Abstract

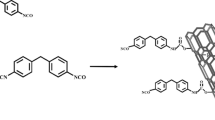

Carbon nanotube (CNT) grafted with hyperbranched poly(amidoamine) (PAMAM) dendrimer (CNTD) were used as a multifunctional curing and composite agent of polyurethane (PU) terminated with epoxy units. Amino-functionalized CNT was used as the core for grafting the first generation of PAMAM dendrimer by sequential addition of methyl acrylate and ethylenediamine. Two different epoxy-terminated PUs (PUB and PU-PMDA) were prepared from the reaction of poly(ethylene glycol), excess amounts of hexamethylene diisocyanate, and different chain extenders (1,4-butanediol for PUB and pyromellitic dianhydride (PMDA) for PU-PMDA), and subsequent end group transformation of the isocyanate groups to epoxy functionalities using glycidol. Fourier transform infrared spectra and thermogravimetric analysis (TGA) results showed that CNTD was successfully prepared. TGA thermograms revealed that thermal decomposition of composites were carried out in two main steps related to the soft and hard segments. In addition, char content and thermal stability of the composites were increased with increasing the CNTD content. Most importantly, the PMDA chain extender resulted in high thermal stability of the epoxy-terminated PU composites. X-ray diffraction and scanning and transmission electron microscopies presented morphological and structural properties of nanotubes and hybrid composites.

Similar content being viewed by others

References

Gupta A, Kim BS (2019) Shape memory polyurethane biocomposites based on toughened polycaprolactone promoted by nano-chitosan. Nanomaterials 9:225

Kausar A (2019) Interpenetrating polymer network and nanocomposite IPN of polyurethane/epoxy: a review on fundamentals and advancements. Polym Technol Mater 58:691–706

Li Y, Duan L, Cheng L, Yang Y, Li Y, Cheng Y, Song D (2019) Thermal analysis and crystallization kinetics of polyurethane. J Therm Anal Calorim 135:2843–2848

Yang W, Li R, Fang C, Hao W (2019) Surface modification of polyamide nanofiber membranes by polyurethane to simultaneously improve their mechanical strength and hydrophobicity for breathable and waterproof applications. Prog Org Coat 131:67–72

Li M, Chen J, Shi M, Zhang H, Ma PX, Guo B (2019) Electroactive anti-oxidant polyurethane elastomers with shape memory property as non-adherent wound dressing to enhance wound healing. Chem Eng J 375:121999

Xiao S, Laux KA, Wang H, Hu F, Sue HJ (2019) Physical correlation between abrasive wear performance and scratch resistance in model polyurethane elastomers. Wear 418–419:281–289

Wang C, Hong L, Tian C (2019) Preparation and properties of flame-retardant damping polyurethane and its application in floating deck. Polym Eng Sci 59:2136–2147

Zhang S, Liu H, Yang S, Shi X, Zhang D, Shan C, Mi L, Liu C, Shen C, Guo Z (2019) Ultrasensitive and highly compressible piezoresistive sensor based on polyurethane sponge coated with a cracked cellulose nanofibril/silver nanowire layer. ACS Appl Mater Interfaces 11:10922–10932

Xi W, Qian L, Li L (2019) Flame retardant behavior of ternary synergistic systems in rigid polyurethane foams. Polymers (Basel) 11:207

Xie F, Zhang T, Bryant P, Kurusingal V, Colwell JM, Laycock B (2019) Degradation and stabilization of polyurethane elastomers. Prog Polym Sci 90:211–268

Golling FE, Pires R, Hecking A, Weikard J, Richter F, Danielmeier K, Dijkstra D (2019) Polyurethanes for coatings and adhesives—chemistry and applications. Polym Int 68:848–855

Hu J, Zhu Y, Huang H, Lu J (2012) Recent advances in shape—memory polymers : structure, mechanism, functionality, modeling and applications. Prog Polym Sci 37:1720–1763

Hager MD, Bode S, Weber C, Schubert US (2015) Shape memory polymers: past, present and future developments. Prog Polym Sci 49–50:3–33

Masiulanis B, Zielin̂ski R (1985) Mechanical, thermal, and electric properties of polyurethaneimide elastomers. J Appl Polym Sci 30:2731–2741

Petrovic ZS, Zavargo Z, Flynn JH, Macknight WJ (1994) Thermal degradation of segmented polyurethanes. J Appl Polym Sci 51:1087–1095

