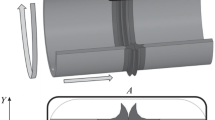

The methods of transmission and scanning electron microscopy are used to study the evolution of the structure of a welded joint of steels 32G2 and 40KhN in the thermomechanically affected zone (TAZ) under rotary friction welding (RFW). EBSD analysis is used to certify the microstructure in different parts of the TAZ and to calculate the densities of the low- and high-angle boundaries. It is shown that complex processes of dynamic recrystallization combining several mechanisms develop in all these regions of the TAZ. Typical differences in the structures of the mobile (steel 40KhN) and immobile (steel 32G2) parts of the billets are described.

Similar content being viewed by others

References

Nisarg Shete and S. U. Deokar, “A review paper on rotary friction welding,” Int. Conf. Ideas, Impact and Innovation in Mechan. Eng., 5(6), 1557 – 1560 (2017).

Ramesh Aswin Pranav, Subramaniyan Madheswaran, and Eswaran Prakash, “Review on friction welding of similar/dissimilar metals,” J. Phys., Conf. Ser., 1362 (2019) (doi: https://doi.org/10.1088/1742-6596/1362/1/012032).

F. C. Liu and T. W. Nelson, “Grain structure evolution, grain boundary sliding and material flow resistance in friction welding of alloy 718,” Mater. Sci. Eng. A, 710, 280 – 288 (2018).

R. Damodaram, Sundara Raman S. Ganesh, and Rao K. Prasad, “Effect of post-weld heat treatments on microstructure and mechanical properties of friction welded alloy 781 joints,” Mater. Design, 53, 954 – 961 (2014).

Markus Slutz, Ricardo Buzolin, Florian Pixner, et al., “Microstructure development of molybdenum during rotary friction welding,” Mater. Charact., 151, 506 – 518 (2019).

Guilong Wang, Junglong Li, Weilang Wang, et al., “Study on the effect of energy-input on the joint mechanical properties of rotary friction-welding,” Metals, 8(11) (2018) (doi: https://doi.org/10.3390/met8110908).

E. Yu. Priymak, A. S. Atamashkin, E. A. Kuz’mina, and E. S. Tulibaev, “Application of rotary friction welding in manufacturing of geologic exploration drill tubes: industrial experience and research,” Chern. Met., No. 4, 37 – 42 (2020).

V. I. Vil, Friction Welding of Metals [in Russian], Mashinostroenie, Moscow (1970), 176 p.

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Oxford (1996), 497 p.

T. Sakai, A. Belyakov, R. Kaibyshev, et al., “Dynamic and post dynamic recrystallization under hot, cold and severe plastic deformation,” Progr. Mater. Sci., 60(1), 130 – 207 (2014).

A. Belyakov, N. Dudova, M. Tikhonova, et al., “Dynamic recrystallization mechanisms operating under different processing conditions,” Mater. Sci. Forum, 706 – 709, 2704 – 2709 (2012).

S. Gourdet and F. Montheillet, “A model of continuous dynamic recrystallization,” Acta Mater., 51, 2685 – 2699 (2003).

A. Salandari-Robori, A. Zarei-Hanzaki, H. R. Abdeli, et al., “Micro and macro texture evolution during multiaxial forging of a WE43 magnesium alloy,” J. Alloys Compd., 739, 249 – 259 (2018).

E. S. Gorkunov, S.M. Zadvorkin, S. M. Goruleva, et al., “Structure and mechanical properties of high-carbon steel subjected to severe deformation impact,” Fiz. Met. Metalloved., 118(10), 1055 – 1064 (2017).

M. G. Jiang, C. Xu, H. Yan, et al., “Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion,” Acta Mater., 157, 53 – 71 (2018).

M. Tikhonova, A. Belyakov, and R. Kaibyshev, “Strain-induced grain evolution in an austenitic stainless steel under warm multiple forging,” Mater. Sci. Eng. A, 564, 413 – 422 (2013).

S. S. Gorelik, M. L. Bernshtein, S. V. Dobatkin, and L. M. Kaputkina, Recrystallization of Metals and Alloys [in Russian], MISiS, Moscow (2005), 432 p.

E. Y. Priymak, I. L. Yakovleva, N. A. Tereshchenko, et al., “Evolution of the structure and mechanisms of the formation of welded joints of medium-carbon steels upon rotary friction welding,” Phys. Met. Metallogr., 120(11), 1091 – 1096 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 9 – 16, December, 2020.

Rights and permissions

About this article

Cite this article

Priymak, E.Y., Yakovlev, I.L., Atamashkin, A.S. et al. Evolution of Microstructure in the Thermomechanically Affected Zone of Welded Joints of Medium-Carbon Steels in the Process of Rotary Friction Welding. Met Sci Heat Treat 62, 731–737 (2021). https://doi.org/10.1007/s11041-021-00630-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00630-8