Abstract

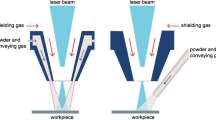

A detailed study of microstructure and microhardness distribution at clad-to-substrate interlayer dilution zone as well as elemental profiling were carried out for individual laser clads. Tungsten carbide (44 712-10) and nickel alloy (1560) powders were used for individual clad synthesis at the surface of low alloy steel by coaxial laser cladding technique. Scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX) revealed partial tungsten carbide (WC) melting and secondary chromium carbides formation near WC grains. Iron and nickel elemental profiles were quantified by EDX technique to estimate interlayer dilution zone dimensions. Interlayer zone depth in the clad center increased from 15 to 80 µm when laser power was changed from 0.8 to 1.5 kW while at the outer clad regions it varied in 3–20 µm range. Interlayer clad-to-substrate zone microhardness study revealed a non-uniform dependence of hardness distribution for single clads synthesized with varying laser power.

Similar content being viewed by others

REFERENCES

A. J. Pinkerton, “Lasers in additive manufacturing,” Opt. Laser Technol. 78, 25–32 (2016). https://doi.org/10.1016/j.optlastec.2015.09.025

F. Shu, Z. Tian, H. Zhao, W. He, S. Sui, and B. Liu, “Synthesis of amorphous coating by laser cladding multi-layer Co-based self-fluxed alloy powder,” Mater. Lett. 176, 306–309 (2016). https://doi.org/10.1016/j.matlet.2016.04.118

I. Hemmati, V. Ocelík, and J. T. M. De Hosson, “Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys,” Mater. Lett. 84, 69–72 (2012). https://doi.org/10.1016/j.matlet.2012.06.054

X. J. Yan, H. Gugel, S. Huth, and W. Theisen, “Microstructures and properties of laser cladding NiTi alloy with W for biomedical applications,” Mater. Lett. 65, 2934–2936 (2011). https://doi.org/10.1016/j.matlet.2011.06.040

L. Zhong, Y. Yan, V.E. Ovcharenko, X. Cai, X. Zhang, and Y. Xu, “Microstructural and mechanical properties of in situ WC–Fe/Fe composites,” J. Mater. Eng. Perform. 24, 4561–4568 (2015). https://doi.org/10.1007/s11665-015-1742-4

C. Cai, L. Li, W. Tao, G. Peng, and X. Wang, “Weld bead size, microstructure and corrosion behavior of zirconium alloys joints welded by pulsed laser spot welding,” J. Mater. Eng. Perform. 25, 3783–3792 (2016). https://doi.org/10.1007/s11665-016-2250-x

A. M. Orishich, A. G. Malikov, V. D. Shelyagin, V. Y. Khaskin, and A. A. Chayka, “Optimisation of the processes of laser, microplasma and hybrid laser–microplasma welding of aluminium alloys,” Weld. Int. 30, 957–961 (2016). https://doi.org/10.1080/09507116.2016.1157338

V. Y. Haskin, V. D. Shelyagin, and A. V. Bernatsky, “Modern state and challenges for development of laser and hybrid surfacing technologies,” Pat. Weld. J. 26–29 (2015).

V. P. Biryukov, D. Y. Tatarkin, E. V. Khriptovich, and A. A. Fishkov, “Determination of influence of laser welding modes and powder material composition on wear resistance of coatings,” J. Mach. Manuf. Reliab. 46, 53–56 (2017). https://doi.org/10.3103/S1052618817010034

V. P. Biryukov, “Effect of laser strengthening and beam defocusing on the geometrical parameters of hardened zones,” J. Mach. Manuf. Reliab. 47, 550–556 (2018). https://doi.org/10.3103/S1052618818660019

V. Biryukov, A. Fishkill, D. Tatarkin, E. Khriptovich, D. Bykovsky, and V. Petrovsky, Influence of modes of laser cladding and composition of powder materials on abrasion resistance of the coatings,” Photonics 3, 32–41 (2016).

