Abstract

The microstructure and high temperature properties of the AXE622 Mg alloy were investigated after the conventional and semisolid casting processes. The tensile test was conducted at room temperature, and 473 K. Impression creep test was performed at a temperature range of 423–498 K under the stress range of 450–600 MPa. The microstructure of the conventional and semisolid alloys contains α-Mg dendrites, the eutectic phase, secondary phases including (Mg–Al)2Ca, eutectic Mg17Al12, and Al11RE3. During semisolid processing, coarse dendrites of the α-Mg became fine, globular, and Rosetta shape. The average length of the secondary phases in the semisolid alloy decreased from 4.21 to 2 μm and the average grain size of the α-Mg reduced from 113 to 96 μm. Semisolid processing caused a significant improvement in the tensile and creep resistance of the AXE622 Mg alloy. The stress exponent for creep was calculated in the range 5.6–7.7 for the conventional alloy and in the range 10.3–11 for the semisolid alloy. The activation energy for conventional and semisolid alloy was determined as 71.4 kJ/mol and 78.3 kJ/mol, respectively. It was concluded that the dominant creep mechanism in the conventional alloy was the grain boundary diffusion-controlled dislocation climb, while in the semisolid alloy was the power-law breakdown.

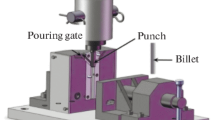

Graphic Abstract

Similar content being viewed by others

References

B. Mordike, T. Ebert, Mater. Sci. Eng. A 13, 302 (2001)

I. Moreno, T. Nandy, J. Jones, J. Allison, T. Pollock, Scripta Mater. 48, 1029–1034 (2003)

B. Nami, H. Razavi, S. Mirdamadi, S. Shabestari, S. Miresmaeili, Metall. Mater. Trans. A 41, 1973–1982 (2010)

D. Amberger, P. Eisenlohr, M. Göken, Mater. Sci. Eng. A 510, 398–402 (2009)

C. Wang, A. Chen, L. Zhang, W. Liu, G. Wu, W. Ding, Mater. Design 84, 53–63 (2015)

W. Blum, P. Zhang, B. Watzinger, B. Grossmann, H. Haldenwanger, Mater. Sci. Eng. A 319, 735–740 (2001)

B. Kondori, R. Mahmudi, Mater. Sci. Eng. A 700, 438–447 (2017)

X. Feng, M. Xuegang, S. Yangshan, J. Mater. Sci. 41, 4725–4731 (2006)

B. Nami, S. Shabestari, H. Razavi, S. Mirdamadi, S. Miresmaeili, Mater. Sci. Eng. A 528, 1261–1267 (2011)

J. Deng, Y. Lin, S.-S. Li, J. Chen, Y. Ding, Mater. Design 49, 209–219 (2013)

A. Fata, G. Faraji, M. Mashhadi, V. Tavakkoli, Mater. Sci. Eng. A 674, 9–17 (2016)

L. Shang, S. Yue, R. Verma, P. Krajewski, C. Galvani, E. Essadiqi, Mater. Sci. Eng. A 528, 3761–3770 (2011)

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, G. Myilsamy, Met. Mater. Int. 26, 409–430 (2020)

R.S. Rudi, S. Kamado, N. Ikeya, T. Araki, Y. Kojima, Mater. Sci. Forum 7, 79–86 (2016)

S.-M. Zhu, J. Nie, B. Mordike, Metall. Mater. Trans. A 37, 1221–1229 (2006)

X.C. Luo, D.T. Zhang, G.H. Cao, C. Qiu, D.L. Chen, Mater. Sci. Eng. A 759, 234–240 (2019)

T. Campanella, C. Charbon, M. Rappaz, Metall. Mater. Trans. A 35, 3201–3210 (2004)

S.F. Liu, L.Y. Liu, L.G. Kang, J. Alloy. Compd. 450, 546–550 (2008)

