum content and thermal behaviour of nano-aluminum particles passivated during synthesis using thermal plasma route. Appl. Surf. Sci. 368, 16–26 (2016)

V. Jaiswal, M. Samant, A. Kadir, K. Chaturvedi, A.B. Nawale, V.L. Mathe, P.M. Dongre, UV radiation protection by thermal plasma synthesized zinc oxide nanosheets. J. Inorg. Organomet. Polym. Mater. 27(5), 1211–1219 (2017)

S. Sengupta, M.L. Jana, D. Sengupta, A.K. Naskar, A note on the estimation of microbial glycosidase activities by dinitrosalicylic acid reagent. Appl. Microbiol. Biotechnol. 53(6), 732–735 (2000)

M. Waghmare, B. Khade, P. Chaudhari, P. Dongre, Multiple layer formation of bovine serum albumin on silver nanoparticles revealed by dynamic light scattering and spectroscopic techniques. J. Nanopart. Res. 20(7), 185 (2018)

T. Funami, Atomic force microscopy imaging of food polysaccharides. Food Sci. Technol. Res. 16(1), 1–12 (2010)

Y.D. Ivanov, T.O. Pleshakova, I.D. Shumov, A.F. Kozlov, I.A. Ivanova, A.A. Valueva, V.Y. Tatur, M.V. Smelov, N.D. Ivanova, V.S. Ziborov, AFM imaging of protein aggregation in studying the impact of knotted electromagnetic field on a peroxidase. Sci. Rep. 10(1), 1–9 (2020)

I. Horcas, R. Fernández, J.M. Gomez-Rodriguez, J.W.S.X. Colchero, J.W.S.X.M. Gómez-Herrero, A.M. Baro, WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 78(1), 013705 (2007)

P. Gawali, B.L. Jadhav, Synthesis of Ag/AgCl nanoparticles and their action on human serum albumin: A fluorescence study. Process Biochem. 69, 106–122 (2018)

C.J. Barbe, F. Arendse, P. Comte, M. Jirousek, F. Lenzmann, V. Shklover, M. Grätzel, Nanocrystalline titanium oxide electrodes for photovoltaic applications. J. Am. Ceram. Soc. 80(12), 3157–3171 (1997)

J.B. Baxter, E.S. Aydil, Nanowire-based dye-sensitized solar cells. Appl. Phys. Lett. 86(5), 053114 (2005)

B. O'regan, M. Grätzel, A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO 2 films. Nature (6346), 353, 737–740 (1991)

M.R. Hoffmann, S.T. Martin, W. Choi, D.W. Bahnemann, Environmental applications of semiconductor photocatalysis. Chem. Rev. 95(1), 69–96 (1995)

G.E. Briggs, J.B.S. Haldane, A note on the kinetics of enzyme action. Biochem. J. 19(2), 338–339 (1925)

D.E. Koshland Jr., Application of a theory of enzyme specificity to protein synthesis. Proc. Natl. Acad. Sci. U. S. A. 44(2), 98 (1958)

G. Dey, V. Nagpal, R. Banerjee, Immobilization of α-amylase from Bacillus circulans GRS 313 on coconut fiber. Appl. Biochem. Biotechnol. 102(1–6), 303–313 (2002)

U. Guzik, K. Hupert-Kocurek, D. Wojcieszyńska, Immobilization as a strategy for improving enzyme properties-application to oxidoreductases. Molecules 19(7), 8995–9018 (2014)

A. Homaei, D. Saberi, Immobilization of α-amylase on gold nanorods: An ideal system for starch processing. Process Biochem. 50(9), 1394–1399 (2015)

Tymoczko, J.L., Berg, J.M. and Stryer, L., 2011. Biochemistry: A Short Course. Macmillan

N. Sohrabi, N. Rasouli, M. Torkzadeh, Enhanced stability and catalytic activity of immobilized α-amylase on modified Fe3O4 nanoparticles. Chem. Eng. J. 240, 426–433 (2014)

M. Amirbandeh, A. Taheri-Kafrani, Immobilization of glucoamylase on triazine-functionalized Fe3O4/graphene oxide nanocomposite: Improved stability and reusability. Int. J. Biol. Macromol. 93(Pt A), 1183–1191 (2016)

M. Defaei, A. Taheri-Kafrani, M. Miroliaei, P. Yaghmaei, Improvement of stability and reusability of α-amylase immobilized on naringin functionalized magnetic nanoparticles: A robust nanobiocatalyst. Int. J. Biol. Macromol. 113, 354–360 (2018)

B. Ranjbar, P. Gill, Circular dichroism techniques: Biomolecular and nanostructural analyses-a review. Chem. Biol. Drug Des. 74(2), 101–120 (2009)

Acknowledgments

This work was financially funded by Rajiv Gandhi National Fellowship (UGC-RGNF) No. F1-17.1/2013-14/RGNF-2013-14-SC-MAH-51841/ (SA-III), University Grant Commission, Scheme under XII plan, New Delhi, India, to the first author. The author is grateful to Dr. V.L. Mathe, Department of Physics, Savitribai Phule Pune University, for providing ZnO material and Sophisticated Analytical Instrument Facility (SAIF) IIT Bombay for TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

No conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khade, B.S., Gawali, P.G., Waghmare, M.M. et al. Adsorption of α-amylase and Starch on Porous Zinc Oxide Nanosheet: Biophysical Study. Food Biophysics 16, 280–291 (2021). https://doi.org/10.1007/s11483-021-09669-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-021-09669-9