Abstract

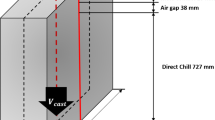

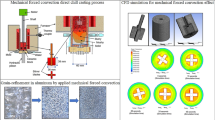

A multi-scale approach for simulating hot tearing during the DC casting of aluminum alloys is presented. The novelty of this approach lies in the combination of a macro-scale finite element simulation of the DC casting process with direct prediction of hot tears via a meso-scale multi-physics granular model. This approach is capable of simulating hot tearing initiation, growth, and propagation within a representative volume element of the mushy zone. The change of cooling conditions experienced by the DC cast billet as a result of variations in casting speed as well as non-uniformity of heat extraction from different locations of the billet affect the deformation state, cooling rate, and thermal gradient, which further influence the strain rate, grain size, permeability, and feeding coefficient. Considering all the mentioned parameters, the multi-scale approach emphasizes the fact that hot tearing is a phenomenon resulting from the combination of the tensile deformation and restricted feeding of the mushy zone. The developed hot tearing formation maps identify the locations where hot tearing will occur as predicted by the multi-scale approach for two alloys—AA5182 and AA3104—thus demonstrating the approach’s sensitivity to both processing parameters and alloy composition.

Similar content being viewed by others

References

B.G. Thomas and M. Bellet: Modeling of stress, distortion, and hot tearing, in ASM Handbook, American Society of Metals, 2008, pp. 449–61.

S. Li, D. Apelian, International Journal of Metalcasting 5(1), 23–40 (2011)

J. Verö, The Metals Industry 48, 431–34 (1936)

D. Warrington, D. McCartney, Cast metals 3(4), 202–08 (1990)

R. Rosenberg, M. Flemings, H. Taylor, AFS Trans 69, 518–28 (1960)

M. Easton, J.F. Grandfield, D.H. StJohn, and B. Rinderer: in Materials Science Forum, vol. 519, Trans Tech Publ, Zurich-Uetikon, 2006, pp. 1675–80.

W. Kool and L. Katgerman: in Materials Science Forum, vol. 396, Trans Tech Publications Ltd., Zurich-Uetikon, Switzerland, 2002), pp. 179–84.

C.W. Briggs: The Metallurgy of Steel Castings, McGraw-Hill Book Company, Incorporated, 1946.

J.M. Drezet, M. Rappaz, G.U. Grün, M. Gremaud, Metallurgical and Materials Transactions A 31(6), 1627–34 (2000)

J. Sengupta, B. Thomas, M. Wells, Metallurgical and Materials Transactions A 36(1), 187–204 (2005)

S. Vernede, P. Jarry, M. Rappaz, Acta Materialia 54(15), 4023–34 (2006)

M. Rappaz, Current Opinion in Solid State and Materials Science 20(1), 37–45 (2016)

D. Lahaie, M. Bouchard, Metallurgical and materials Transactions B 32(4), 697–705 (2001)

S. Vernède, J.A. Dantzig, M. Rappaz, Acta Materialia 57(5), 1554–69 (2009)

J.M. Drezet, M. Sistaninia, M. Rappaz, Matériaux & Techniques 98(4), 261–67 (2010)

M. Sistaninia, A. Phillion, J.M. Drezet, and M. Rappaz: IOP Conf. Ser: Mater. Sci. Eng., 2012, vol. 33, art. no. 012070.

M. Sistaninia, A. Phillion, J.M. Drezet, M. Rappaz, Acta materialia 60(9), 3902–11 (2012)

S. Terzi, L. Salvo, M. Suéry, N. Limodin, J. Adrien, E. Maire, Y. Pannier, M. Bornert, D. Bernard, M. Felberbaum, M. Rappaz, Scripta Materialia 61(5), 449–52 (2009)

N. Jamaly, A. Phillion, J.M. Drezet, Metallurgical and Materials Transactions B 44(5), 1287–95 (2013)

R. Dou, A. Phillion, Metallurgical and Materials Transactions A 47(8), 4217–25 (2016)

M. Sistaninia, A. Phillion, J.M. Drezet, M. Rappaz, Acta Materialia 60(19), 6793–803 (2012)

M. Sistaninia, A. Phillion, J.M. Drezet, M. Rappaz, Metallurgical and Materials Transactions A 42(1), 239–48 (2011)

A. Phillion, S. Thompson, S. Cockcroft, M. Wells, Materials Science and Engineering: A 497(1-2), 388–94 (2008)

A. Alankar, M.A. Wells, Materials Science and Engineering: A 527(29-30), 7812–20 (2010)

S. Lin, C. Aliravci, M. Pekguleryuz, Metallurgical and Materials Transactions A 38(5), 1056–68 (2007)

A. Phillion, S. Cockcroft, P. Lee, Modelling and Simulation in Materials science and Engineering 17(5), art. no. 055011 (2009)

C. Monroe, C. Beckermann, Jom 66(8), 1439–45 (2014)

M.A. Easton, D.H. StJohn, Materials Science and Engineering: A 486(1-2), 8–13 (2008)

J.M. Drezet and D. Allehaux: in Hot Cracking Phenomena in Welds II, Springer, 2008, pp. 27–45.

M. Mhamdi, S. Benum, D. Mortensen, H. Fjaer, J.M. Drezet, Metallurgical and Materials Transactions A 34(9), 1941–52 (2003)

Acknowledgments

The authors wish to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted Novermber 2, 2020; accepted February 6, 2021.

Rights and permissions

About this article

Cite this article

Khodaei, N., Phillion, A.B. A Study on Hot Tearing in Direct Chill Casting of Al-Mn-Mg Alloys Using a Multi-scale Approach. Metall Mater Trans B 52, 1424–1435 (2021). https://doi.org/10.1007/s11663-021-02108-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02108-7