V. G. Gilev and E. A. Morozov, “Laser melt injection of austenitic cast iron Ch16D7GKh with titanium,” Russ. J. Non-Ferrous Met. 57, 625–632 (2016). https://doi.org/10.3103/S1067821216060055

P. Y. Peretyagin, I. V. Zhirnov, Y. G. Vladimirov, T. V. Tarasova, and A. A. Okun’kova, “Track geometry in selective laser melting,” Russ. Eng. Res. 35, 473–476 (2015). https://doi.org/10.3103/S1068798X15060143

I. Y. Smurov, A. A. Okun’kova, M. P. Pavlov, and A. P. Nazarov, Optimal configuration of equipment for selective laser melting, Russ. Eng. Res. 33, 495–498 (2013). https://doi.org/10.3103/S1068798X13080145

H. Peng, C. Liu, H. Guo, Y. Yuan, S. Gong, and H. Xu, “Fabrication of WCp/NiBSi metal matrix composite by electron beam melting,” Mater. Sci. Eng., A 666, 320–323 (2016). https://doi.org/10.1016/j.msea.2016.04.079

K. Van Acker, D. Vanhoyweghen, R. Persoons, and J. Vangrunderbeek, “Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings,” Wear 258, 194–202 (2005). https://doi.org/10.1016/j.wear.2004.09.041

R. A. Savrai, A. V. Makarov, N. N. Soboleva, I. Y. Malygina, and A. L. Osintseva, “The behavior of gas powder laser clad NiCrBSi coatings under contact loading,” J. Mater. Eng. Perform. 25, 1068–1075 (2016). https://doi.org/10.1007/s11665-016-1925-7

H. F. El-Labban, E. R. I. Mahmoud, and H. Al-Wadai, “Laser cladding of Ti–6AI–4V alloy with vanadium carbide particles,” Adv. Prod. Eng. Manage. 9, 159 (2014).

M. Dhanda, B. Haldar, and P. Saha, “Development and characterization of hard and wear resistant MMC coating on Ti-6Al-4V substrate by laser cladding,” Procedia Mater. Sci. 6, 1226–1232 (2014). https://doi.org/10.1016/j.mspro.2014.07.196

C. Zhenda, L. Leong Chew, and Q. Ming, ”Laser cladding of WC-Ni composite,” J. Mater. Process. Technol. 62, 321–323 (1996). https://doi.org/10.1016/S0924-0136(96)02428-4

Q. Ming, L. C. Lim, and Z. D. Chen, “Laser cladding of nickel-based hardfacing alloys,” Surf. Coat. Technol. 106, 174–182 (1998). https://doi.org/10.1016/S0257-8972(98)00524-6

M. J. Tobar, C. Álvarez, J. M. Amado, G. Rodríguez, and A. Yáñez, “Morphology and characterization of laser clad composite NiCrBSi–WC coatings on stainless steel,” Surf. Coat. Technol. 200, 6313–6317 (2006). https://doi.org/10.1016/j.surfcoat.2005.11.093

C. P. Paul, H. Alemohammad, E. Toyserkani, A. Khajepour, and S. Corbin, “Cladding of WC–12 Co on low carbon steel using a pulsed Nd:YAG laser,” Mater. Sci. Eng., A 464, 170–176 (2007). https://doi.org/10.1016/j.msea.2007.01.132

A. G. Grigoryants, A. Y. Stavertiy, K .O. Bazaleeva, T. Y. Yudina, N. A. Smirnova, R. S. Tretyakov, and A. I. Misyurov, “Laser surfacing of nickel-based composite war-resisting coatings reinforced with tungsten carbide,” Weld. Int., 1–6 (2016). https://doi.org/10.1080/09507116.2016.1213039

G.L. Goswami, S. Kumar, R. Galun, B.L. Mordike, “Laser cladding of Nickel based carbide dispersion alloys for hardfacing applications,” Lasers Eng. 13, 35–44 (2003).

A. Ghabchi, M. Rombouts, K. Holmberg, and R. Persoons, “Microstructure and failure modes during scratch testing of laser cladded WC–NiCrBSi coatings with spherical and angular carbides,” Tribol.-Mater., Surf. Interfaces 7, 13–20 (2013). https://doi.org/10.1179/1751584X13Y.0000000023

Funding

The authors gratefully acknowledge the financial support of the Russian Science Foundation (agreement no. 16-19-10656) for cladding experiments and sample cross-section preparation. M.N. Filippov thanks funding of the Russian Foundation for Basic Research (project 19-03-00271) for SEM and EDX measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lednev, V.N., Sdvizhenskii, P.A., Filippov, M.N. et al. Interlayer Dilution Zone Elemental Profiling and Microhardness Measurements for Individual Laser Clads. Phys. Metals Metallogr. 121, 1473–1477 (2020). https://doi.org/10.1134/S0031918X20130098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20130098