Koberstein JT, Galembos AF, Leung LM (1992) Compression-molded polyurethane block copolymers. 1. Microdomain morphology and thermomechanical properties. Macromolecules 25:6195–6204

Chen TK, Chui JY, Shieh TS (1997) Glass transition behaviors of a polyurethane hard segment based on 4,4′-diisocyanatodiphenylmethane and 1,4-butanediol and the calculation of microdomain composition. Macromolecules 30:5068–5074

Yeganeh H, Shamekhi MA (2004) Poly(urethane-imide-imide), a new generation of thermoplastic polyurethane elastomers with enhanced thermal stability. Polymer (Guildf) 45:359–365

Liu J, Ma D, Li Z (2002) FTIR studies on the compatibility of hard—soft segments for polyurethane—imide copolymers with different soft segments. Eur Polym J 38:661–665

Patel NB, Mistry DB (2004) Synthesis and properties of polymers containing s-triazine rings in the main chain. Int J Polym Mater Polym Biomater 53:653–658

Behnam R, Roghani-Mamaqani H, Salami-Kalajahi M, Mardani H (2020) Effect of aliphatic and aromatic chain extenders on thermal stability of graphene oxide/polyurethane hybrid composites prepared by sol–gel method. ChemistrySelect 5:962–967

Tien YI, Wei KH (2001) Hydrogen bonding and mechanical properties in segmented montmorillonite/polyurethane nanocomposites of different hard segment ratios. Polymer (Guildf) 42:3213–3221

Yazdi M, Haddadi Asl V, Pourmohammadi M, Roghani-Mamaqani H (2019) Mechanical properties, crystallinity, and self-nucleation of carbon nanotube-polyurethane nanocomposites. Polym Test 79:106011

Pourmohammadi-Mahunaki M, Haddadi-Asl V, Roghani-Mamaqani H, Koosha M, Yazdi M (2020) Halloysite-reinforced thermoplastic polyurethane nanocomposites: physico-mechanical, rheological, and thermal investigations. Polym Compos 41:3260–3270

Caracciolo PC, Lores NJ, Abraham GA (2019) Polyurethane-based structures obtained by additive manufacturing technologies. Mater Biomed Eng 235–258

Liu X, Guo J, Tang W, Li H, Gu X, Sun J, Zhang S (2019) Enhancing the flame retardancy of thermoplastic polyurethane by introducing montmorillonite nanosheets modified with phosphorylated chitosan. Compos Part A Appl Sci Manuf 119:291–298

Majka TM, Raftopoulos KN, Pielichowski K (2018) The influence of POSS nanoparticles on selected thermal properties of polyurethane-based hybrids. J Therm Anal Calorim 133:289–301

Hezma AM, Elashmawi IS, Abdelrazek EM, Rajeh A, Kamal M (2017) Enhancement of the thermal and mechanical properties of polyurethane/polyvinyl chloride blend by loading single walled carbon nanotubes. Prog Nat Sci Mater Int 27:338–343

Xu S, Yu W, Jing M, Huang R, Zhang Q, Fu Q (2017) Largely enhanced stretching sensitivity of polyurethane/carbon nanotube nanocomposites via incorporation of cellulose nanofiber. J Phys Chem C 121:2108–2117

Szatkowski P, Pielichowska K, Blazewicz S (2017) Mechanical and thermal properties of carbon-nanotube-reinforced self-healing polyurethanes. J Mater Sci 52:12221–12234

Abdollahi A, Roghani-Mamaqani H, Salami-Kalajahi M, Mousavi A, Razavi B, Shahi S (2018) Preparation of organic-inorganic hybrid nanocomposites from chemically modified epoxy and novolac resins and silica-attached carbon nanotubes by sol-gel process: investigation of thermal degradation and stability. Prog Org Coat 117:154–165

Yeganeh H, Atai M, Talemi PH, Jamshidi S (2006) Synthesis, characterization and properties of novel poly(urethane-imide) networks as electrical insulators with improved thermal stability. Macromol Mater Eng 291:883–894

Levchik SV, Weil ED (2004) Thermal decomposition, combustion and flame-retardancy of epoxy resins—a review of the recent literature. Polym Int 53:1901–1929

