Abstract

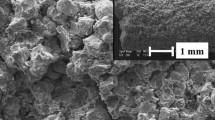

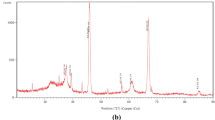

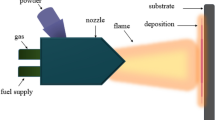

The flame sprayed aluminum coatings are widely used in the marine industries due to considerable corrosion resistance, but their tribological weakness is a drawback. In this study, Al and Al–(5–10 and 15%)TiO2 composites were flame sprayed on carbon steel to combine corrosion and wear resistance. Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) were used to study the coatings and worn and corroded surfaces. Polarization and electrochemical impedance spectroscopy (EIS) tests in simulated 3.5% NaCl solution were used to investigate corrosion behavior of coatings. Also, the pin-on-disc test was used to investigate tribological behavior. The tribological study showed that the composite coating of 5 and 10% TiO2 had better wear resistance than pure aluminum and Al–15% TiO2 coatings. The main wear mechanism in composite coatings was delamination, while pure aluminum coating delamination and adhesion mechanisms were dominant. The corrosion study showed that the corrosion potential of Al‒10% TiO2 coating is nobler than other coats, and pitting corrosion was realized via the dominant corrosion mechanism in all coatings.

Similar content being viewed by others

REFERENCES

F. Ahnia, Y. Khelfaoui, B. Zaid, F.J. Perez, D. Miroud, A. Si Ahmed, and G. Alcala, “Thermally sprayed Al/Mo coatings on industrial steel E335 and effects on electrochemical parameters in simulated acid rain,” J. Alloys Compd. 696, 1282–1291(2017).

A. Fattah-Alhosseini, H. Yazdani Khan, and A. Heidarpour, “Comparison of anti-corrosive properties between hot alkaline nitrate blackening and hydrothermal blackening routes,” J. Alloys Compd. 676, 474–480 (2016).

J. Huang, Y. Liu, J. Yuan, and H. Li, “Al/Al2O3 composite coating deposited by flame spraying for marine applications: Alumina skeleton enhances anti-corrosion and wear performances,” J. Therm. Spray Technol. 23, 676–683 (2014).

X. Chen, J. Yuan, J. Huang, K. Ren, Y. Liu, S. Lu, and H. Li, “Large-scale fabrication of superhydrophobic polyurethane/nano-Al2O3 coatings by suspension flame spraying for anti-corrosion applications,” Appl. Surf. Sci. 311, 864–869 (2014).

K.A. Habib, J.J. Saura, C. Ferrer, M.S. Damra, E. Giménez, and L. Cabedo, “Comparison of flame sprayed Al2O3/TiO2 coatings: Their microstructure, mechanical properties and tribology behavior,” Surf. Coat. Technol. 201, 1436–1443 (2006).

D. Chaliampalias, G. Vourlias, E. Pavlidou, G. Stergioudis, S. Skolianos, and K. Chrissafis, “High temperature oxidation and corrosion in marine environments of thermal spray deposited coatings,” Appl. Surf. Sci. 255, 3104–3111 (2008).

Z. Jia, Y. Liu, Y. Wang, Y. Gong, P. Jin, X. Suo, and H. Li, “Flame spray fabrication of polyethylene-Cu composite coatings with enwrapped structures: A new route for constructing antifouling layers,” Surf. Coat. Technol. 309, 872–879 (2017).

P. L. Fauchais, J. V. R. Heberlein, and M. I. Boulos, Thermal Spray Fundamentals (Springer, Berlin, 2014).

J. Xu, B. Zou, X. Fan, S. Zhao, Y. Hui, Y. Wang, X. Zhou, X. Cai, S. Tao, H. Ma, and X. Cao, “Reactive plasma spraying synthesis and characterization of TiB2–TiC–Al2O3/Al composite coatings on a magnesium alloy,” J. Alloys Compd. 596, 10–18 (2014).

D. Chaliampalias, S. Andronis, N. Pliatsikas, E. Pavlidou, D. Tsipas, S. Skolianos, K. Chrissafis, G. Stergioudis, P. Patsalas, and G. Vourlias, “Formation and oxidation resistance of Al/Ni coatings on low carbon steel by flame spray,” Surf. Coat. Technol. 255, 62–68 (2014).

N. Kahraman and B. Gülenç, “Abrasive wear behavior of powder flame sprayed coatings on steel substrates,” Mater. Des. 23, 721–725 (2002).

A. Nistal, E. García, C. García-Diego, M. I. Osendi, and P. Miranzo, “Flame spraying of adherent silicon coatings on SiC substrates,” Surf. Coat. Technol. 270, 8–15 (2015).

