Abstract—

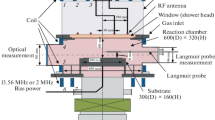

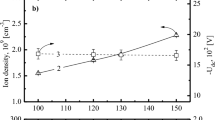

A magnetized inductively coupled plasma ion beam etcher (MICP-IBE) was designed by employing electromagnets around the etcher (IBE). A magnetic field can be set up such that the magnitude of the magnetic flux density on the screen grid increases or decreases with the radial distance from the screen grid center. Four different types of magnetic field conditions were considered. The plasma densities and electron temperatures were measured as functions of radial distance from the screen grid center under each condition. In addition, ion flux was measured with respect to radial distance from the substrate center using ion energy analyzer (IEA), after which the uniformity characteristics of the ion flux in the substrate were investigated. The dry etching characteristics of CoFeB, a typical alloy being used in the magnetic memory device, were investigated. The uniformity characteristics of the ion flux and the etch rate can be improved with the proper design of magnetic field conditions; however, the improvement was confirmed to be limited. In this respect, a new screen and acceleration grid were designed that have different grid hole densities with radial distance from the grid center (hereafter referred to as the proposed grid). Using the proposed grid, the ion flux and etch rate of CoFeB were measured with respect to radial distance from the substrate center, to see if the radial etch rate uniformity can be improved further. The CoFeB etch rate non-uniformity in the proposed grid (11.65%) was lower than that for the conventional grid (17.5%).

Similar content being viewed by others

REFERENCES

W. K. Chu, J. W. Mayer, M.-A. Nicolet, T. M. Buck, G. Amsel, and F. Eisen, Thin Solid Films 17, 1 (1973).

E. H. Lee, Nucl. Instrum. Methods Phys. Res., Sect. B 151, 29 (1999).

M. Yamashita and J. B. Fenn, J. Phys. Chem. 88, 4451 (1984).

S. Matsuo and Y. Adachi, Jpn. J. Appl. Phys. 21, L4 (1982).

J. W. Kim, H. W. Cheong, Y. T. Hong, and K. W. Whang, Plasma Sources Sci. Technol. 26, 035008 (2017).

K. Kinoshita, H. Utsumi, K. Suemitsu, H. Hada, and T. Sugibayashi, Jpn. J. Appl. Phys. 49, 08JB02 (2010).

S. Takahashi, T. Kai, N. Shimomura, T. Ueda, M. Amano, M. Yoshikawa, E. Kitagawa, Y. Asao, S. Ikegawa, T. Kishi, H. Yoda, K. Nagahara, T. Mukai, and H. Hada, IEEE Trans. Magn. 42, 2745 (2006).

R. C. Sousa, and I. L. Prejbeanu, C. R. Phys. 6, 1013 (2005).

T. Kawahara, K. Ito, R. Takemura, and H. Ohno, Microelectron. Reliab. 52, 613 (2012).

J.-G. Zhu, and C. Park, Mater. Today 9 (11), 36 (2006).

K. Sugiura, S. Takahashi, M. Amano, T. Kajiyama, M. Iwayama, Y. Asao, N. Shimomura, T. Kishi, S. Ikegawa, H. Yoda, and A. Nitayama, Jpn. J. Appl. Phys. 48 (8S1), 08HD02 (2009).

S. W. Chun, D. H. Kim, J. H. Kwon, B. H. Kim, S. J. Choi, and S. B. Lee, J. Appl. Phys. 111, 07C722 (2012).

X. Peng, S. Wakeham, A. Morrone, S. Axdal, M. Feldbaum, J. Hwu, T. Boonstra, Y. Chen, and J. Ding, Vacuum 83, 1007 (2009)

G. Aston, H. R. Kaufman, and P. J. Wilbur, AIAA J. 16, 516 (2012).

Y. Fujiwara, H. Sakakita, A. Nakamiya, Y. Hirano, and S. Kiyama, Rev. Sci. Instrum. 87, 02B930 (2016).

D. Flamm and M. Zeuner, Surf. Coat. Technol. 116-119, 1089 (1999).

J. W. Coburn and E. Kay, J. Appl. Phys. 43, 4965 (1972).

S. G. Ingram and N. St. J. Braithwaite, J. Phys. D: Appl. Phys. 21, 1496 (1988).

A. D. Kuypers and H. J. Hopman, J. Appl. Phys. 63, 1894 (1988).

C. Böhm and J. Perrin, Rev. Sci. Instrum. 64, 31 (1993).

G. D. Conway, A. J. Perry, and R. W. Boswell, Plasma Sources Sci. Technol. 7, 337 (1998).

W. H. Lee, H. Kim, J. W. Kim, H. W. Cheong, I. G. Koo, S. Lee, H. Seong, and K. W. Whang, in Proceedings of the 66th Annual Gaseous Electronics Conference, Princeton, NJ, 2013, Bull. Am. Phys. Soc. 58, HW1.00068 (2013). http://meetings.aps.org/link/BAPS.2013.GEC.HW1.68

H. J. Lee, I. D. Yang, and K. W. Whang, Plasma Sources Sci. Technol. 5, 383 (1996).

M. A. Lieberman and A. J. Lichtenberg, Principles of Plasma Discharges and Materials Processing (Wiley, Hoboken, NJ, 2005).

D. V. Rose, T. C. Genoni, D. R. Welch, T. A. Mehlhorn, J. L. Porter, and T. Ditmire, Phys. Plasmas 13, 092507 (2006).

W. H. Lee, H. W. Cheong, J. W. Kim, and K. W. Whang, Plasma Sources Sci. Technol. 24, 065012 (2015).

Funding

This research was supported by the Academic Research Fund of Hoseo University in 2018 (2018-0355).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheong, HW., Kim, JW., Kim, K. et al. A Study on the Improvement of Etch Uniformity in an Ion Beam Etcher with a Magnetized Inductively Coupled Plasma Source. Plasma Phys. Rep. 47, 289–297 (2021). https://doi.org/10.1134/S1063780X21030053

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063780X21030053