Gholipour-mahmoudalilou M, Roghani-mamaqani H, Azimi R, Abdollahi A (2018) Synthesis of hyperbranched poly(amidoamine)-grafted graphene nanolayers as a composite and curing agent for epoxy resin. Appl Surf Sci 428:1061–1069

Samadaei F, Salami-Kalajahi M, Roghani-Mamaqani H, Banaei M (2015) A structural study on ethylenediamine- and poly(amidoamine)-functionalized graphene oxide: simultaneous reduction, functionalization, and formation of 3D structure. RSC Adv 5:71835–71843

Samadaei F, Salami-Kalajahi M, Roghani-Mamaqani H (2016) Grafting of poly(acrylic acid) onto poly(amidoamine)-functionalized graphene oxide via surface-mediated reversible addition-fragmentation chain transfer polymerization. Int J Polym Mater Polym Biomater 65:302–309

Nonahal M, Rastin H, Saeb MR, Sari MG, Moghadam MH, Zarrintaj P, Ramezanzadeh B (2018) Epoxy/PAMAM dendrimer-modified graphene oxide nanocomposite coatings: nonisothermal cure kinetics study. Prog Org Coat 114:233–243

Keramatinia M, Najafi F, Saeb MR (2017) Synthesis and viscoelastic properties of acrylated hyperbranched polyamidoamine UV-curable coatings with variable microstructures. Prog Org Coat 113:151–159

Azimi R, Roghani-mamaqani H, Gholipour-mahmoudalilou M (2017) Grafting poly(amidoamine) dendrimer-modified silica nanoparticles to graphene oxide for preparation of a composite and curing agent for epoxy resin Reza. Polymer (Guildf) 126:152–161

Wan J, Fan H, Li BG, Xu CJ, Bu ZY (2011) Synthesis and nonisothermal reaction of a novel acrylonitrile-capped poly(propyleneimine) dendrimer with epoxy resin. J Therm Anal Calorim 103:685–692

Cheng Y, Chen D, Fu R, He P (2005) Behavior of polyamidoamine dendrimers as curing agents in bis-phenol A epoxy resin systems. Polym Int 54:495–499

Pourhosseini-Pakdel Z, Roghani-Mamaqani H, Azimi R, Gholipour-Mahmoudalilou M (2018) Multifunctional curing component for epoxidized novolac resin by grafting poly(amidoamine) on carbon nanotubes using a divergent method. Polym Adv Technol 29:2216–2223

Peterson J, Allikmaa V, Subbi J, Pehk T, Lopp M (2003) Structural deviations in poly(amidoamine) dendrimers: a MALDI-TOF MS analysis. Eur Polym J 39:33–42

Yiyun C, Tongwen X (2005) Solubility of nicotinic acid in polyamidoamine dendrimer solutions. Eur J Med Chem 40:1384–1389

Yeganeh H, Lakouraj MM, Jamshidi S (2005) Synthesis and properties of biodegradable elastomeric epoxy modified polyurethanes based on poly(ε-caprolactone) and poly(ethylene glycol). Eur Polym J 41:2370–2379

Song J, Wu G, Shi J, Ding Y, Chen G, Li Q (2010) Properties and morphology of interpenetrating polymer networks based on poly(urethane-imide) and epoxy resin. Macromol Res 18:944–950

Lin M, Shu Y, Tsen W, Chuang F (1999) Synthesis of polyurethane–imide (PU–imide) copolymers with different dianhydrides and their properties. Polym Int 48:433–445

Ebrahimi H, Roghani-Mamaqani H, Salami-Kalajahi M (2018) Preparation of carbon nanotube-containing hybrid composites from epoxy, novolac, and epoxidized novolac resins using sol–gel method. J Therm Anal Calorim 132:513–524

Yang L, Chen J, Wei X, Liu B, Kuang Y (2007) Ethylene diamine-grafted carbon nanotubes: A promising catalyst support for methanol electro-oxidation. Electrochim Acta 53:777–784

Zang Z, Hu Z, Li Z, He Q, Chang X (2009) Synthesis, characterization and application of ethylenediamine-modified multiwalled carbon nanotubes for selective solid-phase extraction and preconcentration of metal ions. J Hazard Mater 172:958–963

Behnam R, Roghani-Mamaqani H, Salami-Kalajahi M (2019) Preparation of carbon nanotube and polyurethane-imide hybrid composites by sol–gel reaction. Polym Compos 40:E1903–E1909