H. Han, S. Liu, L. Kang, L. Liu, Journal of Wuhan University of Technology-Mater. Sci. Ed. 23, 194–197 (2008)

B. Kondori, R. Mahmudi, Metall. Mater. Trans. A 40, 2007–2015 (2009)

S. Liang, R. Chen, J. Blandin, M. Suery, E. Han, Mater. Sci. Eng. A 480, 365–372 (2008)

B. Nami, S.M. Miresmaeili, F. Jamshidi, I. Khoubrou, T. Nonferr. Metal. Soc. 29, 2056–2065 (2019)

S.H. Allameh, M. Emamy, J. Mater. Eng. Perform. 26, 2151–2161 (2017)

K. Deng, K. Wu, Y. Wu, K. Nie, M. Zheng, J. Alloy. Compd. 504, 542–547 (2010)

M.K. Aghayani, B. Niroumand, J. Alloy. Compd. 509, 114–122 (2011)

H.L. Cox, Br. J. Appl. Phys. 3, 72–79 (1952)

V.C. Nardone, K.M. Prewo, Scripta Metall. 20, 43–48 (1986)

H. Sekine, R. Chent, Composites 26, 183–188 (1995)

D. Hull, D.J. Bacon, Introduction to Dislocations (Fifth Edition), (Butterworth-Heinemann, Oxford, 2011), pp. 21–41

B. Nami, H. Razavi, S. Miresmaeili, S. Mirdamadi, S. Shabestari, Scripta Mater. 65, 221–224 (2011)

S. Rashno, B. Nami, S. Miresmaeili, Mater. Design 60, 289–294 (2014)

I. Khoubrou, B. Nami, S.M. Miresmaeili, Met. Mater. Int. 26, 196–204 (2020)

H. Khalilpour, S.M. Miresmaeili, A. Baghani, Mater. Sci. Eng. A 652, 365–369 (2016)

R. Mahmudi, S. Moeendarbari, Mater. Sci. Eng. A 566, 30–39 (2013)

W. Blum, Y.J. Li, X.H. Zeng, P. Zhang, B. von Großmann, C. Haberling, Metall. Mater. Trans. A 36, 1721–1728 (2005)

Y. Terada, R. Sota, N. Ishimatsu, T. Sato, K. Ohori, Metall. Mater. Trans. A 35, 3029–3032 (2004)

R. Gupta, B. Daniel, Mater. Sci. Eng. A 733, 257–266 (2018)

H.J. Frost, M.F. Ashby, Deformation Mechanism Maps (Pergamon Press, Oxford, 1982)

B. Nami, S. Rashno, S. Miresmaeili, J. Alloy. Compd. 639, 308–314 (2015)

F. Kabirian, R. Mahmudi, Metall. Mater. Trans. A 40, 116 (2009)

A. Geranmayeh, R. Mahmudi, Mater. Chem. Phys. 139, 79–86 (2013)

Y. Huang, T.G. Langdon, Jom 55, 15–20 (2003)

C. Park, X. Long, S. Haberman, S. Ma, I. Dutta, R. Mahajan, S. Jadhav, J. Mater. Sci. 42, 5182–5187 (2007)

S. Chu, J. Li, J. Mater. Sci. 12, 2200–2208 (1977)

H. Somekawa, K. Hirai, H. Watanabe, Y. Takigawa, K. Higashi, Mater. Sci. Eng. A 407, 53–61 (2005)

S. Robinson, O. Sherby, Acta Metall. 17, 109–125 (1969)

K. Hirai, H. Somekawa, Y. Takigawa, K. Higashi, Mater. Sci. Eng. A 403, 276–280 (2005)

Acknowledgements

Financial support provided by Shahid Chamran University of Ahvaz (Ahvaz, Iran) through Grant No. SCU.EM98.788 is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eftekhar, A.H., Sadrossadat, S.M. & Reihanian, M. Microstructural Investigation and High Temperature Mechanical Behavior of AXE622 Cast Mg Alloy. Met. Mater. Int. 28, 1062–1074 (2022). https://doi.org/10.1007/s12540-021-00984-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00984-x