R. Jamshidi, O. Bayat, and A. Heidarpour, “Tribological and corrosion behavior of flame sprayed Al–10 wt % Ti3SiC2 composite coating on carbon steel,” Surf. Coat. Technol. 358, 1–10 (2018).

S. Kumar, S. K. Reddy, and S. V. Joshi, “Microstructure and performance of cold sprayed Al–SiC composite coatings with high fraction of particulates,” Surf. Coat. Technol. 318, 62–71 (2017).

P. Rodrigo, M. Campo, B. Torres, M. D. Escalera, E. Otero, and J. Rams, “Microstructure and wear resistance of Al–SiC composites coatings on ZE41 magnesium alloy,” Appl. Surf. Sci. 255, 9174–9181 (2009).

K. Spencer, D. M. Fabijanic, and M. X. Zhang, “The use of Al–Al2O3 cold spray coatings to improve the surface properties of magnesium alloys,” Surf. Coat. Technol. 204, 336–344 (2009).

M. Campo, M. Carboneras, M. D. López, B. Torres, P. Rodrigo, E. Otero, and J. Rams, “Corrosion resistance of thermally sprayed Al and Al/SiC coatings on Mg,” Surf. Coat. Technol. 203, 3224–3230 (2009).

B. Torres, M. Campo, M. Lieblich, and J. Rams, “Oxy-acetylene flame thermal sprayed coatings of aluminum matrix composites reinforced with MoSi2 intermetallic particles,” Surf. Coat. Technol. 236, 274–283 (2013).

Y. Fu, X. Chen, B. Zhang, Y. Gong, H. Zhang, and H. Li, “Fabrication of nanodiamond reinforced aluminum composite coatings by flame spraying for marine applications,” Mater. Today Commun. 17, 46–52 (2018).

D. Cong, Z. Li, Q. He, H. Chen, Z. Zhao, L. Zhang, and H. Wu, “Wear behavior of corroded Al–Al2O3 composite coatings prepared by cold spray,” Surf. Coat. Technol. 326, 247–254 (2017).

M.A. Bradai, N. Bounar, A. Benabbas, and A. Ati, “Study of microstructure, phases and microhardness of metallic coatings deposited by flame thermal spray,” J. Mater. Process. Technol. 200, 410–415 (2008).

V. Fervel, B. Normand, and C. Coddet, “Tribological behavior of plasma sprayed Al2O3-based cermet coatings,” Wear 230, 70–77 (1999).

B. S. Schorr, K. J. Stein, and A. R. Marder, “Characterization of thermal spray coatings,” Mater. Charact. 42, 93–100 (1999).

R. R. M. H. Pombo, R. S. C. Paredes, S. H. Wido, and A. Calixto, “Comparison of aluminum coatings deposited by flame spray and by electric arc spray,” Surf. Coat. Technol. 202, 172–179 (2007).

R. Arrabal, A. Pardo, M. C. Merino, M. Mohedano, P. Casajús, and S. Merino, “Al/SiC thermal spray coatings for corrosion protection of Mg–Al alloys in humid and saline environments,” Surf. Coat. Technol. 204, 2767–2774 (2010).

M. H. A. Malek, N. H. Saad, S. K. Abas, N. R. N. Roselina, and N. M. Shah, “Performance and microstructure analysis of 99.5% aluminum coating by thermal arc spray technique,” Procedia Eng. 68, 558–565 (2013).

D.P. Schmidt, B. A. Shaw, E. Sikora, W. W. Shaw, and L. H. Laliberte, “Corrosion protection assessment of sacrificial coating systems as a function of exposure time in a marine environment,” Prog. Org. Coat. 57, 352–364 (2006).

M. M. Jalilvand, Y. Mazaheri, A. Heidarpour, and M. Roknian,” Development of A356/Al2O3 + SiO2 surface hybrid nanocomposite by friction stir processing,” Surf. Coat. Technol. 360, 121–132 (2019).

G.E. Kiourtsidis, S. M. Skolianos, and E. G. Pavlidou, “A study on pitting behaviour of AA2024/SiC(p) composites using the double cycle polarization technique,” Corros. Sci. 41, 1185–1203 (1999).

F. Gharavi, K. A. Matori, R. Yunus, N. K. Othman, and F. Fadaeifard, “Corrosion behavior of Al6061 alloy weldment produced by friction stir welding process,” J. Mater. Res. Technol. 4, 314–322 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salimi, N., Bayat, O. & Heidarpour, A. Investigation of TiO2 Addition on Tribological and Corrosion Behavior of Flame Sprayed Al Coating. Phys. Metals Metallogr. 121, 1431–1439 (2020). https://doi.org/10.1134/S0031918X20140148

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20140148