Gnanarajan TP, Nasar AS, Iyer NP, Radhakrishnan G (2000) Synthesis of poly(urethane-imide) using aromatic secondary amine-blocked polyurethane prepolymer. J Polym Sci Part A Polym Chem 38:4032–4037

Noparvar-Qarebagh A, Roghani-Mamaqani H, Salami-Kalajahi M (2015) Functionalization of carbon nanotubes by furfuryl alcohol moieties for preparation of novolac phenolic resin composites with high carbon yield values. Colloid Polym Sci 293:3623–3631

Deng XY, Xie H, Du L, Fan CJ, Cheng CY, Yang KK, Wang YZ (2019) Polyurethane networks based on disulfide bonds: from tunable multi-shape memory effects to simultaneous self-healing. Sci China Mater 62:437–447

Sahoo NG, Jung YC, Yoo HJ, Cho JW (2006) Effect of functionalized carbon nanotubes on molecular interaction and properties of polyurethane composites. Macromol Chem Phys 207:1773–1780

Roghani-mamaqani H, Haddadi-asl V (2014) Reverse atom transfer radical polymerization of methyl methacrylate in the presence of Azo-functionalized carbon nanotubes: a grafting from approach. Colloid Polym Sci 292:2971–2981

Irani M, Mir Mohamad Sadeghi G, Haririan I (2018) Electrospun biocompatible poly(ε-caprolactonediol)-based polyurethane core/shell nanofibrous scaffold for controlled release of temozolomide. Int J Polym Mater Polym Biomater 67:361–366

Chen S, Ma C, Zhang G (2017) Biodegradable polymer as controlled release system of organic antifoulant to prevent marine biofouling. Prog Org Coat 104:58–63

Nemati H, Roghani-Mamaqani H, Salami-Kalajahi M (2019) Preparation of polyurethane-acrylate and silica nanoparticle hybrid composites by a free radical network formation method. Bull Mater Sci 42:219

Behnam R, Roghani-Mamaqani H, Salami-Kalajahi M (2019) Incorporation of silica nanoparticles and polyurethane into hybrid composites for increase of char residue. J Therm Anal Calorim 135:3311–3319

Wu T, Liu Y, Li N, Huang GW, Qu CB, Xiao HM (2019) Cryogenic mechanical properties of epoxy resin toughened by hydroxyl-terminated polyurethane. Polym Test 74:45–56

He X, Liu G, Yan B, Suo H, Zhao C (2016) Significant enhancement of electrochemical behaviour by incorporation of carboxyl group functionalized carbon nanotubes into polyaniline based supercapacitor. Eur Polym J 83:53–59

Najafi-Shoa S, Roghani-Mamaqani H, Salami-Kalajahi M, Azimi R, Gholipour-Mahmoudalilou M (2016) Incorporation of epoxy resin and carbon nanotube into silica/siloxane network for improving thermal properties. J Mater Sci 51:9057–9073

Roghani-Mamaqani H, Haddadi-Asl V, Mortezaei M, Khezri K (2014) Furfuryl alcohol functionalized graphene nanosheets for synthesis of high carbon yield novolak composites. J Appl Polym Sci 131:1–8

Risoluti R, Gullifa G, Carcassi E, Masotti A (2020) TGA/chemometrics addressing innovative preparation strategies for functionalized carbon nanotubes. J Pharm Anal 10:351–355

Lee RS, Chen WH, Lin JH (2011) Polymer-grafted multi-walled carbon nanotubes through surface-initiated ring-opening polymerization and click reaction. Polymer (Guildf) 52:2180–2188

Mardani H, Roghani H, Khezri K, Salami M (2020) Polystyrene-attached graphene oxide with different graft densities via reversible addition-fragmentation chain transfer polymerization and grafting through approach. Appl Phys A 126:1–11

Acknowledgements

Iran National Science Foundation (INSF) is highly appreciated for the financial support (Project Number: 99011497).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest with publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Izadi, M., Mardani, H., Roghani-Mamaqani, H. et al. Poly(amidoamine) dendrimer-grafted carbon nanotubes as a hybrid multifunctional curing agent for epoxy-modified polyurethane. Carbon Lett. 31, 677–688 (2021). https://doi.org/10.1007/s42823-021-00242-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-021-00242-5